$')"&*+"+,+'!&'$' .$')"&*+"+,+'!&'$' .

!'$)*!"(('*"+').$')"!!'$)*!"(('*"+').$')"!

!**&"**)++"'&*

*+"& +!0.'*')"'',$"& '&+)'$*+"& +!0.'*')"'',$"& '&+)'$

) )+&&++" "

'$$'-+!"*&"+"'&$-')#*+!++(*)('*"+')./+,+

)+'+!&' )(!.'%%'&*

TESTING THE EFFICACY OF UVC LEDS FOR BIOFOULING CONTROL

By

MARGARET JEANNETTE GIGGIE

B.S., Oakland University

A thesis submitted to

the Department of Ocean Engineering and Marine Sciences

of Florida Institute of Technology in

partial fulfillment of the requirements for the degree of

MASTER OF SCIENCE

in

BIOLOGICAL OCEANOGRAPHY

Melbourne, Florida

May 2022

TESTING THE EFFICACY OF UVC LEDS FOR BIOFOULING CONTROL

A THESIS

By

MARGARET JEANNETTE GIGGIE

Approved as to style and content by:

Kelli Z. Hunsucker, Ph.D.

Assistant Professor

Major Advisor, Ocean Engineering and Marine Sciences

Geoffrey Swain, Ph.D.

Professor

Ocean Engineering and Marine Sciences

Glenn Miller, Ph.D.

Instructor

Ocean Engineering and Marine Sciences

Richard B. Aronson, Ph.D.

Professor and Department Head

Ocean Engineering and Marine Sciences

May 2022

iii

ABSTRACT

TESTING THE EFFICACY OF UVC LEDS FOR BIOFOULING CONTROL

by Margaret Giggie, B.S., Oakland University

Chairperson of Advisory Committee: Kelli Z. Hunsucker, Ph.D.

The use of ultraviolet-C (UVC) light as a biofouling preventative has been

successfully demonstrated using mercury-based lamps. However, these lamps have

several limitations (such as fragility and use of mercury), and the use of UVC

LEDs (light-emitting diodes) has been suggested as an alternative. Several

experiments were conducted to assess the efficacy of LED strips (29 W, 270 nm,

emittance angle of 130º) for biofouling control, as well as to compare them to a

classic lamp (25 W, 254 nm, emits UVC light at 360º). Experiment #1 assessed the

biofouling abundance and community composition on test panels exposed to either

UVC LEDs (270 nm) or a lamp (254 nm) at a field site in Port Canaveral, Florida.

An intermittent dose (43.2 min/day) from the LEDs prevented a majority (>90%) of

growth after 12 weeks. The lamp (10 min/day) outperformed the LEDs, but both

sources prevented all macrofouling formation, with the LED allowing for a greater

biofilm coverage. The different wavelengths (270 nm from LEDs vs. 254 nm from

lamp) did not lead to a different fouling community composition. Experiment #2

determined the transmission of UVC in waters of varying turbidity (0 – 50 FNU) at

set distances (every 2.54 cm for 63.5 cm) from a light source (LED strip vs. a 7 W

iv

lamp). The transmission for both the LED and lamp was greatly reduced with an

increased in turbidity. The lower powered LEDs had a shorter maximum distance

of transmission at all turbidities. For example, in a turbidity of 30 FNU, the LED

was recorded at 17.78 cm as compared to the lamp which was still recorded at

21.17 cm. Lastly, Experiment #3 compared the LED and the 25 W lamp for

impacts on three types of marine coatings (epoxy, fouling release, and antifouling

coatings). The coatings were exposed to continuous or intermittent exposure (10

min/day lamp or 43.2 min/day LED) regimes for 2 weeks and assessed for changes

in mechanical damage, specifically color changes, hardness, coating thickness, and,

for the fouling release coating, adhesion strength. The continuous lamp treated

fouling release coating slides exhibited some mechanical damage, with adhesion

strength increasing from 0.114 MPa to 0.123 MPa and the coating became lighter

in color. Continuous treatment for both light sources led to qualitative changes in

the other tested coatings as well. The epoxy coating developed a darker and more

yellow shade, and the antifouling coating grew darker. However, there was no

measurable distinction with mechanical damage to either of the epoxy or

antifouling coating. The results of this thesis show that LEDs can be a valuable

alternative to mercury powered lamps for marine biofouling prevention. While they

can prevent biofouling accumulation at a near equivalent rate as the lamps, there

are still some limitations of these systems which should be addressed, such as

excess heat generation and the smaller treatment area.

v

ACKNOWLEDGEMENTS

This work was funded by the Office of Naval Research (Grant #N00014-20-

1-2214).

The author acknowledges the committee members, especially Drs. Kelli

Hunsucker and Geoffrey Swain, for their help in designing, planning, and editing

this thesis, and thanks Dr. Glenn Miller for his help with statistical analysis. The

author would also like to thank Sandy Rech, Morgan Gilligan, Harpoon Seabring,

and Harrison Gardner for their assistance.

vi

TABLE OF CONTENTS

Abstract .................................................................................................................... iii

Acknowledgements .................................................................................................... v

List of Tables.......................................................................................................... viii

List of Figures ............................................................................................................ x

Chapter I: Introduction ............................................................................................... 1

Chapter II: UVC Lamp vs. UVC LEDs in Preventing Biofouling ............................ 8

Introduction ........................................................................................................ 8

Methods and Materials ....................................................................................... 9

Results .............................................................................................................. 13

Discussion ........................................................................................................ 20

Chapter III: Effect of Turbidity on UVC Transmission ........................................... 25

Introduction ...................................................................................................... 25

Methods and Materials ..................................................................................... 26

Results .............................................................................................................. 31

Discussion ........................................................................................................ 34

Chapter IV: Impacts of UVC to Marine Surfaces .................................................... 38

Introduction ...................................................................................................... 38

Methods and Materials ..................................................................................... 39

Results .............................................................................................................. 46

Discussion ........................................................................................................ 58

viii

LIST OF TABLES

Table II.1. RMANOVA results from the field experiment through Week 6. The

df[GG] column represents the new degrees of freedom after the Greenhouse-

Geisser epsilon correction (=0.893) is applied. ........................................................ 17

Table II.2. RMANOVA results from the field experiment through Week 12. The

df[GG] column represents the new degrees of freedom after the Greenhouse-

Geisser epsilon correction (=0.353) is applied. LED panels 7 and 8 from LED Strip

4 were excluded from this analysis. ......................................................................... 19

Table II.3. PERMANOVA results comparing the community composition on the 1

UVC panel and 6 LED panels that exhibited fouling during Week 6. ..................... 20

Table II.4. PERMANOVA results comparing the community composition on the 8

UVC panels and 6 LED panels that exhibited fouling during Week 12. LED panels

7 and 8 from LED Strip 4 were excluded from analysis. ......................................... 20

Table III.1. Factorial ANOVA results from the turbidity tank experiment. ............ 33

Table IV.1. UVC treatment groups with equivalent exposure time......................... 42

Table IV.2. RMANOVA results from testing the epoxy slides’ thickness

measurements. .......................................................................................................... 48

Table IV.3. ANOVA results from the epoxy slides’ scratch hardness test. ............. 49

Table IV.4. RMANOVA results from testing the fouling release coating’s thickness

measurements. .......................................................................................................... 51

Table IV.5. ANOVA results from the fouling release slides’ scratch hardness test.

.................................................................................................................................. 52

ix

Table IV.6. RMANOVA results from the adhesion test on the fouling release

slides. ........................................................................................................................ 53

Table IV.7. RMANOVA results from thickness measurements of the antifouling

coating slides. ........................................................................................................... 56

Table IV.8. ANOVA results from the scratch hardness test on the antifouling

coating slides. ........................................................................................................... 57

x

LIST OF FIGURES

Figure I.1. A picture of the UVC lamp (top) and the UVC LED strip (bottom), with

a ruler for scale. Both light sources are housed in glass sheaths for waterproofing. . 6

Figure II.1. An aerial view of the housing unit holding the UVC lamp. Panels are

suited on either side of the lamp for testing. Four of the eight panels were removed

in order to view the lamp in the middle for this photograph. ................................... 10

Figure II.2. An aerial view of one of the two LED housing units. One of the LED

strips can be seen, and the second LED strip in the glass sheath is on the opposite

side, treating the two panels seen in the picture. ...................................................... 11

Figure II.3. A representative panel from each treatment group at each visual

assessment timepoint over the course of the experiment. The electrical failure of

LED Strip 4 and subsequent increase in fouling coverage can be observed between

Week 6 and Week 8. ................................................................................................ 14

Figure II.4. Percent coverage by treatment over the course of the field experiment

(mean ± SD). LED panels 7 and 8 from LED Strip 4 were not included in the

average. .................................................................................................................... 16

Figure II.5. Average percent coverage of fouling taxa by treatment over the course

of the field experiment. LED panels 7 and 8 from LED Strip 4 were not included.16

Figure II.6. Percent coverage by treatment group through Week 6 (mean ± SD).

