Call 800-535-9545 | www.aeroindustries.com

Indianapolis, IN | Omaha, NE | Kent OH

Attention Dealers: Please give this manual to the customer when product is delivered.

Serving the Truck & Trailer Industry

Since 1944

Installation Instructions

Top Glide Pro

2

Installation Directory

Item Step Page

Important Safety Information 3

Trailer Configuration & Tools Required 4

Trailer Preparation (before installation) 5

Standard Top Glide Pro Vs. 6" Drop 6

Prepare Front Assembly for Installation 1a 7

Install Front Assembly 1b 8-9

Install Electrical Hardware (Electric Drive) 2a 10-12

Install Remote with Current Sense 2b 13-15

Lead Pup Schematic 2c 15

Install Crank Assembly (Manual Drive) 2d 16

Install Rear Idlers 3 17-18

Assembly Bows and Place on Trailer 4 19

Install Power Bow Extender (Optional) 5 20

Install Drive Cable 6 21-22

Install Wind Deflector 7 22

Install Tarp on Trailer 8a 23

Install Tarp on Ground (Optional) 8b 24-25

Set the Power Bow Location and Attach Tarp to Power Bow 8c 26

Attach Tarp to Wind Deflector 8d 26-27

Anti-Lift Installation 9 28

Install Label 10 29

Finish Installation 11 29

Setting Torque Limiter 12 30

Note: For the 6" drop see additional instruction booklet.

Top Glide Pro

3

This manual explains how to install and maintain the Top Glide Pro tarp

system.

Explanation of Signal Words

DANGER: Indicates a hazardous situation which, if not avoided will result in death

or serious injury.

WARNING: Indicates a hazardous situation which, if not avoided could result in

death or serious injury.

CAUTION: Indicates a hazardous situation which, if not avoided could result in

minor or moderate injury.

General Safety Messages

WARNING: Read this entire manual before installing and operating this product.

Read all safety messages before installing and operating.

WARNING: Be sure that your working platform is secure as you work on the truck.

Use OHSA approved ladders or scaffolding to work above ground level.

WARNING: Always wear safety glasses during installation and operation.

CAUTION: Keep all clothing clear of moving parts.

Important Safety Information

IMPORTANT: Contains information critical to installation, operation, or warranty policy.

NOTICE: Risk of product or vehicle being damaged.

NOTE: Contains information critical to the installation or operation of this product.

Top Glide Pro

4

Lifting Device

Marker or Felt Pen

Tape Measure

Hammer

Vice Grip Pliers (2 pair)

Razor Knife

Electric or Air Drill

Straight Edge

C - clamp (2)

Drill Bits: .257" (F drill), 9/32", .316" (O drill),

13/32", 17/32", 9/16"

Sockets: 7/16", 9/16"

Open End or Box Wrenches: 7/16", 9/16", 3/4"

Black Electrical Tape

1/4" cable x 5' long (2 pcs.)

1/4" cable clamps (4)

2" x 4" x 8' boards (2)

Tools Required for Installation

Trailer Congurations

The Top Glide Pro is designed for use on various makes and models of trailers.

Some original equipment manufacturers (OEM) trailers may need to be modified to

ensure efficient operation of the Top Glide Pro.

Preparation

Unpack box(es) and layout all parts. Check parts off of parts list to ensure you

have all components necessary to install on trailer.

NOTE: To ensure correct mounting, double check that you have the right mounting

brackets for the trailer you are installing. Variations in trailer manufacturing may require

Aero to produce different mounting brackets for different trailers.

Trailer Width

System Width

Cable Center

Sheave for Cable

Sheave for Cable

SYSTEM WIDTH

Top Glide Pro

5

Trailer Preparation (before installation)

The Top Glide Pro must be able to slide on the top rail from the rear of the dump all the way to the front.

Also all components must be able to mount without interference.

• Check the bulkhead and the front corners for:

• Obstructions that may interfere with mounting the front assembly.

• Angled or irregular surfaces that may require custom mounting brackets or hardware.

• Check to see if the bulkhead is square with the sides. Shims may be required so front assembly is

square with sides.

• Check top rail for:

• Is at and continuos (no gaps) from the front to the rear (including cab shield)

• If tapered front to back, taper must be continuous.

• Nothing preventing the bows (bolts, brackets, or pins) from traveling from the front to the rear.

• Check the rear of the trailer for:

• There are no obtrusion from properly mounting the rear idler.

• Flat surface to mount the rear idler

• Check sides of the trailer for:

• Rear idler can be mounted so the sheaves (pulleys) are the same width as the ones on the front

assembly.

• Idler location will not interfere with the lift gate or swing of the tailgate.

• Protrusions that would interfere with the operation of the cables and ant-lift.

Make required modications before installing unit.

Obtain special hardware that may be needed to mount components.

Make or purchase custom brackets needed to mount components securely.

Top rail is at and continuos (no gaps)

from front to rear (including cab shield).

Eliminate Gaps

Custom brackets may be

needed for mounting.

