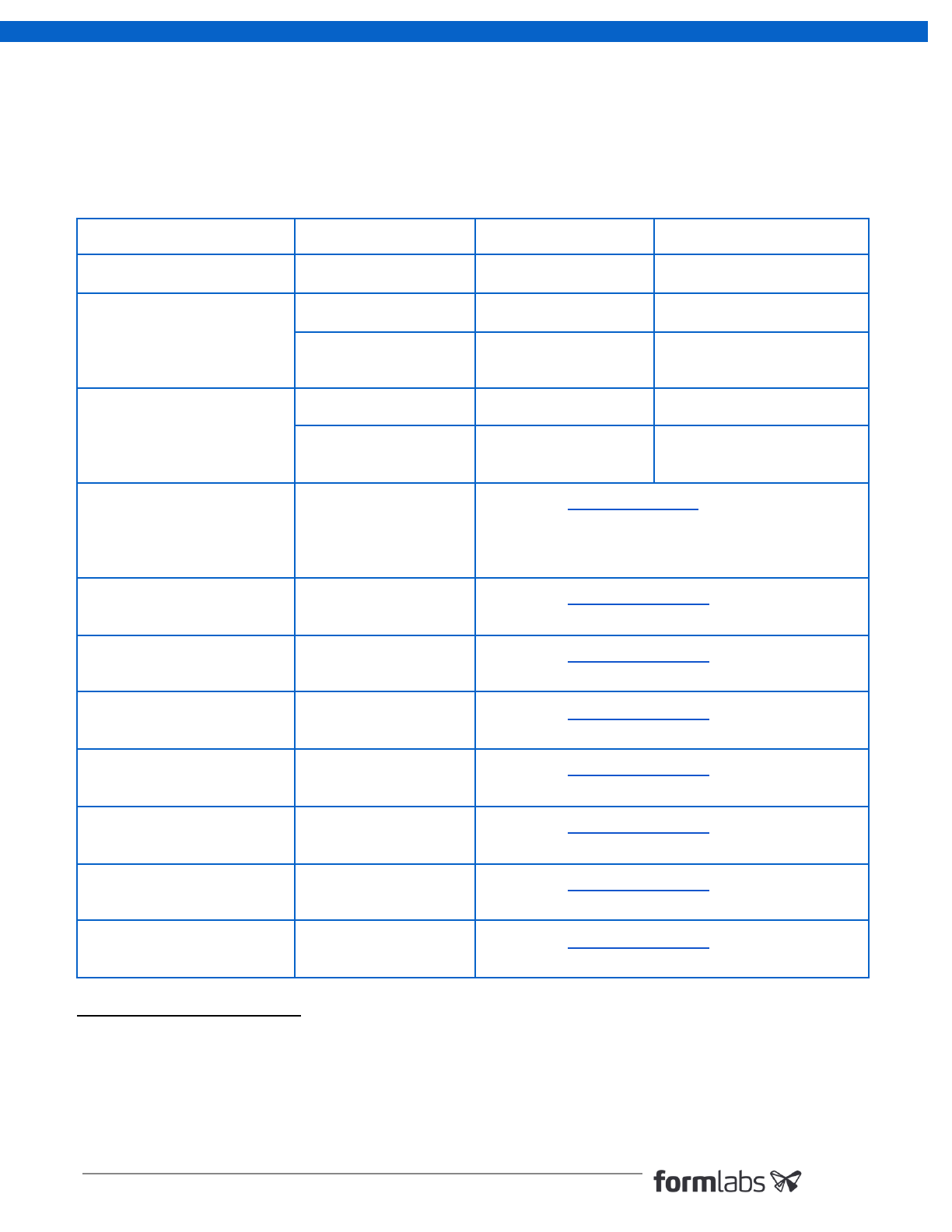

Form Cure time and temperature settings

Post-cure printed parts after washing to achieve optimal material properties. Refer to

formlabs.com/cure-support for the most updated information about post-curing printed parts with the

Form Cure.

RESIN

POST-CURE SETTING

POST-CURE TIME

POST-CURE TEMPERATURE

Alumina 4N Resin

N/A

4

N/A

N/A

Black Resin V4

Color Resin

Grey Resin V4

White Resin V4

Recommended

1

30 min

60 °C

Full post-cure

60 min

60 °C

Black Resin V5

Clear Resin V5

Grey Resin V5

White Resin V5

Default

1

5 min

No heat

Enhanced mechanical

properties

15 min

60 °C

BEGO™ VarseoSmileⓇ

TriniQⓇ Resin

Full post-cure

2

Refer to the Instructions for Use for washing and

post-curing instructions for this resin. Enter the item

number (REF) from the resin cartridge label to access

the IFU.

BioMed Amber Resin

Full post-cure

3

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

BioMed Black Resin

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

BioMed Clear Resin

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

BioMed Durable Resin V1

BioMed Durable Resin V1.1

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

BioMed Elastic 50A Resin

11

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

BioMed Flex 80A Resin

11

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

BioMed White Resin

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

3

This post-cure setting ensures that parts achieve both biocompatibility and optimum mechanical properties.

Read the Manufacturing Guide for a full description of the workflow.

2

This post-cure setting ensures that parts achieve both biocompatibility and optimum mechanical properties.