Different letters indicate significant differences between groups. F = 94.12,

p<0.0001. ................................................................................................................. 18

xi

Figure II.7. Percent coverage by treatment group through the duration of the 12

week experiment (mean ± SD). LED panels 7 and 8 were excluded from this

analysis. Different letters indicate significant differences between groups. F =

104.9, p<0.0001. ...................................................................................................... 19

Figure III.1. A close up of the UVC wand (left) and the LED strip (right). ............ 27

Figure III.2. An overhead view of the turbidity tank experiment at 0 FNU. The

LED strip in the glass sheath is seen at the top left held at the corner of the tank,

while the Solar Light sensor (PMA2180) is moved along the tank edge. The YSI

turbidity sensor is seen at the bottom of the picture for continuous monitoring. The

UVC wand is inactive in the top right of the tank. .................................................. 29

Figure III.3. An overhead view of the turbidity tank experiment at 10 FNU. The

UVC wand is being actively measured by the PMA2122 sensor and the LED in the

glass sheath rests in the upper right corner of the tank. The YSI turbidity sensor is

seen at the bottom of the picture for continuous monitoring. .................................. 30

Figure III.4. Irradiance (in mW/cm

2

) measured over distance (cm) using the UVC

wand. The key indicates different turbidities. .......................................................... 32

Figure III.5. Irradiance (in mW/cm2) measured over distance (cm) from the UVC

LED strip. The key indicates different turbidities. The y-axis is the same scale as

Fig. IV.4 for easier visual comparison of the two sources. ...................................... 32

Figure III.6. Maximum distance of transmission (in cm) of different UVC sources

in a range of turbidities (FNU) (mean ± SD). .......................................................... 34

xii

Figure IV.1. Close up of a pseudobarnacle used to measure adhesion, measuring

2.3 cm in height and 1 cm in base diameter. ............................................................ 41

Figure IV.2. The lamp in its holder inside a tank of fresh water. The 12 slides can

be seen underneath the operating lamp, affixed to a plastic microscope slide holder.

.................................................................................................................................. 44

Figure IV.3. One of the LED tubes in its holder inside a tank of fresh water. Four of

the slides can be seen attached to a plastic microscope slide holder and are treated

by the unseen LED strip on the opposite side of the aluminum heat sink. .............. 44

Figure IV.4. A representative epoxy-coated slide from each treatment group. The

color in the middle of each slide is residual Sharpie from the scratch hardness test.

.................................................................................................................................. 47

Figure IV.5. Thickness of the epoxy slides from each group before and after

treatment, measured in micrometers (mean ± SD). For treatment: F = 0.02, p =

0.999. ........................................................................................................................ 48

Figure IV.6. Hardness number (in Gigapascals) of the epoxy slides by treatment

group (mean ± SD). Different letters indicate significant differences between

groups. F = 5.763, p = 0.00515. ............................................................................... 49

Figure IV.7. A representative fouling release-coated slide from each treatment

group. The color in the middle of each slide is residual Sharpie from the scratch

hardness test. ............................................................................................................ 50

xiii

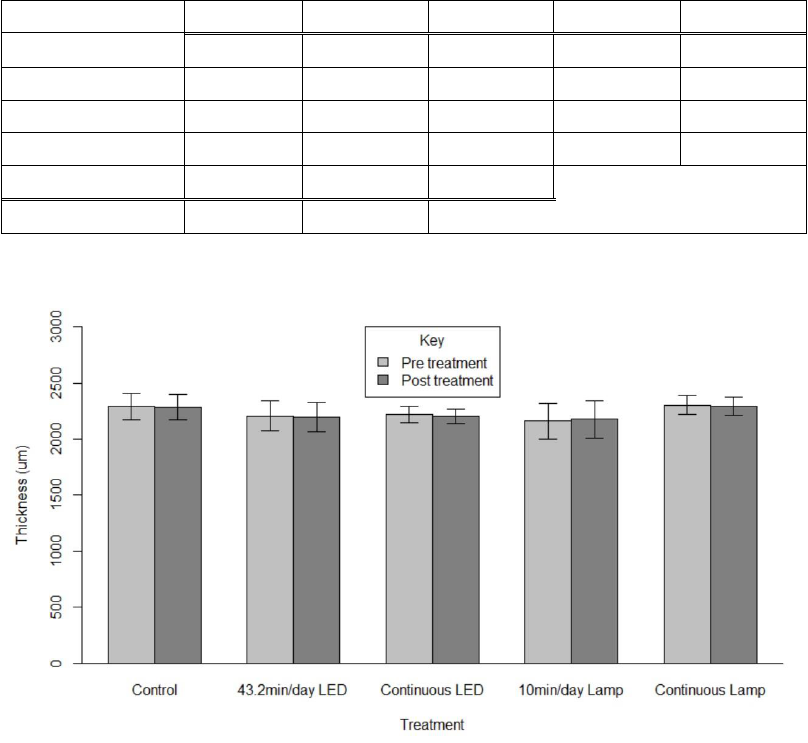

Figure IV.8. Thickness of the fouling release slides from each group before and

after treatment, measured in micrometers (mean ± SD). For treatment: F = 0.915, p

= 0.481. .................................................................................................................... 51

Figure IV.9. Hardness number (in Gigapascals) by treatment group of the fouling

release-coated slides (mean ± SD). F = 1.659, p = 0.212. ....................................... 52

Figure IV.10. Adhesion test results before and after treatment from the fouling

release-coated slides (mean ± SD). For treatment: F = 0.685, p = 0.613. ................ 54

Figure IV.11. A representative antifouling coating slide from each treatment group.

The darker spot on the control slide is residual Sharpie from the scratch hardness

test. ........................................................................................................................... 55

Figure IV.12. Thickness of the antifouling coating slides from each group before

and after treatment, measured in micrometers (mean ± SD). For treatment: F =

0.749, p = 0.574. ...................................................................................................... 56

Figure IV.13. Hardness number (in Gigapascals) by treatment group of the

antifouling coating slides (mean ± SD). Different letters indicate significant

differences between groups. F = 6.12, p = 0.00398. ................................................ 57

Figure IV.14. Close up of the LED strip after 8 weeks of operation with visible

brown condensation inside its glass sheath. ............................................................. 65

1

CHAPTER I

INTRODUCTION

Biofouling, or the unwanted growth of organisms on submerged surfaces, is

a costly nuisance for many marine industries. For the shipping industry, biofouling

compels increased energy costs to overcome biofouling-induced drag, consequently

increasing greenhouse gas emissions (Murthy et al. 2009, Schultz et al. 2011,

Swain and Lund 2016, Qiu et al. 2022). Biofouling also represents a significant

environmental threat, as ships become vectors for the global spread of invasive

species (Bax et al. 2003, Georgiades et al. 2021, Hunsucker et al. 2019a).

Therefore, resources must be devoted to preventative treatments, such as manual

grooming by divers, grooming of the hull by remotely operated vehicles (ROVs),

marine coatings and their upkeep, or a combination of these processes (Swain

2010, Swain 2017, Swain et al. 2022).

