S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

7

-

1

Chapter 7 – Earned Value Management

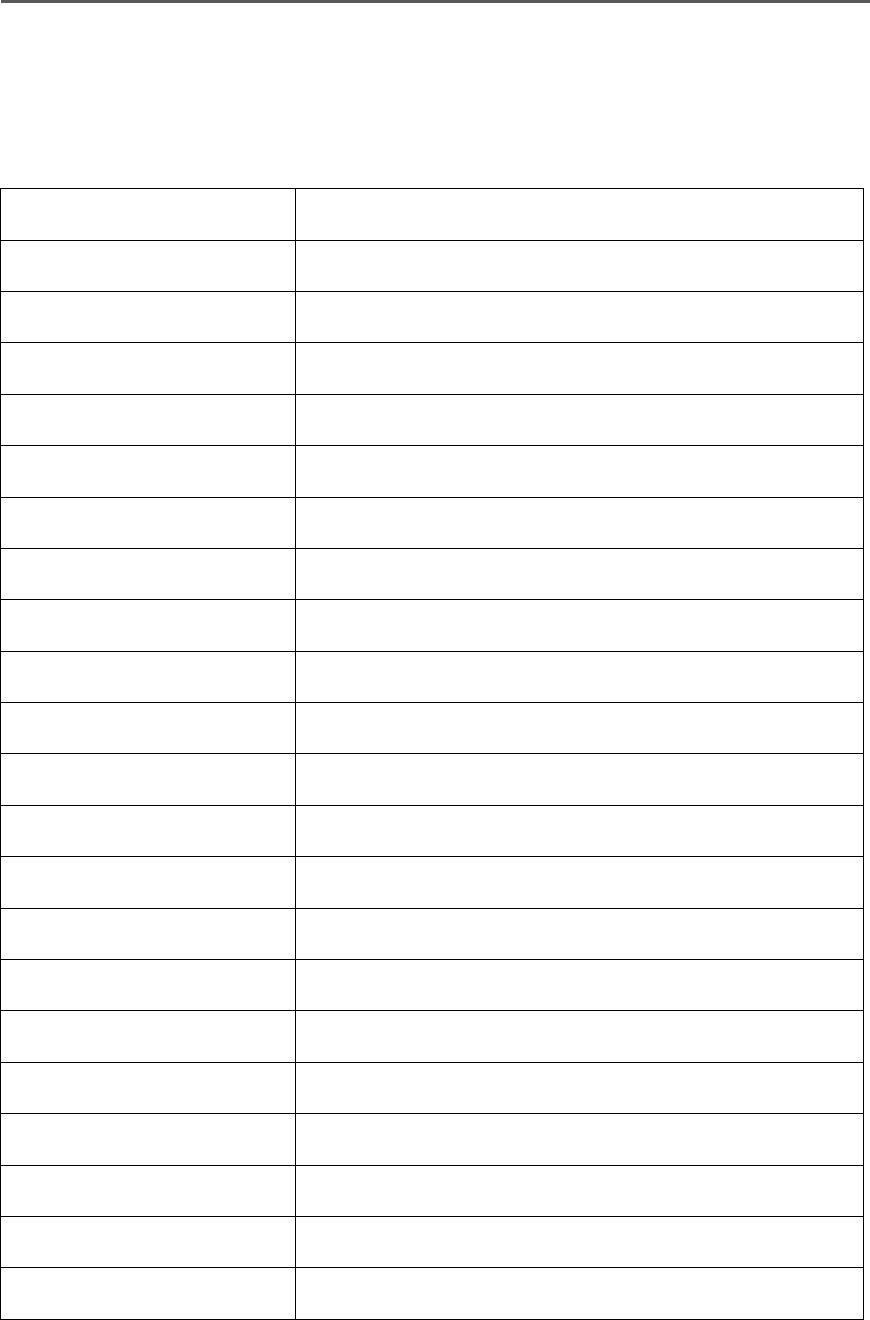

Table of Contents

7.1 Introduction 7-4

7.2 Policy and Directives 7-4

7.3 Roles and Responsibilities 7-5

7.3.1 Integrated Program Management (IPM) Division of OUSD AAP 7-5

7.3.2 Defense Contract Management Agency (DCMA) 7-6

7.3.3 Component EVMS Focal Point 7-6

7.3.4 NAVSEA (Procuring Activity) 7-6

7.3.5 SUPSHIP 7-8

7.4 EVMS Guidelines Concept 7-9

7.4.1 EVMS Guidelines 7-9

7.4.1.1 Key Attributes of EVMS 7-10

7.4.1.2 EIA Standard 748 Guidelines 7-10

7.5 EVM Overview 7-11

7.5.1 Basic EVM Description 7-11

7.5.2 Components and Processes of an Earned Value Management System 7-12

7.5.2.1 Statement of Work (SOW) 7-12

7.5.2.2 Work Breakdown Structure (WBS) 7-12

7.5.2.3 Contractor Program Organization 7-12

7.5.2.4 Program Schedule 7-13

7.5.2.5 Budget Allocation and Resource Planning 7-14

7.5.2.5.1 Establishing Control Accounts (CA) and Control Account Budgets 7-15

7.5.2.5.2 Performance Measurement Baseline (PMB) 7-15

7.5.2.5.3 Integrated Baseline Review (IBR) 7-16

7.5.2.5.3.1 IBR Policy and Guidance 7-17

7.5.2.6 Accounting Considerations 7-17

7.5.2.7 Earned Value Techniques 7-18

7.5.2.7.1 Planning and Control of Level of Effort Activities 7-19

7.5.2.8 Performance Measurement and Analysis 7-19

7.5.2.8.1 Significant Variances 7-19

7.5.2.8.1.1 Schedule Variance (SV) 7-20

7.5.2.8.1.2 Cost Variance (CV) 7-20

7.5.2.9 Estimates at Completion (EAC) 7-21

7.5.2.10 Revisions and Data Maintenance 7-22

7.5.2.10.1 Customer-Directed Changes 7-22

7.5.2.10.2 Traceability to Previous Budgets 7-22

