LECTURE NOTES

ON

ELECTRICAL INSTALLATION &

ESTIMATING

Mrs. Lipsarani Bagh

Lecturer, Electrical Engineering Department

GOVERNMENT POLYTECHNIC, SAMBALPUR

CAPTER-1

INDIAN ELECTRICITY RULES

1.1 Denions, Ampere, Apparatus, Accessible, Bare, cable, circuit, circuit breaker, conductor

voltage (low, medium, high, EH), live, dead, cut-out, conduit, system, danger, Installaon,

earthing system, span, volt, switch gear, etc.

1.2 General safety precauons, rule 29, 30, 31, 32, 33, 34, 35, 36, 40, 41, 43, 44, 45, 46.

1.3 General condions relang to supply and use of energy : rule 47, 48, 49, 50, 51, 54, 55, 56,

57, 58, 59, 60, 61, 62, 63, 64, 65, 66, 67, 68, 70.

1.4 OH lines : Rule 74, 75, 76, 77, 78, 79, 80, 86, 87, 88, 89, 90, 91

1.1 DEFINITIONS

AMPERE

Ampere is the unit of electric current in IS unit.

An ampere is a unit of measure of rate of electron ow in an electrical conductor. One

ampere of current represents one coulomb of electric charge charge(6.24x10

18

) moving a

specic point in one second.

APPARATUS

It is a technical equipment or machinery needed for a parcular acvity or purpose. OR

It is a set of materials or equipment designed for a parcular use. OR

Apparatus” means electrical apparatus and includes all machines, ngs,

accessories and appliances in which conductors are used.

ACCESSIBLE

Accessible means easy to approach, reach, enter, speak with or use.

BARE

Bare means the conductor which is not covered with insulang materials.

CABLE

“Cable” means a length of insulated single conductor. The conductor may be solid or stranded

, two no of more than two no and each provided with its own insulaon. Such insulated

conductor or conductors may or may not be provided with an overall mechanical protecve

covering.

CIRCUIT

“Circuit” means an arrangement of conductor or conductors for the purpose

of conveying energy and forming a system or a branch of a system.

OR

Circuit is an interconnecon of electrical components and conductors which form a complete

path for the current to ow through it.

CIRCUIT BREAKER

“Circuit breaker” means a device which is capable of making and breaking the

circuit under all condions.

OR

A circuit breaker is an electrical protecve device which protect the circuit from damaged

caused by overcurrent, overload or short circuit by breaking the circuit.

CONDUCTOR VOLTAGE

It is the voltage/potenal dierence between any two conductor or voltage/potenal

dierence between any conductor and neutral.

Low voltage-voltage level below 250volt.

Medium voltage- voltage level between 250volt to 650volt.

High voltage-voltage level less than or equal to 33000volt.

Extra high voltage- Voltage level greater than 33000volt.

LIVE - Live term in electrical means electrically charged.

DEAD

“Dead” means at or about earth potenal and disconnected from any live

System. The term “dead” is used only with reference to current carrying parts when

these parts are not live.

CUT-OUT

“Cut-out” means any appliance for automacally interrupng the

transmission of energy through any conductor when the current rises above a predetermined

amount.

CONDUIT

“Conduit” means rigid or exible metallic tubing or mechanically strong and

re resisng non-metallic tubing into which a cable or cables may be drawn for the

purpose of aording it or for mechanical protecon.

SYSTEM

System means an electrical system in which all the conductors and

apparatus are electrically connected to a common source of electric supply.

VOLT

“Volt” means a unit of electromove force and is the electric pressure,

which, when steadily applied to a conductor, the resistance of which is one ohm,

will produce a current of one amphere.

SWITCHGEAR

“Switchgear” shall denote switches, circuit breakers, cut-outs and other

apparatus used for the operaon, regulaon and control of circuits

“Span” means the horizontal distance between two adjacent supporng

points of an overhead conductor.

INSTALLATION

“Installaon” means any composite electrical unit used for the purpose of

generang, transforming, transming, converng, distribung or ulizing energy;

EARTHING SYSTEM

“Earthing system” means an electrical system in which all the conductors

are earthed

“Earthed” or “connected with earth” means connected with the general

mass of earth in such manner as to ensure at all mes an immediate discharge of

energy without danger

DANGER

“Danger” means danger to health or danger to life or any part of body from

shock, burn or other injury to persons, or property, or from re or explosion,

aendant upon the generaon, transmission, transformaon, conversion,

distribuon or use of energy

LIGHTING ARRESTOR

“Lighng arrestor” means a device which has the property of diverng to

earth any electrical surge of excessively high amplitude applied to its terminals

and is capable of interrupng follow current if present and restoring itself thereaer

to its original operang condions.

1.2 General safety precauons

RULE 29-Construcon, installaon, protecon, operaon and maintenance of electric supply

lines and apparatus.

All electric supply lines and apparatus shall be of sucient rangs for

power, insulaon and of sucient mechanical strength. They shall be constructed, installed,

protected, worked and maintained in such a manner as to ensure safety of human beings,

animals and property.

The material and apparatus used shall conformed to have relevant specicaons as per

Bureau of Indian Standards.

RULE 30- Service lines and apparatus on consumer’s premises-

(1) The supplier shall ensure that all electric supply lines, wires, ngs and

apparatus belonging to him or under his control, which are on a consumer’s

premises, are in a safe condion and in all respects t for supplying energy and

the supplier shall take due precauons to avoid danger arising on such premises

from such supply lines, wires, ngs and apparatus.

(2) Service-lines placed by the supplier on the premises of a consumer which

are underground or which are accessible shall be so insulated and protected by

the supplier.

(3) The consumer shall, as far as circumstances permit, take precauons for

the safe custody of the equipment on his premises belonging to the supplier.

(4) The consumer shall also ensure that the installaon under his control is

maintained in a safe condion.

RULE 31- Cut-out on consumer’s premises

The supplier shall provide a suitable cut-out in each conductor of every

service-line other than an earthed or earthed neutral conductor or the earthed

external conductor of a concentric cable within a consumer’s premises, in an

accessible posion.

Where more than one consumer is supplied through a common service-line, each

such consumer shall be provided with an independent cut-out at the point of

juncon to the common service.

RULE-32. Idencaon of earthed and earthed neutral conductors and posion of

switches and cut-outs.

(1) An indicaon of a permanent nature shall be provided by the owner of the

earthed or earthed neutral conductor, or the conductor which is to be connected

there to, to enable such conductor to be disnguished from any live conductor.

(2) No cut-out, link or switch other than a linked switch arranged to operate

simultaneously on the earthed or earthed neutral conductor and live conductors

shall be inserted or remain inserted in any earthed or earthed neutral conductor of

a two wire-system or in any earthed or earthed neutral conductor of a mul-wire

system .

RULE-33. Earthed terminal on consumer’s premises-

(1) The supplier shall provide and maintain on the consumer’s premises for the

consumer’s use a suitable earthed terminal in an accessible posion at or near the

point of commencement of supply as dened under rule 58.

(2) The consumer shall take all reasonable precauons to prevent mechanical

damage to the earthed terminal and its lead belonging to the supplier.

1[(3) The supplier may recover from the consumer the cost of installaon of earthing.

RULE-34. Accessibility of bare conductors- Where bare conductors are used in a

building, the owner of such conductors shall-

(a) Ensure that they are inaccessible;

(b) Provide in readily accessible posion switches for rendering them dead

whenever necessary; and

(c) Take such other safety measures as are considered necessary by the

Inspector.

Rule-35. Danger Noces- The owner of every medium, high and extra-high voltage

installaon shall ax permanently in a conspicuous posion a danger noce in

Hindi or English and the local language of the district, with a sign of skull and

bones

RULE-36. Handling of electric supply lines and apparatus-

(1) Before any conductor or apparatus is handled adequate precauons shall

be taken, by earthing or other suitable means, to discharge electrically such

conductor or apparatus.

Every person who is working on an electric supply line or apparatus or both shall

be provided with tools and devices such as gloves, rubber shoes, safety belts,

ladders, earthing devices, helmets, line testers, hand lines and the like for

protecng him from mechanical and electrical injury. Such tools and devices shall

always be maintained in sound and ecient working condions:

(2) No person shall work on any live electric supply line or apparatus and no

person shall assist such person on such work, unless he is authorised in that

behalf, and takes the safety measures approved by the Inspector.

(3) Every telecommunicaon line on supports carrying a high or extra-high

voltage line shall, for the purpose of working there on, be deemed to be a high

voltage line.

RULE-37. Supply to vehicles, cranes, etc.

Every person owning a vehicle, travelling crane or the like to which energy is supplied from an

external source shall ensure that it is eciently controlled by a suitable switch enabling all

voltage to be cut o in one operaon and, where such vehicle, travelling crane or the like runs

on metal rails, the owner shall ensure that the rails are electrically connuous and earthed.

RULE-38. Cables for portable or transportable apparatus-

(1) Flexible cables shall not be used for portable or transportable motors,

generators, transformer recers, electric drills, electric sprayers, welding sets or

any other portable or transportable apparatus unless they are heavily insulated

and adequately protected from mechanical injury.