Antifouling coatings rely on leaching biocides to prevent biofouling growth,

requiring regular reapplication and consequently limiting the lifespan of the paint

(Lejars et al. 2012). Additionally, the biocides used are often toxic to nontarget

organisms and bioaccumulate in sediment, causing unforeseen ecological

consequences (Evans et al. 2000, Lejars et al. 2012). Such was the case with

tributyltin (TBT), a tin-based biocide, which was linked to the development of male

sex organs in female gastropods and reproductive failure in oyster populations

(Callow and Callow 2002, Evans et al. 2000, Qiu et al. 2022 ). After the ban on

2

TBT in 2008, copper became a very popular biocide for use in antifouling coatings

(Lejars et al. 2012, Swain 2010). However, several fouling species, including the

barnacle Balanus amphitrite, are copper tolerant, decreasing the effectiveness of

copper-based antifouling coatings (Hunsucker et al. 2019a). Fouling release

coatings may be more environmentally friendly by not containing any toxins,

relying instead on chemical properties from silicone or fluorine to prevent strong

adhesion of fouling organisms (Lejars et al. 2012, Kavanagh et al. 2005Swain

1999, Qiu et al. 2022). Yet these coatings are easily damaged, expensive, and rely

on movement through water to properly perform; ships in dock may still require

grooming with brushes in order to maintain a clean surface (Callow and Callow

2002, Kavanagh et al. 2001, Qiu et al. 2022, Tribou and Swain 2010). While the

use of antifouling and fouling release coatings has proved effective overall, they are

not enough by themselves to completely prevent fouling, especially on more niche

areas of a ship, like propeller shafts and seachests (Bixler and Bhushan 2012, Piola

et al. 2016).

A preventative biofouling treatment that has garnered attention in recent

years is the use of UVC (ultraviolet-C) light (Salters and Piola 2017). The

germicidal effects of UVC have been understood for over a century, and UVC has

been used to disinfect air, drinking water, wastewater, surfaces, food, and medical

equipment (Bixler and Bhushan 2012, Carré et al. 2018, Kim et al. 2016, Kowalski

2009). UVC has also been tested successfully as an antifoulant for marine sensors

and reverse osmosis membranes (MacKenzie et al. 2019, Sperle et al. 2020). UVC

3

denotes light from 200 to 280 nm of wavelength, which includes the 260 nm peak

absorption for DNA (Kim et al. 2016). When DNA is subjected to UVC, the double

helix shape is disturbed through the formation of neighboring thymine bonds,

inhibiting cellular functions and leaving the microorganism unable to reproduce

(Kowalski 2009). This antimicrobial property of UVC has been shown to prevent

the formation of biofouling on underwater surfaces (Salters and Piola 2017). The

Center for Corrosion and Biofouling Control (CCBC) at the Florida Institute of

Technology has continued to conduct much of this novel research using a low-

pressure mercury UVC lamp (Braga et al. 2020a, Braga et al. 2020b, Hunsucker et

al. 2019b, Richard et al. 2021).

Experiments with UVC lamps have yielded promising results,

demonstrating that they are effective at preventing biofouling when applied

intermittently at short distances and have greatest success when used in

combination with marine coatings (Braga et al. 2020a, Hunsucker et al. 2019b,

Richard et al. 2021). However, these lamps have a number of drawbacks, such as

fragility, time needed to warm up, and the use of mercury (Kim et al. 2016). UVC

lamps may also cause damage to the surface in which biofouling is unwanted

(Hunsucker et al. 2019b). In addition, these lamps are constricted to emitting light

at 254 nm (Li et al. 2017).

The mercury in UVC lamps is especially problematic as mercury is a

dangerous environmental pollutant and can bioaccumulate in aquatic food webs if a

lamp was to break (Kessler 2013). Through the United Nations Environment

4

Programme, the Minamata Convention of Mercury came into effect in 2017 (EPA

2021). The treaty requires countries to limit environmental mercury emissions

through processes such as eliminating mining mercury, enhanced regulation of

trade, and phasing out mercury in products such as batteries (EPA 2021, Kessler

2013, Kim and Kang 2020, Nguyen et al. 2019). The Minamata Convention of

Mercury does not specifically mention UVC lamps (Nguyen et al. 2019). However,

the implications for the future of global mercury use are clear, and industries are

under pressure to find alternative solutions.

For UVC lighting, an emerging technology could be the solution to these

issues: UVC-emitting LEDs (light-emitting diodes). An LED is a semiconductor

that emits light when a current is applied (Hsu et al. 2021). LEDs do not contain

mercury, can be produced at any specific wavelength, and have lower voltages

(Kooshan et al. 2022, Li et al. 2017). UVC LEDs have already successfully been

utilized for disinfection, as well as biofouling prevention (Salters and Piola 2017,

Shur 2021). Since the early 2000s, numerous companies have developed their own

UV LEDs in a range of wavelengths. However, a limitation to LEDs is that one

diode is a fraction of the size of the UVC lamp, or roughly 100x shorter and 5x

narrower. To combat this, manufacturers are releasing products containing more

than one LED arranged in a module or array, such as 12 diodes in a 16 cm strip.

The market for UVC LEDs is anticipated to reach $2.5 billion by 2025, an

estimate no doubt supported by the Minamata Convention leading to the

obsolescence of lamps and the increased use of UVC LEDs during the COVID-19

5

pandemic (Shur 2021). However, as LEDs replace lamps, few studies have

attempted to compare the light sources’ effects (Kim et al. 2016, Li et al. 2017,

Wood et al. 2020). While both Kim et al. (2016) and Li et al. (2017) found the

LEDs to be more efficacious than the lamp, these studies were limited to the use of

UVC for bacterial inactivation. To date, no study has attempted to compare and

contrast a UVC lamp and UVC LEDs as they relate to biofouling, representing a

dearth of knowledge that necessitates this thesis.

The purpose of this thesis is to conduct a comprehensive and thorough

investigation into the efficacy of UVC LEDs for biofouling control and compare

their effects to a mercury-based UVC lamp. The lamp used was a 25 W low-

pressure mercury lamp that emits UVC light at 254 nm in 360º, sourced from Aqua

Ultraviolet (Figure I.1). The lamp was connected to a transformer, which supplied a

voltage of 120 V and a current of 0.48 A. It measured 37.7 cm long with a diameter

of about 2 cm. In order to adequately compare LEDs to the lamp, a module design

was chosen that contained several LEDs along a length of aluminum nitride,

mimicking the lamp’s proportions in two dimensions. The Klaran light engine (LE-

24V-12V-HC) contained 12 KL265-50V-SM-WD LEDs (measuring 0.35 x 0.35

cm each), which were already integrated into attached circuitry. This was

advantageous because it meant the light engine only had to be connected to a power

supply before it could be operated, allowing for easy laboratory testing and

eliminating any demand for manual soldering of LEDs, which is not recommended

by many manufacturers. The LED strip measured 1.2 x 16 cm (Figure I.1). Each

6

LED emitted UVC light at 260 – 275 nm with a peak at 270 nm and had an

emittance angle of 130º. The strip required 24 V at 1.5 A, resulting in a power

consumption of 29 W. The lower voltage of the LEDs is often cited as an

advantage over lamps, suggesting safer use and the ability to operate on a battery or

photovoltaic cell (Kooshan et al. 2022, Würtele et al. 2011).

Figure I.1. A picture of the UVC lamp (top) and the UVC LED strip (bottom), with a ruler

for scale. Both light sources are housed in glass sheaths for waterproofing.

The research presented in this thesis is arranged in the subsequent three

chapters. The second chapter (Experiment #1) is a field study comparing the

efficacies of the LED strip and the lamp as biofouling preventatives on an uncoated

surface. The field experiment also tests if there is a difference in biofouling

community composition when exposed to 270 nm or 254 nm UVC light. The third

chapter of this thesis (Experiment #2) is a laboratory study assessing the

transmission of different wavelengths of UVC light through water with a range of

turbidities. The fourth chapter (Experiment #3) is a laboratory experiment

evaluating the effects of UVC exposure on marine coatings. In total, the three

7

experiments provide a detailed comparison of a UVC lamp and UVC LEDs and

their efficacy of utilization for biofouling control in the marine environment.

8

CHAPTER II

UVC LAMP VS. UVC LEDS IN PREVENTING BIOFOULING

INTRODUCTION

The efficacy of UVC as a biofouling preventative previously been

demonstrated through the application of both lamps and LEDs. Braga et al. (2020a)

and Hunsucker et al. (2019b) found that continuous operation of the 25W Aqua

Ultraviolet lamp (described in Chapter I) kept epoxy-coated test panels completely

free of biofouling after 2 months of immersion in a marine environment. Further

testing of the lamp at different exposure intervals indicated that 10 minutes of UVC

light per day prevented the formation of all macrofouling (Richard et al. 2021).

