Your Power Solutions Partner

Cordex 24-3.1kW

Modular Switched Mode Rectifier System

Installation & Operation Manual

Part # 030-803-J0

Effective: 02/2014

member of The Group

™

9400010-J1 Rev A

Important Safety Instructions

SAVE THESE INSTRUCTIONS:

This manual contains important safety instructions that must

be followed during the installation, servicing, and maintenance of the product. Keep it in a safe place. Review the

drawings and illustrations contained in this manual before proceeding. If there are any questions re

g

ar

d

ing the safe

installation or operation of this product, contact Alpha Technologies or the nearest Alpha

representa

tive. Save this

document for future referen

c

e.

Safety Symbols

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following symbols

have been placed throughout this manual. Where these symbols appear, use extra care and attention.

The use of ATTENTION indicates specific regulatory/code requirements that may affect the

placement of equipment and /or installation procedures.

NOTE:

A NOTE provides additional information to help complete a specific task or

procedure.

CAUTION!

CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment. Cautions are designated with a shock hazard icon, the word CAUTION,

and a rule beneath which the information appears.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to

personnel. Warnings are indicated by a shock hazard icon, the word WARNING, and

a rule beneath which the information appears.

HOT!

The use of HOT presents safety information to PREVENT BURNS to the technician

or user.

General Safety

WARNING!

This system is designed to be installed in a restricted access location that is

inaccessible to the general public.

Mechanical Safety

• Keep hands and tools clear of fans. Fans are thermostatically controlled and switch on automatically.

• Power supplies can reach extreme temperatures under

load.

•

Use caution around sheet metal components and sharp

edges.

9400010-J1 Rev A

Electrical Safety

WARNING!

Hazardous voltages are present at the input of power systems. The DC output from

rectifiers and batteries, though not dangerous in voltage, has a high short-circuit

current capacity that may cause severe burns and electrical arcing.

Before working with any live battery or power system, follow these precautions:

• Remove all metallic jewelry, such as watches, rings, metal rimmed glasses, or ne

c

kla

c

es

• Wear safety glasses with side shields at all times during the installation.

• Use OSHA approved insulated hand tools.

WARNING!

Lethal voltages are present within the power system. Always assume that an electrical

connection or conductor is energized. Check the circuit with a voltmeter with respect to

the grounded portion of the enclosure (both AC and DC) before performing any

installation or removal procedure.

• Do not work alone under hazardous

conditions.

• A licensed electrician is required to install permanently wired equipment. Input voltages can range up to

• 240 Vac. Ensure that the utility power is disconnected and locked out before performing any installation or

removal

pr

ocedur

e.

• Ensure that no liquids or wet clothes come into contact with internal

components.

• Hazardous electrically live parts inside this unit are energized from the batteries even when the AC

input

power

is

disconnected.

Battery Safety

• Servicing and connection of batteries must be performed by, or under the direct supervision of,

personnel

knowledgeable of batteries and the required safety

pr

ecautions.

• Always wear eye protection, rubber gloves, and a protective vest when working near batteries. Remove all

metallic objects from your hands and

neck.

• Use OSHA approved insulated hand tools. Do not rest tools on top of

batteries.

• Batteries contain or emit chemicals known to cause cancer and birth defects or other reproductive harm.

• Battery post terminals and related accessories contain lead and lead compounds. Wash your hands after

handling

batteries.

WARNING!

Follow battery manufacturer’s safety recommendations when working around battery

systems. Do not smoke or introduce an open flame when batteries (especially vented

batteries) are charging. When charging, batteries vent hydrogen gas, which can

explode.

• Batteries are hazardous to the environment and should be disposed at a recycling facility. Consult the

bat

tery

manufacturer for recommended local authorized r

ecyclers.

#9400011-J1 Rev A

Seguridad

GUARDE ESTAS INSTRUCCIONES:

Este manual contiene instrucciones de seguridad

importantes que deben seguirse durante la instalación, reparación y mantenimiento del producto. Manténgalas

en un lugar seguro. Inspeccione los dibujos y las ilustraciones contenidas en este manual antes de continuar. Si

existe cualquier pregunta relacionada con la instalación u operación segura de este producto, póngase en

contacto con Alpha Technologies o con su representante de Alpha más cercano. Guarde este documento para

referencia futura.

Símbolos de Seguridad

Para reducir el riesgo de lesión o muerte y para asegurar la operación continua segura de este producto, se han

colocado los siguientes símbolos a lo largo de este manual. En las partes donde aparecen estos símbolos, preste

atención y cuidado adicional.

Atención:

El uso de ATENCIÓN indica requisitos de código o regulatorios específicos que pueden

afectar la ubicación del equipo y/o los procedimientos de instalación.

NOTA:

Una NOTA (NOTE)provee información adicional para ayudar a completar una tarea o un

procedimiento específico.

¡CUIDADO

!

CUIDADO (CAUTION) indica información de seguridad con el propósito de PREVENIR

DAÑOS al material o al equipo. Los avisos de cuidado están designados con un icono de

peligro de choque, la palabra CUIDADO y una línea debajo de la cual aparece la

información.

¡ADVERTENCIA

!

Una ADVERTENCIA (WARNING) presenta información de seguridad para PREVENIR LESIÓN O

MUERTE al personal. Las advertencias se indican con un icono de peligro de choque, la palabra

ADVERTENCIA y una línea debajo de la cual aparece la información

¡CALIENTE!

El uso de CALIENTE (HOT) presenta información de seguridad para PREVENIR

QUEMADURAS al técnico o al usuario.

Seguridad General

¡ADVERTENCIA

!

Este sistema está diseñado para instalarse en una ubicación con acceso restringido

que no sea accesible para el público general.

Seguridad Mecánica

• Mantenga las manos y las herramientas alejadas de los ventiladores. Los ventiladores están controlados de forma

termostática y se encienden automáticamente.

• Las fuentes de alimentación pueden alcanzar temperaturas extremas bajo carga.

•

Tenga cuidado cerca de bordes filosos y componentes de chapa

.

#9400011-J1 Rev A

Seguridad Eléctrica

¡ADVERTENCIA

!

Hay voltajes peligrosos en la entrada de los sistemas de alimentación. La salida de CC de

rectificadores y baterías, si bien no es peligrosa en cuanto al voltaje, cuenta con una alta

capacidad de conducción de cortocircuito que puede causar quemaduras graves y arcos

eléctricos.

Antes de trabajar con una batería activa o un sistema de alimentación, siga estas precauciones

:

• Quítese toda joyería metálica, como relojes, anillos, anteojos con montura de metal o collares.

• Use antiparras de seguridad con protecciones laterales en todo momento durante la instalación.

• Use herramientas manuales aisladas aprobadas por OSHA.

¡ADVERTENCIA

!

El sistema de alimentación presenta voltajes mortales en su interior. Suponga

siempre que las conexiones o los conductores eléctricos están energizados. Revise el

circuito con un voltímetro con respecto de la porción a tierra del cerramiento (tanto

CA como CC) antes de realizar cualquier procedimiento de instalación o remoción.

• No trabaje solo en condiciones peligrosas

.

• Se requiere que un electricista matriculado se ocupe de instalar equipos con conexión permanente. Los

voltajes de entrada pueden llegar a los 240 VCA. Asegúrese de que la fuente de alimentación eléctrica del

servicio esté desconectada y bloqueada antes de realizar un procedimiento de instalación o remoción.

• Asegúrese de que ningún líquido ni ropa húmeda en contacto con los componentes internos

.

• Las partes eléctricamente activas peligrosas dentro de esta unidad están energizadas por las baterías incluso

cuando se desconecta la alimentación de entrada de CA

.

Seguridad de la Batería Externa

• El mantenimiento y la conexión de las baterías debe ser realizado por, o bajo la supervisión directa de,

personal experto en baterías y tomando las precauciones de seguridad requeridas

.