Top Glide Pro

6

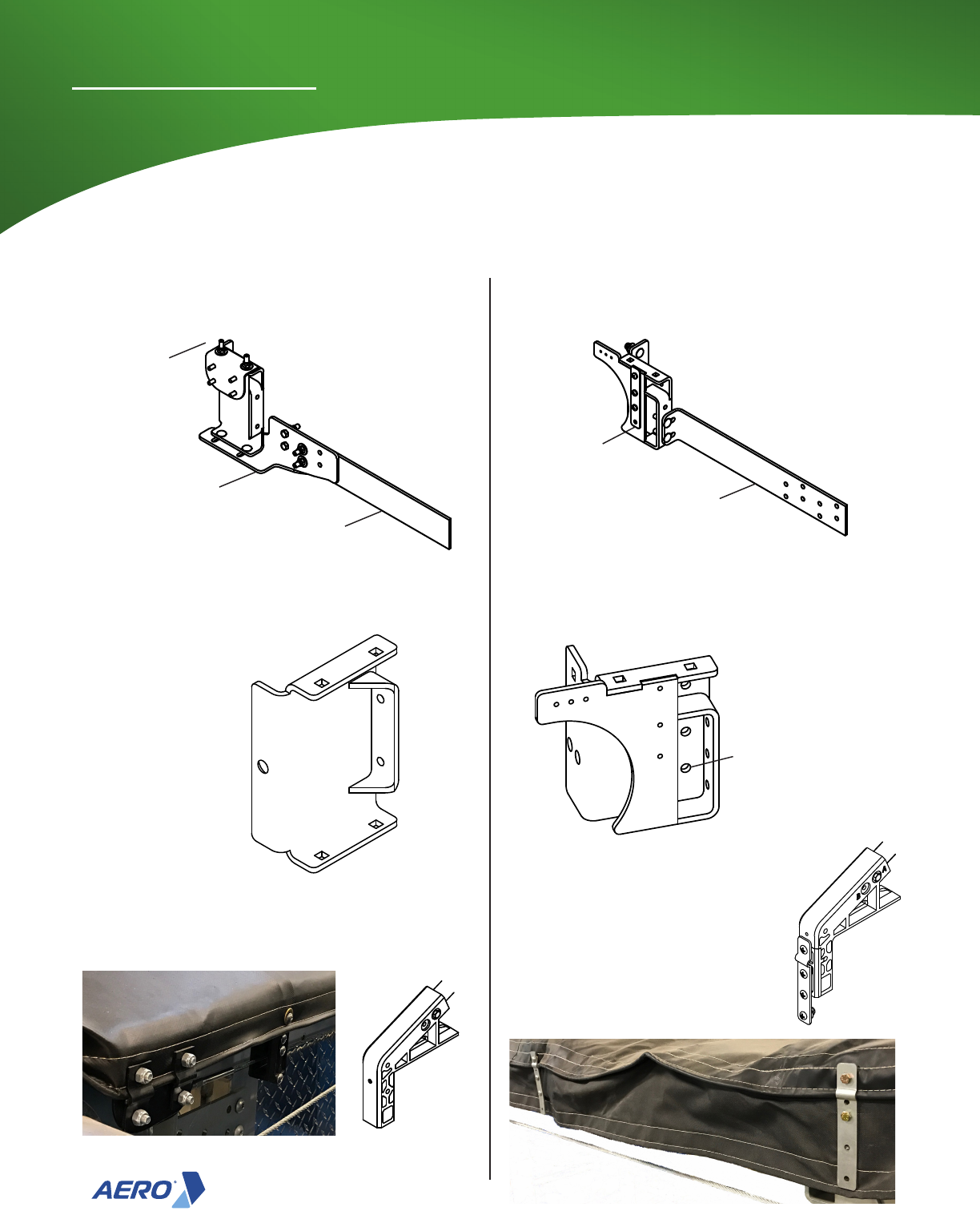

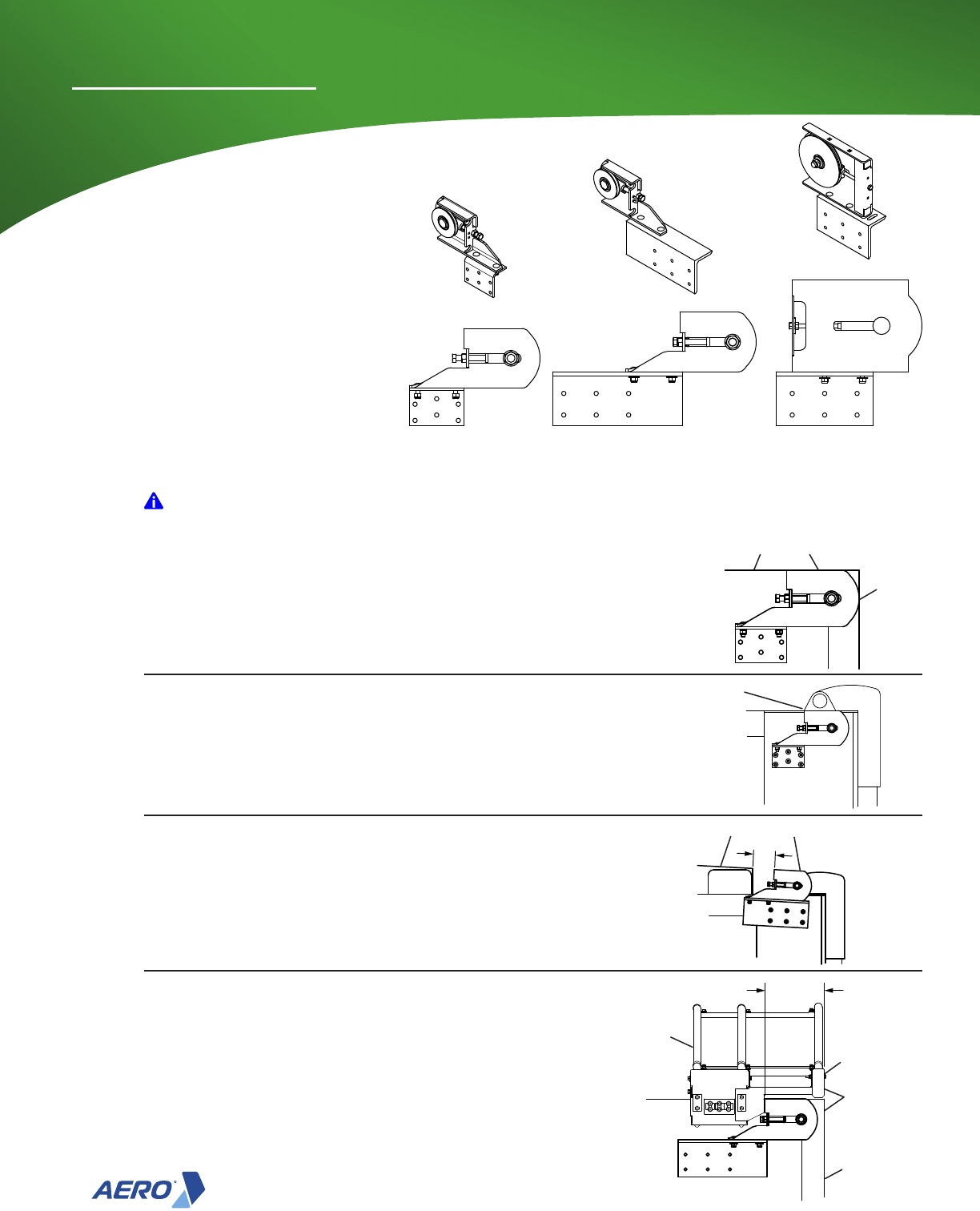

Front Assembly Mounting Brackets

Standard 6" Drop

Tarp Clamp

Tarp Clamp

Adjust mounting bracket

to width of bed.

Mounting Bracket

Extension Bracket

Extension Bracket

Shim to attach bracket

or adjust extension.

Mounting Holes

NOTE: See insert for mounting

6" drop front assembly

Standard Top Glide Pro Vs. 6" Drop

Tarp

Tarp

Bow End

Bow End

Note: For the 6" drop see additional

instruction booklet.

Top Glide Pro

7

Installation Instructions

Step 1a

Prepare Front Assembly for Installation

Note: The bows and tarp can be installed before or after

installing the front assembly and the rear idlers.

Hanger

Qty - 4

Note: Hanger brackets need to be removed when the top rail on the front of the trailer is

higher than the top rail on the sides like a raised bulkhead. (See graphics on following

pages)

Hanger

Qty - 4

Tension Cable

Bracket

Front Bracket Extension

Used on radius trailers

Mounting Bracket DS

Adjust all the way out

Move Brackets to sit on

at face of Bulkhead

Equally Spaced

Hanger

This is to prepare the front assembly to be attached to the bulkhead of the trailer.