Studies utilizing UVC LEDs have yielded similar results. Salters and Piola (2017)

found that LEDs embedded in silicone kept the surface completely clean when

operating continuously. Another study investigating interval testing revealed that as

little as 24 minutes a day of LED exposure can prevent all macrofouling growth on

uncoated glass (MacKenzie et al. 2019). However, none of these studies offer a

comparative analysis of lamps and LEDs. Based on this prior research, an

experiment was undertaken to investigate the effects of equivalent intermittent

doses from a mercury powered lamp compared to LED strips.

9

Hypothesis 1:

Since the LEDs from Klaran emit UVC light containing the peak absorption

wavelength for DNA (260 nm), they will be more effective at preventing the

formation of biofouling on test panels than the lamp (254 nm).

METHODS AND MATERIALS

Four UVC LED light strips, as described in Chapter I, were sourced from

Klaran. Two strips were cemented on opposite sides of an aluminum bar heat sink,

and then each aluminum bar was inserted into its own cylindrical quartz glass

sheath and sealed to be waterproof. A UVC lamp, sourced from Aqua Ultraviolet

(specifications described in Chapter I), was also tested in its biofouling efficacy. A

quartz glass sheath also held the lamp.

The LED strips measured 1.2 x 16 cm, while the lamp measured 2 x 37.7

cm. This meant that one LED strip could only treat two test panels (9.7 x 19.3cm)

due to the LEDs’ narrow emittance angle (~130º) and the strip’s short length, while

the lamp could treat eight panels.

To hold the test panels, three housing units were constructed from

aluminum angles and 3D-printed plastic. They were then coated with epoxy

(International Intergard) followed by a top coat of a copper antifouling paint

(Interspeed BRA640). Each housing unit measured 45.7 x 7.7 x 20 cm and could

hold a possible eight panels, four on opposite sides, with the glass sheath running

down the middle (Figure II.1). The panels sat 2.5 cm away from the light source

10

(Hunsucker et al. 2019b). The test panels were uncoated 9.7 x 0.3 x 19.3 cm

polycarbonate. They were attached to the housing units with screws and nuts for

simple removal during visual assessments.

One housing unit held the UVC lamp and eight panels (Figure II.1). Since

UVC light cannot transmit through opaque materials, the back sides of these eight

panels were analyzed as controls with no UVC exposure (Kowalski 2009). The

other two housing units held the four LED strips and their combined eight test

panels (Figure II.2).

Figure II.1. An aerial view of the housing unit holding the UVC lamp. Panels are suited on

either side of the lamp for testing. Four of the eight panels were removed in order to

view the lamp in the middle for this photograph.

11

Figure II.2. An aerial view of one of the two LED housing units. One of the LED strips can

be seen, and the second LED strip in the glass sheath is on the opposite side, treating

the two panels seen in the picture.

Frequency of exposure for the lamp was chosen as 10 minutes/day, based

on previous biofouling studies demonstrating a short intermittent dose can prevent

all macrofouling (Richard et al. 2021). The lamp and LEDs emit at difference

wavelengths (254 nm vs. 270 nm, respectively) and have different intensities. In

order to calculate an equivalent exposure time from the LED strip, a UVC sensor in

the strip’s wavelength range was purchased from Solar Light (PMA2180). The

light output of the strip was measured from 2.5 cm away at various spots over the

strip in freshwater (the same distance between the LED strip and test panel within

the housing unit). The LED strip’s average intensity measured 0.342 mW/cm

2

. The

lamp’s average intensity (already known from previous CCBC studies) was

12

measured to be 1.478 mW/cm

2

, which when multiplied by a time interval of 10

minutes (=600 seconds) yields a daily dose of 886.8 mJ/cm

2

. Therefore, the time

needed of LED operation for an equivalent dose is 2,593 seconds per day, or

roughly 43.2 minutes.

Published literature and preliminary work with the LED strips revealed that

they generate heat very quickly, thus the need for the attachment to the aluminum

heat sink (Hsu et al. 2021). In order to further protect the quality of the electrical

connections, each strip was operated with a 5 seconds on, 5 seconds off duty cycle.

Additionally, the 2 LED strips in the same glass tube (sharing a heat sink) were

operated sequentially as opposed to concurrently. To accomplish this, a code was

written in the program Arduino and uploaded to an Arduino Nano to properly

control the four LED strips. The lamp was connected to an outdoor programmable

timer (BN-LINK) and set for 10 minutes daily.

The field experiment was deployed on November 8, 2021 and ran until

January 31, 2022, for a total of 12 weeks. The experiment was conducted from the

CCBC test barge (28°24′31.01"N, 80°37′39.54"W). The surrounding water has an

average salinity of 34 ± 2 ppt, an average temperature of 27 ± 2 °C, and high

fouling pressure year round. The housing units were checked weekly for proper

operation, and a visual assessment was conducted every two weeks. For a visual

assessment, all panels were detached, photographed with a Nikon COOLPIX W300

13

digital camera, and reattached. The photographs were then analyzed for percent

growth of fouling organisms according to ASTM Standard D6990-05 (ASTM

International 2005).

Percent coverage between treatment groups was analyzed in R (Version

4.1.1) with a repeated measures ANOVA, in which treatment was the main factor,

panels were treated as experimental units nested in treatment, and there was a

possible treatment*week interaction. Significant main factors were subjected to a

Games-Howell post hoc test (Zar 2010). To determine if the fouling community

composition differed between the UVC-treated groups, a PERMANOVA using a

Bray-Curtis similarity matrix was conducted on panels exhibiting fouling growth

with the R package “vegan”. Graphs were composed in R using the package

“GrapheR”, as well as in Microsoft Excel.

RESULTS

After twelve weeks immersion, both the UVC lamp and UVC LEDs were

able to prevent significant biofouling growth compared to control panels. Around

Week 7, LED Strip 4 suffered an electrical malfunction, leading to a large increase

in fouling on LED test panels 7 and 8 compared to the other LED strips’ panels

(Figure II.3). Because of this, the data were analyzed in two parts. One analysis

included all panels through Week 6, and the second analysis included all panels

except for LED panels 7 and 8 through Week 12.

14

Figure II.3. A representative panel from each treatment group at each visual assessment

timepoint over the course of the experiment. The electrical failure of LED Strip 4

and subsequent increase in fouling coverage can be observed between Week 6 and

Week 8.

Week 2

Week 4

Week 6

Week 8

Week 10

Week 12

15

The control panels reached 100% coverage by Week 4 (Figure II.4).

Initially, the control panels were fouled with biofilm, green algae, calcareous

tubeworms, and tunicates (Figure II.5). By Week 6, there was also the presence of

arborescent and encrusting bryozoans (Figure II.5). The final visual assessment

during Week 12 also found sponges, sea anemone, barnacle, and silt tube-building

amphipods (Figure II.5). While some of the LED panels assessed in Week 12 had

silt buildup, neither of the UVC-treated groups (lamp or LED) experienced any

hard fouling (Figure II.5). The lamp’s panels remained almost completely clean

through Week 12. The growth they did develop was a small amount of green algae

(Figure II.5). The LED strips’ panels remained clean in the middle. The progression

of fouling developing from the edges of the panels can be observed throughout the

weeks in Fig. II. 3 (p. 14). Through Week 10, the growth on the LED panels was

mostly biofilm (Figure II.5). By Week 12, the fouling growth included green algae.

16

Figure II.4. Percent coverage by treatment over the course of the field experiment (mean ±

SD). LED panels 7 and 8 from LED Strip 4 were not included in the average.

Figure II.5. Average percent coverage of fouling taxa by treatment over the course of the

field experiment. LED panels 7 and 8 from LED Strip 4 were not included.

The first RMANOVA was conducted on the percent fouling coverage data

from all panels through Week 6. The data required a fourth root transformation to

meet normality assumptions and a Greenhouse-Geisser epsilon correction (=0.893)

17

in order to pass Mauchly’s sphericity test. The results showed the treatment groups

had significantly different coverages (p<0.0001) (Table II.1, Figure II.6). While

panel was significant (p<0.0001), this variable corresponds to experimental unit

and was not interpreted further. Week was also found to be significant (p=0.0003),

but a post diagnostic test could not detect a statistically significant difference

between them (Table II.1). The treatment*week interaction was also significant

(p=0.0458) (Table II.1). This signifies that the effect of treatment was not

equivalent across the 12 weeks of the experiment. However, the interaction was not

relevant to the research question and was simple and orderly, so was not interpreted

further.