7.5.2.10.3 Control Internal Changes to the PMB 7-22

7.5.2.10.4 Over Target Baseline (OTB) and Over Target Schedules (OTS) 7-23

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

7

-

2

7.6 Contract Requirements 7-24

7.6.1 Evaluation 7-24

7.6.2 Contract Award 7-24

7.6.3 Post-Contract Award 7-25

7.6.3.1 EVMS System Validation 7-25

7.6.3.2 Integrated Baseline Review (IBR) 7-25

7.6.4 Deficiencies in Validated EVM Systems 7-25

Appendix 7-A: Graphical Representation of EVMS Terms 7-27

Appendix 7-B: Glossary 7-29

Appendix 7-C: Acronyms 7-33

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

7

-

3

References

(a) Federal Acquisition Regulation (FAR)

(b)

Defense Federal Acquisition Regulation Supplement (DFARS)

(c)

Electronic Industries Alliance Standard 748, Rev D (EIA-748D)

(d)

DoDI 5000.02, Operation of the Adaptive Acquisition Framework

(e)

DoDI 5000.02T, Operation of the Defense Acquisition System

(f)

NAVSEAINST 7000.4H, Earned Value Management

(g)

Department of Navy Earned Value Management Implementation Guide (DON

EVMIG, 8 August 2017)

(h)

DoD Earned Value Management System Interpretation Guide (14 March 2019)

(i)

ASN(RDA) memo of 9 Apr 2007, Center of Excellence for Earned Value

Management (CEVM)

(j)

OUSD AT&L memo of 1 Sep 2015, Class Deviation - Earned Value Management

System Threshold

(k)

NAVSEAINST 4000.6B, Data Management Program

(l)

SECNAVIST 5000.2F, Defense Acquisition System and Joint Capabilities

Integration and Development System Implementation

(m)

NAVSEAINST 5400.111A , NAVSEA Engineering and Technical Authority Policy

(n)

NAVSEA SUPSHIP EVMS Surveillance Operating Procedure (May 2020)

(o)