• Siempre que trabaje con baterías utilice protección para los ojos, guantes de goma y un chaleco protector.

Quítese todos los objetos metálicos de las manos y el cuello

.

• Use herramientas manuales aisladas aprobadas por OSHA. No apoye las herramientas sobre las baterías

.

• Las baterías contienen o emiten elementos químicos que causan cáncer y defectos de nacimiento u otros

problemas reproductivos.

• Los terminales de batería y accesorios similares contienen plomo y compuestos del plomo. Lávese las manos

después de manipular baterías

.

¡ADVERTENCIA!

Siga las recomendaciones del fabricante de las baterías cuando trabaje cerca de

sistemas de baterías. No fume ni introduzca una llama abierta cuando las baterías

(en especial las baterías ventiladas) se están cargando. Mientras se cargan, las

baterías ventilan gas hidrógeno que puede explotar.

• Las baterías son peligrosas para el medioambiente y deben desecharse en un centro de reciclado. Consulte al

fabricante de las baterías acerca de centros de reciclado autorizados locales recomendados

.

9400012-J1 Rev A

Sécurité

CONSERVEZ CES INSTRUCTIONS:

Le présent manuel contient des consignes de sécurité importantes

à suivre pendant l'installation, l'entretien et la maintenance du produit. Rangez-le dans un endroit sûr. Examinez les schémas et illustrations

contenus dans ce manuel avant de poursuivre. En cas de questions sur l'installation ou le fonctionnement en toute sécurité de ce produit,

contactez Alpha Technologies ou le représentant d'Alpha le plus près. Conservez ce document pour référence future.

Symboles de Sécurité

Pour réduire le risque de blessures ou d'accident mortel et assurer le maintien de conditions d'exploitation sécuritaires de ce produit,

les symboles ci-après ont été utilisés systématiquement dans ce manuel. Lorsque ces symboles sont utilisés, prenez des précautions

supplémentaires.

L'utilisation du symbole « ATTENTION » indique l'existence d'exigences réglementaires ou normatives qui

peuvent affecter l'emplacement de l'équipement ou les procédures d'installation.

REMARQUE:

Une REMARQUE (NOTE) fournit des informations supplémentaires destinées à aider à la réalisation

d'une tâche ou d'une procédure spécifique.

PRUDENCE !

Le symbole PRUDENCE (CAUTION) indique une information de sécurité destinée à ÉVITER DES

DOMMAGES au matériel ou à l'équipement. Ce symbole est représenté par une icône de danger

de décharge électrique, le terme PRUDENCE et une ligne en dessous de laquelle l'information est

affichée.

AVERTISSEMENT!

Le symbole AVERTISSEMENT (WARNING) donne des informations sur la sécurité permettant au personnel d'ÉVITER

DES BLESSURES OU DES ACCIDENTS MORTELS. Les avertissements sont identifiés par une icône de danger de

décharge électrique, le terme AVERTISSEMENT et une ligne en dessous de laquelle l'information est affichée.

CHAUD!

Le symbole CHAUD (HOT) est associé à des informations de sécurité destinées à ÉVITER

DES BRÛLURES au technicien ou à l'utilisateur.

Avertissements et Mises en Garde D'ordre Général

AVERTISSEMENT !

Ce système est conçu pour être installé dans un endroit restreint inaccessible au

public.

Sécurité Mécanique

• Gardez les mains et les outils à l’écart des ventilateurs. Les ventilateurs sont thermostatés et s’allument

automatiquement.

• Les blocs d’alimentation peuvent atteindre des températures extrêmes lorsqu’ils sont sous tension.

• Procédez avec prudence autour des composants en tôle et des bords tranchants.

9400012-J1 Rev A

Sécurité Electrique

AVERTISSEMENT !

Des tensions dangereuses sont présentes à l’entrée des systèmes électriques. La

sortie CC des redresseurs et des batteries, bien que non dangereuse en termes de

tension, a une capacité de courant de court-circuit élevée qui peut causer de graves

brûlures et des arcs électriques.

Avant de travailler sur une batterie ou un système électrique alimenté(e), suivez ces précautions :

• Retirez tout bijou métallique, tel qu’une montre, une alliance, des montures métalliques ou un collier.

• Portez des lunettes de sécurité avec des écrans latéraux de protection à tout moment durant l’installation.

• Utilisez des outils à mains isolés et approuvés par OSHA.

AVERTISSEMENT !

Des tensions mortelles sont présentes dans le système électrique. Considérez

toujours une connexion électrique ou un conducteur comme étant sous tension.

Vérifiez le circuit avec un voltmètre au niveau de la partie mise à la terre du boîtier (CA

et CC) avant de lancer une procédure d’installation ou de retrait.

• Ne travaillez pas seul lorsque les conditions sont dangereuses

.

• Un électricien agréé est requis pour installer un équipement câblé de façon permanente. Les tensions d’entrée

peuvent atteindre

• 240 V CA. Assurez-vous que l’électricité de service est débranchée et verrouillée avant de lancer une procédure

d’installation ou de retrait.

• Assurez-vous qu’aucun liquide ou vêtement mouillé n’entre en contact avec les composants internes.

• Les pièces électriques dangereuses à l’intérieur de cette unité sont alimentées par les batteries même lorsque

l’alimentation CA en entrée est débranchée

.

Sécurité de la Batterie

• L'entretien et la connexion des batteries doivent être effectués par un spécialiste des batteries ou sous la

supervision directe d'un tel spécialiste, en prenant les précautions de sécurité requises.

• Portez toujours une protection pour les yeux, des gants en caoutchouc et un gilet de protection lorsque vous

travaillez à proximité de batteries. Retirez tous les objets métalliques de vos mains et de votre coup.

• Utilisez des outils à main isolés et approuvés par OSHA. Ne déposez pas les outils sur les batteries.

• Les batteries contiennent ou émettent des produits chimiques identifiés comme cause de cancer et de

malformations congénitales ou d'autres troubles de l'appareil reproducteur. Les bornes des batteries et leurs

accessoires contiennent du plomb et des composés de plomb. Lavez-vous les mains après avoir manipulé des

batteries.

AVERTISSEMENT !

Observez les recommandations de sécurité du fabricant quand vous travaillez avec

des systèmes de batteries. Ne fumez pas, ou n'introduisez pas de flamme nue quand

les batteries (surtout les batteries ouvertes) sont en cours de charge. En cours de

charge, les batteries dégagent de l'hydrogène gazeux susceptible d'exploser.

• Les batteries sont néfastes pour l'environnement et doivent être mises au rebut dans un centre de recyclage.

Consultez le fabricant de la batterie pour connaître les centres de recyclages agréés locaux

.

9400013-J1 Rev A

Wichtige Sicherheitshinweise

BEWAHREN SIE DIESE ANWEISUNGEN AUF:

Dieses Handbuch enthält

wichtige Sicherheitshinweise, die bei der Installation, Wartung und Instandhaltung des Produkts beachtet werden

müssen. Bewahren Sie es an einem sicheren Ort auf. Sehen Sie sich die Zeichnungen und Illustrationen in diesem

Handbuch genau an, bevor Sie fortfahren. Sollten Sie Fragen zur sicheren Installation oder zum Betrieb dieses

Produkts haben, wenden Sie sich bitte an Alpha Technologies oder den nächstgelegenen Alpha-Vertreter.

Bewahren Sie dieses Dokument für den zukünftigen Gebrauch auf.

Sicherheitssymbole

Um das Risiko von Verletzungen oder Todesfällen zu reduzieren und den weiteren sicheren Betrieb dieses

Produkts zu gewährleisten, wurden in diesem Handbuch die folgenden Symbole verwendet. Seien Sie besonders

vorsichtig und aufmerksam, wenn diese Symbole abgebildet sind.

