GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 4.23

25May2021 1 | P a g e

Implementation Example for the Requirement of Barrier Technology (Isolator and

Restricted Access Barrier Systems, RABS) and Barrier Glove Integrity Testing (section 4.23)

Context:

This is one of several examples that have been developed by different industry associations to help

inform the IWG as to the levels of complexity these types of changes can have as they consider

Annex 1 implantation timing. The examples provided are from the top 5 requirements identified in

the letter from the Annex 1 Associations’ Coordination Meeting Team dated 14 March 2021 and

have been developed as if the requirements in the revised EU GMP Annex 1 draft (version 12) were

to be included in the final Annex 1 revision as currently written. As such they do not take into

consideration any changes made to the current draft version of Annex 1.

The examples are intended to be informative only and as such were not taken through a consensus

process across the associations. They should not be considered as industry guidance on

implementation approaches or specific timing. It is important to stress that each individual

situation, in regard to implementation, will in most cases be unique based on process, product, and

facility differences and taking into account the Contamination Control Strategy outcomes. As such,

this specific example is not meant to provide an industry vetted acceptable path or guidance to

achieve an acceptable path to compliance with the requirements noted in section 4.23.

It is important to note that these examples are not intended to imply agreement with the revised EU

GMP Annex 1 draft (version 12) as written, as reflected in the industry comments submitted in the

2020 targeted consultation.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 4.23

25May2021 2 | P a g e

This example focuses on the challenges resulting from implementation of revised EU GMP Annex 1

draft (version 12) relating to the requirement of integrity testing of barrier technology; Isolators and

RABS together with associated barrier gloves.

Annex 1 Requirement:

4.23

“The materials used for glove systems (for both RABS and isolators), as well as other

parts of an isolator, should be demonstrated to have good mechanical and chemical

resistance. Integrity testing of the barrier systems, and leak testing of the glove system

and the isolator should be performed using a methodology demonstrated to be suitable

for the task and criticality. The testing should be performed at defined periods, at a

minimum at the beginning and end of each batch, and should include a visual inspection

following any intervention that may affect the integrity of the system. For single unit

batch sizes, integrity may be verified based on other criteria, such as the beginning and

end of each manufacturing session. RABS gloves used in Grade A zone should be

sterilized before installation and sterilized (or effectively decontaminated by a validated

method which achieves the same objective) prior to each manufacturing campaign. The

frequency of glove replacement should be defined within the CCS.”

Considerations and Impact of Requirement 4.23; Barrier and Glove Integrity Testing:

Considering the principal requirement of Annex 1 regarding; 4.23 ‘’Integrity testing of the barrier

systems, and leak testing of the glove system and the isolator should be performed using a

methodology demonstrated to be suitable for the task and criticality’’ there are developed integrity

test technologies for barriers and gloves. Currently, however, not all barrier technology systems

have integrated integrity testing and In some cases, further development is required to meet the

required sensitivity/ detectability.

The criticality of the ‘barriers’ physical separation of Grade A to surrounding environment, where

operators are present, should be considered as one of the contamination control attributes that

enable Grade A conditions to be established within a defined boundary. The physical integrity of the

barrier needs to be maintained within set limits to mitigate risks of Grade A compromise.

To maintain this level of control the leak integrity test method must have the required sensitivity

and in the process of test execution not put undue stress on the barrier that may by default cause an

integrity failure. Barrier leak integrity levels may also need to meet requirements of safety including

a greater integrity if processing toxic or highly potent products and for Isolators (and in some cases

Closed RABS systems) to contain hydrogen peroxide vapour or other bio-decontamination agents.

Further, considering 4.23 ‘’The testing should be performed at defined periods, at a minimum at the

beginning and end of each batch, and should include a visual inspection following any intervention

that may affect the integrity of the system’’. In a production setting barrier and glove integrity

testing requires integration into the barrier environmental control system so automated (non-

intrusive) leak integrity testing can be completed, typically by a pressure decay method over a short

(rapid) test period so the impact of temperature and barometric changes are mitigated.

More manual, intrusive leak integrity tests may be appropriate at factory qualification testing of

barrier systems or at IQOQ qualification stages. For routine process monitoring a qualified integrity

test system requires integrated control and non-intrusive application of pressurising sources

together with control to reach target test pressure set-points, allow stabilisation and monitoring of

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 4.23

25May2021 3 | P a g e

pressure decay over a set decay period with a clear determination of ‘pass – fail’ result. In addition

integrity test result reporting that meets requirements of data integrity is expected.

Leak integrity testing of barrier gloves requires different strategies for Isolators and RABS but if

tested in-place on the barrier Glove ports require to be closed/ sealed via a test cover that has the

appropriate level of integrity so risks of false failure (inferred integrity failure) are mitigated. In

these cases, the glove-sleeve, glove port and glove integrity test system (glove port sealing device)

are a combined system.

Currently not all glove ports have a suitable method to close and seal the glove port so a glove

integrity test can be completed. Alternatively the glove integrity test system provided does not have

the required detectability or appropriate qualification methodology – more development is

required. For production scale modern Isolator systems wireless Lan automated Glove integrity test

systems are developed that meet Pharma 4.0 levels of control connectivity, reporting and data

integrity management but it is not expected this ‘gold standard’ would apply to all applications. For

each case, requirements of criticality, functionality, detectability and robustness need to be

considered.

Considering the requirement; ‘’barrier gloves used in RABS Grade A zones should be sterilized before

installation. For RABS barrier gloves that may be exposed to the background environment during

operation, disinfection using an approved methodology following each exposure should be used’’.

In this case RABS gloves integrity testing, both visual and physical, should be completed before

sterilisation and installation into the barrier system together with, as a minimum, visual inspection

for defects on a daily basis during operations. Based on risk assessment, RABS gloves may also be

physically integrity tested in-place with a suitable methodology.

If this is the case then RABS glove ports and compatible glove integrity test systems may need

installation as a compatible system set replacing existing glove ports that are not suitable to connect

a glove integrity tester.

For testing barrier glove integrity in-place there is a limit of detection of 100-micron pin-hole size

within the glove material. During integrity testing via pressurisation and monitoring of pressure

decay it follows that contamination may be introduced via the pin hole if the glove-sleeve is

pressurised into the Grade A zone. For Isolators, this contamination risk is typically mitigated by leak

integrity testing gloves before the vapourised hydrogen peroxide (VHP/vH202) Bio-decontamination

cycle (or other automated disinfection method) and after batch production so the Grade A

environment is not compromised during processing of sterile products.

For campaigns where glove integrity testing may be required mid batch there is available glove

integrity test systems that pressurise the barrier glove outwards so any loss of integrity does not

introduce contamination into the Grade A zone. Not all Isolator manufacturers have developed this

‘Campaign Glove testing’ technology and further development may be required.

Implementation Times for Integrity Testing of Barrier Technology and Gloves:

This example justification is meant to illustrate where and why additional implementation time may

be needed for barrier technology and glove integrity testing.

Based on the considerations for barrier and glove integrity testing the following technical changes

may be required, in-part or all depending on how advanced the barrier technology may be.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 4.23

25May2021 4 | P a g e

Barrier leak integrity testing – potential technical changes to meet intent of Annex 1

• Change of Isolator control system may be required (software or control boards) to facilitate

an automated pressure decay test of the barrier technology. Typically applies to Isolators

(with Grade D or C background) or in some cases to Closed RABS systems with a Grade B

background that apply integrated Gaseous bio-decontamination e.g. VHP/ vH202. This case

the Closed RABS would require barrier leak integrity testing to assure safe containment of

VHP/vH202.