(2) Where the protecon is by means of metallic covering, the covering shall be

in metallic connecon with the frame of any such apparatus and earth.

(3) The cables shall be three core type and four-core type for portable and

transportable apparatus working on single phase and three phases supply

respecvely and the wire meant to be used for ground connecon shall be easily

idenable.

RULE-39. Cables protected by bituminous materials-

(a) Where the supplier or the owner has brought into use an electric supply line

(other than an overhead line) which is not completely enclosed in a connuous

metallic covering connected with earth and is insulated or protected in situ by

composion or material of a bituminous character-

(i) Any pipe, conduit or the like into which such electric supply line may have

been drawn or placed shall, unless other arrangements are approved by the

Inspector in any parcular case, be eecvely sealed at its point of entry into any

street box so as to prevent any ow of gas to or from the street box; and

(ii) Such electric supply line shall be periodically inspected and tested where

accessible, and the result of each such inspecon and test shall be duly recorded

by the supplier or the owner.

(2) It shall not be permissible for the supplier or the owner aer the coming into

force of these rules, to bring into use any further electric supply line as aforesaid

which is insulated or protected in situ by any composion or material known to be

liable to produce noxious or explosive gases on excessive heang.

RULE-40. Street boxes-

(1) Street boxes shall not contain gas pipes, and precauons shall be taken to

prevent, as far as reasonably possible, any inux of water or gas.

(2) Where electric supply lines forming part of dierent systems pass through

the same street box, they shall be readily disnguishable from one another and all

electric supply lines at high or extra-high voltage in street boxes shall be

adequately supported and protected to as to prevent risk of damage to or danger

from adjacent electric supply lines.

(3) All street boxes shall be regularly inspected for the purpose of detecng the

presence of gas and if any inux or accumulaon is discovered.

(4) The owners of all street boxes or pillars containing circuits or apparatus

shall ensure that their covers and doors are so provided that they can be opened

only by means of a key or a special appliance.

RULE-41. Disncon of dierent circuits-

The owner of every generang staon, substaon,

juncon-box or pillar in which there are any circuits or apparatus, whether

intended for operaon at dierent voltages or at the same voltage, shall ensure by

means of indicaon of a permanent nature that the respecve circuits are readily

disnguishable from one another.

RULE-42. Accidental charge-

The owners of all circuits and apparatus shall soarrange them that there shall be no danger of

any part thereof becoming accidentally charged to any voltage beyond the limits of voltage

for which they are intended.

Where A.C. and D.C. circuits are installed on the same support they shall be so

arranged and protected that they shall not come into contact with each other when

live.

RULE-43. Provisions applicable to protecve equipment-

(1) Fire buckets lled with clean dry sand ,re exngguishers must be kept in all generang

stson,enclosed sub-staons etc to exnguish re.

(2The re exnguishes shall be tested for sasfactory operaon at least once a year

and record of such tests shall be maintained.

(2) First-aid boxes or cupboards, conspicuously marked and equipped with

such contents as the State Government may specify, shall be provided and

maintained in every generang staon, enclosed sub-staon and enclosed switch

staon so as to be readily accessible during all working hours. All such boxes and

cupboards shall, except in the case of unaended sub-staons and switch

staons, be kept in charge of responsible persons who are trained in rst-aid

treatment and one of such person shall be available during working hours.

(3) Gas masks shall be provided conspicuously and installed and

maintained at accessible places in every generang staon with capacity of 5 MW

and above and enclosed sub-staon with transformaon capacity of 5 MVA and

above for use in the event of re or smoke.

RULE-44. Instrucons for restoraon of persons suering from electric shock-

(1) Instrucons for restoraon of persons suering from electric shock in English ,Hindi or

local language shall be axed by the owner.

(2) In every high voltage or extra high voltage generang staon ,substaon etc, an arcial

respirator shall be provided and kept on good working condion.

(3) The owner of every generang staon, enclosed sub-staon, enclosed

switch-staon and every factory should that all the persons employed by him are acquainted

with these instrucons and must apply.

RULE-45. Precauons to be adopted by consumers 1[owners occupiers], electrical

contractors, electrical workmen and suppliers-

(1) No electrical installaon work, including addions, alteraons, repairs and

adjustments to exisng installaons, except such replacement of low voltage domesc

appliances shall be carried out by the user. Other installaon works like addion of extra

circuit, alteraons, adjustments to the exisng installaon shall be carried out by an electrical

contractor who is licensed by state government.

RULE-46. Periodical inspecon and tesng of consumer’s installaon. -

(1) Installaons shall be periodically inspected and tested in every 5 years.

(2) Fees for such inspecon and test be determined by the central or the state

Government.

General condions relang to supply and use of energy

Rule-47 Tesng d consumer's installaon

---If a consumer needs a new or addional supply of energy, he has a to submit applicaon to

the suppler. Then the supplier shall inspect and test the consumer's installaon.

→Aer geng approval from Inspector new Supply of energy or reconnecon of the Supply

aer a period of six months is provided to the consumer.

→ Aer inspecon if the inspector & feels that the installaon is not safe and can be

dangerous to consumer, then the inspector will give noce fo modicaons

→ No Consumer shall commission his generang plant of a capacity exceeding 10KW without

wrien approval of the Inspector.

Rule-48 Precauons against leakage before Connecon

→ The supplier shall not provide energy Supply to the installaon ore apparatus unless he is

Sased that there is no leakage from the installaon or any apparatus.

→ For example insulaon resistance of medium and low voltage installaon shall be at least 1

Mega ohm.

Rule 49 Leakage on Consumer's Premises

If the supplier/inspector found that insulaon resistance is low and which is likely to cause

danger , he shall disconnue the supply of energy to the installaon and gave 48 hours,

disconnecon of supply and shall not reconnect unl the cause of leakage has been removed.

Rule 50→ Supply and use of energy

→ Energy shall not be supplied, trans formed, converted or wed unll the following

arrangements are not done

Arrangement must be done to completely isolate the supply to the installaon. A leaked

Switch with fure(s) are a Circuit breaker must be used for low and medium voltage Consumer.

and High voltage consumer also. Similarly a circuit breaker is used for HV( 11 KV to 3kV) and

EHV consumer. Every consumer shall ensure that no person other than the supplier shall

interfere with the service lines and apparatus placed by the supplier.

Rule 50A Addional provision for supply use of energy in mul-storied building

1 ) Before 30 days the consumer must gave applicaon for commencement of supply (new or

old ) to the inspector with all parculars. The supply of energy shall not be commenced or

recommenced within this period.

2) The supplier shall provide cut out or breaker at a posion not more than 2.75 meters

3) The owner of a mulstoried building shall ensure the safety of installaon

4) No other service popes shall be taken along with the power cable.

Rule 51.→ All conductors other than overhead lines Shall be completely enclosed in

mechanically strong metal casng or metallic covering

→All metal works, enclosing shall be connected with an earthing system

→ A clearance of 1 meter shall be provided in front of switchboard

→ If the installaon is done where gases/chemicals are produced, the installaons,

Equipments and apparatus must be provided ame proof, dust ght, totally enclosed

protecon.

Rule-52 Appeal to Inspector in regard to defects:-

If any applicant dissased with the acon of supplier in declining for a to commence he may

appeal to the inspector to test the installaon.

Rule-53 Cost of inspecon and rest of consumer's Installaon→ The cast of rst inspecon

and test of consumer's installaon Carried out shall be paid by the consumer

Rule-54 Voltage Regulaon.

→ In case of low ore medium voltage the supply Voltage shall not more than 6 percent .

→ In case of high voltage, voltage shall not more than 6% on higher side and 9% on lower

side.

→Fore extra high voltage→

1) higher side → 10%

2) Lower side → 12.5/

Rule-55 Declared frequency of supply to Consumer

The supply frequency should shall be allowed to vary between +3%. to -3%..

Rule-56 Sealing of meters and cut outs.

→ A Supplies may ax one or more seals to Cut-out and to any meter, maximum demand

indicator on the consumer's premises.

→The consumer shall ensure that no such seal broken other than supplier.

Rule-57 Meters, maximum demand indicators and other apparatus on consumer's premises

Error of any meter/maximum demand indicators / other apparatus placed on consumer's

premises should not exceed 3 percent above or below the accurate value.

→ No meter shall register at no load.

→ Every supplier shall examine, test and regulate all meters, maximum demand indicators

etc. before their rst installaon

→Every supplier shall maintain a register of meters showing the date of last test, last error,

limit of accuracy aer adjustment.

Rule 58 -The point of commencement of supply

The point of commencement of supply of energy to a consumer shall be considered to be the

point at which incoming terminal of the wet-outs installed by the consumer.

Rule 59-Precauons against failure of supply

The layout of elecon supply lines in an area shall be seconalized and provided with cut-outs

or circuit breakers . So the fault occurring in any part of a circuit can not transmits to other.