Das Symbol VORSICHT (ATTENTION) deutet auf spezifische Anforderungen von

aufsichtsrechtlichen Vorschriften oder Normen hin, welche Einfluss auf die Platzierung von

Geräten und/oder Installationsverfahren haben können.

HINWEIS:

Ein HINWEIS (NOTE) liefert zusätzliche Informationen, die Ihnen helfen, eine bestimmte

Aufgabe zu lösen bzw. ein bestimmtes Verfahren durchzuführen. Hinweise sind mit einem

Häkchen, dem Wort HINWEIS und einem Strich, unter dem die Informationen aufgeführt sind,

gekennzeichnet.

ACHTUNG!

ACHTUNG (CAUTION) kennzeichnet Sicherheitsinformationen, die darauf abzielen, SCHÄDEN an

Materialien oder Geräten ZU VERHINDERN. Diese Warnhinweise sind mit einem gelben

Warndreieck, dem Wort ACHTUNG und einem Strich, unter dem die Informationen aufgeführt

sind, gekennzeichnet.

WARNUNG!

Eine WARNUNG (WARNING) enthält Sicherheitsinformationen zur VERHINDERUNG VON

VERLETZUNGEN ODER TODESFÄLLEN bei Mitarbeitern. Diese Warnhinweise sind mit einem

Stromschlagsymbol, dem Wort WARNUNG und einem Strich, unter dem die Informationen

aufgeführt sind, gekennzeichnet.

HEISS!

Die Warnung HEISS! (HOT) liefert Sicherheitsinformationen, die dazu dienen,

VERBRENNUNGEN des Technikers oder Benutzers zu VERHINDERN.

Allgemeine Sicherheit

WARNUNG!

Dieses System wurde für eine Aufstellung an einem Standort mit Zugangsbeschränkung

entworfen, der für die allgemeine Öffentlichkeit nicht zugänglich ist.

Mechanische Sicherheit

• Achten Sie darauf, dass Hände und Werkzeuge nicht mit den Lüftern in Berührung kommen. Die Lüfter werden

thermostatisch kontrolliert und schalten sich automatisch ein.

• Die Netzteile können unter Last Extremtemperaturen erreichen.

•

Gehen Sie in der Nähe von Blechteilen und scharfen Kanten vorsichtig vor.

9400013-J1 Rev A

Elektrische Sicherheit

WARNUNG!

Am Punkt der Stromeinspeisung liegen gefährliche Spannungen vor. Der Gleichstromausgang

von Gleichrichtern und Batterien weist zwar keine gefährliche Spannung auf, die

Kurzschlussstrom-Kapazität ist jedoch sehr hoch, was zu ernsthaften Verbrennungen und

Lichtbögen führen kann.

Befolgen Sie die folgenden Vorsichtsmaßnahmen, bevor Sie mit einer spannungsführenden Batterie oder einem

Stromversorgungssystem arbeiten:

• Legen Sie sämtlichen Schmuck aus Metall wie z.B. Armbanduhren, Ringe, Brillen mit Metallrahmen oder

Halsketten ab.

• Tragen Sie während der Installationsarbeiten jederzeit Schutzbrillen mit Seitenschutz.

• Verwenden Sie nur geprüftes isoliertes Werkzeug.

WARNUNG!

Innerhalb des Stromversorgungssystems herrschen lebensgefährliche Spannungen vor.

Gehen Sie jederzeit davon aus, dass eine elektrische Verbindung oder ein Leiter Strom führt.

Überprüfen Sie den Stromkreis mit einem Spannungsmesser bezüglich des geerdeten Teils

des Gehäuses (sowohl Wechsel- als auch Gleichstrom), bevor Sie eine Installation oder

Demontage durchführen.

• Arbeiten Sie unter gefährlichen Bedingungen niemals alleine.

• Die Installation festverdrahteter Geräte muss durch einen zugelassenen Elektriker vorgenommen werden. Die

Eingangsspannungen können bis zu 240 VAC betragen. Stellen Sie sicher, dass die Verbindung zum

Netzstrom getrennt und gegen Wiedereinschalten gesichert ist, bevor Sie eine Installation oder Demontage

durchführen.

• Stellen Sie sicher, dass keine Flüssigkeiten oder nasse Kleidungsstücke mit innenliegenden Komponenten in

Berührung kommen.

• Gefährliche stromführende Teile innerhalb dieses Geräts werden auch bei Trennung der Netzverbindung noch

über die Batterien versorgt.

Batteriesicherheit

• Die Wartung und der Anschluss von Batterien muss von Mitarbeitern durchgeführt bzw. direkt beaufsichtigt

werden, die über Kenntnisse über Batterien und die erforderlichen Sicherheitsmaßnahmen verfügen.

• Tragen Sie jederzeit Augenschutz, Gummihandschuhe und eine Schutzweste, wenn Sie in der Nähe von

Batterien arbeiten. Entfernen Sie sämtliche Metallgegenstände von Ihren Händen und Ihrem Hals.

• Verwenden Sie von der OSHA genehmigte isolierte Handwerkzeuge. Legen Sie Werkzeuge nicht auf Batterien

ab.

• Verwenden Sie nur geprüftes isoliertes Werkzeug. Legen Sie Werkzeug niemals auf Batterien ab.

• •Batterien enthalten Chemikalien bzw. setzen Chemikalien frei, von denen bekannt ist, dass sie Krebs oder

Geburtsfehler verursachen oder die Fortpflanzungsfähigkeit anderweitig schädigen.

• Batterieanschlüsse und entsprechendes Zubehör enthalten Blei und Bleiverbindungen. Waschen Sie nach

dem Umgang mit Batterien Ihre Hände.

• verursachen oder die Fortpflanzungsfähigkeit anderweitig schädigen.

WARNUNG!

Befolgen Sie die Sicherheitsempfehlungen von Batterieherstellern, wenn Sie mit

Batteriesystemen arbeiten. Während Batterien (insbesondere geschlossene Batterien)

aufgeladen werden, darf weder geraucht noch offenes Feuer verwendet werden. Beim

Aufladen setzen Batterien Wasserstoffgas frei, das explodieren kann.

• Batterien sind schädlich für die Umwelt und sollten im Sondermüll entsorgt werden. Wenden Sie sich an den

Batteriehersteller, um sich über empfohlene zugelassene örtliche Recyclingstellen zu informieren.

Cordex 24-3.1kW

Modular Switched Mode Rectifier System

030-803-J0 Rev B

(030-736-20 non-RoHS)

The following documents and drawings are included in this manual to provide the necessary information re-

quired for installation, operation and fault diagnosis of the unit:

• Specifications, Cordex 24-3.1kW: 010-601-B1 Rev B

• Specifications, CXCM4: 018-586-B1 (018-574-20 non-RoHS)

• CSA/NRTL Equivalence: 048-554-10

• Outline Drawing, 23” Shelf: 030-736-06 (RoHS: 030-803-20)

• Customer Connections, 23” Shelf: 030-736-08 (RoHS: 030-803-20)

• Outline Drawing, 19” Shelf: 030-737-06 (RoHS: 030-804-20)

• Customer Connections, 19” Shelf: 030-737-08 (RoHS: 030-804-20)

• Customer Connections, CXCM4: 018-574-08 (RoHS: 018-586-20)

• Customer Connections, CXCM4 Interface: 747-275-08

i

TABLE OF CONTENTS

1 INTRODUCTION ............................................................................................................................................................. 1

1.1 Scope of the Manual ..................................................................................................................................... 1

1.2 Product Overview .......................................................................................................................................... 1

1.3 Part Numbers and List Options ..................................................................................................................... 2

2 RECTIFIER FEATURES ................................................................................................................................................... 3

2.1 Front Panel .................................................................................................................................................... 3

2.2 Rear Panel .................................................................................................................................................... 4

2.3 True Module Fail Alarm ................................................................................................................................. 4

2.4 Heat Dissipation ............................................................................................................................................ 4