Electric Manual

Top rail even height Raised Bulkhead

Tension Cable

Bracket

Mounting Bracket DS

Adjust all the way out

Front Bracket Extension

Used on radius trailers

Tarp Clamp

Mounting Brackets reversed

to clear obstruction

Mounting Brackets

typical mounting

Obstruction

Square Front without

extension

Extension without

hanger brackets

Square Front without

extension

Extension without

hanger brackets

Top Glide Pro

8

Installation Instructions

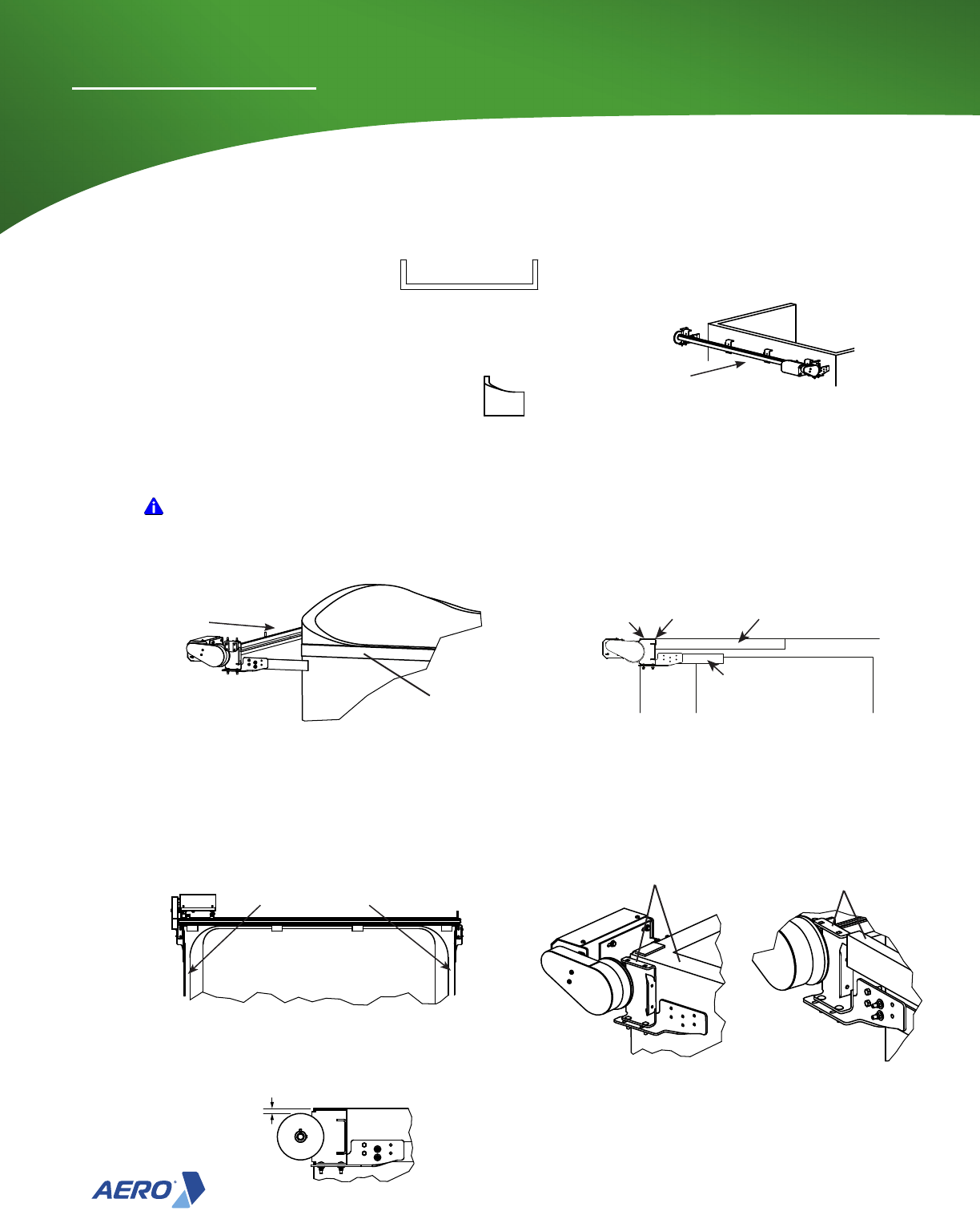

NOTE: TOP of drive sheaves must be 3/4" to 7/8"

BELOW top rail surface.

1a) Figure 1-1. Using lifting slings, place Front Assembly in

position with hanger brackets sitting on the top rail. A square

bulkhead does not need the mounting bracket extension.

Step 1b

Install Front Assembly

IMPORTANT: Trailers where the top rail is NOT the same height at the front and sides and the

hanger brackets are not used the Tension Cable Bracket is set flush with the top rail. Use a

straight edge flush to the top rail on both sides and 5" back or more from the front of the trailer can help

align front assembly.

2) Figure 1-4. Center Front Assembly so there is equal spacing on either side of trailer.

3) Figure 1-3 & 1-5. Align TOP of tension bracket ush with top rail. Hanger brackets places the unit at the

correct height.

STRAIGHT EDGE

TENSION

BRACKET

FLUSH

EXTENSION

NOTE: Front Assembly shown with

hanger brackets removed.

Square bulkhead

Top rail the same front and sides.

1b) Figure 1-2. Using lifting slings, place Front Assembly in

position without hanger brackets and align Tension Cable

Bracket with top of rail.

Straight edge

ush with top rail

Raised bulkhead

Top rail is NOT the same front and sides.

NOTE: Shown with Tarp Clamp removed.

3/4” - 7/8”

NOTE: If Glide Strips are to be installed they must be in

place before setting front assembly on trailer.

Figure 1-1

Figure 1-2 Figure 1-3

Align top of Tension Cable Bracket with top rail.

NOTE: Shown with Tarp Clamp removed.

Figure 1-5

Equal Spacing

Figure 1-4

Figure 1-6

Top Glide Pro

9

Installation Instructions

4) FIGURE 1-7. Verify Front Assembly is on center, square

to running surface, straight and at correct height.

7) Figure 1-9. Install side brackets with bolts, both sides of trailer.

Step 1b (cont.)

NOTE: Complete drive preparation next.

For Electric Drive see Electrical installation (STEP 2a)

For Manual Drive see Crank installation (STEP 2c)

NOTE: Shim front assembly out as needed to maintain

straightness. Drive shaft must not be installed

bent. Do NOT cause Front Assembly to bow.

90°

90°

8) Figure 1-10. Install Hanger brackets with Bolts.

Mounting Brackets

Adjust against dump body

6) FIGURE 1-8. Adjust mounting brackets

against the side of the dump body and

tighten bolts.

5) Verify side brackets are parallel to top rail running surface, then remove 2 x 4 x 8’ lumber if used.