ELECTRIC SUPPLY LINES, SYSTEMS AND APPARATUR FOR LOW AND NEDIUM VOLTAGE

Rule-60-Test for resistance of insulaon

If any closer supply line of low or medium voltage has been disconnected from a System or

addion of new circuit or repair is done by disconnecng the supply , such electric Supply line

shall not be reconnected to the system unl the following test is done as per rule 48.

(leakage or insulaon resistance)

Rule 61- Connecon with Earth.

→ Neutral conductor of a 3-phase 4 wire system and middle conductor of a 2 phase 3- wire

system shall be earthed.

→ If a system consist of concentric Cables, the external conductor must be earthed

→The frame of every generator, motor, mate metallic part of all transformer shall be earthed.

→All earthing syst Systems shall be test earth resistance on dry days tesng fore

Rule-62 System at medium Voltage:- Where a medium voltage supply system is employed,

the voltage between Earth and any conductor forming part of the same system shall not i

under normal condions, exceed low voltage

Rule-63. Approved by Inspector. →If an installaon has been disconnected for one year , to

recommence the supply the supplier and owner must ensure that the supply lines and

apparatus are placed in posion, properly tested and examined. Then applicaon is given to

the inspector for inspecon.

→ The owner of any high or extra high voltage installaon can not make addional

installaon or altercaon to the system unl he has the wrien approval from inspector.

Rule- 64. Use of energy at high and extra high voltage →

All conductors and apparatus situated on Consumer premises should be at inaccessible

posion, all operaon related to the all items should be done by authorized sard person only.

→The consumer must place the apparatus and meter of the supplier in a separate building for

all me assess of the supplier.

→ All pole type sub-staons are constructed and maintained in accordance with BIS.

Rule 65-Tesng, operaon & Maintenance.

→New HV OR EHV, apparatus, supply line, cables shall be commissioned aer site test as pert

BIS

→ If HV or EMV apparatus , supply line or cables has disconnected fore 6 months are more

fore recommission of the items tesng. must be done as per BIS

→ All apparatus, supply line ore cables shall be maintained en "healthy condions and

periodical tests should be carried out.

→ Records of all tests, maintenance work and repairs of apparatus, Supply line and Cables

shall be duly kept.

Rule-66- Metal sheathed electric supply line, Precauon against excess leakage.

→ The metal sheathing of conductor must be electrically connuous and connected with

earth.

→ the resistance of earth connected with metallic sheath shall be kept low.

→If electric-Supply line has concentric Cable the outer conductor may shall be Connected

with earth.

Rule 67- Connecon to earth

All non-current carrying metal parts, associated with HV/EHV installaon shall be eecvely

earthed to a ground System or Mat.

Rule-68 General condions for transformaon and control of energy.

→ Sub-staons and switching staons shall be preferably elected above the ground. If it is

required to build an underground substaon , proper Venlaon system proper must be

provided.

Rule-70- Condensers

Suitable provision shall be made for immediate and automac discharge of every Stac

condenser on disconnecon of supply.

OVERHEAD LINES

Rule-74. Material and strength

→All conductors of over head lines shall have breaking strength of not less than 150kg if

voltage is low and the span is less than 15m.

→ If the span is more than 15m and voltage is low, medium or high than breaking strength of

the overhead lines should not be less than 350kg.

Rule-75

→ Joints between conductors of overhead lines shall be mechanically and electrically secure

under the condions of operaon.

→ Ulmate strength of the joint shall not be less than 95 percent of the original conductor

and electrical conducvity shall not be less than that of original conductor

Rule-76.

Factor of Safety= Breaking strength/ Working strength or stress

* For metal supports = 1.5

* For mechanically processed concrete Supports = 2:0

* For hand-molded concrete supports = 2-5

* Wood supports = 3.0

*Stay wire, guard wire. = 2.5

Rule-77. Clearance above ground of the lowest conductor

If the supply line is across any street:-

*Low and Medium Voltage = 5.8m

*For high voltage line = 6.1m

If the supply line is along with any street:-

*Low and Medium Voltage = 5.5m

*For high voltage line = 5.8m

If the supply line is away from any street or populaon:-

*Low and Medium Voltage = 4.6m

*For high voltage line = 4m

For high voltage line above 11kv = 5.2m

Rule-78- Clearance between conductors and trolley wires

*Low and medium voltage lines →1.2m

*High voltage line upto 11 kv →1.8m

*High voltage live above 11KV→2.5m

* Extra-high voltage line→3.0m

Rule 79-clearcances from building of low and medium voltage lines and service lines.

Low and medium voltage→

a) Vercal clearance from a building. = 2.5m

b) Horizontal clearance from a building = 1.2m

Rule-80-Clearance between building and high cand extra high voltage line

a) Vercal clearance -

*Voltage upto 33KV →= 3.7m

*For E-H-V line→3.7m+0.3m (for addional 11KV)

b) Horizontal clearance.

*upto 11KV →1.2m

*11KV to 33KV → 2m

* EHV lives. →2m+ 0-3 (for addional 33 KV)

Rule 86. Condions to apply where telecommunicaon lines and power lines are

carried on same supports-

(1) Every overhead telecommunicaon line erected on supports carrying a

power line shall consist of conductors each having a breaking strength of not less

than 270 kg.

(2) Every telephone used on a telecommunicaon line erected on supports

carrying a power line shall be suitably guarded against lightning and shall be

protected by cutouts.

(3) Where a telecommunicaon line is erected on supports carrying a high or

extra-high voltage power line arrangement shall be made to safeguard any

person using the telephone against injury resulng from contact, leakage or

inducon between such power and telecommunicaon lines.

Where an overhead line crosses another overhead line, clearances shall be as

Rule 87. Lines crossing or approaching each other-

Where an overhead line crosses another overhead line, clearances shall be as

under: -

Sl.

No.

Nominal System

Voltage

11-66

KV

110-132

KV

220 KV

400 KV

800 KV

1.

2.

3.

4.

5.

6.

Low & Medium

11-66 KV

110-132 KV

220 KV

400 KV

800 KV

2.44

2.44

3.05

4.58

5.49

7.94

3.05

3.05

3.05

4.58

5.49

7.94

4.58

4.58

4.58

4.58

5.49

7.94

5.49

5.49

5.49

5.49

5.49

7.94

7.94

7.94

7.94

7.94

7.94

7.94

Rule 88. Guarding-

*Every guard-wire shall be connected with earth at each point at which its

electrical connuity is broken.

*Every guard-wire shall have an actual breaking strength of not less than

635 kg and if made of iron or steel, shall be galvanized.

*Where there is only one trolley-wire, two guard-wires shall be erected as

in diagram A.

Rule 89. Service-lines from Overhead lines- No Service-line or tapping shall be

taken o an overhead line except at a point of support.

Rule 90. Earthing-

(1) All metal supports and all reinforced and prestressed cement concrete

supports of overhead lines and metallic ngs aached thereto, shall be

permanently and eciently earthed. For this purpose a connuous earth wire

shall be provided and securely fastened to each pole and connected with earth

ordinarily at three points in every km., the spacing between the points being as

nearly equidistance as possible. Alternavely, each support and the metallic

ng aached thereto shall be eciently earthed.

(2) Each stay-wire shall be similarly earthed unless insulator has been placed

in it at a height not less than 3.0 m from the ground.

Rule 91. Safety and protecve devices-

(1) Every overhead line, (not being suspended from a dead bearer wire and

not being covered with insulang material and not being a trolley-wire) erected

over any part of street or other public place or in any factory or mine or on any

consumers’ premises shall be protected with a device approved by the Inspector

for rendering the line electrically harmless in case it breaks.

(2) An Inspector may by noce in wring require the owner of any such

overhead line wherever it may be erected to protect it in the manner specied in

sub-rule(l).

ELECTRICAL INSTALLATIONS

2. 1 Electrical installaons, domescs, industrial, Wiring System, Internal distribuon of

Electrical Energy. Methods of wiring, systems of wiring, wire and cable, conductor materials

used in cables, insulang materials mechanical protecon. Types of cables used in internal

wiring, mul-stranded cables, voltage grinding of cables, general specicaons of cables.

2. 2 ACCESSORIES: Main switch and distribuon boards, conduits, conduit accessories and

ngs, lighng accessories and ngs, fuses, important denions, determinaon of size of

fuse – wire, fuse units. Earthing conductor, earthing, IS specicaons regarding earthing of

electrical installaons, points to be earthed. Determinaon of size of earth wire and earth

plate for domesc and industrial installaons. Material required for GI pipe earthing.

2. 3 LIGHTING SCHEME: Aspects of good lighng services. Types of lighng schemes, design of

lighng schemes, factory lighng, public lighng installaons, street lighng, general rules for

wiring, determinaon of number of points (light, fan, socket, outlets), determinaon of total

load, determinaon of Number of sub-circuits.

ELECTRICAL INSTALLATION

WIRE:- single core strand may be bare or cover with insulaons known as wire.