2.5 Over Temperature Protection ....................................................................................................................... 4

2.6 Wide AC Range ............................................................................................................................................ 5

2.7 AC Inrush/Transient Suppression ................................................................................................................. 5

2.8 Soft Start ....................................................................................................................................................... 5

2.9 Start Delay .................................................................................................................................................... 5

2.10 Current Limit/Short Circuit Protection ........................................................................................................... 5

2.11 Power Limiting ............................................................................................................................................... 5

2.12 High Voltage Shutdown (HVSD) ................................................................................................................... 5

2.13 Battery Eliminator Operation ......................................................................................................................... 6

3 CXCM4 FEATURES ...................................................................................................................................................... 7

3.1 Front Panel .................................................................................................................................................... 7

3.2 Analog Input Channels .................................................................................................................................. 8

3.3 Digital Input Channels ................................................................................................................................... 9

3.4 Alarm and Control Output Relays ................................................................................................................. 9

3.5 System Fail Alarm/Relay ............................................................................................................................... 9

3.6 Network Connection and Remote Communications ..................................................................................... 9

4 INSPECTION................................................................................................................................................................ 10

4.1 Packing Materials ........................................................................................................................................ 10

4.2 Check for Damage ...................................................................................................................................... 10

5 INSTALLATION ............................................................................................................................................................ 11

5.1 Safety Precautions ...................................................................................................................................... 11

5.2 Shelf Preparation/Mounting ........................................................................................................................ 11

5.3 Rectifier Module Insertion/Removal ............................................................................................................ 11

5.4 CXCM4 Module Insertion/Removal ............................................................................................................. 12

6 WIRING AND CONNECTIONS ........................................................................................................................................ 13

6.1 Safety Precautions ...................................................................................................................................... 13

6.2 Tools Required ............................................................................................................................................ 13

6.3 Power System Chassis Ground and DC Ground Reference ...................................................................... 13

6.4 AC Feeder Protection/Sizing ....................................................................................................................... 13

6.5 AC Input Connections ................................................................................................................................. 13

6.6 Calculating Output Wire Size Requirements............................................................................................... 14

6.7 DC Output Connections .............................................................................................................................. 14

6.8 CAN Serial Ports ......................................................................................................................................... 15

6.9 Network Connection and Remote Communications via CXC ..................................................................... 16

6.10 Signal Wiring Connections for CXCM4 ....................................................................................................... 17

7 OPERATION ................................................................................................................................................................ 19

7.1 Main Rectifier States ................................................................................................................................... 19

ii

7.2

Main Rectifier Modes .................................................................................................................................. 20

7.3 Can Bus Communications .......................................................................................................................... 20

7.4 Factory Ranges and Defaults ..................................................................................................................... 21

8 SYSTEM STARTUP ...................................................................................................................................................... 22

8.1 Check System Connections ........................................................................................................................ 22

8.2 Verify AC and Power the Shelf ................................................................................................................... 22

8.3 Check Battery Polarity and Connect ........................................................................................................... 22

8.4 CXC Reset .................................................................................................................................................. 22

9 MAINTENANCE ........................................................................................................................................................... 23

9.1 Fan or Filter Replacement .......................................................................................................................... 23

9.2 MOV Replacement ...................................................................................................................................... 24

10 WARRANTY ................................................................................................................................................................ 25

10.1 Warranty ...................................................................................................................................................... 25

11 ACRONYMS AND DEFINITIONS ..................................................................................................................................... 26

FIGURES

Figure 1–Cordex 24-3.1kW modular switched mode rectifier system .............................................................................. 1

Figure 2–Cordex 24-3.1kW modular switched mode rectifier (shown with optional charcoal finish) ............................... 3

Figure 3–Cordex CXCM4 model system controller front panel (shown with optional gray finish) ................................... 7

Figure 4–LVD control card option ................................................................................................................................... 12

Figure 5–CAN serial ports and termination selection ..................................................................................................... 15

Figure 6–Null modem pinouts ......................................................................................................................................... 16

Figure 7–Showing relay connections .............................................................................................................................. 17

Figure 8–Showing digital input connection method ........................................................................................................ 18

Figure 9–Fan (or filter) replacement ............................................................................................................................... 23

Figure 10–MOV replacement ......................................................................................................................................... 24

030-803-J0 Rev B Page 1 of 26

1 Introduction

1.1 Scope of the Manual

This instruction manual explains the installation, interconnection, and operation of Alpha Technologies’ Cordex

24-3.1kW modular switched mode rectifier system.

NOTE: To aid the user with installation, frequent reference is made to drawings located at the rear of the manual.

1.2 Product Overview

A complete Cordex rectifier system consists of one or more power modules in a common shelf enclosure. The

shelf has connections for AC inputs, DC output, and system communications.

Cordex rectifier modules use a high frequency, switched mode conversion technique to provide a fully regulated

and isolated DC output from the AC mains. The rectifier input is wide range to allow use on 208/220/240Vac

50/60Hz electrical service.

Rectifier power modules are “hot swappable” meaning they can be inserted or removed from the shelf without

cutting power to or from the system or the load.

Additional power modules can be included with the system at the time of ordering or added after the shelf has

been installed.

The shelf rectifier system is designed to operate with the Alpha Cordex System Controller (CXC).

The CXC allows the user to configure, monitor and control the entire DC power system from its touch screen

display similar to that used in a Personal Digital Assistant (PDA). Other features of the unit include temperature

compensation, auto equalization, remote access, dial out on alarm, battery diagnostics, as well as Web server

and SNMP support for configuration and monitoring.

Details of controller operation are provided in the current version software manual.

There are two external CXC models of the system controller that communicate with the shelf via offset RJ-12

shelf connectors. The CXCR is mounted in a rack and the CXCP is (factory) mounted in a panel.

The CXCM4 is a 4 RU model designed for integrated use with the rectifier shelf; requires a connection interface

(adapter) for modular installation and uses the shelf space of the leftmost rectifier position (as viewed from the

front). This CXC model also has a touch screen display.

Features and details for wiring are provided in the respective chapters of this documentation package.

Figure 1–Cordex 24-3.1kW modular switched mode rectifier system

030-803-J0 Rev B Page 2 of 26

1.3 Part Numbers and List Options

This product is available to order under the following part numbers and list options:

Description Part Number/List Option

Cordex 24-3.1kW 23” shelf, flush or mid-mounting (see options) (non-RoHS 030-736-20) ...................... 030-803-20

Basic shelf, may be equipped with up to six Cordex 24-3.1kW modules** ....................................................... *List 0

24V system ........................................................................................................................................................ *List 1

Mid-mounting ................................................................................................................................................... *List 23

Flush mounting ................................................................................................................................................... List 25

DC output, bus bar adapters, 16” deep .............................................................................................................. List 82

AC input, dual three phase (no neutral required) ............................................................................................... List 83

AC input, dual three phase (neutral required, Wye source) ............................................................................... List 84

AC input, single phase ..................................................................................................................................... *List 85

Kydex rear cover ................................................................................................................................................ List 89

Module blank ...................................................................................................................................................... List 90

Cordex 24-3.1kW 19” shelf, flush mounting (see also mid-mounting options), AC input, single phase .... 030-804-20

Basic shelf, may be equipped with up to five Cordex 24-3.1kW modules** (non-RoHS 030-737-20) .............. *List 0

24V system ........................................................................................................................................................ *List 1

Mid-mounting, 19” rack ...................................................................................................................................... List 19

Mid-mounting, 23” rack ...................................................................................................................................... List 23

DC output, bus bar adapters, 16” deep .............................................................................................................. List 82

Kydex rear cover ................................................................................................................................................ List 89

Module blank ...................................................................................................................................................... List 90

Cordex 24-3.1kW rectifier power module (non-RoHS 010-572-20) ........................................................... 010-601-20

Basic module ...................................................................................................................................................... *List 0