Table II.1. RMANOVA results from the field experiment through Week 6. The df[GG]

column represents the new degrees of freedom after the Greenhouse-Geisser epsilon

correction (=0.893) is applied.

df

df[GG]

SS

MS

F

p

Treatment

2

2

106.31

53.15

94.12

<0.0001

Week

2

1.79

3.30

1.84

13.17

0.0003

Panel

21

21

11.86

0.56

4.123

<0.0001

Treatment*Week

4

3.58

1.38

0.39

2.75

0.0458

Error

42

42

5.75

0.14

Total

71

70.37

128.60

18

Figure II.6. Percent coverage by treatment group through Week 6 (mean ± SD). Different

letters indicate significant differences between groups. F = 94.12, p<0.0001.

The second RMANOVA was performed on the percent fouling coverage of

all panels throughout Week 12, excluding LED panels 7 and 8. This data also

required a fourth root transformation and a Greenhouse-Geisser epsilon correction

(=0.353). The treatments were still statistically different (p<0.0001), as was panel

(p<0.0001), week (p<0.0001), and treatment*week (p=0.01) (Table II.2, Figure

II.7). The experimental unit was not interpreted further, and the post diagnostic test

could not reveal a significant difference between weeks. The interaction was also

found to still be simple and orderly.

19

Table II.2. RMANOVA results from the field experiment through Week 12. The df[GG]

column represents the new degrees of freedom after the Greenhouse-Geisser epsilon

correction (=0.353) is applied. LED panels 7 and 8 from LED Strip 4 were excluded

from this analysis.

df

df[GG]

SS

MS

F

p

Treatment

2

2

193.75

96.88

104.9

<0.0001

Week

5

1.76

11.64

6.61

60.13

<0.0001

Panel

19

19

17.54

0.92

8.36

<0.0001

Treatment*Week

10

3.53

4.77

1.35

12.27

0.0100

Error

95

95

10.85

0.11

Total

131

121.29

238.55

Figure II.7. Percent coverage by treatment group through the duration of the 12 week

experiment (mean ± SD). LED panels 7 and 8 were excluded from this analysis.

Different letters indicate significant differences between groups. F = 104.9,

p<0.0001.

Community composition comparisons were also applied to the data in two

parts. The first PERMANOVA included the 1 UVC panel (out of a possible 8) and

6 LED panels (out of 8) that had fouling growth at Week 6. The two treatments’

20

fouling communities were not different (p=0.145) (Table II.3). The second

PERMANOVA included all 8 UVC panels and 6 LED panels that exhibited fouling

during Week 12, excluding LED panels 7 and 8. The UVC-treated fouling

communities during Week 12 were not different (p=0.148, Table II.4).

Table II.3. PERMANOVA results comparing the community composition on the 1 UVC

panel and 6 LED panels that exhibited fouling during Week 6.

df

SS

MS

F

R

2

p

Treatment

1

0.64442

0.64442

17.556

0.77833

0.145

Error

5

0.18353

0.03671

0.22167

Total

6

0.82795

1.00000

Table II.4. PERMANOVA results comparing the community composition on the 8 UVC

panels and 6 LED panels that exhibited fouling during Week 12. LED panels 7 and

8 from LED Strip 4 were excluded from analysis.

df

SS

MS

F

R

2

p

Treatment

1

0.5106

0.51062

2.062

0.14664

0.148

Error

12

2.9716

0.24763

0.85336

Total

13

3.4822

1.00000

DISCUSSION

The LED panels (excluding the two which were removed from analysis - 7

and 8) never exceeded a maximum percent coverage average of 7.5%, which

consisted of light biofilm and green algae. However, this was still found to be

statistically significantly different from the UVC lamp treated panels. As seen in

the photographs from Figure II.3 (p. 14), fouling growth observed on the LED

panels began near the screw holes and developed along the panel edges while the

21

middle of the panels remained clean. The rectangular test panels used in this

experiment were 9.6 cm longer than their width. Previous studies utilizing UVC

LEDs as a biofouling preventative have demonstrated their success when treating

small circular surfaces (MacKenzie et al. 2019, Salters and Piola 2017).

Additionally, if there is a small shadow effect preventing UVC application,

substantial fouling growth can occur (Ryan et al. 2020). It is likely that the screws

provided a shadow effect, allowing biofilm development. The biofilm then spread

along the panel edges which received a lower dose of UVC than the middle of the

panel. Fouling growth beginning on the edges of panels and spreading towards the

middle has also been observed on UVC lamp treated panels in other experiments,

suggesting the additional influence of an underlying biological pattern (Hunsucker

et al. 2019b).

The UVC-treated panels only exhibited growth of biofilm and green algae.

This suggests a higher tolerance to UVC than organisms only found on the control

panels, such as calcareous organisms (tubeworm, barnacle, and encrusting

bryozoans), which is in agreement with results from other UVC biofouling studies

(Hunsucker et al. 2019b, MacKenzie et al. 2019). Biofilms, a matrix containing a

compilation of bacterial populations, are especially resistant to damage from UVC

light because the biofilm with its extracellular secretions acts as a physical barrier

protecting the bacteria (Gora et al. 2019, Elasri and Miller 1999). This property can

help explain how biofilm could grow on parts of the LED panels that were not

subjected to the full UVC dose. Biofilms also experience a greater resistance to

22

UVC with age, indicating that once the biofilm community has settled, it will be

more difficult to halt biofouling progression (Naik et al. 2022). Nonetheless, the

LEDs were able to prevent recruitment of higher fouling organisms, suggesting that

the lower dose of UVC changed may have altered that aspect of the biofilm (Hung

et al. 2005). The observation of minimal fouling on the UVC treated panels was to

be expected from this experimental setup, as even continuous UVC application has

been shown to experience breakthrough biofilm growth (Torkzadeh and Cates

2021).

The results from the two PERMANOVAs indicated that even though the

two UVC treatments varied by specific wavelength, their fouling community

composition was not statistically different. Since the visual assessments could only

be completed accurately to the familial level, it is possible that genetic or

microscopic research could find a difference. Both multispecies and monospecies

biofilms’ abilities to attract larval settlement is reduced by UVC exposure (Hung et

al 2005); it is not possible to tell from this data if 254 nm UVC leads to a different

biofilm composition than 270 nm, and this could be teased out during future

studies.

While the exact reason why LED Strip 4 failed is unknown, it was observed

to have issues prior to Week 7. The glass sheath holding LED Strips 3 and 4 in one

of the housing units developed noticeable condensation inside, requiring its

disassembling, cleaning, and reassemble on Week 3. It is possible that even though

both LED tubes were waterproofed in the same way that the tube containing LED

23

Strip 4 was not completely sealed. It is also possible that the soldered electrical

connections came unattached due to physical movement from storms or wave

action, or the connections failed because of excess heat.

The small differences observed between the lamp and LED may also be a

factor of using a single dose of UVC versus a pulsed or intermittent exposure,

which would repeatedly disturb the surface. More frequent disturbances to a

community can lead to cumulative damage and less resiliency than observed with a

one-off event (Carnell and Keough 2020). This additive effect of frequency could

have enhanced the performance of the lower powered LED strips, although the less

frequent, more severe disturbance from the lamp prevented more fouling.

These results show the effects of short, intermittent UVC doses to be

effective at preventing most biofouling formation in a high pressure fouling

environment. Future research could improve upon this data by allowing the

experiment to run for a longer time period or increase the dose of the LED strips so

that the edge of the rectangular panels is subjected to an equivalent dose as the

center of the lamp’s panels. Additionally, the interaction of the two UVC sources

with antifouling coatings should be tested in the field. As demonstrated in this

chapter and Richard et al. (2021), 10 min/day of exposure from the UVC lamp is

powerful enough to prevent most biofouling formation on an inert surface. When

combined with a fouling release or biocidal antifouling coating, doses as low as 1

min/day can produce similar results (Hunsucker et al. 2019b). Comparable

24

experimental setups could be used to examine the predicted synergistic effect of

UVC LEDs with antifouling coatings.