CABLE:-Several wire stranded together is known as cable. (Cover with insulaon)

NECESSITY IN A CONDUCTOR/WIRE/CORE:

Good conductor of electricity (low resisvity)

Cheaper in cost.

Safety (not provide leakage current )

Easily available.

High mechanical strength, durable.

Melng point should be high.

High resisvity to corrosion, oxidaon, withstand dampness.

High resisvity towards chemical reacon.

PARTS OF CABLE:

Cable consists of three parts

a) Conductor/Wire/Core

b) Insulaon/Dielectric

c) Cable jacket

-

a) Conductor/core:-It carries current.

b) Insulaon/Dielectric:-covering part is used to avoid leakage current from the conductor.

c) Cable jacket;-The protecve covering for protecon of insulaon from mechanical

damage.

CONDUCTOR MATERIAL USED IN CABLES:-

1. COPPER

2. ALUMINIUM

3. SILVER

4. GOLD

5. LEAD & TIN

6. STEEL

7. GALVANISED STEEL

1.COPPER:-

It has high conducvity.

Less resisvity, durable and ducle.

Mechanically strong, hard

High resisvity to corrosion, oxidaon, high temperature.

Welded easily, soldered.

Cheaper in cost.

2.ALUMINIUM

Cheaper in cost

Long distance power distribuon ( use in place of copper for bare electric cable)

Aluminium

copper

1. Less

conducvity than

copper (60% of

copper).

2. required

Aluminium is

1.61mes that of

copper in volume.

1. More conducvity

than cthththaththancoppercccccccaluminium.

aluminium.

INSULATING MATERIALS:- It is used to prevent the leakage current from conductor.

Properes of insulang material:-

High resisvity.

High exibility.

High dielectric strength.

Non-inammable (not catching re easily/not inammable).

Non-hygroscopic ( it does not absorb water and moisture from atmosphere).

High resisve to moisture, acid, or alkalis.

Capabilies to withstand high rupturing voltage and high temperature.

Capability withstand wind, force, Iceland.

TYPES OF INSULATING MATERIALS:-

1.RUBBER

Advantages:-

It has good dielectric strength(30KV/MM)

It has high insulang properes.

High relave permivity.

Disadvantages:-

It absorbed moisture.

Oen when heated to a temperature of 60 to 70

Ages when expose to light.

Deform when warm and brile when cold.

It is scky in nature.

So, hat pure rubber is not used for insulaon.

2. VIR (VULCANISED INDIAN RUBBER)

Advantages:-

It has great mechanical strength.

It has good dielectric strength (60KV/MM)

It has good insulang properes.

It does not absorb moisture from atmosphere.

It is Durable

VULCANISATION

It is a chemical process for converng natural rubber to more durable material by

adding of sulphur.

Sulphur reacts with copper and corroded the copper surface. So this can be avoided

by providing a nned layers over the copper surface.

It may be used in internal wiring and other low voltage insulaon. (decoraon)

3. SILK& COTTON:-

This is used in low voltage cable.

Conductors may have a single layer or double layer covering depending upon the

requirements of service.

Silk of coon covered wires are usually used for instruments and motor windings

4. IMPREGNATED PAPER

Advantages:-

It has high dielectric strength. ( 30 kv/ mm)

It has good insulaon resistance.

It has low cost.

Disadvantages:-

It absorbed moisture (hygroscopic in nature).So that it always provided with

some protecve covering and never le unshield.

To make it noninammable paper, impregnated with some compound like

paran, napthenic and resin.

5. POLYVINYLE CHLORIDE (PVC)

It has good dielectric strength.

It has good insulang properes.

Good mechanical strength.

It does not absorb moisture.

It does not reacts with acid & alkali (used in house wiring ,cable factories)

It is used for low & medium voltage domesc & industrial light and power installaon.

It is low cost.

MECHANICAL PROTECTION

Insulang materials are mechanically weak so protecon against mechanical injury is

required.

Protecon is provided by steel, aluminium on PVC covering.

Protecon against damage & moisture.

TYPES OF CABLES USED IN INTERNAL WIRING

The wire employed for internal wiring of building may be divided into dierent groups

according to:-

1. Conductors used (according to the conductors material used in cable:-

a) Copper conductor

b) Aluminium conductor

2. According to the numbers of core in cables:-

a) Single core cable c) Three core cable

b) Twin core cable d) Four core cable

3. According to voltage grading, the cables are 2 types:-

a) 250/500 volt cable

b) 660/1100 volt cable

4. According to types of insulaon the cables are:-

a) VIR insulated cables

b) TRS/CTS cables TRS-Tough rubber sheath

c) Lead sheath cable CTS-Cab tyre sheath

d) PVC Cable

e) Waterproof cable/weather proof

f) Flexible cord & cables

1. VIR INSULATED CABLE

The cables are available in 250/500 volt and 660/1100 volt.

It consists of n & copper conductor covered with a layer of VIR Insulaon.

Over the rubber insulaon coon tap sheath covering with moisture resistance

compound bitumen wax to make the cable moisture proof.

Conductor reacts with VIR insulaon therefore to prevent the reacon a n layer is

given in the conductor.

VIR is used to protect the conductor from mechanical injury.

Bitumen & coon tap are used to protect the insulaon from weather & moisture.

2. TRS/CTS CABLE

These cables are available in 250/500 volt and 660/1100.

TRS/CTS cable is vulcanized rubber, insulated conductor with an outer protecve

covering of tough rubber which provides addional insulaon and protecon against

wear & tear.

These cables are water proof and hence can be used in wet condion.

This cable is available in single core, twin core, three cores etc.

The cores are insulated from each other and covered with a common sheathing.

3. LEAD SHEATH CABLE

This cable is available in 250/500 volt.

It consists of vulcanized rubber insulated conductors cover with a sheath of lead.

The lead sheath provides a very good protecon against the moisture and mechanical

injury. So this can be used without casing or conduit system.

This cable is available in single core, twin core, three cores etc.

4. POLYVINYL CABLE (PVC)

These cables are available in 250/500 volt & 660/1100 volt grade.

It is used incasing-capping, baen& conduit wiring system.

Since PVC is harder than rubber it does not require coon tapping over it for

mechanical and moisture protecon.

These type cable conductors are insulated with PVC insulaon.

ADVANTAGES

Beer insulang properes.

Low cost

Beer exibilies.

No chemical eect on metal of the wire.

5. WEATHER PROOF CABLE

These cables are available in 250/600 volt and 660/1100 volt grade.

These cables are either PVC or VIR insulated conductors and then compounded with

weather resisng material.

These cables are not aected by heat, sunlight, rain.

It is used for outdoor wiring, power supply or industrial supply.

6. FLEXIBLE CORD & CABLE

It consist of wire silk, coon, plasc covering.

Flexible cord have n-copper conductor.

Flexibilies and strength is obtained by using conductors having large no. of strand.

This wire or cable are used as connecng wires for such purpose as from ceiling rose to

lamp holder ,socket outlet to portable apparatus such as fan ,lamp, heater ,etc.

MULTISTRAND CABLE

Advantages of mul strand cables w.r.t single solid conductors.

Mul strand cables are more exible and durable and therefore can be handle

conveniently.

The surface area of mul strand cable is more as compare to the surface area of

equivalent single solid conductor .so heat radiang capacity is more in mul strand

cable because of its large area.

Skin eect is beer as conductors are tubular, specially in case of high frequency.

The no. of strand is stranded cable must be 3,7, 19, 37, 61, 91 etc.

VOLTAGE GRADING OF CABLES:-

This species the safe voltage which the insulaon of the cable can withstand.

The cables employed for domesc wiring are graded as 250/500 volt & 660/1100 volt

grade.

GENERAL SPECIFICATION OF CABLES:-

1. SIZE OF CABLE:

19/24

19-No. of strand in cable 24-diameter of each strand in mm

2. Types of conductors used in cable ( co & Al )

3. The no.of core that cable consists of ( single core, twin core ,three core ,four core)

4. Voltage grading (250/500 volt & 660/1100 volt grade)

5. Types of cable with clear descripon regarding insulaon, shielding etc.( PVC etc.)

LIGHTING ACCESSORIES AND FITTINGS

1. SWITCH

2. CEILING ROSE

3. SOCKET OUTLET

4. PLUGS

5. LAMP HOLDER

1. SWITCHES

A switch is used in an electric circuit as a device for making or breaking the electric ckt

in a convenient i.eis by the simple moon of handle or knob to connect together or

disconnect two terminal to switch cables or wires are connected.

2. TYPES OF SWITCH:-

a) ACCORDING TO THE TYPE OF BASE MATERIAL:-

Porcelain switch( high rang)

Bakelite switch( low rang)

b) ACCORDING TO THE COLOUR

black

white

Brown

c) ACCORDING TO OPERATION

One way switch

2 way switch

2 way centre o switch

Double pole main switch

Single pole single throw

Single pole double throw

Double pole double throw

Double pole main switch

Single pole main switch

1. ONE WAY SWITCH

6 amp,250 volt --------light load ( fan, tube light)

16 amp,250 volt -------heavy load(washing machine, heater, AC etc)

2. TWO WAY SWITCH

The switch of this type consist of 3 or 4 terminals

The switch of this type is usually used for staircase wiring or circuit where one point is

to be controlled from two dierent places.