Gray finish with blue silkscreen ........................................................................................................................ *List 50

Charcoal finish with white (contrasting) silkscreen ............................................................................................ List 56

1x420Vac and 2x660Vac MOVs ........................................................................................................................ List 81

CXCM4 (Cordex Controller, Modular, 4RU)[takes the space of one rectifier](non-RoHS 018-574-20) .... 018-586-20

Basic unit ............................................................................................................................................................ *List 0

24V system [requires a connection interface (747-275-20) for modular installation] ........................................... List 1

48V system (not available for this rectifier series) ............................................................................................... List 2

Standard temperature (0 to 65 deg.C) ............................................................................................................... List 40

Extended temperature (-40

to 65 deg.C) ......................................................................................................... *List 42

Gray finish with blue silkscreen .......................................................................................................................... List 50

Charcoal finish with white (contrasting) silkscreen .......................................................................................... *List 56

Expanded Flash memory .................................................................................................................................List 110

Analog input configuration: two voltage, four temperature, two current, no bi-voltage ....................................List 121

Analog input configuration: two voltage, two temperature, four current, two bi-voltage ..................................List 125

CXCM4 connection interface, CXRF 24V [necessary for CXCM4 installation in 3.1kW shelf] .................. 747-275-20

LVD override control and distribution alarm card ....................................................................................... 707-307-20

Fan assembly, (spare for Cordex 24-3.1kW) (non-RoHS 747-212-20) ..................................................... 747-359-20

MOV assembly, (spare for Cordex 24-3.1kW) (non-RoHS 707-374-20) ................................................... 707-471-20

* Default option

** See drawings at the rear of this manual.

The above information is valid at the time of publication. Consult factory for up-to-date ordering information.

030-803-J0 Rev B Page 3 of 26

2 Rectifier Features

2.1 Front Panel

Figure 2–Cordex 24-3.1kW modular switched mode rectifier (shown with optional charcoal finish)

2.1.1 LEDs

The front panel LEDs provide:

• Rectifier status summary,

• Rectifier software upgrade in progress indication,

• Locate module pattern.

Rectifier status summary will show the rectifier alarm status, communication fail status and rectifier on/off status.

2.1.1.1 AC ON

The top LED (green) is on when AC is within valid range. The LED will flash (~2Hz) when AC is

outside the nominal range – AC voltage is invalid if the AC Mains Low or AC Mains High

alarm is active. The LED turns off when AC has failed.

2.1.1.2 DC ON

The middle LED (green) is on when the rectifier is delivering power to the load. The LED will

flash when communication is lost. The LED turns off when the rectifier is off; e.g., when

commanded via the CXC.

2.1.1.3 ALARM

The bottom LED (red) is on continuously in the event of an active Module Fail alarm; if the

module is unable to source power as a result of any of the following conditions:

Output fuse blown

AC Mains Input Fail

Module fail (ramp test fail)

High voltage (OVP) shutdown

Thermal shutdown

Local shutdown

UPF fail

No output power

Fan (1 and 2) fail.

The LED will flash (~2Hz) when a minor alarm is detected; if the modules output capability has

been reduced or a minor component failure is detected during the following conditions:

VAC meter fail

AC foldback

Remote equalize

Fan (1 or 2) fail

Low output voltage

High output voltage

Current limit (programmable option)

Power limit (programmable option)

High temperature foldback

Temperature sense fail

Soft start operation

Communications lost.

LEDs

Thumbscrew

030-803-J0 Rev B Page 4 of 26

The LED remains off in the absence of an alarm. If the unit output is not connected to a battery

or parallel rectifier, the LED will extinguish if no AC power is present.

2.1.1.4 LED Activity During Software Upload

When a rectifier software upload is in progress, the LEDs will behave in a distinctly different way

to indicate new rectifier software is being transferred from the CXC.

When a rectifier data transfer is in progress, all three LEDs will flash in a sequence lasting 1.5

seconds. When the last LED is lit, the sequence is repeated beginning at the first LED.

2.1.1.5 LED Activity During ‘Locate Module’ Command from CXC

When the ‘locate module’ command has been received from the CXC, the LEDs will behave in

another distinct fashion so that the rectifier is easier to visually identify among adjacent

rectifiers.

This state is entered when commanded via the CXC. The LEDs will flash in a ping-pong pattern

repeating every 2 seconds.

The ping-pong pattern lights each LED sequentially. After the last LED is lit, each LED is lit in

reverse sequence. When the first LED is lit, the pattern repeats. The effect makes it appear as if

the light is bouncing between the first and last LED.

2.1.2 Mechanical

A thumbscrew is provided to secure the rectifier into the shelf. During normal operation the rectifier shall be

locked into position. A handle (or grip) is incorporated into the front panel to facilitate the removal of the rectifier

from the shelf. No special tools are required.

2.2 Rear Panel

Located on the rear panel of the rectifier is a single connector for shelf power and communications.

2.3 True Module Fail Alarm

The power modules have a “true” fail alarm. This provides a true indication of the power module’s ability to source

current. When the module’s output current drops below 2.5% of the rated output a low output current condition is

detected and the Module Fail detection circuit is activated. This circuit momentarily ramps up the output voltage to

determine if the module will source current. If no increase in current is detected, the Module Fail alarm is

activated. The module will test once every 60 seconds for the condition until current is detected. Output voltage

ramping will cease upon detection of current

1

. A minimum 2.5% load is required to avoid the Ramp Test Fail

alarm; this can typically be provided with the parallel system battery. Activation of this alarm could indicate a failed

module or a failed load.

NOTE: For Cordex rectifier systems without batteries (or with a very light load; below 2.5% of rated output) it is

recommended that the ramp test be disabled to avoid nuisance alarms. The Ramp Test feature is

enabled/disabled via the CXC menu item: Rectifiers, Configure Settings.

2.4 Heat Dissipation

Each rectifier module is equipped with at least one front-mounted fan. The fan operates at temperatures above

0°C (32°F). Cooling of the module is front-to-rear with the exhaust air exiting at the back. The fan is variable

speed; which is determined by heatsink temperature and load.

2.5 Over Temperature Protection

Each rectifier module is protected in the event of an excessive increase in temperature due to component failure

or cooling airflow blockage. During over temperature conditions, the rectifier limits the output power as well as the

1

Under normal conditions, a battery connected to the output of the rectifier will draw current when the voltage ramp occurs. Therefore the rectifier fail

alarm will not be generated with a battery connected.

030-803-J0 Rev B Page 5 of 26

output current. If temperature continues to increase, a shutdown of the rectifier is initiated. The rectifier shall

restart automatically if the temperature has returned to a safe level.

2.6 Wide AC Range

A minor alarm is generated when the AC input voltage drops below specification. Rectifier output power is

reduced linearly between 176Vac and 150Vac to 75% of the rated output power (the unit will deliver derated

output power down to 80Vac).

At 80Vac, the module will shut down and will not restart until the AC is greater than or equal to 150Vac; however,

the restart voltage depends on the load current. At reduced load current the unit may restart with the input voltage

as low as 100Vac.

For voltages above 277Vac, power factor and total harmonic distortion may be derated. Up to 320Vac, the

rectifier will be operational and shall not suffer any damage.

2.7 AC Inrush/Transient Suppression

The inrush current of the rectifier module is limited to the full load steady state line current to prevent surge on the

AC line. Modules are also protected from input lightning and transient surges in accordance with IEEE/ANSI

C62.41 Category B3.

2.8 Soft Start

To eliminate an instantaneous demand on the AC source, a soft start feature is employed. Soft Start, sometimes

referred to as “current walk-in”, works by gradually (up to five seconds) ramping the current limit up from zero to

the actual or defined customer setting. The rectifier output voltage is ramped up from the minimum voltage to the

float voltage.