3/8 X 1-1/2" TYPE F

21/64" drill into dump body

13/32" clearance hole in extension

13/32" drill

into dump body

3/8-16 X 7" Hex Bolt

3/8-16 Hex Nut Nylon Insert

3/8 Flat Washer

3/8 X 1-1/2" TYPE F or

3/8-16 X 7" Hex Bolt

3/8-16 Hex Nut Nylon Insert

3/8 Flat Washer

Figure 1-7

Figure 1-8

Figure 1-9

Figure 1-10

Top Glide Pro

10

Installation Instructions

Step 2a

Install Electrical Hardware

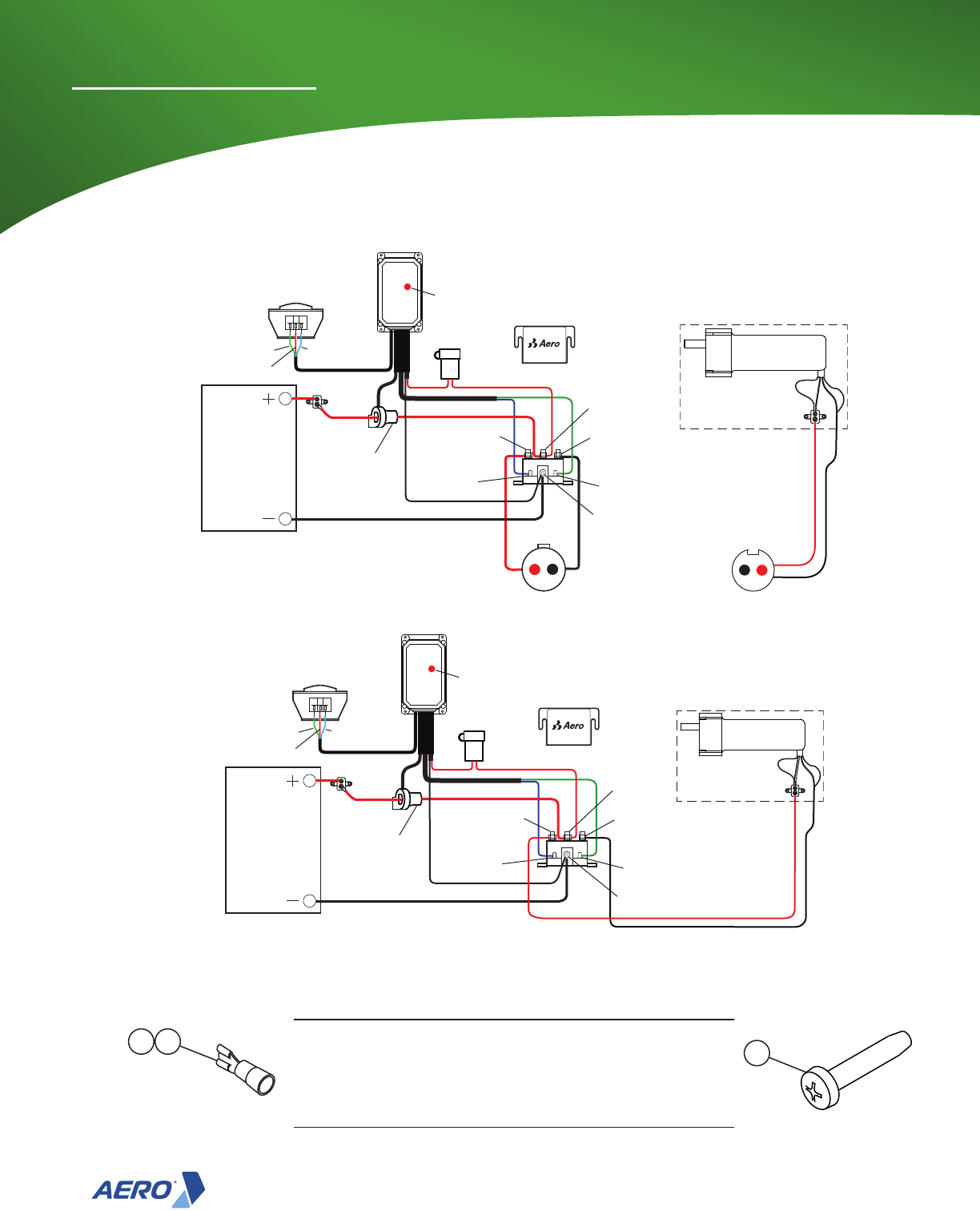

No. Part Number Description QTY

11

0755-626503 WIRE END #6 X 3/8 RING 6

12

0755-626507 WIRE END #6 X #10 RING 4

13

0755-626504 WIRE END #6 X 1/4 RING 2

14

0755-626553 WIRE END #14 x 3/8 RING 1

15

0755-626554 WIRE END #14 X 1/4 PUSH 6

16

0810-650500 BOLT 1/4-20 x 1 2

17

0810-650473 BOLT 1/4-20 x 2 2

18

0815-660456 LOCKNUT 1/4-20 JAM 4

19

0820-680410 WASHER FLAT 1/4" 6

20

0815-660307 NUT HEX 5/16-24 4

21

0820-680520 WASHER LOCK 5/16" 4

22

0815-660121 LOCKNUT #10-32 4

No. Part Number Description QTY

1

0755-962111 HARDWARE KIT (SEE NEXT) 1

2

0755-623510 CIRCUIT BREAKER 25A 2

3

0755-623560 REVERSING DC CONTACT 12V 1

4

0930-861628 WIRING DIAGRAM 1

5

0755-623559 CONTACTOR COVER 1

6

0755-962102 SWITCH - ROCKER 1

7

0850-603757 CLAMP -LOOM 5/8" I.D. 12

8

0755-626500 WIRE END #6 BUTT CONNCT 4

9

0755-626507 WIRE END #6 X #10 RING 8

10

0755-626503 WIRE END #6 X 3/8 RING 2

NOTICE: USING BREAKER GREATER THAN 25 AMP MAY RESULT IN MOTOR FAILURE.

0755-962104

RDCC ELEC KIT

0755-962111

RDCC HARDWARE KIT

MOTOR

MOTOR

Tractor

Trailer

Dump Truck

Top Glide Pro

11

Installation Instructions

Step 2a

Truck Cab Wiring

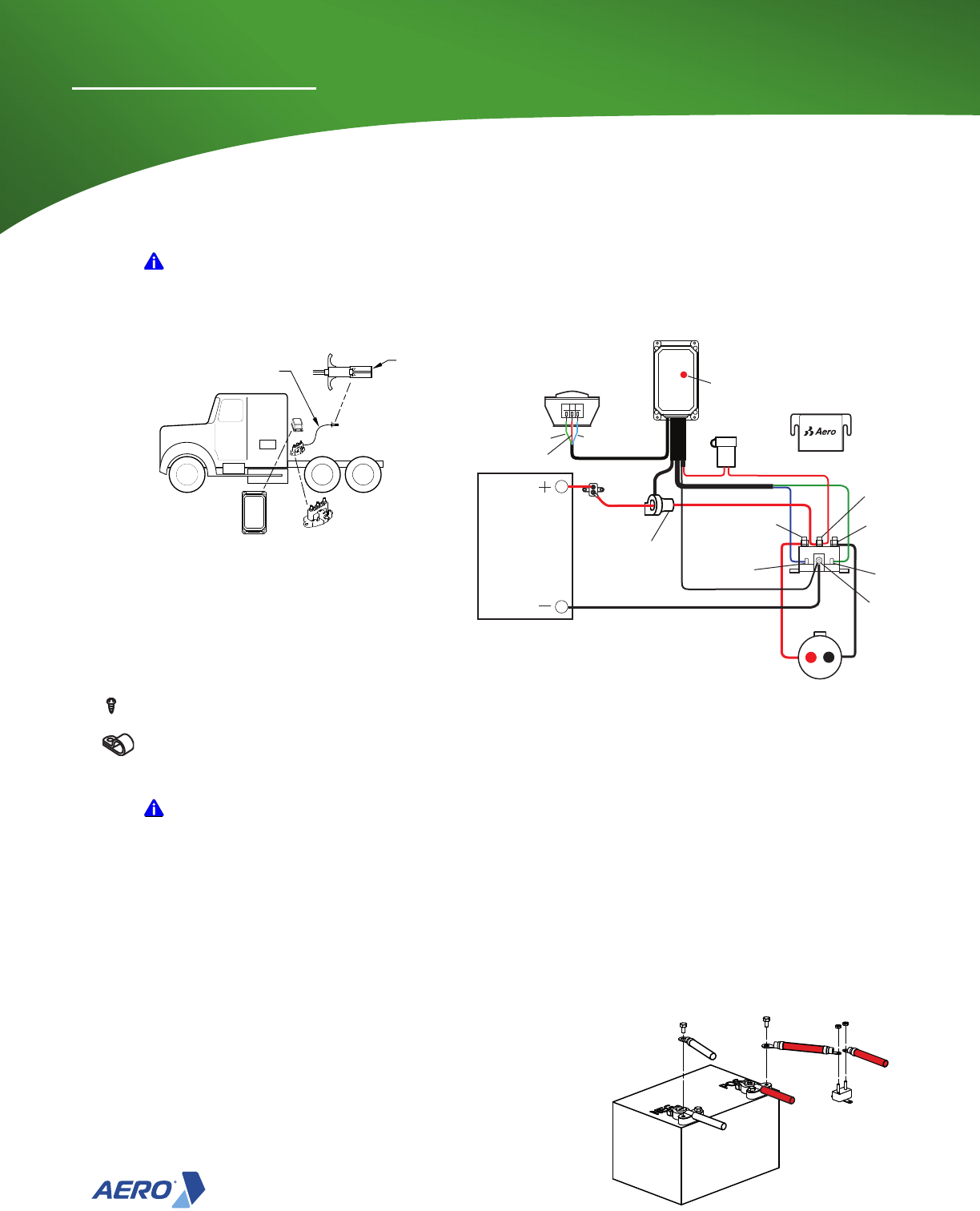

1) Find a convenient place on the driver's side under the dashboard

to mount the rocker switch with 1/4-20 x 1" hex bolts

IMPORTANT: Locate Operation/Maintenance Sheet and keep near switch.