• To execute a pressure decay test the barrier system must be closed, including any air make

up of extract paths used for air exchange/ pressure control within the Isolator/ barrier.

Automated dampers may be required or for simpler isolators closing plates fitted to seal the

air pathway that provide the required level of robust ‘dynamic’ sealing integrity.

• To control the test pressure to a starting point around which acceptance criteria in pressure

decay may be set, compressed air introduction may be required as the control of Isolator fan

ventilators may be inadequate (not sensitive enough).

• The leak integrity test pre-production as a GMP control measure may need combining as a

safety measure for containment if VHP/vH202 is specified. In this case the leak test is also a

safety measure to mitigate risks of advancing to ‘gassing’ if there is an integrity failure. The

Isolator control system needs to accommodate these combined requirements.

Glove leak integrity testing – potential technical changes to meet intent of Annex 1

• Change of glove ports on the barrier technology to facilitate integration of a compatible

Glove integrity test system with the required level of sealing so pressure decay results focus

on the integrity of the glove (not the test device).

• If it is not possible to replace the glove ports in the barrier panel to facilitate integration of a

compatible glove test system the combined barrier panel (vision panel, glass or plastic) and

new glove port systems will require replacement.

• Optimization of the control sequence recipe used for glove integrity testing may be required.

Automated pressure decay tests are typically applied as rapid tests over a short period to

negate any impact from temperature and barometric change over time. Before pressure

decay results can indicate a glove integrity issue there must be a stabilization period that

allows for any test impact from glove stretching and temperature (as result of energy in

pressurization), to prevent false failures. Volume changes due to glove stretching or pressure

changes e.g. from cooling = negative pressure change and heating = positive pressure

change can provide false pass or fail results. Stabilization time needs development and

optimization to accommodate inherent process variables as different glove materials have

different stretch characteristics.

• Efficient glove integrity test systems have a limit of detection of 100-micron hole sizes that

are typically not detected by visual inspection (VI) alone (VI has a limit of detection around

400-500 micron). To achieve this level of sensitivity-detectability test pressures require to be

over 500 pascal and in many cases are typically applied around 1000 pascal. If current glove

integrity test systems have inadequate test pressures and an optimized control sequence

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 4.23

25May2021 5 | P a g e

recipe of stabilization further development of the glove integrity test system may be

required.

All technical changes will take time and together with qualification will extend implementation time.

As process improvements and keeping up to date with current technology are an expectation there

may be a need to develop an implementation plan for improvements and this plan may take

extended time to execute without unduly impacting production operations and capacity output

(medicine supplies).

Example of Project Implementation Activities:

The following example is intended to illustrate the types of activities and associated timing for

implementation of barrier and glove integrity testing:

Activity list:

Project step

Comment

Technology Development

Required where the current technology is not available to meet

the technical (sensitivity) or operational requirements. Timing is

depended on the development of technology.

Receipt of purchase order (PO)

Before project start there is a project team alignment and Kick off

Technology integration schematics

and controls/ automation strategy

Combined integration of barrier technology, barrier integrity test

and glove integrity test technology.

Design reviews – risk assessment

schematics/ automation strategies

Joint meetings with site and Isolator/ integrity test technology

manufacturers.

Detail Design & reviews

Review of barrier integrity test design integration.

Glove integrity test Technology

manufacturing & FQT

Each specialist manufactures technology followed by Factory

Qualification Testing (FQT) and Factory Acceptance Testing (FAT)

to be integrated onto barrier technology. Site representatives

attend with FAT focusing on functionality (detectability and

sensitivity).

Manufacture of sub-system parts for

barrier integrity testing integration

Sub-systems (that can be) pre-installation tests of functionality.

Packaging for shipment to site &

delivery

Delivery times and packaging vary depending on transport method

and global location of site.

Installation at site

Involves specialist personnel from barrier technology/ glove

integrity test system manufacturer. Timing based on facility

availability and allowable shutdown timing in regards to product

supply.

Commissioning

Involves specialist teams from barrier technology manufacturer

Technology Qualification, Site

Acceptance Testing (SAT), IQOQ, &

PQ

Involves specialist teams from barrier technology manufacturer.

For glove integrity testing qualification a reference leak challenge

(at limit of detection) needs to be implemented with clear

indications of integrity failure.

Technology user training

Both classroom and Hands on training

Quality oversight and approvals

Sufficient time needed for quality reviews and approvals

Hand over to end user including all

supporting documentation

Formal process to verify completion of all deliverables

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 4.23

25May2021 6 | P a g e

Site progresses to process platform

Qualification

Preparation of all procedural

controls (SOPs)

Could be completed through the project but requires finalisation

before process operations trainings

QA/ QC oversight and approvals

Sufficient time needed for quality reviews and approvals

Regulatory Submissions

Complexity will be dependent on the specifics of the change and

impact

Supportive data package completion

QA/QC/Production activity

GMP inspection

Interim GMP inspections may be required, depends on site history

Regulator Q&A and Approvals

Timing will vary based on the number and specific countries where

submissions are required.