6 amp, 250volt -------(light load)

Connecon diagram of 2 way switch

3. 2 WAY CENTRE OFF SWITCH

6 amp ,250 volt

4. SINGLE POLE MAIN SWITCH

5. DOUBLE POLE MAIN SWITCH

6. SINGLE POLE SINGLE THROW

7.SINGLE POLE DOUBLE THROW

8.DOUBLE POLE DOUBLE THROW

CEILING ROSE

The ceiling rose is used to connect the pendent lamp, fan and uorescent tube to install

through exible wire.

It consists of 2 parts

1. Base 2.cover

It is made of bakelite, porcelain

TYPES OF CEILING ROSES

1. 2-way ceiling rose:-

It is ed with two terminal plate.

2. 3-way ceiling rose:-

It is ed with 3 terminal plates. Rang 6A, 250 volt

SOCKET OUTLET:-

The socket outlet are used to supply outlet connecon when ever required for electrical

appliances such as TV, iron table fan.

TYPES OF SOCKETS

1 PIN SOCKETS

3 PINSOCKETS

5 PIN SOCKETS

LAMP HOLDER:-

It is used to support the lamp and also to connect of electricity.

These are design for quick removal, replacement. Of the lamp.

It is made of Bakelite with porcelain interiar.

TYPES OF LAMP HOLDER:-

1. Pandent holder

2. Angle holder

3. Slanng holder

PLUG:- Plugs are use to connect the supply from the socket outlet for electrical appliances

such as TV,

Iron

2pin plug 3pin plug

PARALLEL OPERATION ADVANTAGES

The supply voltage is uniform in each load.

In case the light or same other equivalent goes out of order, it will not aect the supply

of current to other light etc as each one of them is individually connected to line.

The voltage in the ckt will be uniform and every will glow with full brightness.

SERIES CONNECTION

The ckt useful for decorave lighng for marriage and other places where

groups of lamps are to be control by switch instead of placing separate switch

for each light.

The major disadvantages are of one light goes out of order , light and other

equipments in that ckt will go o . As the ow of current from one point to

other is stop.

SERIES PARALLEL CONNECTION

(a) With 2-way centre o switch

(b) With 2-way and o switch and one way switch

Series parallel circuit are used either to provide dim light or full bright light through the

same lamp by using special switch such as two way centre o switch .

To operate either both lamp in series or parallel by wiring two pole double throw switch

(c) CIRCUIT FOR ONLY ONE PARTICULAR LAMP BRIGHT OR TWO LAMPS IN SERIES WITH

TWO WAY AND SINGLE WAY SWITCHES

(d) TO OPERATE EITHER BOTH LAMPS IN SERIES OR BOTH IN PARALLEL BY USING 2 POLE

DOUBLE THROW SWITCH

For posion 1-2=The lamp will provide dim lights

For posion 3-4=The lamps are connected in parallel across 230 volt giving full bright light.

FUSE

It is a simple and cheapest device used for interrupng and electrical circuit under short

circuit or over load condion.

The acon of a fuse is based upon the heang eect of the electric current.

ADVANTAGES

It is cheaper form of protecon available.

It needs no maintenance.

Its operaon is completely automac.

It interrupt huge short circuit current without noise, gas, smoke.

DISADVANTAGE

Considerable me is lost in running or replacing a fuse aer operaon.

FUNCTION OF WIRE

To carry the current working current ow without heang.

To break the circuit when the current exceed the liming current.

FUSE ELEMENT MATERIAL

The material used fuse elements must be of low rang point ,high conducvity , low

cost and from deterioraon.

The material commonly use for fuse elements are n, lead ,copper, zinc, aluminium and

alloy of lead and n(60+40)

Fuse element is a low melng point material such as n, lead and zinc.

The alloy of lead and n is used for small current for fuse ( up to 15 amp)

Beyond 15 amp rang circuit copper wire fuse are used.

Either copper or lead n alloy is mostly used as an

ordinary use wire.

TYPES OF FUSE:-

(a) Supply main fuse:-

This fuse is provided by the supplier and is xed just before the service meter .The

rang of supply main fuse will be as from bad current of the consumers.

(b) Consumers main fuse:-

This is another fuse of rang slightly less than that of supply main fuse and placed aer

the consumers main switch.

(c) SUB Circuit fuse:-

The total wiring system is divided in to no. of sub circuit or branch. A separate fuse is

provided for each branch circuit and is known as sub. Circuit or branch circuit use

Metals

Melng

point

silver

980

n

240

zinc

419

lead

328

copper

1090

aluminium

665

(d) POINT FUSE :-

In good quality indoor wiring in building light and plug point is provided with its

individual fuse known as point fuse.

IMPORTANT DEFINATION ( 2 MARK)

FUSE:-

Fuse is a current interrupng device which break or open the circuit by fusing the elements

when the current in the ckt exceed a certain voltage.

FUSE ELEMENTS OR FUSE WIRE:-

It is that point of the fuse which actually melt when an excessive current ow in the circuit

and thus isolate the faulty device from the supply.

CURRENT RATING:-

It is dene as the RMS value of current which the fuse wire can carry connuously without

deterioraon and with temperature rise with in specic limit.

FUSING CURRENT:-

It is dene as the minimum value of current at which the fused elements or fuse wire melt. Its

value will be more than current rang of the fuse element for a round wire the appropriate

value of fusing is given by

I=

Where k= fuse constant, depend upon the metal of the fuse elements

d =diameter of the wire

The fusing current depends upon various factor such as

1. Types of metal used.

2. The cross seconal area i.e whether round or regular secon

3. Diameter of the wire

4. Types enclose employed

5. Type of surface ( stranded)

The fusing current for stranded fuse will be less than the product of the fusing current one

strand and the no. of strand.

FUSING FACTORS:-

It is the rao between minimum fusing current to the current rang of fusing elements is

known as fusing factor and it is always greater than unity.

Fusing factor=

NO. OF

WIRE

1

2

3

4

7

FUSING

CURRENT

1

1.667

1.25

2.75

4

DETERMINATION OF SIZE OF FUSE WIRE

1. Factors responsible for deteriorang the size of the fuse wire in an installaon are:-

Maximum current rang of the circuit.

Current rang of the smallest cable in the circuit protect by the fuse.

EARTHING CONDUCTOR:-

Earthing conductor is of v high conducvity material specially we i. E copper & G.I wire.

I should be protect against mechanical injuries in corrosion.

WHAT IS EARTHING:-

Connecon of non-current carrying part of electrical apparatus such as metallic frame,

metallic covering of cables, earth terminals of sockets outlet, stay wire etc to the general mass

of earth in such a manner that at all me an immediate discharge of electric energy taken

place without danger.

EARTHING IS PROVIDED

To avoid electric shock to the human beings

To avoid risk of re due to earth leakage current through unwanted path.

IS SPECIFICATION REGARDING EARTHHING OF ELETRIC INSTALLATION:-

1. Distance of earth from Building

An earth electrode shall not be situated within a distance of1.5m from the building

whose installaon is being earthed.

2. Size of earthed connuity conductor

The conductor which is used to connect the metal body of an equipments or

appliances to the earth is known as earth connuity conductors (ECC).

It should not be less than 2.9mm

2

or half of installaon conductor size.

3. Resistance of earth

The earth resistance should be low enough to cause ow of current.

The value of earth resistance does not remain constant but change with the

weather as it depends upon the moisture contents of the soil and is maximum

during dry season.

Large power staon =0.5Ω

Major power staon=1Ω

Small sub-staon=2Ω

In other all cases=5Ωmaximum

4. The earth wire and earth electrode shall be of same material.

5. The earth wire shall be taken through G.I pipe of 13 mm diameter for atleast30 cm

length below ground surface to the earth electrode to protect it against mechanical

damage.

6. The earth electrode shall always be placed in vercal posion inside the earth or pit so

that it may be in contact with all the dierent earth layer.

7. All the earth wire run along the various sub circuit shall be terminated and looped

rmly at the main board and from main board, the main earth shall be taken to the

electrode.

POINT TO BE EARTH

Earth pin of 3- pin& 5- pin socket should be permanently and eciently earth.

All metallic covering containing or protecng any electric supply line or apparatus such

as iron clad switches ,iron clad distribuon fuse board, G.I pipes and conduit enclosing

VIR or PVC cable etc should be connected to earth.

The frame of energy generator, staonary motor ,portable motor and the metallic part

of all transformer and any other apparatus used for regulang and controlling energy

and all medium voltage energy consuming apparatus should be a earth by two

separate dierent connecon with earth.

Fabricang steel, transformer line tower, tubular steel or rail poles carrying overhead

conductor should be earthed.

Stay wire provide for overhead lines should be connected to earth buy connecng at

least one strand of the earth wire .