2.9 Start Delay

The rectifier modules are equipped with a delay timer in order to stagger start a series of modules to prevent

excessive loading of generators upon start up. The built-in timer delays the turn on of the module depending on

the value selected (up to 120 seconds) via the CXC. A minimum one-second delay is preset to allow charging of

the input capacitors.

2.10 Current Limit/Short Circuit Protection

The current limit function determines the maximum output current limit of the rectifier module, regardless of output

voltage or power. Maximum output current is limited to a constant value down to short circuit condition. Current

limiting can be used to mate the rectifier output current ampacity to the needs of the load and parallel battery to

minimize excessive battery recharge current.

The rectifier will sustain a short circuit at the output terminals indefinitely. The maximum short circuit current shall

not exceed 105% of the rated full load current.

2.11 Power Limiting

Each rectifier module is designed to limit power output to the module specification. This enables more current to

be supplied at lower output voltages, and allows matching of output to the demand of constant power loads,

normally seen with telecom equipment.

This feature may also be used for a faster recharge of flooded batteries paralleled with the load.

NOTE: Current limiting overrides the power-limiting feature.

2.12 High Voltage Shutdown (HVSD)

This feature provides protection to the load from over voltage conditions originating from the rectifiers. It operates

by shutting down the offending rectifier module when a high output voltage condition occurs. Indication is through

the red Alarm (Module Fail) LED. Modules will restart automatically; however, if more than three over voltage

conditions occur in one minute, the module will latch off and remain shut down until it is reset via the CXC.

030-803-J0 Rev B Page 6 of 26

2.13 Battery Eliminator Operation

Rectifier modules maintain all specifications (except where indicated) with or without a battery attached in parallel

to the output; however, if a battery or another module supplying DC voltage in parallel is not present, there will be

no monitoring or control activity if there is an AC power failure or input fuse failure.

030-803-J0 Rev B Page 7 of 26

3 CXCM4 Features

The CXCM4 (Cordex Controller, Modular, 4RU) is mounted in the rectifier system shelf and brings advanced

monitoring technology to the Cordex series of rectifiers. This compact system controller is designed for seamless

operation and set up of Alpha power systems and is equipped with the complete range of Cordex software

features, including the following:

• Designed to communicate directly with Cordex rectifiers

• Includes battery temperature compensation charging

• Battery performance diagnostics

• Provides local and remote communications

• User definable alarms

• Daily logging of power system events and system statistics.

Behind the CXCM4’s front panel lies the main controller motherboard, which contains a microprocessor, memory,

as well as numerous other electronic components.

The CXCM4 includes a web server providing easy set up and monitoring using an Internet connection with the

standard Windows Internet Explorer browser.

The data logging feature allows the user to capture data from multiple inputs, for AC/DC voltages, load/battery

current, cell voltages & temperatures (automatically for up to 16 user defined logs). Typical applications of the

CXCM4 logging include power system details, thermal performance of outdoor enclosures, battery cell specifics,

or mains variations captured by an AC voltage watchdog.

A built-in audio speaker sounds an intermittent tone during active alarms.

The input/output (I/O) board houses a series of terminal connections; located at the back of the system shelf.

3.1 Front Panel

3.1.1 Display

Located on the front panel is a 160 x 160-pixel graphical LCD with touch screen similar to those used in PDAs.

This graphical user interface (GUI) allows the operator to interact with screen selectable items using a fingertip.

Figure 3–Cordex CXCM4 model system controller front panel (shown with optional gray finish)

RS

-232 (craft port)

Touch screen

Reset (RST) button

System status

LEDs

Ethernet port

030-803-J0 Rev B Page 8 of 26

3.1.2 LEDs

The CXCM4 has three LEDs located on the front panel. These are used to display the alarm status of the power

system, CXCM4 progress and status during startup, file transfers and lamp tests.

3.1.2.1 Alarm Conditions

The CXCM4 illuminates the LED that corresponds to the system alarm status. The following

show the corresponding alarm status for each LED color:

Green – OK, no alarms present

Yellow – Minor alarm is present (no major alarms)

Red – Major alarm is present.

Only one LED is illuminated at a time during alarm conditions.

3.1.2.2 Progress and Status Indication

The LEDs are also used in the following situations:

Base unit validation – all three LEDs are on at the same time.

File transfer – when recovering from invalid firmware application – the red LED is illuminated.

Lamp Test – all three LEDs flash on and off at the same time for 2 seconds.

3.1.3 Reset

A reset button is located on the front panel for restarting the CXCM4’s microprocessor. It takes approximately 15

seconds before the display reappears after pressing the reset button.

NOTE: Refer also to the software manual – always select the shutdown menu item before pressing the reset button.

3.1.4 Ethernet Port

The Ethernet port is designed for CXCM4 connection to a user supplied network (TCP/IP secured by user) via a

front panel RJ-45 jack and a standard network cable.

Local access (e.g. laptop computer) is also possible from the Ethernet port connection using a standard network

crossover cable.

3.1.5 RS-232 Serial (Craft) Port

Local access to the CXCM4 is possible through a front panel RS-232 serial port; using a null modem cable. The

communication protocol supports a web interface (via Microsoft® Internet Explorer 6 or greater). The remote

screen display is an enhanced version of the CXC’s front panel display.

3.2 Analog Input Channels

The CXCM4 has analog input channels for voltage, current, and temperature. See Section 6.10.3.

3.2.1 Voltage Inputs

Two voltage input channels, V1 and V2, provide monitoring of discharge and charge voltage. The CXCM4

software is pre-configured to monitor V1 for load voltage and V2 for battery voltage. V2 is used as the system

reference for rectifier float voltage, low voltage disconnect (LVD), system high voltage alarm, and system low

voltage alarm.

3.2.2 Current Inputs

The CXCM4 software is pre-configured to monitor I1 for load current using an external 50mV current shunt.

030-803-J0 Rev B Page 9 of 26

3.2.3 Temperature Inputs

Two temperature input channels, T1 and T2, provide monitoring of battery temperature and temperature

compensation (temp comp) or room/ambient temperature. A voltage is supplied to these terminals to power the

temperature sensors.

3.3 Digital Input Channels

The CXCM4 can accommodate up to four channels and can monitor digital alarm/control signals from rectifiers,

converters and many other types of equipment. See Section 6.10.2.

3.4 Alarm and Control Output Relays

The CXCM4 contains eight Form C digital alarm output relays to extend alarms and control external apparatus.

Each internally generated alarm or control signal may be mapped to any one of the relays, or, several signals may

be mapped to just one relay or none at all. See Section 6.10.1.

3.4.1 LVD Control (External Option)

The LVD Control functions can be hardwired directly from the assigned relay output to an optional LVD override

control and distribution alarm card. This provides a safety measure to protect against load disconnect during

CXCM4 reset or replacement; e.g. when the controller is off-line. Operators may also perform test and

maintenance procedures on the CXCM4 without disturbing the load.

3.5 System Fail Alarm/Relay

The CXCM4 system fail alarm activates because of a major internal failure. During such a condition, the unit will

attempt to reset, but if this fails, an alarm condition will be extended to a relay and the red LED on the front panel

will illuminate. This is a fail-safe signal to the remote monitoring equipment; i.e. alarm will be extended even if

power to the unit is interrupted.

3.6 Network Connection and Remote Communications

The Cordex system can be set up, monitored and tested via ETHERNET 10/100 Base-T serial data connection.

The communication protocol supports a web interface. All alarming and control of Cordex rectifiers is

accomplished with a CXC via a CAN bus.

A step-by-step connection wizard – provided to establish remote communications with your CXC – is available via

the Alpha website (www.alpha.ca).

When connected to the CXC remotely, an online help guide is provided to supplement the software manual with

regard to the features of the web interface.

030-803-J0 Rev B Page 10 of 26

4 Inspection

4.1 Packing Materials

All Alpha products are shipped in rugged, double walled boxes and suspended via solid inserts to minimize shock

that may occur during transportation. Packaging assemblies and methods are tested to International Safe Transit

Association standards.