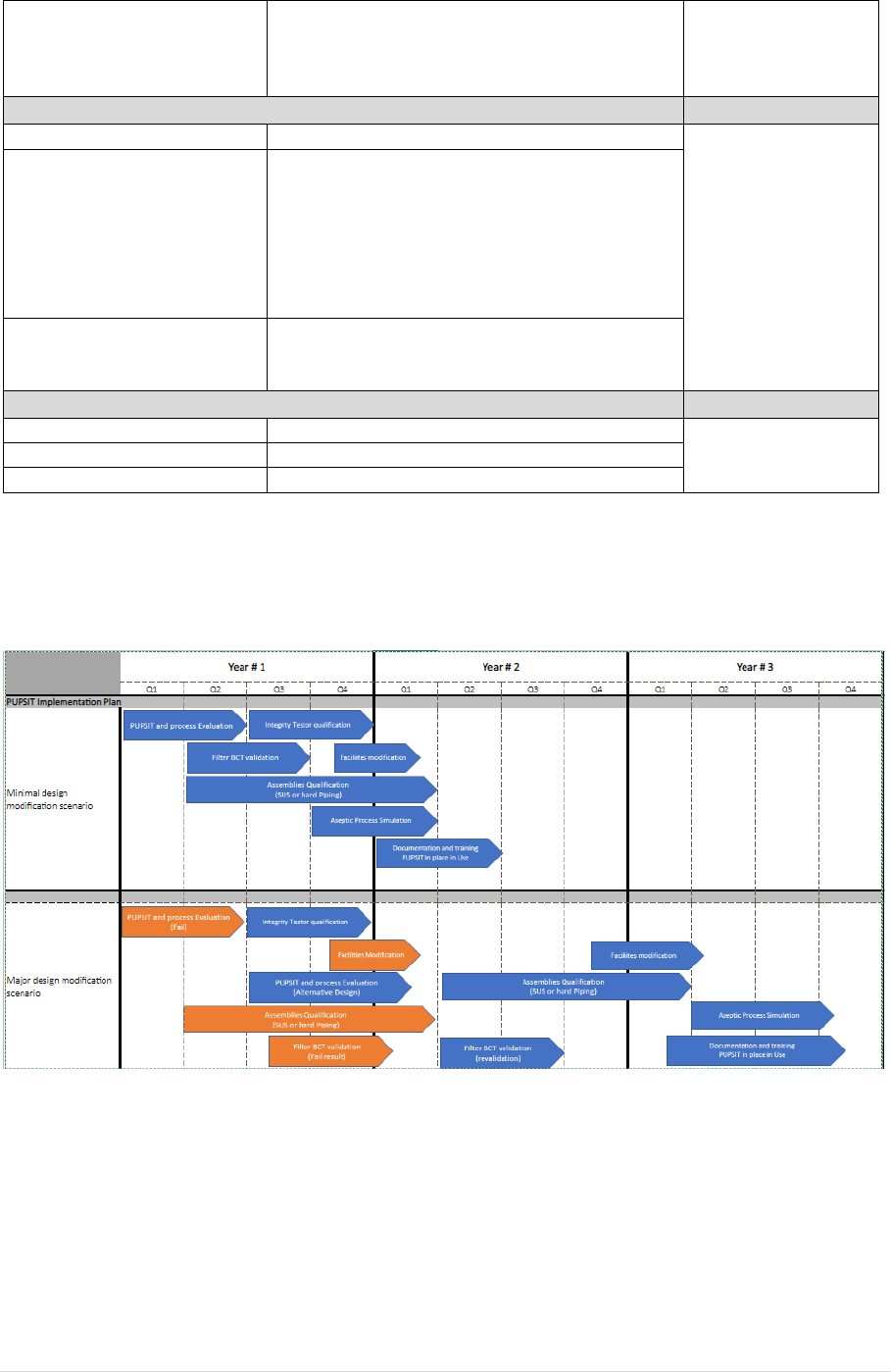

Example Timeline: Optimized

The timeline for each specific project will be determined based on many factors. The intent of the

timeline provided is to provide a general idea of the activities and timing with optimized project

steps that follow in sequence. Figure (1) presents a sequence of events based on the above

description, with some illustrative timelines. These timelines may require modification of timing

depending on implementation complexity and study results.

Figure 1

Summary:

Although barrier and glove integrity testing technologies are developed at a suitable level of

functionality (rapid test) and detectability/ sensitivity not all barrier technology manufacturers have

integrity test technology at the required level of functionality/ detectability so technology

development/ process improvement may be required to meet the full intent of draft Annex 1.

Current barrier technology, in some cases, may not have integrated barrier integrity and/or glove

integrity test technology so integration of current technology onto the barrier may be required.

For barrier technology (Isolators and Closed RABS that apply VHP/vH202 or alternative automated

bio-decontamination processes) both mechanical changes to the barrier and software/ control board

changes may be required to implement an integrated barrier leak integrity test for use during

production operations (before and end of batch, minimum).

Where in-place glove integrity test technology is required there may be a need to replace existing

glove ports (or as assembly with vision panel) to facilitate use of a compatible glove integrity test

technology (as an integrated test system).

Technology Development if Required

(Development outcome dependent)

Integration Strategy/Detailed Design

Equipment Fabrication/Suppler Testing

(Dependent on extent of development)

FQT/FAT of Glove integrity test systems and

Sub components for barrier integrity test

Pack/Shipping/Receipt

(Location Dependent)

Receipt and Installation

(contingent on barrier technology availability)

Optimization; Recipe development

Qualification

(Line time/test material availability)

Regulatory Submissions/Q&A/Approvals

(Global)

16 – 18 Months

12 – 16 Months

3 – 36 Months

*

*

An estimated time for this activity can not be determined as it is contingent on the status of current development at the

specific barrier technology and glove integrity test system manufactures.

Possibly during shutdowns

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 4.23

25May2021 7 | P a g e

Following integrity test technology selection an implementation plan will be required and prepared

case by case to align project requirements and regulatory expectation. The implementation plan will

be referenced in the CCS that will evolve through the product life cycle as continuous improvements

are implemented.

Conclusion:

Including the required regulatory approvals, the implementation of suitable (criticality dependent)

barrier and glove integrity testing could require 3+ years if current technology integration is required

(case specific). Where a significant level of integrity test technology development is required longer

timelines are expected.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 5.5 and 8.12

25May2021 1 | P a g e

Implementation Example for the Requirement of Sterilization of In-direct Product

Contact Parts (section 5.5 and 8.12)

Context:

This is one of several examples that have been developed by different industry associations to help

inform the IWG as to the levels of complexity these types of changes can have as they consider

Annex 1 implantation timing. The examples provided are from the top 5 requirements identified in

the letter from the Annex 1 Associations’ Coordination Meeting Team dated 14 March 2021 and

have been developed as if the requirements in the revised EU GMP Annex 1 draft (version 12) were

to be included in the final Annex 1 revision as currently written. As such they do not take into

consideration any changes made to the current draft version of Annex 1.

The examples are intended to be informative only and as such were not taken through a consensus

process across the associations. They should not be considered as industry guidance on

implementation approaches or specific timing. It is important to stress that each individual

situation, in regard to implementation, will in most cases be unique based on process, product, and

facility differences and taking into account the Contamination Control Strategy outcomes. As such,

this specific example is not meant to provide an industry vetted acceptable path or guidance to

achieve an acceptable path to compliance with the requirements noted in sections 5.5 and 8.12.

It is important to note that the examples developed are not intended to imply agreement with the

revised EU GMP Annex 1 draft (version 12) as written, as reflected in the industry comments

submitted in the 2020 targeted consultation.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 5.5 and 8.12

25May2021 2 | P a g e

This example focuses on the challenges resulting from implementation of the revised Annex 1 draft

(version 12) relating to the requirement of sterilization of in-direct product contact parts sections 5.5

and 8.12.

Annex 1 Requirement:

5.5

“Direct and indirect contact parts should be sterilized. Direct contact parts are those that

the product passes through, such as filling needles or pumps. Indirect product contact

parts are equipment parts that come into contact with sterilized critical items and

components”

8.12

“For sterile products that cannot be filtered, the following should be considered:

i. All product and component contact equipment should be sterilized prior to use.”

Sterilization of In-direct Contact Parts:

Section 5.5 is clear in stating direct and in-direct product contact parts should be sterilized.

Sterilization in context would be considered as a process documented in pharmacopeia as a

penetrative process e.g., moist heat, dry heat, gamma and ETO. For direct product contact parts this

is an accepted practice.

However due to complexities in process operations within Isolator barrier technology, over the

years, different practices have been applied to in-direct product contact surfaces that are

impermeable stainless steel surfaces and are considered suitable for surface sterilization. In some

cases the method of ‘surface sterilization’ that is applied in vaporized hydrogen peroxide vH

2

0

2

/VHP

based on the claim 6log+ sporicidal efficacy of surfaces can be achieved.

The regulatory concern around the Fragility of vH

2

0

2

/VHP because of the limitations of penetration

to protective or high density bioburden layers (including spore clumps) as exhibited in ‘Rogue BI’

biological indicator unexpected growth within a qualified bio-decontamination cycle has put the use

of vH

2

0

2

/VHP as a surface sterilization method into question. Further there is no reference to

vH

2

0

2

/VHP as a sterilization process in pharmacopeia or differentiation between penetrative

sterilization and ‘surface sterilization’.

It is understood the regulatory expectation for compliance to Annex 1 is that direct and in-direct

product contact parts are sterilized and by default, sterilization would be a pharmacopeia recognized

process.

As vH

2

0

2

/VHP is not a recognized pharmacopeia sterilization process and although there are other

references e.g., USP guidance, that defines vH

2

0

2

/VHP as a sterilization process. When considering

Annex 1 compliance, USP claims for this type of ‘surface sterilization’ process executed within barrier

technology may not be justified to fully meet the intent of Annex 1, particularly if bioburden control

and qualifications fall short of expectations.