MIL-STD-881E, DoD Standard Practice Work Breakdown Structures for Defense

Materiel Items

(p)

DoD Integrated Master Plan and Integrated Master Schedule Preparation and User

Guide (21 Oct 2005)

(q)

Program Manager’s Guide to the Integrated Baseline Review Process (4 Jun 2003)

(r)

NAVSEA letter Ser 022/007 - Contractor Business Systems Guidance of 28 Nov

2018

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

4

Chapter 7 – Earned Value Management

7.1 Introduction

This chapter provides information regarding the principles of Earned Value Management

(EVM), DoD’s requirements for EVM, the guidelines used to approve a contractor’s Earned

Value Management System (EVMS), and the responsibilities of SUPSHIPs and other

activities regarding EVM. It also provides guidance concerning the SUPSHIP organization for

EVMS support and analysis of shipbuilder cost performance and integrated program

management reports submitted under covered contracts.

EVM has proven its value over many years. Effective implementation and application of

EVM systems by contractors ensures that they possess and use an adequate management

system that integrates cost, schedule, and technical performance. This approach provides

better overall planning and control discipline on government contracts. A properly employed,

compliant EVMS provides the Program Manager (PM) and SUPSHIP with valid cost,

schedule, and technical progress information needed for effective decision-making, risk

management, and contract administration.

The contractor's EVMS is considered to be a contractor business system as defined by

DFARS 242.7000. Qualifying contracts are to include the DFARS clauses 252.234-7002

,

Earned Value Management System, and 252.242-7005, Contractor Business Systems.

These clauses establish the requirement for the contractor to establish and maintain

acceptable business systems in accordance with the terms and conditions of the contract. If

a business system is found to have a significant deficiency, the Contractor Business System

clause permits contract withholdings to occur. See

SOM 3.18.6, Contractor Business System

Specifics, for a more detailed treatment of this topic.

7.2 Policy and Directives

In accordance with reference (a), FAR 34.2, an Earned Value Management System is

required for major acquisitions for development and for other acquisitions in accordance with

agency procedures. For DoD acquisitions,

DFARS Subpart 234.201, reference (b), imposes

the following EVMS contract requirements:

a. For cost or incentive contracts and subcontracts valued at $20 million or more, the EVMS

shall comply with the guidelines in Electronic Industries Alliance Standard 748D (

EIA-

748D), reference (c).

b. For cost or incentive contracts and subcontracts valued at $100 million or more, the

contractor shall have an EVMS that has been determined by the cognizant Federal

agency to be in compliance with the guidelines in EIA-748.

c. For cost or incentive contracts and subcontracts valued at less than $20 million:

(1) The application of EVM is optional and is a risk-based decision.

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

5

(2) A decision to apply EVM shall be documented in the contract file.

(3) A cost-benefit analysis shall be conducted following the procedures at

DFARS PGI

234.201 (1) (iii).

d. For firm-fixed-price contracts and subcontracts of any dollar value:

(1) The application of EVM is discouraged.

(2) Follow procedures at DFARS PGI 234.201

(1) (iv) for obtaining a waiver before

applying EVM.

Note: EVM is not required on contracts, subcontracts, intragovernment work agreements,

and other agreements less than 18 months in duration, including options, per reference (d),

DoDI 5000.02, Operation of the Adaptive Acquisition Framework, and the prior DoDI

5000.02T (transitional document), Operation of the Defense Acquisition System, reference

(e).

Reference (f), NAVSEAINST 7000.4H**, Earned Value Management, establishes NAVSEA

policies, procedures, and responsibilities for the implementation of Earned Value

Management in NAVSEA procurements. Reference (g), the

Department of Navy Earned

Value Management Implementation Guide (DON EVMIG), provides uniform procedures

within DON concerning EVM. Reference (h), the DoD Earned Value Management System

Interpretation Guide (DoD EVMSIG), provides the basis for DoD to assess EVMS

compliance to the EIA-748 guidelines.