2) Mount reversing contactor in the battery box or

outside near back of cab with 1/4-20 x 2" hex bolts.

6) Connect the red wire to the breaker and

to the positive terminal on the battery and

secure with zip ties. Connect the black wire

to the negative terminal on the battery.

3) Run 3 #14 gray wires from switch to reversing contactor. Connect to wires to

the switch and the reversing contactor per schematic using supplied hardware.

IMPORTANT: Switch is not rated for outdoor use.

Semi-Trailer Trucks get a plug

To Motor

To Motor

T1 to Switch

To Battery

To Switch

T2 to Switch

Battery /

Breaker

4) Run #6 red/black wire from battery to reversing contactor. Secure all wire with clamps.

5) Connect #6 red/black wire to reversing

contactor per schematic.

Top Glide Pro

12

Installation Instructions

For End Dumps

6b) See Figure 20. Run #6 wire from receptacle to rear of

trailer, onto dump bed, back to the front of the trailer

and up to the motor. Secure all wire with clamps.

For Bottom Dumps

6c) See Figure 21. Run #6 wire from receptacle up

to the motor. Secure all wire with clamps.

For Dump Trucks

4a) See Figure 20. Run #6 wire from Reversing DC Contactor

to rear of trailer, onto dump bed, back to the front of the

trailer and up to the motor. Secure all wire with clamps.

4b) Run wires from reversing contactor

to plug, making sure there is

enough wire to reach the receptacle.

5b) Place cover on reversing contactor.

For Semi-Trailer Trucks

#6 WIRE

Circuit Breaker 25A

Wire End #6 X #10 Ring

Locknut #10-32

#6 Wire with Red Stripe

Motor Housing Assembly

7) Wire per schematic red stripe wire to circuit breaker

and black wire to brake wire and black wire.

MOTOR

#6 Wire

CIRCUIT BREAKER 25A

Wire End #6 X #10 Ring

LOCKNUT #10-32

#6 Wire with Red Stripe

Motor Housing Assembly

Brake

Wire

Go to Step 2a-7 at bottom of page

Step 2a (cont.)

POS

NEG

+

-

FWD

REV

POS

NEG

+

-

FWD

PLUG RECEPTACLE

Top Glide Pro

13

Installation Instructions

Step 2a

Install Smart Electronics Hardware

MOTOR

Tractor Trailer

Dump Truck

MOTOR

0755-960000 Smart Circuit Breaker

No. Part No. Description QTY

1

0755-623520 Kit,Cir Brk,Cur Sen,TF4 1

2

0755-962150 SMT CIR BRK HARDWARE PACK 1

0755-962150 SMT CIR BRK HARDWARE PACK

No. Part No. Description QTY

3

0755-962151 INSULATED .25" MALE SPADE 1

4

0755-962152 INSULATED .25" FEMALE 2

5

0825-670364 SCREW #10X1" PAN HEAD 4

43

5

NOTICE: USING BREAKER GREATER THAN 25 AMP MAY RESULT IN MOTOR FAILURE.

Top Glide Pro

14

Installation Instructions

Step 2b

Smart Electronics

IMPORTANT: For best range select an open area to mount the controller outside the cab and not

surround by metal. Place in an area void of tire and road debris.

NOTE: This starts from Step 2a (3) before wiring the switch and the reversing contactor has

been mounted

2) Mount the tarp controller to the back of

the cab with the provided screws.

3) Run the cable from the tarp controller to the

reversing contactor. Secure with clamps.

7) Connect the black #6 wire and the black wire

from the tarp controller to GND terminal on

the reversing contactor.

6) Connect the red #6 wire and the red wire

from the 5 amp fuse (tarp controller) to +BAT

terminal on the reversing contactor.

5) Place the red #6 wire through the current sensor with

the tab pointing towards the end of the cable. Secure

the cable to the sensor with a zip tie.

1) Mount reversing contactor in the

battery box or outside near back of cab

with 1/4-20 x 2" hex bolts.

4) Run #6 red/black wire from the battery to reversing contactor. Secure all wire with clamps.

IMPORTANT: The tab on the current sensor must be pointed towards

the reversing contactor. If this sensor is backwards, the controller will not

operate in automatic mode. It will operate only as long as the button is held.

8) Connect the red wire to the breaker and to the positive

terminal on the battery and secure with zip ties.

9) Connect the black wire to the negative terminal

on the battery.

NOTE: For greater safety the 5A fuse can be

removed until the battery is connected.

Top Glide Pro

15

Installation Instructions

Step 2b (cont.)

10) Connect the green wire from the tarp

controller to terminal T2

11) Connect the blue wire from the tarp

controller to terminal T1

IMPORTANT: Switch is not rated for outdoor use.

13) Run 3 #14 gray wires from switch to tarp controller and secure with clamps.

Optional Cab Mounted Switch

12) Find a convenient place on the driver's side under the

dashboard to mount the rocker switch with 1/4-20 x 1" hex bolts

NOTE: Remember to put the 5A fuse back in if it was removed.

14) Connect wires to the switch and the tarp controller per schematic using

supplied hardware.

MOTOR

MOTOR

Step 2c

Lead Pup Schematic

IMPORTANT: Do NOT operate both switches at the same time.

Operating both switches at the same time will trip the breaker.

Top Glide Pro

16

Installation Instructions

Step 2d

Install Crank Assembly (manual drive only)

1) Figure 2-1. Wrap the Chain around the Sprocket on the Front Assembly.

2) Wrap the Chain around the Sprocket on the Crank Assembly and position the Crank Assembly at the

intended mounting location.

3) Figure 2-1. Trace the four mounting slots in the crank assembly onto the trailer, making sure the slots are

oriented vertically.

4) At the bottom edge of the slots just marked, drill four 11/32” holes through the trailer. Placement of the

holes is important to allow tensioning in paragraph 7 of this procedure.

CHAIN

CRANK

ASSEMBLY

NOTICE: Figure 2-2. Be sure the chain is properly aligned.

5) Mount the Crank Assembly onto the trailer and install the four 3/8” x

1-1/2” self-tapping screws (4) to hold the crank assembly in place at its

uppermost position. Do not completely tighten the screws at this time.

6) Wrap the chain around the sprockets and mark where the chain is to be

cut. Remove the pin at the mark and rewrap it around the sprockets.

Connect the ends of the chain using the master link.

7) Apply downward pressure on the crank assembly until the chain is taut.

Tighten the bolts.

Figure 2-1

Figure 2-2

Top Glide Pro

17

Installation Instructions

1) Positioning the Rear Idler.

• No obstructions on the top rail: set the back edge ush with

the rear most feature of the trailer (tailgate for example).

• Obstruction on top rail: set the front of the idler ush with the

obstruction. The power bow will stop 2" short of this point.

• Gap in top rail: set the front of the idler 2" behind where the

gap starts.

• Power Bow Extender: Front of idler is 8" from back of tailgate.

NOTE: 7" idler will extend past the tailgate 4". This could allow

the rear idlers to be hit and damaged.

2) Position rear idler ush and parallel with top rail and mark hole

locations.

Step 3

Install Rear Idler

NOTE: Top of rear idler needs to be flush to the top rail.