In the case where vH

2

0

2

/VHP cycle is applied as the only bio-decontamination process for the barrier

and process equipment non-product contact surfaces and in the same cycle ‘surface sterilization’ of

in-direct product contact parts this would have to be justified using QRM principles.

Such principles would need to recognize the different requirements for cleaning and bioburden

control for bio-decontamination of non-product-contact process equipment/ barrier surfaces and

‘surface sterilization’ of in-direct product contact surfaces.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 5.5 and 8.12

25May2021 3 | P a g e

Practice of Assuring Sterility of In-direct Product Contact Parts in Barrier Technology:

In filling lines, in-direct product contact parts e.g. container closure feeder bowls, bowl loading guide

chutes, track ways and insert devices are managed differently for RABS and Isolator barriers.

Typically in Open RABS systems in-direct product contact systems are sterilized out-of-place (it is not

possible to sterilize such items in-place within barrier technology) using a pharmacopeia recognized

process e.g. Moist heat – autoclaving and then assembled aseptically into a pre-established Grade A

environment. To protect the sterilized parts at installation within the RABS barrier system protective

airflows, good aseptic technique is applied that assures the sterility of in-direct product contact

parts. After the installation procedure and the RABS barrier door is closed, filing operation can

commence. Only rare open door interventions are considered justified once filling operations are

started. The intent in operations would be considered that barrier doors remain closed through

batch filling operations.

The practice is very different for Isolator barrier technology used in sterile product aseptic process

filling because any pre-sterilized in-direct product contact parts are not installed into a pre-

established Grade A environment. Such conditions are only established within the barrier after

assembly in-place of indirect product contact parts and the vH

2

0

2

/VHP automated 6log+ sporicidal

bio-decontamination process is completed.

Direct product contact parts are sterilized and only enter the barrier technology after the vH

2

0

2

/VHP

cycle and Grade A conditions are established.

In the case of in-direct product contact parts there has to be a focus on bioburden control in transfer

of parts from the sterilizer to the filling line and through the installation of the parts into the barrier

technology. The background environmental to the Isolator barrier system is typically Grade C (D

minimum) and there is no overhead uni-directional airflow protection over the open barrier door.

During installation a series of bioburden control measures are required to limit the risk as far as

possible of sterilized in-direct product contact surface contamination before the final 6log+

vH

2

0

2

/VHP bio-decontamination process assures zero CFU recovery from in-direct product contact

and other surfaces within the Grade A processing environment.

Considering the fact there may be different starting points to achieve Annex 1 compliance and fully

meet the intent of the Annex there will be different complexities and potential process changes or

improvements to make as the basis of a justified extended implementation:

Case 1: In-direct product contacting parts are sterilized out-of-place with a pharmacopeia recognized

process but via CCS preparation and following QRM principles there are identified process

improvements to make, as example: in bioburden control measures, procedural controls and

associated qualifications, all in association with the final vH

2

0

2

/VHP bio-decontamination process to

meet the full intent of Annex 1, QRM and regulatory expectation. Process improvements would need

additional implementation time.

Case 2: The only process applied for ‘surface sterilization’ is a vH

2

0

2

/VHP bio-decontamination

process but this approach cannot be justified for the intended and specific application therefore a

process change is required to apply an out-of-place recognized sterilization process in association

with bioburden control measures and a final vH

2

0

2

/VHP bio-decontamination process. For such a

significant process change additional implementation time would be required.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 5.5 and 8.12

25May2021 4 | P a g e

Case 1: Implementation times for process improvements e.g. bioburden control, procedural

control, qualifications to assure sterility of In-direct product contact surfaces.

Considerations for process improvements:

• Preparation or update of CCS based on QRM principles together with supporting risk based

rationale and risk assessment.

• Cleaning qualification for in-direct product contact surfaces.

• Improvement of protective wrapping for in-direct product contact part transfer from the

sterilizer to Isolator barrier technology – filling line.

• Improvement of material transfer procedures through GMP area Grade changes.

• Additional gowning for operators at set-up installation of in-direct product contact parts into

Isolator barrier system plus associated gowning qualification.

• Implementation of Isolator uni-directional air flow (UDAF) protective airflow with open

barrier door in preparation for installation of in-direct product contact parts (pressure

control alarms disabled).

• Smoke study airflow visualization through in-direct product contact part installation into the

barrier system.

• Bioburden qualification after transfer and assembly process just before the final vH

2

0

2

/VHP

bio-decontamination process.

• SOP development and training together with operator qualification

• Media fill studies including process improvement.

Case 2: Process change to introduce out-of-place surface sterilization associated bioburden control

in transfers, assembly into place in association with a final vH

2

0

2

/VHP Bio-decontamination step.

Considerations in a process change:

• Preparation or update of CCS based on QRM principles together with supporting risk based

rationale and risk assessment.

• Sourcing or procurement of Sterilizer suitable for in-direct product contact part sterilization.

• Sourcing of protective wrapping for in-direct product contact parts.

• Pre-sterilization surface cleaning/ bioburden qualification.

• Sterilizer load sterilization cycle development and qualification.

• SOP development and qualification for In-direct product contact part material transfer from

the Sterilizer to filling line (including GMP Grade to Grade changes).

• Sourcing and qualification of additional operator gowning for in-direct product contact part

set-up installation into the Isolator barrier ahead of the final vH

2

0

2

/VHP bio-

decontamination process.

• SOP development of in-direct product contact part assembly into place within the Isolator

barrier system.

• Bioburden qualification studies following transfer/ staging/ assembly procedures for indirect

product contact parts ahead of final vH

2

0

2

/VHP bio-decontamination process.

• Operator training, qualification and media fill APS.

Example Timelines:

Case 1: process improvement in bioburden control to enhance assurance of sterility for indirect

product contact parts.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 5.5 and 8.12

25May2021 5 | P a g e

The timeline for each specific project will be determined based on many factors. The intent of these

estimated timelines is to provide a general idea of the activities and timing with optimized project

steps that follow in sequence. Figure (1) & (2) presents a sequence of events based on the above

Case 1 and Case 2 descriptions, with some illustrative timelines. These timelines may require

modification of timing depending on implementation complexity and CCS outcomes.

Figure 1: Timeline indicating 22-27 months possible implementation time (optimized steps).

Case 2: process change to introduce a recognized out-of-place sterilisation process ahead of

bioburden control in transfer of assembly of in-direct product contact parts ahead of a final

vH

2

0

2

/VHP Bio-decontamination process in assurance of sterility for indirect product contact parts.

Figure 2: Timeline indicating 28-36+ months possible implementation time (optimized steps).

CCS implementation and risk assessment

Identification of process improvements

Changes to Isolator software controls:

UDAF operation in open door set up

together with airflow smoke visualization

Sourcing of additional gowning for set-up

Improvement of protective wrappings

Sterilized in-direct PCP transfer/ assembly SOP

development, operator training, qualification

Bioburden control qualifications

Media Fill/ APS

Regulatory Submissions/Q&A/Approvals

(Global)

16 – 18 Months

6 – 9 Months

*

An estimated time for this activity can not be determined as it is contingent on CCS outcomes and

extent of process improvements required plus extent of process change and tome regulatory/ QA

approvals

22 – 27 Months implementation

*

*

CCS implementation and risk assessment with

Outcomes that identify process change.