The neutral conductor of a 3phase, 4 wire system and the middle conductor of a 2pjase

,3 wire system should be earthed by two separate and dierent connecon in earth at

the generang staon and at the substaon

DETRMINATION OF SIZE OF EARTH WIRE AND EARTH PLATE FOR DOMESTIC OF MOTOR

INSTALLATION

THE LIST OF MATERIALS WITH COMPLETE SPECIFICATION FOR G.I PIPE EARTHING IS GIVEN

BELOW

MAIN SWITCH AND DISTRIBUTION BOARD

Main switch is provided immediately aer the meter board. The link main switch and

fuse unit may be provided as one unit or as separate unit.

Switch, fuse is a combined unit and is known as iron clad switch, being made of iron.

I. DPIC- Double pole iron clad switch(1 phase,2 wires)

II. TPIC-Triple pole iron clad switch (3phase,3 wires)

III. TPNIC-Triple pole with neutral link iron clad switch (3phase ,4 wires)

Since no fuse is to be provided in neutral in DPIC switch fuses,where provision is made

for fuses in both the wires , one fuse carrier is furnished with fuse elements and the

other a thick copper wire.

SWITCH FUSE REQUIREMENT GENERAL

The switches & fuse shall be enclosed in a strong metallic enclosure.

It should be dust free and weather proof and have a mounng arrangements on the

wall.

The metallic enclosure will have an earthing terminal.

The ON & OFF shall be clearly marked on it .

The xed contact and other metal parts shall be nickel plates or n where it is desirable.

DISTRIBUTION BOARD

Distribuon board is an assembly of parts, including one or more fuse or circuit breaker,

arranged for the distribuon of electrical energy to various circuit or other distribuon

board known as sub-main distribuon board.

The boards are usually metal cased, in sheet steel where earthing terminals and locking

arrangements are provided.

The number of ways depends upon the circuit or sub-circuit to be fed.

Separate distribuon fuse boxes should be provided for light and power circuit.

CONDUITS

General conduits can be classied as :-

1. Light gauge steel-plain conduit

2. Heavy gauge steel-screw conduit

3. Flexible conduit

4. PVC conduit

1.Light gauge steel-plain conduit

The external diameter of 12 mm, 16mm, 19mm, 25mm, 31mm, 38mm & 50 mm are

available.

This type of conduit is used on the surface usually in connecon with special grip ng.

It is a cheapest and quickest of the conduit installaon.

It should be used where the locaon is dry and there is lile livelihood of mechanical

damage.

2.heavy gauge steel-screw conduit

It is expensive, this type of conduit provides a permanents installaon with a maximum

protecon for the cable.

The joints into ngs are by means of screw threaded which provide mechanical

strength and good electrical connuity.

They are available in approximate 3 m. length and are threaded at the two ends.

3.Flexible steel conduit

This usually consists of light gauge galvanized steel, spirally wound and to some extent,

inter-lock so as to form a tube

The size from 19mm to 50 mm are present .

Since conduits are exible and has easily bend no elbow is required.

It is costlier than the rigid conduit.

One of the most common uses of exible metal conduit is for protecng the nal

connecon to motor.

4.PVC conduits

It is used for internal wiring because it is light in weight, shock-proof, self xing and re

resistance, acid , alkali and corrosion resistance having high insulaon value and

dielectric strength.

Such conduits can be used for both surface and concealed type wiring. Here a separate

earth wire must be run inside the tube.

CONDUITS ACCESSORIES& FITTINGS

1. CONDUIT COUPLER

It is used to joint two length of conduit. The length of screw conduits are always

threated at both end on outer side.

2. GRIP COUPLER

In grip coupler, no extra labour is required for making threads. The ends of conduits are

placed in the grip coupler and screw it ghtly.

It is covered above two conductor and the screw is used to make it ght.

3. FLEXIBLE CONDUIT COUPLER

For coupling a exible conduit to the rigid conduit a combine coupling is used.

4. BENDS ,ELBOW, & TEES

BEND:- Bends are usually used for change in direcon of conduit.

ELBOW:

Elbows are of shorter radius, are only used where sudden right turn is required.

TEES

CONDUIT BUSHINGS

This are used when the rigid conduit enter the conduit box or a hole which is not threaded.

This are used to prevent cable from being cut by the edges.

It is up two types.

a) Male -outer threads

b) Female-inner threads

CONDUIT REDUCER

Conduit reducers are used when the size of conduit change.

Conduit reducer have both male & female threads.

FIXING OF CONDUIT

It is used to x the conduit over the wall.

CLIP:- Clip are used for xing the conduit on rough brick walls and in concealed wiring.

SADDLE:

Saddle are used for xing the conduit where clips cannot provide a rm enough hold or a

single screw cannot be dependent upon for xing.

LOCKNUTS/CHECK NUTS:

This are used when rigid conduit enter a conduit box.

CONDUIT NIPPLES

This serve the same purpose as conduit bushing.

This are rarely used due to their higher cost.

CONDUIT BOXES

The conduit boxes are used in surface conduit wiring as well as concealed conduit wiring. It

serve the following purpose.

It is used to provide connecon to rigid fan and other point.

for pulling of cable into the conduit. Boxes serving this purpose are known as inspecon box .

this are provided aer every 30 cm length straight run.

For housing juncon of cables, the conduit boxes serving this purpose are known as juncon

box.

WIRING SYSTEM

A network of wires connecng various accessories for distribuon of electrical energy from

the supply meter board to the numerous electrical energy consuming device such as lamps &

fan and other domesc appliances through controlling & safety device is known as wiring

system.

TYPICAL HOUSE WIRING SYSTEM

SYSTEM OF DISTRIBUTION OF ELCTRICAL ENERGY

As per recommendaon of Indian standard, the maximum number of points of light, fan and

5A sockets outlet that can be connected in one circuit is 10and the maximum load that can be

connected in such circuit is 800 wa, in case more load or points are required to be connected

to the supply, then it is to be done by having more than one circuit.

The system of distribuon of electrical energy is two types

a) Distribuon board system

b) Tee system

a) DISTRIBUTION BOARD SYSTEM

TREE SYSTEM

METHODS OF WIRING

There are two methods of wirings known as joints box system (tee system ) and loop in system

wiring.

JOINTS BOX/ TEE SYSTEM

INTERNAL WIRING

3 . 1 Type of internal wiring, cleat wiring, CTS wiring, wooden casing capping, metal sheathed

wiring, conduit wiring, their advantage and disadvantages comparison and applicaons.

3 . 2 Prepare one esmate of materials required for CTS wiring for small domesc installaon

of one room and one verandah within 25 m2 with given light, fan & plug points.

3 . 3 Prepare one esmate of materials required for conduit wiring for small domesc

installaon of one room and one verandha within 25 m2 with given light, fan & plug points.

3 . 4 Prepare one esmate of materials required for concealed wiring for domesc installaon

of two rooms and one latrine, bath, kitchen & verandah within 80m2 with given light, fan &

plug points.

3 . 5 Prepare one esmate of materials required for erecon of conduct wiring to a small

workshop installaon about 30m2 and load within 10 KW.

CHAPTER-3 INTERNAL WIRING

TYPES OFINTERBNAL WIRING

Following are the type of internal wiring usually employed in industries and house

wiring;-

1. Cleat wiring

2. Wooden casing & capping wiring

3. C.T.S/T.R.S or baen wiring

4. Lead sheathed or metal sheathed wiring

5. Conduit wiring

1. CLEAT WIRIG

In this type of internal wiring the cable used are either VIR or PVC.

The cables are held by porcelain, cleat above wall or ceiling.

The cleats are made in two halves one is base and other is cap.

The base is groove to accommodate the cable and the cap is put over it and a whole of

it then screwed on wooden plug (gus) over the wall or ceiling.

The cleat are up three types

One groove-one cable

Two groove-two cable

Three groove-three cable

The cleat should be usually used at interval of 30 cm and in no case at more than 60 cm.

ADVANTAGES

It is cheapest system of internal wiring.

It’s installaon and dismantlement is easy and quick.

Inspecon, alternaon and addion can be easily made.

Skill required is lile.

DISADVANTAGES

It is not good looking.

It is quite temporary & destroy quickly.

The insulaon dampness from the atmosphere hence this system of wiring can be used

in damp place.

Oil& smoke are injurious to VIR insulaon.

FIELD APPLICATION

The wiring of this type is very suitable for temporary installaon in dry places, where

appearance is not so important and cost is the main consideraon.

2. WOODEN CASING & CAPING WIRING

This is one of the earliest systems of wiring.

The cables used in this type of wirings are either VIR or PVC.

It has two halves, one is casing and another is capping.

The casing consist of V – shaped grooves and is covered at the top buy means of

rectangular strip of wood known as capping.

The varnished is used to protect wood from white ants.

ADVANTAGES

Cheaper in cost as compare to lead sheath wiring.

Easy to install and rewire.

It provides good insulaon as conductors are at a good distance apart.

Easy to inspect by opening the capping.