7.3 Roles and Responsibilities

The responsibility for EVM in DoD for shipbuilding is shared by five organizations:

• Integrated Program Management Division of the

Office of the Undersecretary of

Defense Office for Acquisition, Analytics and Policy (OUSD AAP)

• Defense Contract Management Agency (DCMA)

• Component EVMS Focal Point (e.g., the Naval Center for Earned Value

Management (CEVM))

• Procuring Activity (e.g., NAVSEA)

• SUPSHIP as the assigned Contract Administration Office (CAO)

The following sections discuss the general responsibilities associated with each of these

activities.

7.3.1 Integrated Program Management (IPM) Division of OUSD AAP

The IPM Division of OUSD AAP serves as the DoD focal point for all policy, guidance, and

competency relating to EVM. One of the division’s goals is to increase earned value’s

constructive attributes for the DoD firms managing acquisition programs by reducing the

economic burden of inefficient implementation of EVM. The IPM Division is dedicated to the

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

6

idea that EVM is an essential integrated program management tool and not merely a

contractually required report. The division has formal cognizance over the EVMS

Interpretation Guide (EVMSIG), which is to be used as the basis for DoD to assess EVMS

compliance to the EIA-748 guidelines.

7.3.2 Defense Contract Management Agency (DCMA)

Per DFARS 234.201(3), DCMA is responsible for determining earned value management

system compliance when DoD is the cognizant Federal agency. To this end, DCMA works

with various government and industry teams to develop practical EVMS guidance,

administers contractual activities, and conducts Compliance Reviews (CRs), ensuring initial

and ongoing compliance with the DoD EVMS criteria as outlined in the DoD EVMSIG

.

7.3.3 Component EVMS Focal Point

Each military service component establishes a focal point to serve as the point of contact for

coordination and exchange of information on EVM. In accordance with reference (i),

ASN(RDA) memo of 9 Apr 2007, the Department of the Navy’s EVM focal point is the Naval

Center for Earned Value Management (CEVM) within the ASN(RDA) office. The EVMS focal

point is responsible for effective policy implementation within their service, including ensuring

consistency with DoD policy. In support of this responsibility, the CEVM has issued the

Department of the Navy Earned Value Implementation Guide (

DON EVMIG). As previously

noted, the guide provides uniform procedures for all matters concerning implementation of

EVM on DON acquisition programs.

7.3.4 NAVSEA (Procuring Activity)

DON EVMIG, paragraph 2.1.3.6, defines the Procuring Activity as the Program Management

Office (PMO), the contracting organization, and the Integrated Product Teams (IPTs) that

support the PMO. The PM and the PMO help ensure that all solicitations and contracts

contain the correct EVMS and/or Integrated Master Schedule (IMS) requirements, tailored as

appropriate for the specific nature of the program in accordance with DoD policy. The PM

and PMO also have the responsibility to conduct the IBR, perform integrated performance

analysis, proactively manage the program utilizing performance data, and accurately report

performance to decisionmakers. In shipbuilding, the PM/PMO are supported by several

NAVSEA deputy commanders and functional offices. The roles and responsibilities for each

of the organizations are detailed below and are contained in their entirety in

NAVSEAINST

7000.4H**.

Deputy Commander for Ship Design Integration & Engineering (NAVSEA 05)

1. Perform EVM analysis and development of independent Estimates at Completion

(EAC) in support of NAVSEA and program offices.

2. Support the Procuring Contracting Officers (PCO) and program offices in determining

and recommending EVM requirements in solicitations and contracts that meet the

various thresholds for EVMS.

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

7

3. Coordinate with program offices on development of cost reporting/EVM related data

item requirements, i.e., Contract Data Requirements List items (CDRL), before

issuance of solicitations and subsequent review and coordination on any

modifications before and after contract award.

Program Manager

1. Include all appropriate requirements set forth in higher level documents, acquisition

plans or acquisition papers, solicitations and contracts meeting threshold levels of

Table 8 in DoDI 5000.02T. Enclosure (1) of reference (j), OUSD AT&L memo of 1

Sep 2015, provides a summary of the thresholds and EVM requirements.