Process and detailed Design

Sourcing and qualification of a sterilizer

suitable for in-direct product contact parts

Installation and qualification of a Sterilizer

In-direct product contact part cycle load

Development including protective wrapping

SOP In-direct product contact part transfer

From Sterilizer to Isolator filling line

Sourcing additional gowning and SOP

development for Set-up/ assembly of parts

Qualification of set-up including bio-burden

Studies and operator training

Media fills APS

Regulatory/ QA approvals

16 – 18 Months

12 – 18 Months

28 – 36 Months

implementation plus *

*

*

An estimated time for this activity can not be determined as it is contingent on

CCS outcomes and extent of regulatory approvals for a process change

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 5.5 and 8.12

25May2021 6 | P a g e

Summary:

These examples relate to additional time to implement either a process improvement (Case 1) or

process change (Case 2) for assured sterility of in-direct product contact parts within Isolator barrier

technology filling operations to fully comply with the Annex 1 section 5.5 and intent of the Annex to

follow QRM principles.

Annex 1 Section 5.5 requirements are clear for direct product contact parts and are based on current

practice so justifications for extended implementation time are not considered in these examples.

Annex 1 Section 5.5 requirements are clear for RABS barrier technology applications and are based

on current practice and alternative approaches (case 1 & 2) relate only to Isolator barrier

technology.

In Case 1: Isolator barrier application of in-direct product contact parts the challenge of transferring/

staging and installing sterilized parts into an Isolator barrier may as a result of CCS outcome that

follows QRM principles require a process improvement in bioburden control steps and such a

process change would require additional implementation time.

In Case 2: Isolator barrier application of in-direct product contact parts if the current process does

not include an out-of-place Sterilization step before transfer and installation into an Isolator Barrier

system followed by a final vH

2

0

2

/VHP bio-decontamination process. Such a process relies on the

vH

2

0

2

/VHP process only to achieve surface sterilization but in the specific case this process cannot be

justified then the process change to add a sterilizer would be significant and require much longer

implementation time.

Considering the application within barrier Isolator technology where any sterilization would typically

be out-of-place in a qualified sterilizer these examples consider the complete process and challenges

in transfer of sterilized materials, staging of materials ready for installation into the barrier, set-up

assembly installation into an Isolator barrier technology where Grade A conditions are not yet

established. There is necessary bioburden control before a final vH

2

0

2

/VHP process and it is these

connected process steps that justify the additional implementation time.

Section 5.5 of Annex 1 is relatively short and has a focus on the need to sterilize direct and in-direct

product contact parts. The default regulatory expectation is clear for a sterilization process but case

by case it would need consideration if an out-of-place sterilization process is not practical and an

alternative approach of bioburden control via in-place cleaning/ disinfection followed by a final

vH

2

0

2

/VHP process can be justified following QRM principles.

Conclusion:

In the two cases given, estimated implementation times are given in the range 22 months to 36+

months.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 6.22 and 8.112

25May2021 Page 1 of 4

Implementation Example for the Requirement of Leak Testing (section 6.22) and

Sterilsation before Each Batch in Case of Manual Loading or Unloading (section 8.112)

Context:

This is one of several examples that have been developed by different industry associations to help

inform the IWG as to the levels of complexity these types of changes can have as they consider

Annex 1 implantation timing. The examples provided are from the top 5 requirements identified in

the letter from the Annex 1 Associations’ Coordination Meeting Team dated 14 March 2021 and have

been developed as if the requirements in the EU GMP Annex 1 draft (version 12) were to be included

in the final Annex 1 revision as currently written. As such they do not take into consideration any

changes made to the current draft version of Annex 1.

The examples are intended to be informative only and as such were not taken through a consensus

process across the associations. They should not be considered as industry guidance on

implementation approaches or specific timing. It is important to stress that each individual situation,

in regard to implementation, will in most cases be unique based on process, product, and facility

differences and taking into account the Contamination Control Strategy outcomes. As such, this

specific example is not meant to provide an industry vetted acceptable path or guidance to achieve

an acceptable path to compliance with the requirements noted in sections 6.22 and 8.112.

It is important to note that these examples are not intended to imply agreement with the revised EU

GMP Annex 1 draft (version 12) as written, as reflected in the industry comments submitted in the

2020 targeted consultation.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 6.22 and 8.112

25May2021 Page 2 of 4

This document focuses on the challenges resulting from implementation of the revised EU GMP

Annex 1 draft (version 12) relating to the requirement of leak testing (section 6.22) and

sterilsation before each batch in case of manual loading or unloading (section 8.112).

Annex 1 Requirements:

6.22

Heating and cooling and hydraulic systems

6.22

“Any leaks from these systems that would present a risk to the product should be detectable (i.e.

an indication system for leakage)”

8.112

Lyophilization

8.112

“Lyophilizers that are manually loaded or unloaded should normally be sterilized before each

load. For lyophilizers loaded by automated closed systems or located within systems that

exclude operator intervention, the frequency of sterilization should be justified and documented

as part of the CCS.”

6.22 Implementation Time Extension for: heating, cooling and hydraulic systems

1) Heating and cooling media (e.g. silicone oil) and hydraulic systems

Lyophilizers in operation that do not have leak detection systems will need to be upgraded

(where technically still feasible) or the equipment be exchanged. The implementation to be

compliant with the Annex 1 paragraph will require an additional period of time for upgrade

and/or procurement of equipment.

8.112 Implementation Time Extension for: Lyophilizer sterilisation with manual loading / unloading.

1) Manual loading and unloading for Lyophilizers with the requirement of a sterilization cycle in

between each batch for vials.

Several companies are operating Lyophilizers with manual loading and unloading without

sterilization operation between each batch of the same product, based on risk assessments

and respective process validation work. Changing from this type of campaign manufacture to a

batch-by-batch sterilizing manufacturing requirement in a short period of time to be compliant

with the Annex 1 paragraph will reduce the production capacity significantly as the equipment

and required process capacity have not been sized for such sterilization frequency; impact on

market supply for sterile medicines cannot be excluded. A longer implementation period is

required regarding the steps needed to either upgrade an existing equipment (where an

upgrade is feasible) or procure and install a new automated lyophilization equipment or a

completely new manufacturing line.

Consequently, switching to comply to automatic lyophilizer loading & unloading to allow

production capacity to be restored to the required supply level will require additional

investment and, in many cases, additional manufacturing space/rooms design.

2) Automated loading and unloading for sterile API bulk products

Some processes will need equipment development, as the automated unloading technology

does not exist (e.g. automated aseptic unloading of sterile bulk powder API after freeze drying).

As automated unloading solutions are not yet available recently developed additional barrier

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 6.22 and 8.112

25May2021 Page 3 of 4

systems will have to be implemented to avoid direct manual intervention, providing increased

protection in critical areas. Those additional barrier systems installed in front of the lyophilizers

require sufficient space to operate. This additional space is typically not available in existing

facilities, thus upgrade of existing lines may not be possible. Any upgrade to this semi-

automatic barrier systems can only be realized as a new line expansion project.

Some of the requirements listed above, if not already in operation in the companies, will

require significant facility, process, equipment and process changes including regulatory

approval. These points could require an extension of the implementation time, based on a

schedule developed by the company to improve its facility.

Example of Implementation Technologies on Site:

The following table describes the main steps to implement a new equipment on site incorporating

some new technologies. This is not an exhaustive list but represents the main project steps and

people involved. This schedule could also be used to implement equipment upgrade.

Project step

Comment

Technology Development

Required where the current technology is not available to meet

the technical or operational requirements. Timing is depended on

the development of technology.