Products are also packaged with Cortex. This plastic wrap contains a corrosive-inhibitor that protects the product

from corrosion for up to two years.

4.1.1 Returns for Service

Save the original shipping container. If the product needs to be returned for service, it should be packaged in its

original shipping container. If the original container is unavailable, make sure the product is packed with at least

three inches of shock-absorbing material to prevent shipping damage.

NOTE: Alpha Technologies is not responsible for damage caused by the improper packaging of returned products.

4.2 Check for Damage

Prior to unpacking the product, note any damage to the shipping container. Unpack the product and inspect the

exterior for damage. If any damage is observed contact the carrier immediately.

Continue the inspection for any internal damage. In the unlikely event of internal damage, please inform the

carrier and contact Alpha Technologies for advice on the impact of any damage.

Verify that you have all the necessary parts per your order for proper assembly.

030-803-J0 Rev B Page 11 of 26

5 Installation

This chapter is provided for qualified personnel to install the product, which shall be mounted in a clean and dry

environment.

NOTE: To aid the user with installation, frequent reference is made to drawings located at the rear of the manual.

5.1 Safety Precautions

WARNING

Hazardous voltages are present at the input of power systems. The DC output from the rectifiers

and battery system, though not dangerous in voltage, has a high short circuit current capacity

that may cause severe burns and electrical arcing.

Before working with any live battery or power system/distribution center, follow these precautions:

• Remove all metallic jewelry; e.g., watches, rings, metal rimmed glasses, necklaces.

• Wear safety glasses with side shields (and prescription lenses if necessary) at all times during installation.

Metallic tools must be insulated.

The installer should follow all applicable local rules and regulations for electrical and battery installations; e.g.,

CSA, UL, CEC, NEC, OSHA, and local fire codes.

5.2 Shelf Preparation/Mounting

The 19” shelf has been designed for flush mounting in a standard EIA relay rack. Options for mid-mounting in a

19” or 23” rack are also available.

The 23” shelf may be flush or mid-mounted in a 23” relay rack.

NOTE: The shelf shall be mounted in a clean and dry environment. Allow at least 1.75” of free space in front of the unit

for unrestricted cooling airflow.

Mounting brackets accommodate either 1” or 1-3/4” rack spacing. The shelf should be mounted to the rack using

at least two #12 – 24 x 1/2” screws in each bracket. Philips-type screws and screwdriver should be used to

eliminate the possibility of slippage and scratching of the unit’s exterior. Washers (such as internal tooth) or

special screws that are designed to cut through the painted surface should be used to ensure a good chassis

ground.

5.3 Rectifier Module Insertion/Removal

Insert by placing the rectifier module on the shelf bottom and sliding the module into the rear connector (inside of

the shelf). Apply pressure on the module handle to engage the rear connector in the shelf receptacle.

NOTE: It is recommended that the first module be inserted into the front leftmost position using the side of the shelf (or

the optional shelf-mounted controller) as a guide. Subsequent modules may be inserted using the previous

module as a guide.

Tighten the screw on the bottom of the faceplate to secure the module to the shelf.

NOTE: Do not force a module into position if it does not seat properly. All modules are keyed to ensure that the correct

module (voltage/polarity) type is used.

To remove a module, loosen the screw on the bottom of the faceplate. Grasp handle and pull out, sliding the

module away from the rear connector and out of the shelf.

030-803-J0 Rev B Page 12 of 26

5.4 CXCM4 Module Insertion/Removal

Insert by placing the controller on the shelf bottom and sliding the module into the CXCM4 connection interface

(inside of the shelf, see drawing 747-275-08). Apply pressure on the metal faceplate to engage the rear

connectors.

Tighten the screw on the bottom of the faceplate to secure the module to the shelf.

NOTE: Do not force a module into position if it does not seat properly. All modules are keyed to ensure that the correct

module (voltage/polarity) type is used.

WARNING

Before removing a CXCM4 from a live system, an external LVD override is required to avoid a

disruption of service.

Figure 4–LVD control card option

The LVD Control functions can be hardwired directly from the assigned relay output to an optional LVD override

control and distribution alarm card (shown above).

Place the LVD Control switch to the OVERRIDE IN position to keep the LVD contactor engaged.

To remove a module, loosen the screw on the bottom of the faceplate. Slide the module away from the rear

connectors and out of the shelf.

Insert the replacement controller (as described above). The front-panel LED’s will illuminate temporarily, but will

extinguish after the system has finished its 15 second self-test.

WARNING

Do not leave the switch in the OVERRIDE IN position. Doing so may result in a complete discharge

of the batteries during a power failure situation.

To allow the CXCM4 to resume automatic control of the LVD contactor, return the LVD Control switch to the

AUTO IN position.

OVERRIDE IN or Inhibit

(amber) LED

LVD control switch

AUTO IN (green) LED

030-803-J0 Rev B Page 13 of 26

6 Wiring and Connections

This chapter provides cabling details and notes on cable sizing for DC applications with respect to the Alpha

Cordex 24-3.1kW modular switched mode rectifier system.

6.1 Safety Precautions

WARNING

Hazardous AC voltages may be present. Ensure power at the AC service panel is off before

attempting work on the AC connections. Use a voltmeter to verify the absence of voltage. Clearly

mark the correct polarity of the battery leads before commencing work on DC connections.

Refer to the previous (Installation) chapter for additional safety precautions.

6.2 Tools Required

Various tools are essential for product installation. Use this list as a guide:

• Philips head screwdriver, #1 (tip size 5/32”)

• Philips head screwdriver, #2 (tip size 3/16”)

• Slot head screwdriver (blade size 1/4”)

• Digital voltmeter equipped with test leads

• Adjustable 24Vdc load (optional)

• Cutters and wire strippers (#10 to #22AWG) (6 to 0.34mm

2

)

• Crimping tool (optional for large gauge wire)

• Socket and rachet set (Imperial measure)

• Anti-static wrist strap

• Computer (laptop) with Microsoft Internet Explorer 6 or greater

• Crossover cable RJ-45 (for access using the Ethernet port).

6.3 Power System Chassis Ground and DC Ground Reference

WARNING

For safety reasons, ensure the system is properly bonded to the building’s ground grid.

Both the shelf chassis ground (via power system chassis ground) and common return shall be connected to the

site ground to ensure correct operation of the system and to prevent drifting floating analog (especially current)

readings.

6.4 AC Feeder Protection/Sizing

To maximize system reliability, each power module should be fed from a dedicated protection feeder breaker

located at the AC distribution panel. The feeder breaker can also act as the disconnect device for the connected

module. Refer to the specifications at the front of this manual for Alpha recommendations.

6.5 AC Input Connections

WARNING

Use care when removing or replacing the covers for the AC input connections. Never assume that

an electrical connection or conductor is not energized.

CAUTION: AC input wires should be routed in flexible or rigid conduit as far away as possible

from the DC power wires to minimize EMI disturbances.

Ensure all modules are removed from the shelf.

The wireway is designed for two customer-supplied 1” conduit fittings for AC supply located one on each side of

the shelf. Attach the conduit retainers to the wireway hole(s) and route the AC cables through. Secure the wires to

the AC input and chassis ground terminals as required (see below). Tighten the cable connector to the AC cable

(conduit similar).

030-803-J0 Rev B Page 14 of 26

Replace rear cover(s) once all connections have been completed.

6.5.1 Single Phase

Remove the metal covers (2 places) from the rear of the shelf to expose the AC input terminal blocks, L1 and L2

for each rectifier. Each terminal pair relates to an individual power module as marked.

6.5.2 Dual Three Phase (23” shelf only)

Remove the metal covers (2 places) from the rear of the shelf to expose the AC input terminal blocks, L1, 2 and 3

for each rectifier grouping. N (for neutral) will also be used for the option selected when a Wye source is provided.