NOTE: Mounting bracket for rear idler needs to be parallel to the top rail.

2”

Flush and parallel

8.00

Power Bow

Extender

Tailgate

Power

Bow

Flush

Flush and parallel

Flush

Front ush with

obstruction

IMPORTANT: Avoid allowing the rear idler to extend past the tailgate or interfere with

the operation of the tailgate in any way (like 2-way tailgates).

NOTE: There are 3 different

Rear Idlers.

4" Steel Bracket

4" Aluminum Bracket

7" Aluminum Bracket

(6" Drop)

Top Glide Pro

18

Installation Instructions

5) Figure 3-2 & 3-3. Set sheave (pulley) center to center

measurement to match system width and tighten bolts.

4) Figure 3-1. Bolt Idler Angle Bracket to trailer both sides of trailer.

NOTE: Mount rear idler with 4 bolts thru, 2 bolts thru & 2 taping or 6 taping bolts.

3/8 X 1-1/2" TYPE F or

3/8-16 X 7" Hex Bolt

3/8-16 Hex Nut Nylon Insert

3/8 Flat Washer

SYSTEM WIDTH

SYSTEM WIDTH

21/64" drill into dump body

13/32" clearance hole in extension

13/32" drill into dump body

6) Figure 3-3 & 3-4 Verify Idler Assemblies are at correct width.

7) Figure 3-4 Verify rear Idler Pulleys are equal distance from front Drive

Sheaves.

8) Figure 3-4 Verify that diagonal 1 is equal to diagonal 2. This ensures

the system is square.

Align sheaves

and tighten bolts

D.S. Length

P.S. Length

99.00

105.00

99.00

105.00

Diagonal 1

Diagonal 2

Step 3 (cont.)

Figure 3-1

Figure 3-2

Figure 3-3

Figure 3-4

Top Glide Pro

19

Installation Instructions

NOTE: The bows can be attached to the tarp either on the ground or on the trailer.

NOTE: If Glide Strips are to be installed they must be in place before setting front assembly

on trailer!

NOTE: Top Glide Pro bows are shipped disassembled.

NOTE: One (1) plastic Bow End is bolted on each bow at the factory.

NOTE: Figure 4-1 to verify proper Bow End assembly and Bow End hole usage.

NOTE: Power Bows are assembled at the factory.

Step 4

Assembly Bows and Place on Trailer

B

A

A

B

SYSTEM WIDTH

1) Figure 4-3. Insert a bow end onto each end of a bow.

2) Figure 4-1 & 4-3. Bolt each bow end according to chart

above.

4) Figure 4-2. Verify cable hole center to center measurement

on all bows match system width (+/- 1/2").

1/4-20 x 1.75

Bolt

1/4 - Flat Washer

1/4-20 Nylon Lock Nut

5) Figure 4-4. Place power bow near rear idler and place

assembled bows together in front of the power bow.

IMPORTANT: Go to Step 6a if assembling

bows to tarp on the ground.

Figure 4-1

Figure 4-2

Figure 4-3

Figure 4-4

Top Glide Pro

20

Installation Instructions

Step 5

Install Power Bow Extender (Optional)

1) Figure 5-1 & 5-2. Remove nut and washer from the

bow assembly and attach the power bow extender

bracket. There is a driver side and a passenger side.

Note: The Bow Assembly for the power bow extender

has the bottom portion of the bow end removed.

Bow End

Bottom portion

removed

Bow Assembly

Power Bow Extender Bracket

Passenger Side Shown

2) Figure 5-3. Remove bolt, nut, and washer from the

power bow and attach the power bow extender bracket.

Remove bolt to attach

Power Bow Extender

3) Figure 5-4, 5-5, &5-6. Tie the 3 bows together with the bow

spacer strap.

• Use 1/4-20 x 3/4" hex bolt, conduit clamp, and 1/4-20

nylon hex nut to attach the bows.

• The center strap 3 washers are need under the conduit

clamp for the extender bow.

Add washers to extender

bow on center strap

Bow Spacer Strap

Conduit Clamp

1/4-20 x 3/4"

Hex Bolt

1/4 Flat Washer

1/4-20 nylon

Hex Nut

Center Strap

Figure 5-1

Figure 5-2

Figure 5-3

Figure 5-4

Figure 5-5

Figure 5-6

Top Glide Pro

21

Installation Instructions

1

2

6) Wrap drive cable (bottom cable run) around sheave on Rear Idler and route through Cable Clamp Assembly

from REAR to FRONT. Place a cable clamp securely (temporary) at the rear edge of power bow box.

2) Unwind drive cable removing any kinks. Lay the cable along

the length of the dump body with the two cable ends at the

rear.

3) Figure 6-2. Wrap the cable around the Front Drive Sheave.

Step 6

Install Drive Cable

4) Figure 6-2, 6-3, & 6-4. Route drive cable (top cable run) through the drive cable holes on Bow Ends and

through Cable Clamp Assembly from FRONT to REAR.

5) Figure 6-5 Place a cable clamp securely (temporary) at the rear edge of power bow box.

TARP NOT SHOWN

1) Figure 6-1 Adjust Rear Idlers all the way forward.

Front

Rear

Note: Front sheaves have a gripping taper. Once cable is inserted into groove it will become

difcult to slide.

Wrap Cable Around Sheave

Bottom cable Run

Sheave

Top cable Run

Accessory Hole

Drive Cable Hole

Anti-Lift Cable Hole

Bow End

Cable Clamp Assembly

Cable Clamps

Pull

Hex Nuts

Cable Clamp

Bottom cable Run

Top cable Run

Pull

7) Figure 6-5 Place cable clamp (temporary) on REAR end of drive cable so that it cannot slip out of bows.

9) Figure 6-5 Tighten all three (3)

Power Bow Cable Clamps.

8) Pull as much slack as possible from

cable,while keeping Power Bow

against Idler Brackets.

Figure 6-1

Figure 6-2

Figure 6-3

Figure 6-4

Figure 6-5

Top Glide Pro

22

Installation Instructions

10) Figure 6-6. Tension cable appropriately with Rear Idler

Adjustment Bolt.

Step 6 (cont.)

Adjustment Bolt

11) Repeat Steps 5.1 - 5.10 cable process on other side of trailer.

13) Figure 6-8. Remove temporary clamps. Cut cable 2”

from each side of the Power Bow. Apply heat shrink

tubing or tape to prevent cable fray.

2”

2”

12) Figure 6-7. Verify cables are equally tensioned by comparing

slack drop distance on each side.

Step 7

Install Wind Deector

1) Figure 7-1. Locate bolts in track

to match up with holes in the wind

deector.

2) Figure 7-1. Place wind deector on

front assemble and secure with 1/2"

washers and 1/2-13 nylon lock nuts.

1/2-13 Nylon Lock Nuts

1/2 Flat Washers

Bolts in Track

Wind Deector

SLACK

DROP

Figure 6-6

Figure 6-7

Figure 6-8

Figure 7-1

Top Glide Pro

23

Installation Instructions

3) Figure 8-2 Line up bows with aps underneath side of tarp and Bow Ends with

grommet in tarp.

4) Figure 8-3. Insert zip tie through hole in ap and wrap around Bow. Trim excess off

of zip tie.

2) Unfold Tarp and stretch across top of bows with the tail in the rear.

24.00

24.00

1) Figure 8-1 Space bow approximately 24" apart.

Step 8a

Install Tarp on Trailer

6) Figure 8-5. Pull tarp sections between bows UP to form uniform pleats.

7) Figure 8-6. Train pleats by crimping tarp edge cable between each bow and at the grommet.