Receipt of purchase order (PO)

Before project start there is a project team alignment and Kick off

Technology integration schematics

and controls/ automation strategy

Combined integration of Filling platform, Lyophilizer and barrier

technology (with material transfers) for sterile product processing.

Design reviews – risk assessment

schematics/ automation strategies

Joint meetings with Alliance partners: Filling + Barrier Technology +

automated loading of Lyophilizer

Detail Design & reviews

3D models and CAD drawing reviews, control strategy preparation

Technology manufacturing & FQT

Each specialist manufacturer’s technology manufactured?

followed by Factory Qualification Testing (FQT) of each technology

to be integrated

Technology integration

Integration of loading technologies; at Freeze drying platform

manufacturer

Technology testing/

commissioning.

Typically, at lyophilizer platform manufacturer with alliance

partners

Integrated Technology FAT

Site representatives attend with FAT focusing on functionality

Dis-assembly & Packaging for

shipment to site & delivery

Delivery times and packaging vary depending on transport method

and global location of site.

Installation at site

Involves specialist teams from alliance partners. Timing based on

facility availability and allowable shutdown timing in regard to

product supply.

Commissioning

Involves specialist teams from alliance partners

Technology Qualification SAT,

IQOQ, & PQ

Involves specialist teams from alliance partners

Technology user training

Both classroom and hands-on training

Quality oversight and approvals

Sufficient time needed for quality reviews and approvals

Hand over to end user including all

supporting documentation

Formal process to verify completion of all deliverables

Looking at this tasks list and based on standard engineering processes to upgrade the facilities, this

schedule could require at least 3 years and possibly more following suppliers’ ability to provide

materials and to upgrade the equipment. This program does not include the time to establish new

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 6.22 and 8.112

25May2021 Page 4 of 4

manufacturing areas if the existing ones are too small to host additional freeze dryers to maintain the

existing capacity.

Figure 1: Timeline indicating 30-35 months possible implementation time (optimized steps).

The timeline for each specific project will be determined based on many factors. The intent of the

timeline provided is to provide a general idea of the activities and timing with optimized project

steps that follow in sequence. Figure (1) presents a sequence of events based on the above

description, with some illustrative timelines. These timelines may require modification of timing

depending on implementation complexity and study results.

Summary:

When companies are operating several lyophilizers with the same process, each lyophilizer will need

to be upgraded for compliance with the revised Annex1. This will require an increased

implementation time based on project development including Risk Assessment, avoiding temporary

loss of capacity that may lead to risk of drug shortages.

Companies manufacturing with lyophilizers utilizing manual loading and/or unloading processes,

could utilize implementation times to develop new technology and meanwhile, based on a risk

assessment and integrated as part of the Contamination Control Strategy, continue with currently

applied campaign manufacturing principles. During the extended implementation time, improved

monitoring of their processes may be considered for manual operations under grade A conditions.

For some technologies such as unloading bulk sterile API powder from the lyophilizers, automated

unloading technologies will require technology development which could require additional

implementation time or may not even be possible.

Conclusion:

Including the required regulatory approvals, the implementation of 100% automated lyophilizers is

expected to require 3+ years. Where significant levels of development are required, longer timelines

are expected.

CCS Implementtion and risk assessment with outcomes

that identify process change

Process and detail design Room extension

Process and detail design Automated loading system

Construction and sourcing of automatic loading system

Installation and qualification of loading

SOP for automated lyophilizerr loading

Qualification of rooms and equipment including bio

burden and operator training

Aseptic Process Simulation

Regulatory / QA Approval.

*

* More time for this task which cannot be estimated

18-24 months

12-18 months

28-36 months months

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 8.21

25May2021 1 | P a g e

Implementation Example for the Requirement of 100% CCIT of Containers

Closed by Fusion (section 8.21)

This is one of several examples that have been developed by different industry associations to help

inform the IWG as to the levels of complexity these types of changes can have as they consider

Annex 1 implantation timing. The examples provided are from the top 5 requirements identified in

the letter from the Annex 1 Associations’ Coordination Meeting Team dated 14 March 2021 and

have been developed as if the requirements in the revised EU GMP Annex 1 draft (version 12) were

to be included in the final Annex 1 revision as currently written. As such they do not take into

consideration any changes made to the current draft version of Annex 1.

The examples are intended to be informative only and as such were not taken through a consensus

process across the associations. They should not be considered as industry guidance on

implementation approaches or specific timing. It is important to stress that each individual

situation, in regard to implementation, will in most cases be unique based on process, product, and

facility differences and taking into account the Contamination Control Strategy outcomes. As such,

this specific example is not meant to provide an industry vetted acceptable path or guidance to

achieve an acceptable path to compliance with the requirements noted in section 8.21.

It is important to note that these examples are not intended to imply agreement with the revised EU

GMP Annex 1 draft (version 12) as written, as reflected in the industry comments submitted in the

2020 targeted consultation.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 8.21

25May2021 2 | P a g e

The purpose of this document is to provide additional detail in the form of an example justification

for extending the implementation time to meet a specific requirement included in the revised EU

GMP Annex 1 draft (version 12).

At the time of writing the revision of Annex 1 was not complete and published and this justification

example is not intended to infer revisions of Annex 1 and the clauses in the final version are in

consensus with industry and representing group association’s expectations, particularly on clarity.

This document focuses on the challenges resulting from implementation of Annex 1 revision relating

to the requirement of 100% container closure integrity testing (CCIT) that requires integration of an

integrity testing technology into a process platform (on-line) or process flow (off-line) to fully meet

the intent of the GMP requirement. The example is meant to illustrate where and why additional

implementation time may be needed.

The following information is intended to provide an overview and insight into project integration

challenges of 100% CCIT. It is not meant to provide an industry vetted acceptable path or guidance

to achieve an acceptable path to compliance with the requirements noted in section 8.21.

Annex 1 Requirement:

8.21

“Containers should be closed by appropriately validated methods. Containers closed

by fusion, e.g. Blow-fill-seal (BFS), Form-Fill-Seal (FFS), Small and Large Volume

Parenteral (SVP & LVP) bags, glass or plastic ampoules, should be subject to 100%

integrity testing. Samples of containers closed by other methods should be taken

and checked for integrity using validated methods. The frequency of testing should

be based on the knowledge and experience of the container and closure systems

being used. A scientifically valid sampling plan should be utilized. The sample size

should be based on information such as supplier approval, packaging component

specifications and process knowledge. It should be noted that visual inspection

alone is not considered as an acceptable integrity test method.”

Implementation Times for 100% CCIT:

As containers, closures, and their products come in different shapes/sizes requiring different

processing conditions, there is no one CCIT technology that fits all. CCIT technology may require

integration into a filling platform or because of operational needs designed as an offline process.

The requirement of 100% CCIT of filled containers closed by fusion covers many container types and

some are more challenging than others, particularly multi chamber container bags (for TPN) with

peelable seals between compartments as only limited pressure may be applied in an integrity test.

Also the addition of an over pouch for multi chamber or single bags adds to complexity in achieving

the required sensitivity in an integrity test (on-line or off-line) and development may be required.

CCIT technology development and selection is critical to ensuring that the appropriate level of

sensitivity, robustness, and ability to meet the operational needs can be achieved.

Time is required to identify the appropriate CCIT solution. In cases where CCIT test methods have

not been previously applied to a container type or where technology must be developed

implementation time must include time for development of an integrated solution and its

optimization.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 8.21

25May2021 3 | P a g e

Some (not all) of the considerations that need to be included in the evaluation of any CCIT solution

are:

• The types of CCIT technology available and its potential application to the specific

container/closure/product type.