DISADVANTAGES

This type of wiring is also coated with pain to varnish to protect from dampness. So it

can be used in damp place.

Since there is a risk of re. It cannot be used where there is a possibility of re hazard.

This type of wiring can be used only on surface and can be concealed in plaster.

Since it require beer work skills, the labour cost is higher.

FIELD APPLICATION

This type of wiring is suitable for low voltage domesc installaon in dry places and

where there is no risk of re.

PVC CASING & CAPING WIRING

Due to increased cost of teak wood, the wooden casing & capping are becoming

absolute and PVC casing &capping are being used.

This type of wiring is achieved by using hollow channel made of PVC plasc.

3. C.T.S/ T.R.S OR BATTEN WIRING

T.R.S-Tough rubber sheathed wiring

C.T.S-Cab Tyre sheathed wiring

In this type of wiring the cables used may be single core, twin core or three core T.R.S

cable with a circular shape.

T.R.S cables are suciently chemical proof, water proof, steam proof but are slightly

aected by lubricang oil.

T.R.S cables are run on perfectly straight and well varnished teak wood baen.

The width of baen depends upon number and size of cables to be carried by it.

The wood baens are screw to wood by plugs at an interval not exceeding 75 cm.

The cables are held on the wood baen by means of n-brass links clips at an interval of

10 cm or 15cm.

ADVANTAGES

Its installaon is easy and quick.

Its life is suciently long.

Within certain limits it is re proof.

It can withstand the acon of most chemical such as acids &alkalis.

It is cheaper than other types of wiring excepts cleat wiring.

If the job is carried out with a care it gives a nice appearance.

DISADVANTAGES

Good workmanships is required forth is type of wiring.

This type of wiring cannot be recommended for use in situaon open to sun & rain

FIELD APPLICATION

The T.R.S wiring is suitable for low voltage installaon in domesc & commercial

building.

It cannot be used in damp places.

4 .LEADSHEATHED / METAL SHEATHED WIRING

In this type of wiring the cables used are T.R.S or P.V.C with an outer covering of sheath

of lead aluminium alloy containing about 95% of lead.

This metal sheath protecon to the cables from mechanical injuries, dampness and

atmospheric corrosion.

The whole lead covering is made electrically connuous and is connected to earth at

the point of entry to protect against leakage current.

ADVANTAGES

It provides protecon against mechanical injuries beer than that of T.R.S wiring.

It is easy to x and look nice.

Its life is long if proper earth connuity is maintain throughout.

It can be used in damp situaon provided protecon against moisture.

It can be used in situaon exposed to rain & sun.

DISADVANTAGES

It is costlier than T.R.S wiring.

In case of damage of insulaon the metal sheath becomes alive and gives shock.

Skilled labour & proper supervision is required.

5.CONDUIT WIRING

In this system of wiring al wires are enclosed in steel pipe known as conduit ( PVC or

VIR).

There are3types of conduit wiring

1. Concealed conduit wiring.

2. Surface conduit wiring

3. Flexible conduit wiring

1. CONCEALED CONDUIT WIRING

The conduit are embedded along wall or ceiling in plaster at the me of construcon.

The conduit should be electrically& mechanically connuous and connected to earth at

suitable place through earth wire.

The conduit used for this purposes is up two types.

1. Light gauge conduit

2. Heavy gauge conduit

PVC conduit pipes are also available now and are increasing being employed in place of

steel conduit.

PVC. Conduits are cheaper in cost. It required less me to install. Such conduits are

resist to acids, alkalis, oil & moisture.

2.SURFACED CONDUIT WIRING

The conduit in surface conduit wiring is placed on the surface of the wall and hold with

the of conduit saddle.

This system of wiring is applied in the industrial wiring.

3.FLEXIBLE CONDUIT WIRING

The exible conduit pipe is a pipe which can bend or twist without the change in its

diameter.

The exible conduits are not used for general electrical wiring system. it is used for

connecng rigid conduit with machine terminal box in case of motor wiring, energy

meter and main switch in case industrial & domesc wiring system.

ADVANTAGES

It provides protecon against mechanical damage.

The whole system is water proof.

Replacement and alternaon of defecve wiring is easy.

Its life is long if the work is properly executed.

It is shock proof if earthing &bonding is properly done.

DISADVANTAGES

It is a very costly system of wiring.

Experience & highly skilled labour needed for carrying out the job.

Q.1 The plan of a single room of size 5mtsX4mts is given below .The room is required to be

provided with one lamp, one fan, uorescent tube and one 5 Amp socket –outlet. Each of

the points is controlled by its individual switch. Mark the locaon of the electrical points

suitably and draw the installaon plan. Also draw the wiring diagram. Calculate the total

length of wire and other materials and prepare complete list of materials required for wiring

the room in concealed steel conduit system of wiring .No main switch is to be provided as

the entry of the sub-circuit is from adjoining room.

Soluon

Assume

a) Total height from oor to ceiling=3.5 mts

b) Height of H.R from oor=3.0 mts

c) Height of switch board from oor=1.5mts

d) Light and tube points from ceiling=0.5 mts

Calculaon for length of conduits pipe of 20 mm diameter

from SB to HR=1.5 mts

from entry of circuit into room upto take o points=2.0+0.5=2.5mts

from HR to lamp point=0.5mt+4+0.5=5mts

from fan to tube points=2.5+0.5=3 mts

total length of conduit pipe=(1.5+2.5+5+3)mts=12mts

taking 10% for wastage=1.2 mts

total length of conduit pipe required for wiring the room=13.2 mts

Calculaon for length of phase wire

from point of entry of circuit into room upto SB= 2(HR)+1.5(VR)=3.5 mts

from SB to fan =1.5(VR)+0.5(HR)+0.5+2=4.5mts

from SB to lamp=4.5+2+0.5=7 mts

from SB to tube point=4.5+2.5+0.5=7.5 mts

total length of phase wire=(3.5+4.5+7+7.5)mts=22.5mts

taking 15% for wastage=3.37mts

total length of phase wire required for wiring the room=22.5+3.37=25.075mts

Calculaon for length of neutral wire

from point of entry of circuit into room up to SB= 2(HR)+1.5(VR)=3.5 mts

from SB to fan =1.5(VR)+0.5(HR)+0.5+2=4.5mts

from fan to lamp points=2+0.5=2.5mts

from fan to tube point=2.5+0.5=3mts

total length of neutral wire=(3.5+4.5+2.5+3)mts=13.5mts

taking 15% for wastage=2.02

total length of neutral wire required for wiring the room=13.5 +2.02=15.52mts

calculaon for length of earth wire (14 SWG)

length of earth wire=0.25 mt.

Material Table

Si

no

.

descripon of materials with specicaons

Quanty

1

total length of conduit pipe (20 mm dia)

13.2 mts

2

total length of phase wire (1 mm

2

)

25.075m

ts

3

total length of neutral wire(0.5 mm

2

)

15.52mt

s

4

total length of earth wire( 14 SWG ,G.I)

0.25 mt.

5

Conduit pipe accessories for 20 mm dia

a. 1-way juncon box

b. 2-way juncon box

c. 3-way juncon box

d. Conduit bends

2 nos

1no.

2nos.

3nos.

6

One way switch,5 amp ,rang

4nos.

7

Socket,5 amp rang, 3 pin

1nos.

8

Ceiling rose, 2-plate,bakelite

2nos.

9

Lamp brass bracket with holder

1nos.

Q.2 A room and a verandah ,the plan of which is given below is required to be provided with

electrical wiring. Mark the locaon of energy meter, main switch and switch board and

electrical points suitably and draw the installaon plan showing supply path to each points

and wiring diagram .calculate the total length of wire required for wiring the room and

verandah in baen system of wiring. Prepare a list of materials with complete specicaon

of each item with approximate cost.