5) Figure 8-4. Line up bow with grommet in tarp. Secure tarp to bow

ends via #14 X 1-1/4 Truss PH screw thru grommets on each side.

Flaps underneath

#14 X 1-1/4 Truss PH screw

Grommet in Tarp

Figure 8-1

Zip Tie through

hole around Bow

Zip Tie through

hole around Bow

Figure 8-3

Figure 8-2

Figure 8-4

Figure 8-5

Figure 8-6

Note: For the 6" drop see additional

instruction booklet.

Top Glide Pro

24

Installation Instructions

Step 8b

Install Tarp on Ground (Optional)

Zip Tie through

hole around Bow

Zip Tie through

hole around Bow

Flaps underneath

3) Figure 8-8. Line up bows with aps underneath and Bow Ends with grommet in tarp.

4) Figure 8-9 Insert zip tie through hole in ap and wrap around Bow. Trim excess off of

zip tie.

5) Figure 8-10. Line up bow with grommet in tarp. Secure tarp to bow

ends via #14 X 1-1/4 Truss PH screw thru grommets on each side.

#14 X 1-1/4 Truss PH screw

Grommet in Tarp

1) Figure 8-7. Unroll tarp upside down (aps for bows up)

on clean, at oor surface.

2) Figure 8-8. Align bows with aps on tarp.

Power bow is near the tail.

6) Figure 8-11, 8-12, & 8-13. Slide bows together and insert a 5’ length of 1/4" cable through accessory

hole of each single Bow End.

NOTE: DO NOT include power bow in stack up Figure 8-12.

NOTE: DO NOT insert cable into drive cable hole Figure 8-13.

Figure 8-7

Figure 8-8

Figure 8-9

Figure 8-10

Figure 8-11 Figure 8-12 Figure 8-13

Top Glide Pro

25

Installation Instructions

7) Figure 8-14. Place a clamp on one end of each cable.

8) Figure 8-15. Compress bow stack and lock in place with second cable clamp.

9) Figure 8-16. Turn tarp assembly right side up.

10) Figure 8-17. Pull tarp sections between

bows UP to form uniform pleats.

11) Figure 8-18. Train pleats by crimping

tarp edge cable between each bow.

12) Figure 8-19. Flip front tarp ap on top of tarp assembly.

13) Figure 8-20. Set power bow assembly on top of tarp assembly.

14) Figure 8-21. Place tarp assembly on top rails approximately 36" from rear of trailer.

36"

Step 8b (cont.)

Figure 8-14 Figure 8-15 Figure 8-16

Figure 8-17 Figure 8-18

Figure 8-19 Figure 8-20 Figure 8-21

Top Glide Pro

26

Installation Instructions

2) Figure 8-23. Pull tarp over edge of power bow

and place tarp cable between studs. Holes will

need to be punched in tarp to go top studs to

go through.

3) Place tarp bracket over studs and secure with

5/16-18 nylon hex nuts. 2 places on both sides

of the unit.

1) Figure 8-22. Run the system back until the power bow is 1" - 2" in front of the rear idler or the adjustment

bolt on the rear idler.

1" - 2"

1" - 2"

1" - 2"

Power Bow stops

at Adjustment Bolt

Power Bow Extension

stops at Rear Idler

Power Bow stops

at Rear Idler

Step 8c

Set the Power Bow Location and Attach Tarp to Power Bow

Tarp Bracket

Tarp Cable

5/16-18 nylon

hex nut

1) Figure 8-24. Pull tarp tight across wind deector (A).

Step 8d

Attach Tarp to Wind Deector

A

A

A

B

B

B

B

3) Run tarp towards the rear to stretch the tarp. If the power bow

hits the rear idler run the power bow forward approximately 1"

4) Remove screws from strap and pull tarp tight and replace strap

and screws.

5) Repeat this steps until power bow stops before hitting rear idler.

Note: It is important to pull tarp as tight as possible

to minimize the travel of the power bow when

closing the system.

2) Figure 8-24 Place tarp strap across mounting ledge and

insert self tapping screws (B). Continue to pull the tarp

tight at each screw location.

Figure 8-22

Figure 8-23

Figure 8-24

Top Glide Pro

27

Installation Instructions

Step 8d (cont.)

8) Figure 8-27. Trim excess tarp away from wind deector (C).

C

Trim Tarp

Tarp Bracket

5/16-18 nylon

hex nut

6) Figure 8-25. Pull tarp over edge of tarp bracket and place

tarp cable between studs. Holes will need to be punched in

tarp to go top studs to go through.

7) Figure 8-26. Place tarp bracket over studs and secure with

5/16-18 nylon hex nuts. 2 places on both sides of the unit.

11) Slowly, using drive unit, run the system forward and backwards to

test the system.

NOTICE: It is critical that power bow is advanced with care. If

any bows begin to tip or snag, STOP and realign immediately!

Figure 8-29.

9) Figure 8-28. Cut tarp cable (using cut off disk) a few inches

in front of the tarp bracket. Insert screw and washer into the

side of the wind deector and wrap the tarp cable around it and

tighten.

10) Repeat for both sides of trailer.

Tarp Bracket

5/16-18

nylon hex nut

Tarp Cable

Screw and

washer

Tarp Cable

Figure 8-25

Figure 8-26

Figure 8-27

Figure 8-28

Figure 8-29

Top Glide Pro

28

Installation Instructions

Step 9

Anti-Lift Installation

1) Figure 9-1. Insert tension cable into tension bracket and start nut onto threads.

2) Run tension cable thru all bows.

3) Figure 9-2. Loop return at U-bolt on idler bracket. Pull tight as possible by hand and install cable clamp.

DO NOT OVER TIGHTEN!

4) Figure 9-1. Increase tension using the adjustment nut onto threaded end to tension cable.

5) Figure 9-1. Tighten the lock nut.

6) Figure 9-2. Cut any excess cable at the rear.

7) Figure 9-3. Install chain bracket 1” BEHIND center

most bow, 1/4” BELOW lower drive cable.

8) Figure 9-3. Install chain assembly as indicated,

locate BETWEEN center bow and chain bracket.

9) Repeat Installation for other side of trailer.

TENSION

CABLE

TENSION

BRACKET

ADJUSTMENT NUT

LOCK NUT

Figure 9-1

CABLE CLAMP

TENSION CABLE

Figure 9-2

INSTALLATION

VIEW

DRIVER SIDE

FRONT

REAR

DRIVE CABLE

TENSION CABLE

DRIVE CABLE

RETURN

Figure 9-3

1) Figure 10-1. Notice label should be located on the driver’s side near the front of the trailer and 6’ from the

ground in a location easily seen. The label should be unobstructed and moving parts should NOT be able

to block or remove by motion. Clean area to apply label with soap and water and let completely dry. If label

becomes unreadable from debris, clean with mild soap, replace if label is unreadable when clean.

Step 10

Install Label

6'

Figure 10-1

Top Glide Pro

29

Installation Instructions

Step 11

Finish Installation

1) Test installation by cycling unit open / close.

2) Run unit to closed position.

3) Verify all fasteners are properly installed.

4) Verify tarp is secure and properly tensioned.

Note: The Motor is equipped with a Torque Limiter (clutch) to protect the TG Pro system

from excessive forces. If slippage occurs on new system, verify that the bed rail is

clear of obstructions and system is properly aligned. If slippage occurs during normal

operation, follow the procedures listed to adjust the Torque Limiter.