• Demonstrated technology reliability for intended use.

• Correlation of the sensitivity of the CCIT technology when applied to known and challenging

characteristics of container types (sensitivity is test method and container specific).

• Identification of defect sensitivity vs. rate of false defects (good product rejects). Use of the

technology needs to be practical for use in the manufacturing operation.

• Throughput requirements based on operation needs (critical for high speed filling

operations).

• Type of filling line and area modification required to incorporate the CCIT technology

(additional manufacturing space may be needed, this can be a concern for both in-line and

offline applications.

• General timing required for installation/qualification/approval (very important for lines with

high utilization rates where extended shutdowns can create supply issues).

• If 100% CCIT will be performed offline due to slower speeds, available WIP chill rooms space

to accommodate the anticipated increase in WIP cold storage.

• Regulator acceptance of the CCIT technology chosen.

CCIT Technology:

The use of CCIT technology is not new (as standalone test methods) and listed below are some

examples of technologies and approaches available. It must be noted that for 100% CCIT additional

development of these or other new technologies as an integrated integrity test solution is needed,

especially for high speed filling operations.

• Force sensing technology

Can be used for some (not all) flexible containers held between two plates with a force-load

sensor against one plate, change in force indicates integrity loss.

• Vacuum decay

Can be used for various container closure types. Uses the decay of a an applied vacuum to

detect integrity loss.

• Headspace Analysis

Can be used for containers where an inert gas overlay is used in the filling process. Detects

ingress of gas into the container to identify integrity loss.

• Pressure decay

Can be used for various container closure types. Used the decay of an applied pressure to

detect integrity loss.

• High Voltage Leak Detection

Can be used for liquid filled glass containers. Identified integrity loss based on change of an

applied high voltage charge to the container.

There is no universal CCIT method that can be applied to all containers. Not all of the methods

described are appropriate for high-speed filling operations and in some cases are used for testing a

sample of containers filled.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 8.21

25May2021 4 | P a g e

Example of Project Implementation Activities:

The following example is intended to illustrate the types of activities and relative timing for

implementation of a CCIT project. This is not intended to be an exhaustive list or exact timeline as

each product will have its own specific challenges as well as the ease at which a solution can be

identified and implemented.

Activity list:

Project step

Comment

Technology Development

Required where the current technology is not available to meet

the technical (sensitivity) or operational requirements. Timing is

depended on the development of technology.

Receipt of purchase order (PO)

Before project start there is a project team alignment and Kick off

Technology integration schematics

and controls/ automation strategy

Combined integration of Filling platform, CCIT and barrier

technology (with material transfers) for sterile product processing.

Design reviews – risk assessment

schematics/ automation strategies

Joint meetings with Alliance partners: Filling + CCIT+ Barrier

Technology

Detail Design & reviews

3D models and CAD drawing reviews, control strategy preparation

Technology manufacturing & FQT

Each specialist manufactures technology followed by Factory

Qualification Testing (FQT) of each technology to be integrated

Technology integration

Integration of technologies; at Filling platform manufacturer

Technology testing/ commissioning.

typically at Filling platform manufacturer with alliance partners

Integrated Technology FAT

Site representatives attend with FAT focusing on functionality

Dis-assembly & Packaging for

shipment to site & delivery

Delivery times and packaging vary depending on transport method

and global location of site.

Installation at site

Involves specialist teams from alliance partners. Timing based on

facility availability and allowable shutdown timing in regards to

product supply.

Commissioning

Involves specialist teams from alliance partners

Technology Qualification SAT, IQOQ,

& PQ

Involves specialist teams from alliance partners

Technology user training

Both classroom and Hands on training

Quality oversight and approvals

Sufficient time needed for quality reviews and approvals

Hand over to end user including all

supporting documentation

Formal process to verify completion of all deliverables

Site progresses to process platform

Qualification

Process risk assessment

Includes specialist teams from alliance partners to support the site

Filling + CCIT process Qualification

Includes specialist teams from alliance partners to support the site

Environmental Control; Classification

and Qualification for the Filling zone

and surrounding environment

Area requalification’s and in the case of Isolator systems if CCIT

occurs within the Isolator VHP qualification (cycle development if

needed based on the amount of change).

QA/ QC oversight and approvals

Sufficient time needed for quality reviews and approvals

Preparation of all procedural

controls (SOPs)

Could be completed through the project but requires finalisation

before trainings

APS; Water fill capacity throughput &

training runs

Technology support (often via remote access) provided by

technologists

APS: Media fills/ qualification

Media fill strategies depend on batch or campaign production.

QA/ QC oversight and approvals

Sufficient time needed for quality reviews and approvals

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 8.21

25May2021 5 | P a g e

PPQ runs

QA/QC/Production activity

Regulatory Submissions

Complexity will be dependent on the specifics of the change

Supportive data package completion

QA/QC/Production activity

GMP inspection

Interim GMP inspections may be required, depends on site history

Regulator Q&A and Approvals

Timing will vary based on the number and specific countries where

submissions are required.

Example Timeline: Optimized.

The timeline for each specific project will be determined based on many factors. The intent of the

timeline provided is to provide a general idea of the activities and timing with optimized project

steps that follow in sequence. Figure (1) presents a sequence of events based on the above

description, with some illustrative timelines. These timelines may require modification of timing

depending on implementation complexity and study results.

Figure 1

Summary:

Technologies for CCIT (Container Closure Integrity Testing) are available but their use is very

container/closure specific so further development may be required.

For some containers and container/closure types the application of 100% CCIT in a production

setting will require additional development and optimization as an integrated integrity test to

achieve the appropriate levels of sensitivity, robustness and capacity throughput. In some cases, the

development of new technologies may be required to meet the full intent of Annex 1.

Following a CCIT technology selection an implementation plan will be required and prepared case by

case to align project requirements and regulatory expectation. The implementation plan will be

referenced in the CCS that will evolve through the product life cycle as continuous improvements are

implemented.

Conclusion:

Including the required regulatory approvals, the implementation of 100% CCIT is expected to require

3+ years. Where significant levels of development is required longer timelines are expected.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 8.82 and 8.88

25May2021 1 | P a g e

Implementation example for requirement of the verification of the integrity of the

sterilized filter assembly before use (section 8.82 and 8.88)

Context:

This is one of several examples that have been developed by different industry associations to help

inform the IWG as to the levels of complexity these types of changes can have as they consider

Annex 1 implantation timing. The examples provided are from the top 5 requirements identified in

the letter from the Annex 1 Associations’ Coordination Meeting Team dated 14 March 2021 and

have been developed as if the requirements in the revised EU GMP Annex 1 draft (version 12) were

to be included in the final Annex 1 revision as currently written. As such they do not take into

consideration any changes made to the current draft version of Annex 1.

The examples are intended to be informative only and as such were not taken through a consensus

process across the associations. They should not be considered as industry guidance on

implementation approaches or specific timing. It is important to stress that each individual

situation, in regard to implementation, will in most cases be unique based on process, product, and

facility differences and taking into account the Contamination Control Strategy outcomes. As such,

this specific example is not meant to provide an industry vetted acceptable path or guidance to

achieve an acceptable path to compliance with the requirements noted in sections 8.82 and 8.88.