25

CHAPTER III

EFFECT OF TURBIDITY ON UVC TRANSMISSION

INTRODUCTION

The practical application of UVC as a biofouling preventative in a marine

environment requires understanding the effects of environmental variables on its

transmission. One such variable is turbidity, a measurement of how much light is

scattered by particles in the water (Anderson 2005). Turbidity is caused by

suspended and dissolved materials, such as clay, silt, dyes, and plankton, and can

be qualitatively observed by the cloudiness and color of the water (Anderson 2005,

ASTM International 2003, Davies-Colley and Smith 2001). Turbidity is calculated

by measuring the angle that a beam of light emitted from a sensor is scattered

(Anderson 2005). Depending on the wavelength of light used, this measurement is

reported in NTU (Nephelometric Turbidity Unit) or FNU (Formazin Nephelometric

Unit), which are considered relatively equivalent.

Previous research conducted by CCBC has demonstrated a clear negative

relationship between turbidity and UVC transmission (Florida Tech, unpublished

data). This was accomplished by measuring the transmission from a mercury-based

UVC light source over distance in a range of turbidities. The UVC light source

utilized in the aforementioned experiment was a sterilization wand (Coospider).

The wand was used because its smaller size (2 x 21.5 cm) meant easier

maneuvering in a glass tank compared to the longer Aqua Ultraviolet brand lamp

26

(described in Chapter I). Both the wand and the lamp emitted light at 254 nm and

had no significant difference in freshwater transmission (p=0.556) (Florida Tech,

unpublished data). The wand had a manufacturer specified voltage of 110 V and

power of 7 W, similar to the lamp’s 120 V.

While this research is useful in attempting to explain turbidity and UVC, it

did not test UVC LEDs. The purpose of the following experiment is to replicate the

results obtained from previous CCBC work while comparing them to the

transmission of UVC LEDs in different turbidities.

Hypothesis 2:

Given that the LEDs emit light at 270 nm, it is hypothesized that they will

transmit further in water than the shorter 254 nm wavelength from the wand.

METHODS AND MATERIALS

The setup for the experiment was replicated from the previously described

CCBC research, so the Coospider UVC wand was used instead of the Aqua

Ultraviolet UVC lamp employed in Chapters II and IV. A 12 UVC LED light

engine from Klaran (270 nm) was tested alongside the UVC wand in order to

compare the transmissions of the two different UVC light sources in various

turbidities (Figure III.1).

27

Figure III.1. A close up of the UVC wand (left) and the LED strip (right).

A glass tank (77 x 32 x 32.5 cm, 75 L) was filled with tap water and

measured with a ProSwap digital water quality meter with attached ProDSS

turbidity sensor (Yellow Springs Instruments) to ensure the turbidity was 0 FNU.

Two Solar Light digital sensors were used throughout the experiment. One sensor

measured at 254 nm for the wand (PMA2122) and the second at 270 nm for the

LED strip (PMA2180). Both attached to the same radiometer (PMA2100, Solar

Light) which provided the irradiance readout as mW/cm

2

(wand) or µW/cm

2

(LED

strip).

A piece of measuring tape was attached to the edge of the tank with tape to

easily measure distance. The wand was held in the corner of the tank and turned on.

The PMA2122 sensor was connected to the radiometer and held at 1 in (2.5 cm)

28

away from the wand. The sensor was suspended in the water by hand at the point

where the chassis was completely submerged (about 5 cm). Irradiance was

measured every inch along the tape measure until no more light could be detected

and the radiometer read 0.000 mW/cm

2

. The spot where the radiometer could no

longer sense the UVC was considered the maximum distance of transmission for

the UVC source. Then the process was repeated two more times for a total of three

trials. Once complete, the wand was turned off and the LED strip was placed in the

corner. The LED strip was repurposed from the field experiment (Chapter II); it

was already attached to an aluminum heat sink and secured inside a quartz glass

sheath. The operating code in the Arduino Nano was rewritten so that only the LED

strip facing the sensor was receiving power and the LED strip on the opposite side

of the heat sink remained off. The LED strip being measured ran on a 30 second

duty cycle to prevent overheating. The same measuring process mentioned above

for the wand was then repeated. The PMA2180 sensor was attached to the

radiometer and held 1 in (2.5 cm) away from the LED strip. The sensor was moved

1 in at a time down the length of the tank until the radiometer read 0.0 µW/cm

2

.

This process was repeated two more times with the LED strip (Figure III.2).

29

Figure III.2. An overhead view of the turbidity tank experiment at 0 FNU. The LED strip in

the glass sheath is seen at the top left held at the corner of the tank, while the Solar

Light sensor (PMA2180) is moved along the tank edge. The YSI turbidity sensor is

seen at the bottom of the picture for continuous monitoring. The UVC wand is

inactive in the top right of the tank.

In order to determine how measurements will change with increased

turbidity, sediment was collected from the Florida Tech Anchorage on February 23,

2022 (28°04'36.9"N 80°36'01.8"W). The Anchorage is located where the mouth of

Crane Creek meets the Indian River Lagoon. It was collected from the shallow (<1

m), nearshore water and transported in a small cooler to a laboratory setting on the

Florida Tech main campus, where it was used in the turbidity tank experiment the

same day. The sediment had a consistency of muddy sand.

30

Sediment from Anchorage was added to the tank to raise the turbidity to 10

FNU. The tank water was agitated with a paint stirrer attached to an electric drill to

achieve uniform suspension. Once the YSI turbidity sensor measured 10 FNU at 5

cm deep, the transmission of the wand was measured according to the steps

outlined above, followed by the LED strip (Figure III.3). Because the LED strip’s

testing took several minutes due to the duty cycle, the tank was intermittently

stirred to maintain proper turbidity readings at the top of the tank. More sediment

was added to the tank to reach a turbidity of 20 FNU, then the two UVC sources’

transmission was measured again. This process was repeated at 30 FNU, 40 FNU,

and 50 FNU, with 3 trials for each source at each turbidity.

Figure III.3. An overhead view of the turbidity tank experiment at 10 FNU. The UVC wand

is being actively measured by the PMA2122 sensor and the LED in the glass sheath

rests in the upper right corner of the tank. The YSI turbidity sensor is seen at the

bottom of the picture for continuous monitoring.

31

The data was analyzed in R (Version 4.1.1) using a two-way factorial

ANOVA, where the main factors were UVC source and turbidity with an

interaction of UVC source*turbidity. Any significant factors were subjected to a

Tukey post-hoc test in R. The irradiance measurements for the LED strip were

converted to mW/cm

2

so the two sources could be compared evenly. The data also

had to be transformed by a fourth root in order to meet the assumptions for

ANOVA. Graphs were constructed in R using the package “GrapheR” and also in

Microsoft Excel.

RESULTS

In clear water, the UVC wand had a maximum recorded irradiance of 0.915

mW/cm

2

, while the LED strip’s maximum was 0.219 mW/cm

2

(Figure III.4, Figure

III.5). At the highest tested turbidity (50 FNU), this measurement was significantly

reduced for both sources. The wand’s maximum irradiance fell to 0.142 mW/cm

2

,

and the LED strip’s was 0.098 mW/cm

2

(Figure III.4, Figure III.5). All maximum

irradiance values were obtained from 2.54 cm away from the light source and

declined with distance.

32

Figure III.4. Irradiance (in mW/cm

2

) measured over distance (cm) using the UVC wand. The

key indicates different turbidities.

Figure III.5. Irradiance (in mW/cm2) measured over distance (cm) from the UVC LED strip.

The key indicates different turbidities. The y-axis is the same scale as Fig. IV.4 for

easier visual comparison of the two sources.

33

When comparing maximum distance of transmission, the two UVC sources

were significantly different from each other (p<0.0001) (Table III.1, Figure III.6).

The UVC wand outperformed the LED strip in each of the tested turbidities (Figure

III.6). It was able to be detected about 3.39 cm further than the LED strip at a

turbidity of 30 FNU, which was the largest difference between the two sources’

maximum distances. The smallest difference was 0.85 cm at a turbidity of 20 FNU.

All UVC transmission values were statistically different for each tested turbidity

(p<0.0001) (Table III.1). There was not a significant effect from the interaction of

source and turbidity (p=0.076) (Table III.1).

Table III.1. Factorial ANOVA results from the turbidity tank experiment.

df

SS

MS

F

p

UVC Source

1

0.086

0.0856

36.840

<0.0001

Turbidity

5

7.093

1.4186

610.832

<0.0001

UVC*Turbidity

5

0.027

0.0054

2.306

0.076

Residuals

24

0.056

0.0023

Total

35

7.262

34

Figure III.6. Maximum distance of transmission (in cm) of different UVC sources in a range

of turbidities (FNU) (mean ± SD).