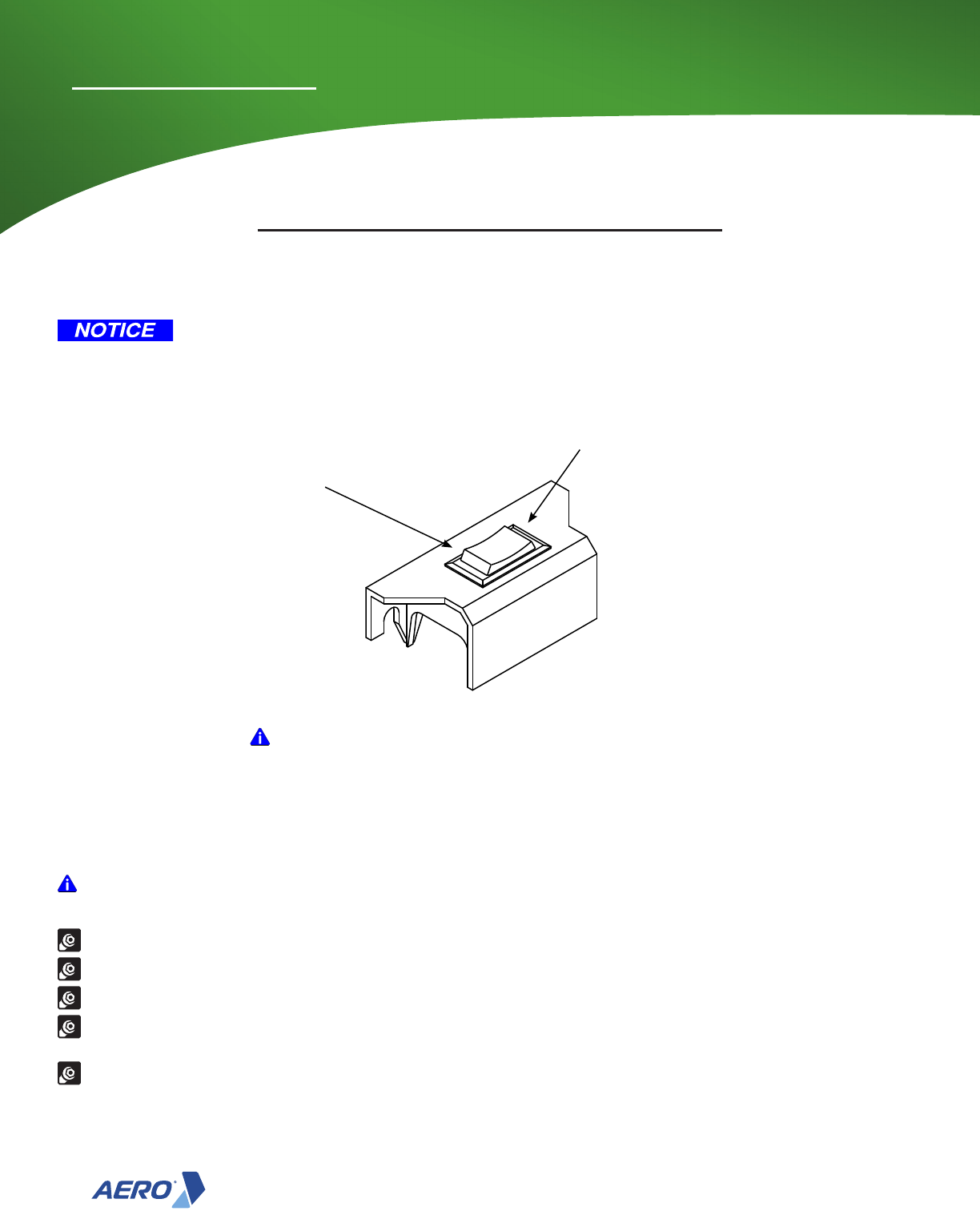

1) Located on the Torque Limiter, you will nd a large hex

nut. This large hex nut is captured by sheet metal tabs to

keep the nut from rotating. Bend these sheet metal tabs

back away from the large hex nut. Allow enough clearance

for the hex nut to turn.

2) Using a Torque Wrench with Socket, increase torque

setting by 2 ft-lbs.

3) Try tarping system to see if the system is still slipping.

Step 12

Setting Torque Limiter

Torque Limiter

CAUTION: Use care when making any adjustments to the Torque Limiter.

NOTICE: Over tightening of the Torque Limiter will cause damage to the Motor or the

tarping system. Do not exceed 40 ft-lbs.

Note: The Motor is equipped with a Torque Limiter (clutch) to protect the TG Pro system

from excessive forces. It is preset at the factory to 35 ft-lbs, If slippage occurs on

new system, verify that the bed rail is clear of obstructions and system is properly

aligned. If slippage occurs during normal operation, follow the procedures listed

below to adjust the Torque Limiter.

4) If the tarping system is still slipping, increase torque setting by 2 ft-lbs tighter. Repeat instructions 2 and 3

until the slipping has been eliminated. Do not exceed 40 ft-lbs.

5) Once the slipping has been eliminated, bend as many sheet metal tabs as possible over the ats of the hex

nut to lock it into place.

Top Glide Pro

30

Installation Instructions

Direction switch operates depends on how it is wired.

Operation Instructions

NOT releasing the switch when in the covered or uncovered position is reached

may cause the motor to burn out.

Push to cover unit and release

when fully covered.

Push to uncover unit and release

when fully uncovered.

Aero Industries recommends a weekly inspection of the following items:

IMPORTANT: Replace all worn or broken parts immediately.

Repairs must ONLY be made after proper instruction.

Inspect Tarp for wear and tears.

Inspect cables for broken wires.

Nuts & Bolts: Make sure all mounting bolts and nuts are in place and tight and that no parts are worn or damaged.

Bearings: Pull the shafts from side to side and in and out. If there is excessive play, replace the bearings. Apply

penetrating oil lightly as needed.

Electrical Connections: Check all electrical connections and tighten any loose connections.

Replacement Parts and instructions may be obtained from your Aero dealer or by contacting Aero Industries.

Maintenance Recommendations

Top Glide Pro Electric Model

IMPORTANT: Do NOT operate both switches at the same time.

Operating both switches at the same time will trip the breaker.

Lead Pup

Operation

Top Glide Pro

31

Installation Instructions

Top Glide Pro Manual Model

Maintenance Recommendations

Aero Industries recommends a weekly inspection of the following items:

IMPORTANT: Replace all worn or broken parts immediately. Repairs must ONLY be made after proper

instruction.

Inspect Tarp for wear and tears.

Inspect cables for broken wires.

Bearings: Pull the shafts from side to side and in and out. If there is excessive play, replace the bearings. Apply

penetrating oil lightly as needed.

Fasteners: Make sure all mounting bolts and nuts are in place and tight and that no parts are worn or damaged.

Chain: Check the chain tension, that links move smoothly, and make sure the master link is on. Lubricate the chain

regularly with penetrating oil.

Replacement Parts and instructions may be obtained from your Aero dealer or by contacting Aero Industries.

Crank handle is only used for uncovering. Remove and store crank handle when not in use.

Lift crank handle and

rotate crank unit to

open or closed.

Lift crank handle

and rotate to place

in notch to lock tarp

into position.

Crank unit open or closed.

Top Glide Pro

Call 1-800-535-9545

www.aeroindustries.com

INDIANAPOLIS, IN

Indianapolis, IN 46241

800-535-9545

FAX: 317-244-1311

OMAHA, NE

Omaha, NE 68137

800-535-9545

FAX: 402-895-6129

KENT, OH

Kent, OH 44240

888-237-2262

FAX: 330-626-3277

Aero Industries, Inc. 0930-022806 10/05/16 Rev F

© 2017 Aero Industries, Inc.

US: 4854630, 6139085, 6481779, 6582007, other patents pending

Canada: 2455928, 2574047