It is important to note that these examples are not intended to imply agreement with the revised EU

GMP Annex 1 draft (version 12) as written, as reflected in the industry comments submitted in the

2020 targeted consultation.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 8.82 and 8.88

25May2021 2 | P a g e

The purpose of this document is to provide additional detail on the challenges resulting from

implementation of the revised EU GMP Annex 1 draft (version 12) requirement that requires the

integrity of the sterilized filter assembly to be verified by integrity testing before use [Pre-Use, Post-

Sterilization Integrity Testing, aka: PUPSIT) and covers the activities associated with PUPSIT

implementation and complexity of certain examples to illustrate where and why additional time may

be needed to implement PUPSIT requirements. For example, complexity challenges considered in

combination with the indicated requirement in the draft Annex (section 8.82) for a sterilizing filtration

immediately prior to filling (i.e., Point Of Fill Filtration, aka: POFF).

Therefore, the following information is related to the sterilizing filter positioning and integrity testing

requirements present in the current version (V.12) of the revised annex draft (respectively in sections

8.82 and 8.88). It intended to provide an overview and insight into project integration challenges of

such a change. It is not meant to provide an industry vetted acceptable path or guidance to achieve

an acceptable path to compliance with the requirements noted in sections 8.82 and 8.88.

Annex 1 Requirement:

8.82,

8.88

“Due to the potential additional risks of a sterile filtration process, as compared with other

sterilization processes, a second filtration through a sterile sterilizing grade filter,

immediately prior to filling, should be considered as part of an overall CCS.”

“The integrity of the sterilized filter assembly should be verified by integrity testing before

use, to check for damage and loss of integrity caused by the filter preparation prior to use. A

sterilizing grade filter that is used to sterilize a fluid should be subject to a non-destructive

integrity test post-use prior to removal of the filter from its housing. Test results should

correlate to the microbial retention capability of the filter established during validation.

Examples of tests that are used include bubble point, diffusive flow, water intrusion or

pressure hold test. It is recognized that pre-use post sterilization integrity testing (PUPSIT)

may not always be possible after sterilization due to process constraints (e.g. the filtration of

very small volumes of solution). In these cases, an alternative approach may be taken

providing that a thorough risk assessment has been performed and compliance is achieved

by the implementation of appropriate controls to mitigate any risk of non-sterility.”

PUPSIT Implementation Considerations:

The requirement of PUPSIT implementation covers all final sterilizing filtration applications. As there

are multiple attributes associated with sterilizing filtration (i.e., using many filter types, different

filtration process parameters, filter system configurations, solutions types to be filtered), there is no

single pathway for introducing PUPSIT or a universal method that can be applied.

PUPSIT implementation, where not currently in place, will require a range of activities and risk

mitigation. For example , where the sterilizing filter is located in Grade A and the aseptic manipulation

risk associated with conducting PUPSIT has been deemed high or where the introduction and location

of an additional filter prior to filling or at point of fill is being considered to address the new 8.82

requirement. , Specifically, process evaluation, process development, process modification, process

revalidation, facilities modification and in some cases new filtration systems may be required to

ensure it is implemented under the most appropriate and robust conditions. This sequence of

implementation and qualification activities will require time to complete which relates to the

complexity and criticality of the filtration system and activity.

Implementation Times for PUPSIT:

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 8.82 and 8.88

25May2021 3 | P a g e

The PUPSIT implementation timeline for existing processes is dictated by the following key steps in

the implementation plan:

As PUPSIT is product specific in case of multiple products are in scope, cumulative effects and impacts

should be considered.

We should consider the following actions:

• Specify the appropriate integrity test (IT) method (e.g., diffusive flow, Bubble Point, etc)

• Define the appropriate integrity test parameters (e.g., test pressure, temperature, wetting fluids

etc.)

• Design the filtration and integrity test assembly to accommodate PUPSIT

• Evaluation of the filter bacterial retention capability under the integrity testing conditions i.e.,

higher test pressures introduced when filter wetted with product.

• If product is used, determine the potential for filter fouling and/or impact of the test gas and test

time on the product within the filter matrix

• Facilities/ Equipment modification to implement PUPSIT, possibly requiring a facility shutdown

period (e.g. compressed air, wetting and waste fluid installation)

• Documentation review and operator training (standard GMP)

• Aseptic Processing Simulation due to manipulations downstream of the filter

• Product License Variation activities

PUPSIT Technology:

For PUPSIT implementation by first intent on a new process or filling line whilst complex, requirements

can be built in as part of the project and less burdened by the challenges associated with the

retrofitting of PUPSIT enabled Single Use System (SUS) assemblies and/or piping systems.

As noted above, for all commercial processes already in place and in use, PUPSIT implementation will

require significant evaluation and modifications. In these situations, the complexity could be further

compounded by the filtration technology already in place. For example:

- Modification of hard Piping configurations, installation and control systems

- Modification of Single Use Filtration Systems (i.e., configuration, minimal impact on aseptic

process, provision of process gases, etc.)

- Addition of connections and vent filters to accommodate the test

Example of Project Implementation Activities:

The following example is intended to illustrate the types of activities and relative timing for

implementation of a PUPSIT step. This is not intended to be an exhaustive list or exact timeline as

each product and filtration set-up will have its own specific challenges as well as the ease at which a

solution can be identified and implemented.

GMP ANNEX 1 DRAFT (VERSION 12)

IMPLEMENTATION TIMING EXAMPLE 8.82 and 8.88

25May2021 4 | P a g e

Activity List for New and Existing Design:

PUPSIT parameters

definition

Comment

Time Required

1. PUPSIT Development and Process evaluation

Determine the adequate

Integrity test (bubble point,

Diffusion flow)

According to supplier specification, IT value must

be defined based on the wetting solution used.

Consider the gas used for the IT and its impact on

the product (oxidation)

3 – 6 Months

Specify which integrity test

method shall be utilized

Assess pressure conditions and needs for process

modifications

Identify the wetting solution

to be used (Product or Water)

Assess the impact of the wetting solution used

including diluting effect, extractable/leachable,

product volume to be rejected

Define the wetting conditions

of the filter before PUPSIT

Adequate volume, differential pressure,

sterilization impact (hydrophobic spot

generation) to avoid false failure result

Assess PUPSIT impact on

product filterability

Filtration is stopped during the integrity test and

can impact the filters capacity

Design adequate assembly

configuration to allow PUPSIT

(Hard piping or SUS)

Additional connections (Compressed Air Process

(CAP), N2, waste, Water for Injection and

associated sampling points), position of the filter

(avoid wetting fluid backflow), integrity (high

pressure during test), additional vent filters,

adequate assessment to reduce sterility

assurance risk due to increased

manipulations/activities

Assess the impact of the

routine Process Temperature

during the test

Product temperature must be stabilized during

the integrity test to avoid IT issue

2. Filter Bacterial Challenge Test (BCT) revalidation (when required)

BCT validation including

PUPSIT conditions

PUPSIT will increase the intervention and

stoppage frequency for the filtration application

process which increase risk for the BCT for all

products subject to clogging and where product

is used as the wetting solution.

Additional to this, the system is brought to high

pressure vs routine conditions during PUPSIT.

Therefore, the BCT filter validation must be

designed to consider the worst case conditions.

6 – 12* Months

*Time constraints

related to Supplier

availability due to the

current COVID-19

situation and post-

COVID backlogs

3. Facilities / Equipment Modification

Filter location/relocation

8.82 constraints related to the positioning of the

filter (e.g. filter located in grade A) may require

relocation of filter outside of grade A or

modification of assembly/ transfer ports to

facilitate the PUPSIT operations in a secure

aseptic manner