DISCUSSION

The effect of turbidity on the efficiency of UVC as a disinfectant has been

mentioned in several studies, specifically suggesting how larger suspended

particles can act as a shield for smaller organisms (Carré et al. 2018, Gregg et al.

2009, Lewis and Whitby 1995, Rajagopal et al. 2012, Sassi et al. 2005). Additional

research has outlined the response of bacteria to various UVC doses in increasing

turbidities (Adhikari et al. 2020, Gullian et al. 2012). However, most, if not all, of

this work is focused on the relationship of turbidity and UVC for the disinfection of

water samples; not much can be found on measured maximum transmissions of

UVC light. Even less information is available specifically regarding UVC LEDs,

probably due to their more recent development.

35

The hypothesis that the longer wavelength of 270 nm from the LED strip

would transmit further in water than the lamp’s shorter 254 nm was incorrect. It is

possible that the difference in transmission could be related to the different

electrical powers of the two sources. The wand has a power source with a voltage

of 110 V while the LED strip operates on 24 V. The difference could also be a

factor of the 130º vs. 360º emittance angles.

The statistically significant difference between all levels of turbidity was

expected, as they were each separated by 10 FNU and the water became noticeably

murkier over time (personal observation). This is explained by each level requiring

more particles that either acted to scatter light (suspended sediment, clay, or silt) or

decrease clarity (dissolved humus, organic dyes, algae) (Anderson 2005). The

levels tested also have environmental relevance. From May 2020 to November of

2021, the surface water at Anchorage had a mean turbidity of 2.78 ± 1.26 FNU

(range: 1.29 – 7.40) (Florida Tech, unpublished data). When measured at Port

Canaveral, Florida, the mean was 1.30 ± 1.23 FNU with a range of 0.09 – 7.68

(Florida Tech, unpublished data). These types of sites are expected to, and

demonstrably do, experience a turbidity range of 1 – 10 NTU, supplying context for

the 0 and 10 FNU turbidity levels (CWT 2004). Water in the San Francisco Bay

has been recorded ranging from 12 – 54 NTU which also encompasses the

turbidities tested (Klein and Jenkins 1981). Further from land, turbidity is

calculated using color satellites and diffuse attenuation coefficients at a specific

wavelength (K

d

). Clear water, represented by a K

d

(490) of less than 0.1 m

-1

, is

36

roughly 95.67% of the open ocean and varies mostly because of plankton blooms,

which themselves yield a turbidity of ~50 NTU (Shi and Wang 2010, Clear Water

Team 2004). The results presented within could be applied to such bodies of water,

providing an estimation of how UVC transmission will be affected given the

relative turbidity.

Hess-Erga et al. (2008) demonstrated the effects of UVC dose on the rotifer

Brachionus. When the rotifers were associated with particles, they required a

sixfold increase in UVC dose to achieve 99.9% inactivation as compared to free-

living Brachionus, supporting the shadow effect of particles in UVC efficiency

(Hess-Erga et al. 2008). A second experiment demonstrated that the addition of

abiotic or biotic particles (resulting in an unspecified turbidity) led to the reduced

performance of UVC on free-living bacteria. The researchers did not find a major

difference in the protection provided by either particle type on the bacteria (Hess-

Erga et al. 2008). Baldasso et al. (2021) further defined the effects of particles

when treating the MS2 bacteriophage with UVC in water. Humic acids,

representative of organic matter, absorbed UVC, which had a substantial effect on

the inactivation rate constant and thus bacteriophage inactivation (Baldasso et al.

2021). In contrast, kaolinite particles (a clay mineral) could not absorb UVC and

influenced transmission only by scattering, which had an insignificant effect on the

inactivation rate constant (Baldasso et al. 2021).

The composition of the experimental sediment sample can be approximated

from literature. Using data from samples where Crane Creek meets the Indian River

37

Lagoon, the sample likely contained an estimated 39 ± 15% silt and clay and 3.2 ±

1.5% total organic carbon (Fuller et al. 2021). It would be unwise to extrapolate a

conclusion about UVC transmission specific to organic matter content from this

experiment’s limited data, but it does raise several questions. Clay, silt, humic

acids, and dissolved organic matter (estimated by organic carbon) all contribute to

measured turbidity. However, if the partial percent of organic matter in a given

body of water can be determined, then a more accurate dose of UVC can be

calculated, eliminating both under and overapplication of UVC. This could

especially be useful when considering the disinfection of temporary water bodies,

like ballast water. Additionally, this process could be applied to smaller, stagnant

equipment that needs UVC treatment for the prevention of biofouling, like marine

sensors.

38

CHAPTER IV

IMPACTS OF UVC TO MARINE SURFACES

INTRODUCTION

Marine coatings are often used to prevent biofouling, thus preventing drag

on ship hulls (Swain 1998). This is accomplished by promoting weak adhesion of

organisms, such as fouling release coatings, or through leaching of a biocide, like

antifouling paints (Hunsucker et al. 2019b, Lejars et al. 2012, Swain 2010).

However, marine coatings have their disadvantages, such as decreased performance

on niche areas of a ship and limited lifespans (Lejars et al. 2012, Piola et al. 2016).

It has been suggested that the use of UVC light could work synergistically with

marine coatings in order to enhance their performance (Hunsucker et al. 2019b).

While the research by Hunsucker et al. (2019b) did support this conclusion, it was

conducted using only a lamp and did not investigate UVC LEDs. Additionally, the

UVC caused physical damage to the copper antifouling coating when applied

continuously (Hunsucker et al. 2019b). Because the results of this study established

a synergistic effect of UVC on marine coatings, the chemical and physical

interactions that led to the coating’s degradation need to be understood. This

experiment attempts to quantify the impacts of UVC on marine coatings by

exposing several coatings to various doses of light from both a lamp and LEDs.

39

Hypothesis 3:

Since the UVC doses will be equivalent, it is hypothesized that the lamp

and LEDs will provide the same amount of degradation to marine coatings.

METHODS AND MATERIALS

SLIDE PREPARATION

Three test coatings were applied to sheets of 12 x 24 x 1/16” PVC (sourced

from McMaster Carr). The sheets were roughened on one side using a sander for

better adhesion of the coatings and then cut into four equal sections, where each

section of PVC could provide 24 surfaces equivalent to microscope slides. (Note –

due to supply chain issues as a result of the COVID-19 pandemic, glass microscope

slides were backordered and not able to be used in this experiment as planned).

The test coatings used were an epoxy barrier coat (International Intergard

264), a fluoropolymer fouling release paint (Intersleek 1100SR), and a copper-free

antifouling coating which contains 6% ECONEA and 4.8% Zinc Pyrithione (Pettit

ECO HRT). All coatings were applied according to manufacturer standards using a

drawdown applicator with adjustable micrometers (Gardco). Once dry, the PVC

was cut down into 2.5 x 7.5 cm “slides”. The antifouling coating slides were placed

in a container of tap water and left to soak for 7 days. These slides were then

removed and allowed to dry for 5 days.

40

Once all slides were dry, initial thickness measurements were obtained

using a 0-1” manual micrometer (Mitutoyo). This data was converted in

micrometers using the following equation:

Initial adhesion measurements were also gathered from the fouling release

slides. This was accomplished by using pseudobarnacles, which are small metal

studs (Figure IV.1). Three pseudobarnacles were attached to each slide using an

epoxy structural adhesive (Loctite EA E-05CL). They were left to dry for 24 hours

and then pushed off using a force gauge (Imada push-pull scale, 10x.1lbs), similar

to field tests which determine how much force is necessary to remove a barnacle

from a test surface (ASTM Standard D5618-20 2020). The force was recorded in

pounds. The surface area of epoxy on each pseudobarnacle was then scanned into a

computer and calculated using GIMP image editor (Version 2.10.30) and ImageJ

(1.53k, National Institutes of Health). The adhesion strength (pounds per unit area)

was converted into megapascals (MPa).

41

Figure IV.1. Close up of a pseudobarnacle used to measure adhesion, measuring 2.3 cm in

height and 1 cm in base diameter.

The 20 slides of each coating were distributed four to a group (with a total

of five groups). They were distributed so that the average coating thickness for each

group was the same as the overall average of the 20 total slides. This yielded five

groups, each with 12 total slides. The groups were then randomly assigned to

treatment (outlined below).