Read the Manufacturing Guide for a full description of the workflow.

1

Recommended post-cure settings achieve close-to-optimal mechanical performance and minimize post-cure

time. Full post-cure settings achieve optimal mechanical properties. Use full post-cure settings when using

materials for functional applications.

Last updated: 5 September 2024

Castable Resin

Full post-cure

4

240 min

60 °C

Castable Wax Resin

Castable Wax 40 Resin

N/A

5

N/A

N/A

Ceramic Resin

N/A

4

N/A

N/A

Clear Cast Resin

Recommended

1

15 min

60 °C

Full post-cure

30 min

60 °C

Clear Resin V4

Recommended

1

15 min

60 °C

Full post-cure

30 min

60 °C

Custom Tray Resin

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

Dental LT Clear Resin V1

Full post-cure

2

20 min

80 °C

Dental LT Clear Resin V2

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

Dental LT Comfort Resin V1

Dental LT Comfort Resin V1.1

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

Denture Base Resin

Full post-cure

6

Refer to the Instructions for Use for washing and

post-curing instructions for this resin.

Denture Teeth Resin

Full post-cure

7

Refer to the Instructions for Use for washing and

post-curing instructions for this resin.

Draft Resin

Better elongation

5 min

No heat

Better UTS

5 min

60 °C

Durable Resin V2

Durable Resin V2.1

Full post-cure

8

60 min

60 °C

Elastic 50A Resin V1

Full post-cure

20 min

60 °C

Elastic 50A Resin V2

Full post-cure

11

10 min preheat

30 min post-cure

70 °C

70 °C

ESD Resin

Full post-cure

60 min

70 °C

8

For parts printed with Durable Resin, the tensile modulus increases throughout the first hour of post-curing.

7

This post-cure setting ensures that parts achieve both biocompatibility and optimum mechanical properties.

Read the Instructions for Use for a full description of the workflow.

6

This post-cure setting ensures that parts achieve both biocompatibility and optimum mechanical properties.

Read the Instructions for Use for a full description of the workflow.

5

Does not require post-curing. After washing, allow parts to fully dry before firing/casting.

4

Cure for 4 hours to increase the part strength. Increasing cure time may improve casting results, particularly for

thicker parts, though casting success depends more on part geometry and casting process.

Last updated: 5 September 2024

Fast Model Resin

Default

1

5 min

No heat

Enhanced mechanical

properties

15 min

60 °C

Flame Retardant Resin

Better toughness

60 min

70 °C

Better HDT

120 min

80 °C

Flexible Resin

Recommended

1

15 min

60 °C

Full post-cure

60 min

60 °C

Flexible 80A Resin V1

Flexible 80A Resin V1.1

Soft Tissue Resin

Full post-cure

10 min

60 °C

Grey Pro Resin

Full post-cure

9

15 min

80 °C

High Temp Resin V1

Recommended

1

30 min

60 °C

Full post-cure

60 min

60 °C

High Temp Resin V2

Recommended

10

120 min

80 °C

Thermal post-cure

180 min

160 °C

IBT Flex Resin

11

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

IBT Resin

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

Model Resin V2

Recommended

1

30 min

60 °C

Full post-cure

60 min

60 °C

Model Resin V3

Full post-cure

5 min

60 °C

Permanent Crown Resin

Full post-cure

9

Refer to the Instructions for Use [EN] [EU] for washing

and post-curing instructions for this resin.

Precision Model Resin

Full post-cure

5 min

35 °C

Premium Teeth Resin

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

Rigid 4000 Resin

Full post-cure

7

15 min

80 °C

Rigid 10K Resin V1

Recommended

8

60 min

70 °C

10

There are several post-curing options for High Temp Resin V2 and Rigid 10K Resin. Refer to the technical data

sheet to understand how different options affect mechanical properties, and choose the post-cure option that is

best suited to the intended application.

9

There is no significant gain in properties after 15 minutes. There is only one recommended post-curing time.

Last updated: 5 September 2024

Rigid 10K Resin V1.1

Thermal post-cure

125 min

90 °C

Silicone 40A Resin

11

Full post-cure

45 min

60 °C

Surgical Guide Resin

Full post-cure

2

Refer to the Manufacturing Guide for washing and

post-curing instructions for this resin.

Temporary CB Resin

Full post-cure

11

Refer to the Instructions for Use for washing and

post-curing instructions for this resin.

Tough 2000 Resin V1

Tough 2000 Resin V1.1

Recommended

1

60 min

70 °C

Tough Resin V5

Recommended

1

60 min

60 °C

Full post-cure

120 min

60 °C

Tough 1500 Resin V1

10

Tough 1500 Resin V1.1

10

Full post-cure

60 min

70 °C

11

This cure setting ensures that parts achieve both biocompatibility and optimum mechanical properties. Remove

supports and sandblast between post-curing cycles. Read the Manufacturing Guide for a full description of the

workflow.

10

If parts printed with Tough 1500 Resin will be used for skin contact use, parts must be post-cured in a Form Cure

at 70°C for 60 minutes.

11

This cure setting ensures that parts achieve both biocompatibility and optimum mechanical properties. Read the

Manufacturing Guide for a full description of the workflow.

Last updated: 5 September 2024