2. Coordinate cost reporting and EVM related CDRLs with SEA 05C and other

appropriate stakeholders before Request for Proposal (RFP) issuance and

subsequent modifications before or following contract award, per reference (k),

NAVSEAINST 4000.6

B**, Data Management Program. Requests to waive EVM

related requirements of DoDI 5000.02, SECNAVIST 5000.2F, reference (l), and

NAVSEAINST 5400.111A**, reference (m), will be developed with SEA 05C support.

3. Coordinate contractor requests for execution of Over Target Baseline (OTB) or Over

Target Schedule (OTS) through SEA 05C, SEA 02, and the CAO for review and

comment before approval.

4. In coordination with SEA 05C, establish a process to support effective

communication across the program EVM team. The team will act as the action agent

for the PM in cost estimating and EVM analysis activities.

a. Suggested membership for the EVM team is program office business,

financial and EVM personnel, SEA 05C cost and EVM analysts, and CAO

(SUPSHIP) EVM analyst. Other stakeholders, such as Ship Design

Managers (SDM) and systems engineering personnel, should participate as

appropriate.

b. The PM and SEA 05C will determine the team's meeting frequency to

support the development of Program Manager EACs through a review of

EVM analyses and EAC recommendations. Where significant variation exists

between the projected EACs of the EVM team members, the EAC

recommendations provided to the PM will include explanations of the

variation to support informed decision-making concerning the establishment

of the PM EAC. The basis of EAC recommendations from the program EVM

team, i.e., program office, SEA 05C and CAO, will be provided by each

organization to support the establishment of the PM EAC.

5. Make full use of Integrated Program Management Reports (IPMRs), Integrated

Program Management Data Analysis Reports (IMPDARs), Contract Performance

Reports (CPRs), Integrated Master Schedules and other EVM related reports in

managing and evaluating contractor performance.

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

8

6. Maintain adequate documentation regarding the implementation of EVM (e.g., MOA,

results of IBRs, re-baseline approvals, EAC development documentation). The

program office will be the normal repository for such information.

Deputy Commanders / PEOs / NAVSEA Functional Offices

Deputy Commanders, Program Executive Officers (PEOs), and NAVSEA Functional

Offices will ensure program managers meet the requirements contained and referenced

in NAVSEAINST 7000.4H**.

Deputy Commander for Logistics, Maintenance and Industrial Operations (SEA 04)

1. Ensure that the requirements contained and referenced in this instruction are fulfilled.

2. Provide guidance, jointly with SEA 05C and with inputs from PEOs, to SUPSHIPs

regarding requirements for shipbuilder EVMS. Support SEA 05C in providing SME

support to SUPHIPs for execution of contractor EVM system responsibilities.

3. Provide required oversight of SUPSHIPs to ensure implementation and effectiveness

of shipbuilder EVMS through Procurement Surveillance Program (PSP) functional

area reviews as requested.

4. Provide EVM direction and guidance to SUPSHIPs, in coordination with SEA 05C,

through the SUPSHIP Operations Manual (SOM) and other appropriate documents.

5. Promote consistent implementation of EVM practices across SUPSHIPs.

6. Act as an advocate for SUPSHIP resource requirements to meet requirements for

EVMS oversight functions.

7.3.5 SUPSHIP

SUPSHIPs serve as the CAO for contracts awarded to major shipbuilders under their

cognizance (see Contract Administration Services Directory (CASD)

). In accordance with

NAVSEAINST 7000.4H** and the DON EVMIG, SUPSHIP actions and responsibilities

include:

a) Support the PCO and program offices in determining and invoking EVM

requirements in solicitations and contracts.

b) Negotiate and execute an advance agreement or letter of acceptance between the

Government and the contractor specifying that the contractor will maintain and use

the contractor's accepted EVM system as an integral management process on the

current as well as future contracts.

c) Conduct EVM surveillance in accordance with reference (n),

NAVSEA SUPSHIP

EVMS Surveillance Operating Procedure (SOP)** (NAVSEA Fusion access

required).

d) Perform IPMR, IPMDAR, CPR, and Contract Funds Status Report (CFSR) analysis

and provide an independent EAC to the cognizant PM per the program office MOA.