6.6 Calculating Output Wire Size Requirements

Wire size is calculated by first determining the appropriate maximum voltage drop requirement. Using the formula

below calculate the CMA wire size requirement. Determine the size and number of conductors required to satisfy

the CMA requirement.

CMA = (A x LF x K) / AVD, where:

CMA = Cross section of wire in circular MIL area

A = Ultimate drain in amps

LF = Conductor loop feet

K = 11.1 constant factor for commercial (TW type) copper wire

AVD = Allowable voltage drop

Check again that the ampacity rating of the cable meets the requirement for the installation application. Consult

local electrical codes (NEC, CEC, etc.) for guidelines. If required, increase the size of the cable to meet the code.

6.7 DC Output Connections

WARNING

Leave cables or bus bars disconnected at battery and verify output polarity using a voltmeter.

Make battery connections only after all other wiring is completed.

DC output wire shall be UL approved XHHW or RHH/RHW (for Canadian users, RW90 Type). Control and sense

wires shall be UL approved Style 1015 (for Canadian users, TEW type).

The common output leg of the rectifier system should be connected to ground. This is typically done at the load

common termination point.

6.7.1 Cable

Terminate cable leads with appropriate crimp lugs for 3/8” holes on 1” centers.

Secure the positive and negative to the shelf output post of the correct polarity; i.e., +Vcable to +Vpost. Ensure

the washers are on the bolts in the same order in which they were shipped from the factory. Tighten the bolts as

per Customer Connections drawing at the rear of this manual.

6.7.2 Bus Bar

Bus bar adapters may be factory-installed, for the option selected, to easily accommodate direct connections to

customers’ vertical bus bars.

Secure the positive and negative to the shelf output post of the correct polarity; i.e., +Vcable to +Vpost. Ensure

the washers are on the bolts in the same order in which they were shipped from the factory. Tighten the bolts as

per Customer Connections drawing at the rear of this manual.

030-803-J0 Rev B Page 15 of 26

6.8 CAN Serial Ports

Two CAN Serial ports (modular jacks with offset latches), are provided for communications with Alpha’s Cordex

rectifiers and other CAN-enabled equipment. These are located on the left side of the shelf (as viewed from the

front).

Daisy-chain from shelf to shelf (CAN OUT of one shelf to CAN IN of another) as necessary and ensure that only

the last shelf is terminated. See Figure 5.

6.8.1 CAN Termination

A jumper (or switch depending on your configuration) allows setting of the CAN OUT to be open (to the next shelf

in the system) or terminated. Termination must be enabled in final shelf on the CAN bus only. Access termination

selection (inside the shelf) by removing the leftmost rectifier #1 (MDL 1).

Figure 5–CAN serial ports and termination selection

030-803-J0 Rev B Page 16 of 26

6.9 Network Connection and Remote Communications via CXC

The Cordex system can be set up, monitored and tested via ETHERNET 10/100 Base-T serial data connection.

The communication protocol supports a web interface.

NOTE: Pinouts are shown in customer connections drawing for CXCM4.

Some standard scenarios are described below:

6.9.1 Ethernet Port for Network Connection (Standard Network Cable)

The Ethernet port is designed for CXC connection to a user supplied network (TCP/IP secured by user) via a front

panel RJ-45 jack. Connect to the Cordex shelf using a standard network cable.

6.9.2 Ethernet Port for Local Connection (Crossover Cable)

Local access (e.g. laptop computer) is also possible from the Ethernet port connection using a standard network

crossover cable.

6.9.3 CXC RS-232 Serial (Craft) Port for Local Connection

Local access to the CXC (CXCM4 or CXCP or CXCR) is possible through the front panel RS-232 serial port using

a null modem cable:

Figure 6–Null modem pinouts

030-803-J0 Rev B Page 17 of 26

6.10 Signal Wiring Connections for CXCM4

The CXCM4 (specifications 018-586-B1) requires an adapter for modular installation (drawing 747-275-08).

NOTE: To aid the user with installation, frequent reference is made to drawings located at the rear of this manual.

Custom configurations may be detailed within the Alpha power system documentation package.

For terminal block connections, the recommended wire sizes are 0.823 to 0.129mm

2

(#18 to #26 AWG) for the

temperature range of 0 to 50 deg. C (as per UL/CSA).

CAUTION: to reduce risk of fire, use only 0.129mm

2

(#26 AWG) or larger wire.

6.10.1 Alarm (Relay) Outputs

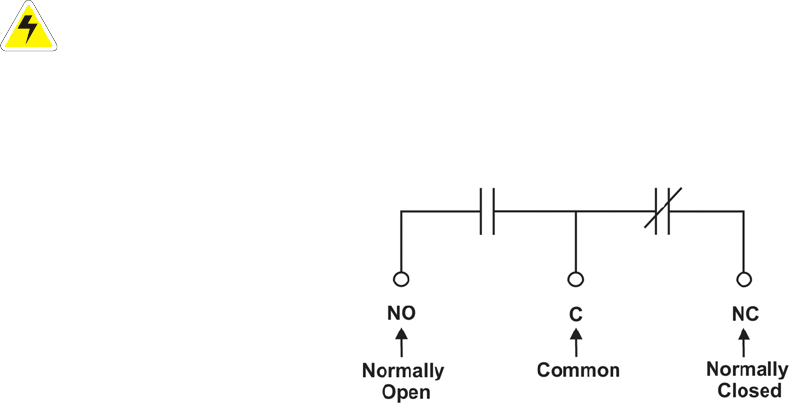

Terminals provide contacts for extending various alarm or control signals. Each relay output can be wired for NO

or NC operation during an alarm or control condition. See Figure 7.

Figure 7–Showing relay connections

Relays can be programmed to energize or de-energize during an alarm condition (see CXC Software manual).

When the CXCM4 reset button is pressed or power is lost, all relays de-energize.

System Fail output relay (K0) is fail-safe and will de-energize during an alarm condition.

6.10.1.1 LVD Control (External Option)

The LVD Control functions can be hardwired directly from the assigned relay output to an

optional LVD override control and distribution alarm card. This provides a safety measure to

protect against load disconnect during CXCM4 reset or replacement (see Section 5.4); e.g.

when the controller is off-line. Operators may also perform test and maintenance procedures on

the CXCM4 without disturbing the load.

6.10.2 Digital Inputs for CXC

The digital input channels (factory-installed) are used to monitor various alarm and control signals. All input

channels are voltage activated and accept a bipolar (i.e. negative or positive) DC signal directly.

6.10.2.1 Connection Method

Typical Alpha systems use the “reset with Hot and trigger with Ground” connection. The digital

input is wired in such a way that the Hot is wired directly into one of the input terminals; e.g.,

positive input for +24V systems. The other input terminal is wired to the Ground (common) of

the system through a relay (dry contact – usually located on the equipment requiring

monitoring). This method (see Figure 8) allows the digital input to receive (or not receive) a

Ground signal on an alarm.

030-803-J0 Rev B Page 18 of 26

Figure 8–Showing digital input connection method

6.10.2.2 Programming the Digital Input

The digital input channels can be programmed for “active high” or “active low.” Active high

indicates “alarm on the presence of a ground signal” and active low indicates “alarm on the

removal of a ground signal.” See CXC Software manual for detailed instruction on

programming.

Voltage Range (VDC)

Voltage Level (VDC)

Considered As “0” (Off)

Voltage Level (VDC)

Considered As “1” (On)

0—60

(system voltage setting)

0—3 18—60

Table A–Voltage level definitions for digital inputs

6.10.3 Analog Inputs

CAUTION: Ensure the correct polarity is used for all input cable terminations.

The analog input channels are used to monitor various types of electrical signals. Some of the analog channels

are reserved for specific signals, while others are designated as general-purpose inputs, which accommodate

various types of analog signals.

The Battery +24V should be connected at the battery system voltage terminal for CXC reference when a battery