Soluon

Assume

a) Total height from oor to ceiling=3.5 mts

b) Height of H.R from oor=3.0 mts

c) Height of switch board from oor=1.5mts

d) Light and tube points from ceiling=0.5 mts

e) Locaon of energy meter and main switch board=0.5 mt. inside verandah on room wall

Calculaon of load

Lamps= 3X60 W=180W

Fan=1X60W=60W

Socket outlet 5 amp.=2X100W=200W

Fluorescent tube=1X40W=40W

Total connected load=480W

Load in ampere=480W/230V=2.1 amp

Selecon and rang of main switch

Rang of DPIC , Main switch =5 ampere ,250 volt grade

Selecon and rang of Distribuon board

There are only seven light/fan/socket points, hence no distribuon board will be used

Calculaon for length of baen

from main board to HR=1.5 mts =13mm X13mm (2 wire)

from SB

1

to HR =1.5mts=31mm X13mm (5wire)

from SB

2

to HR=1.5mts=25mm X13mm (4wire)

from HR above main board to L

1

=1.5mts=13mm X13mm (2 wire)

from L

1

to L

2

=0.5+3+0.5=4mt=13mm X13mm (2 wire)

from HR above SB

2

to fan =0.5+2=2.5 mts=25mm X13mm (4wire)

from fan to L

3

=2+0.5=2.5mt=13mm X13mm (2 wire)

from fan to tube point=2+0.5=2.5mt=13mm X13mm (2 wire)

total length of baen of size

13mm X13mm=1.5+1.5+4+2.5+2.5=12mt

25mm X13mm=1.5+2.5=4mt

31mm X13mm=1.5mt

taking 10% for wastage which is required for wiring the room

13mm X13mm=12mt +1.2=13.2 say 13mt

25mm X13mm=4mt+0.4=4.4mt say 4.5 mt

31mm X13mm=1.5mt+0.15=1.65 mt say 2mt

Calculaon for length of aluminium conductor VIR wire of size 1.5 mm

2

13mm X13mm=12mtX 2 wire=24 mts

25mm X13mm=4mt X 4 wire=16 mts

31mm X13mm=1.5mt X 5 wire=7.5 mts

total length of wire on baen=47.5mts

taking 15% for wastage=7.2mts

total length of phase wire required for wiring the room=47.5+7.2=55.7mts say 56mts

calculaon for length of earth wire (14 SWG)

from MS to SB

2

through SB

1

=1.5+1.5+1.5+0.25(thickness of wall)=4.75mts

taking 15% for wastage=0.47mt

taking 10% for wastage which is required for wiring the room=4.75+0.47=5.2 mts say 5.5 mts

Material Table

Si

no

.

descripon of materials with specicaons

Quanty

DPIC main switch 5 amp rang,250 volt

grade with fuse and NL

1no.

1

total length of Dierent size of Baen

13mm X13mm

25mm X13mm

31mm X13mm

13mt

4.5 mt

2mt

2

total length of phase & neutral wire (1.5 mm

2

)

56mt

4

total length of earth wire( 14 SWG ,G.I)

5.5 mts

5

Conduit pipe accessories for 20 mm dia

a. 1-way juncon box

b. 2-way juncon box

c. 3-way juncon box

d. Conduit bends

2 nos

1no.

2nos.

3nos.

6

One way switch,5 amp ,rang

6nos.

7

Socket,5 amp rang, 3 pin

2nos.

8

Ceiling rose, 2-plate,bakelite

2nos.

9

Lamp brass bracket with holder

2nos.

9

Link clip,aluminium 40 mm long (10 cm

apart)

300 nos

9

Black enamel nails to x clips with baen

100 gms

9

Teak wood plugs (gus) at 0.75 mt interval

30nos.

9

Earthing thimbles 5 amp rang for xing

earth wire to main switch

2nos.

9

Earthing set complete with pipe,earth

wire,charcoal,salt,thimbles,nuts & bolts etc

1 set.

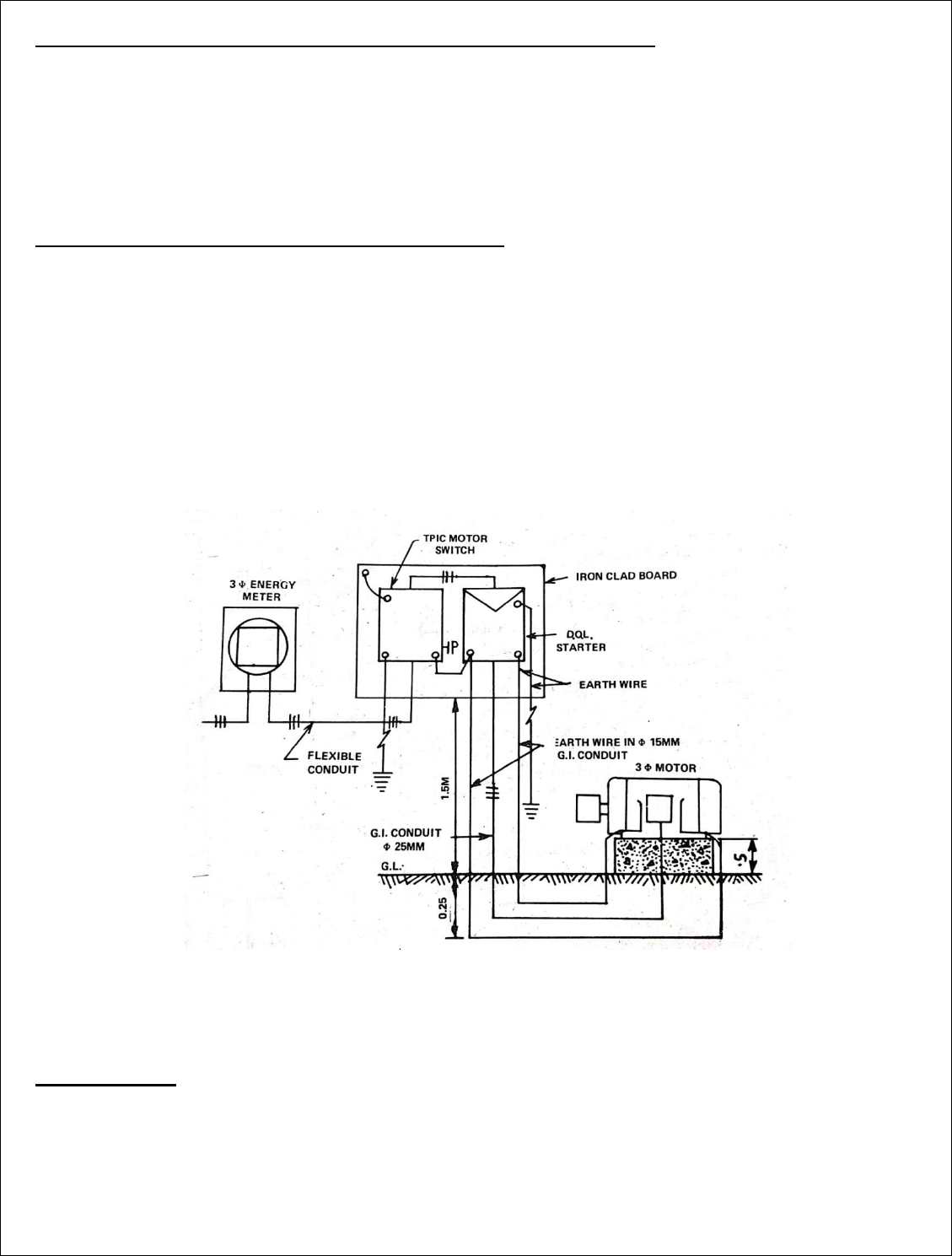

Q.3 It is proposed to install a power connecon of 3 phase 5 HP inducon motor for an

agriculture tube-well in the room of size 3MX3MX3M high. The motor is one metre away

from two nearest walls. Prepare the esmate in the following order.

a) Draw installaon plan showing locaon of MB and motor etc. Also mark path of

wiring by a thick line.

b) Single line diagram. Showing earth wires also.

c) Wiring diagram.

d) Decide the rang and specicaon of important materials and calculate of wire

,conduits,earth wire etc. and prepare a complete list of materials required for wiring

the room with complte specicaon of each item. Also calculate the approximate cost

for the power wiring.

Soluon

Assumpon

a) Total height of main board from oor =1.5 mts

b) Two earth wires enclosed in their respecve 15 mm dia. G.I pipe installed side by side

for earthing the motor.

c) The Motor with pumping set is installed 0.25 mt above oor on a suitable foundaon

Calculaon of load

Running current =

= 9.1 amp say 8 amp

Starng current=1.5 amp

Selecon and rang of MS

It is suggested that a TPIC, Main switch=32 amp,500 volt grade

Selecon and rang of wire

It is suggested that a PVC Insulated aluminium conductor, single core ,660 volts grade of size 6

mm

2

or 1/2.80 mm diameter, should be used for power wiring

Calculaon for length of heavy gauge conduits of 25 mm diameter

From TPIC to motor foundaon=1.5+0.25+1+o.25+0.25=3.25 mts

Taking 10% wastage=0.325mt

Total length of conduit required for wiring the motor =3.25+0.325=3.57 mts say 4 mts

Calculaon for length of heavy gauge conduits of 15 mm diameter

From starter to motor foundaon=(1.5+0.25+1+o.25+0.25)X2=3.25 mts X 2=6.5 mts

Taking 10% wastage=0.65mt

Total length of conduit required for wiring the motor =6.5+0.65=7.1 mts say 7.5 mts

Calculaon for length of exible conduits of 25 mm diameter

From energy meter to main board=1.0 mt

From main switch to starter=0.5 mt

From starter to conduit mouth=0.25mt

From motor foundaon to motor terminal block=0.25mt

Total length of conduit=(1.0+0.5+0.25+0.25)mt=2mt

Taking 10% wastage=0.2mt

Total length of exible conduit required for wiring the motor =2+0.2=2.2mts say 3.25 mts

Calculaon for length of phase wire of 6 mm

2

or 1/2/80 mm dia

From TPIC to motor foundaon=(rigid conduit +exible conduit)X3

=(3.25+2)mts X 3

=15.75 mts

Taking 15% wastage=2.5mt