TANK PREPARATION

In order to test the effects of different UVC sources on different coatings,

the five treatment groups were defined as continuous lamp, 10 min/day of the lamp,

continuous LED, 43.2 min/day LED, and a control group (no UVC exposure)

(Table IV.1). This was based on the same assumption utilized in the field

experiment (Chapter II) that the calculated 43.2 minutes of exposure from the LED

strip is equivalent to 10 minutes from the lamp.

42

Table IV.1. UVC treatment groups with equivalent exposure time.

Group Number

Treatment

1

Continuous lamp for 2 weeks

2

10 min/day lamp (=140min)

3

43.2 min/day LED (~40.3hr)

4

Control (no UVC exposure)

5

Continuous LED totaling 2 weeks

Four LED strips were sourced from Klaran for this experiment, and they

were wired in the same manner as the field experiment (Chapter II). Two strips

were cemented to an aluminum heat sink in a glass sheath so that they emitted light

in opposite directions. Because of the LED strip’s small surface area (1.2 cm x 16

cm), it was concluded that each strip should only treat four slides. Therefore, the

continuous LED group used three of the four strips. Because two of the

aforementioned strips shared a glass sheath, they had to be operated on a duty cycle

to prevent overheating, where one strip was on for 5 seconds, then 5 seconds of

rest, then the second strip on for 5 seconds, then 5 seconds of rest. This meant that

the completion of treatment for the continuous LED group would take four times as

long as the continuous UVC lamp group. Therefore, the continuous lamp and

control groups were scheduled to end after two weeks and the continuous LED

group after 8 weeks (Table IV.1).

In order to conduct the experiment, frames of aluminum angles and 3D-

printed plastic were constructed to hold the glass sheaths in place. Unlike the field

experiment, they were not painted with any antifouling coating due to their use in a

laboratory setting. Three glass tanks (77 x 32 x 32.5 cm, 75 L) were sourced from

43

Aqueon. One tank held the Aqua Ultraviolet UVC lamp and its holder (Figure IV.2.

The lamp in its holder inside a tank of fresh water. The 12 slides can be seen

underneath the operating lamp, affixed to a plastic microscope slide holder.). The

other two tanks each held a glass sheath with 2 LED strips in their respective

frames. The tanks were filled with tap water until the frames were completely

immersed. Each tank also had a digital underwater thermometer to observe

temperature changes. For the control group, a clean bucket was filled with tap

water and given a thermometer. Complete water changes were conducted biweekly.

To keep the slides in one place during immersion, plastic microscope slide

holders (17 x 34 cm) were sourced from Fisher Scientific. Each plastic holder had

spots for 20 possible slides. For Groups 1, 2, and 4, all of the slides from each

group were glued to the middle 12 spots randomly using an epoxy structural

adhesive (Loctite EA E-05CL) (Figure IV.2). For Groups 3 and 5, only four slides

from each group were glued to each plastic holder due to the LED strip’s limited

emittance (Figure IV.3). Once all the glue was cured, the plastic holders were

secured to each frame with zip ties at the start of their treatment. After treatment

was complete, the plastic holder was removed, the slides detached, and then left to

dry for at least 72 hours before data collection.

44

Figure IV.2. The lamp in its holder inside a tank of fresh water. The 12 slides can be seen

underneath the operating lamp, affixed to a plastic microscope slide holder.

Figure IV.3. One of the LED tubes in its holder inside a tank of fresh water. Four of the slides

can be seen attached to a plastic microscope slide holder and are treated by the

unseen LED strip on the opposite side of the aluminum heat sink.

45

Post treatment data collection consisted of thickness measurements using

the micrometer, pseudobarnacle adhesion measurements (only for the fouling

release coated slides), hardness scratch testing, and qualitative comparative

pictures. The hardness scratch test, a measure of coating damage resistance, was

completed according to ASTM Standard G171-03 (2017). A stylus point was

dragged across each slide with a known constant exerted pressure from an attached

weight. The spot where the stylus was dragged was colored in with a Sharpie in

order to more clearly differentiate the edges of the produced scratch from the

surrounding coating. The slide was placed under a Nikon SMZ1270

stereomicroscope with a ruled microscope slide laid on top for scale (NeoSCI). A

picture was taken with the Nikon DS-Ri2 digital camera in the NIS-Elements F

computer program (Version 4.30.01). Then the picture was opened in ImageJ. For

each slide, the scale was determined, and the width of the scratch was measured in

three places. The width measurement (in micrometers) was entered into the

following equation to yield the scratch hardness number in gigapascals:

where P is the pressure exerted on the stylus point in Newtons (known as 5N) and

w is the width of the scratch.

Pictures for qualitative analysis were taken with a Nikon COOLPIX W300

camera. The thickness and adhesion data were each analyzed as a repeated

measures ANOVA in R (Version 4.1.1), where treatment and time were main

46

factors, slides were used as an experimental unit, and there was a possible

treatment*time interaction. If treatment was found to be significant, the main

factors were subjected to a Games-Howell post hoc test (Zar 2010). The scratch

hardness tests results were analyzed by a nested ANOVA in R, with treatment as

the main factor and slides as the experimental unit. Significant main factors were

subjected to a Tukey HSD post hoc test. Graphs were constructed in R using the

package “GrapheR”.

RESULTS

EPOXY

Compared to the control group, the 43.2min/day LED and 10min/day lamp

groups’ epoxy slides developed a darker and slightly yellow shade after treatment

(Fig. III.4). The continuous LED and continuous lamp groups’ slides did not darken

as much but still turned slightly yellow; after these slides completely dried, the

epoxy coating turned chalky and came off when brushed with a finger (Figure IV.4,

personal observation).

47

Figure IV.4. A representative epoxy-coated slide from each treatment group. The color in the

middle of each slide is residual Sharpie from the scratch hardness test.

The average preliminary thickness for each treatment group’s epoxy slides

was 1924.90 ± 1.74 µm (range of group averages: 1921.93 – 1926.17). After

treatment, the average thickness measured 1928.28 ± 9.44 µm (range of group

averages: 1918.76 – 1943.10). The thickness measurements for epoxy slides were

not significant based on treatment (p=0.999), time (p=0.2406), or their interaction

(p=0.1286) (Table IV.2, Figure IV.5). The significance of slide (p<0.0001) was not

interpreted further as experimental unit in favor of analyzing the main factors

(Table IV.2).

48

Table IV.2. RMANOVA results from testing the epoxy slides’ thickness measurements.

df

SS

MS

F

p

Treatment

4

822

205

0.02

0.999

Time

1

115

115

1.493

0.2406

Slide

15

155429

10362

134.964

<0.0001

Treatment*Time

4

651

163

2.121

0.1286

Error

15

1152

77

Total

39

158169

Figure IV.5. Thickness of the epoxy slides from each group before and after treatment,

measured in micrometers (mean ± SD). For treatment: F = 0.02, p = 0.999.

The hardness of the epoxy slides differed significantly by treatment group

(p=0.00515) (Table IV.3). Treatment was again the main factor and the

significance of the slides as experimental units (p=0.00131) was not interpreted

further (Table IV.3). The control group was similar to the continuous LED,

10min/day lamp, and continuous lamp groups’ hardness measurements but

statistically different from the 43.2min/day LED (Figure IV.6). Both of the

49

continuous UVC treatment groups had similar hardness results to each other, as did

both of the intermittent UVC groups (Figure IV.6).

Table IV.3. ANOVA results from the epoxy slides’ scratch hardness test.

df

SS

MS

F

p

Treatment

4

0.005454

0.0013635

5.763

0.00515

Slide

15

0.003549

0.0002366

3.294

0.00131

Error

40

0.0002873

0.0000718

Total

59

0.0092903

Figure IV.6. Hardness number (in Gigapascals) of the epoxy slides by treatment group

(mean ± SD). Different letters indicate significant differences between groups. F =

5.763, p = 0.00515.

FOULING RELEASE COATING

The Intersleek 1100SR fouling release coating produced a shiny, rubbery

finish when first coated, which was still observed after treatment in the control,

43.2min/day LED, continuous LED, and 10min/day lamp groups (Figure IV.7).

50

The continuous lamp group’s fouling release slides developed a lighter colored,

more matte finish that felt softer to the touch (personal observation).