Additional SUPSHIP support to the PM/PMO includes:

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

9

i. Participate in program office processes to support the development of

Program Manager EACs. Provide EVM analysis products to the program

office and other stakeholders per NAVSEA EVMS SOP and the program

office MOA. Support program managers in the development of data

requirements for cost reporting/EVM in new contracts or modifications to

existing contracts.

ii. Participate in IBRs for contracts under the cognizance of the Administrative

Contracting Officer (ACO).

iii. Review and analyze contractor IMS.

e) Support formal review and comment on cost reporting/EVM related data item

requirements, i.e., CDRLs, before issuance of solicitations and subsequent

modifications before or after contract award.

f) Maintain adequate documentation of certification and system surveillance activities to

ensure contractor EVM system compliance. The CAO will be the normal repository

for such information.

7.4 EVMS Guidelines Concept

EVMS guidelines were established on the premise that the Government cannot impose a

single EVMS for all contractors due to variations in organizations, products, and working

relationships.

The guidelines establish a framework within which an adequate integrated cost, schedule,

and technical management system fits. The EVMS guidelines are not prescriptive, but

simply describe the desired outcomes of integrated performance management.

The EVMS guidelines have been published as the EIA Standard 748, Earned Value

Management Systems. In August 1998 DoD adopted the guidelines of EIA-748 for

application to major defense acquisition programs. Industry periodically reviews the

standard, and the current Revision D was approved in January 2019 without change to the

basic guidelines. If the guidelines of the EIA-748 standard are changed or updated, DoD will

review and determine if the document still meets the Government’s requirements.

7.4.1 EVMS Guidelines

EVMS guidelines are intended to be objective and applicable to large, risky, cost-based

government programs. The purpose of the guidelines is to provide the contractor and the

Government with accurate data to monitor the execution of a program and to:

• Preclude the imposition of specific cost and schedule management control systems

by providing uniform evaluation guidelines to ensure contractor cost and schedule

management control systems are adequate.

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

10

• Provide an adequate basis for responsible decision-making by both contractor

management and DoD component personnel by requiring that contractors’ internal

management control systems produce data that:

o Indicate work progress

o Properly relate cost, schedule, and technical accomplishment

o Are timely, accurate, reliable, and auditable

o Provide DoD component managers with information at a practical level of

summarization

• Encourage DoD contractors to adopt management control systems and procedures

that are most effective in meeting requirements and controlling contract performance.

• Provide a baseline requirement against which industry standards, both national and

international, may be evaluated for authorization by Office of the Undersecretary of

Defense Office for Acquisition, Analytics and Policy (OUSD AAP) as substitutes for

DoD EVMS guidelines.

7.4.1.1 Key Attributes of EVMS

EVM systems that comply with EIA-748 facilitate:

• thorough planning of all program work scope to completion

• integration of work scope, schedule, and cost objectives into a single baseline plan

• baseline establishment at the beginning of the contract

• baseline control throughout the contract

• objective measurement of work accomplishment at levels where the work is being

performed

• summarized reporting for management decision-making

• early identification of problems and the corrective actions needed to mitigate the

resulting risk

• development of estimates of final technical, schedule, and contract costs

• visibility into subcontractor performance

7.4.1.2 EIA Standard 748 Guidelines

EIA 748 is composed of 32 EVMS guidelines grouped in the following five major categories:

• organization

• planning, scheduling, and budgeting

• accounting considerations

• analysis and management reports

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

11

• revisions and data maintenance

Refer to the EVMSIG

for a detailed description of the 32 guidelines.

7.5 EVM Overview

EVM is a program management tool that integrates technical, cost, and schedule parameters

to measure contract performance against a baseline plan. EVM provides SUPSHIP and the

PM with contractor cost, schedule, and performance information which:

• relates time-phased budgets to specific contract tasks

• objectively measures work progress

• properly relates cost, schedule, and technical accomplishments

• allows for informed decision-making and corrective action

• is timely, accurate, reliable, and auditable

• allows for statistical estimation of future costs

• supplies managers with status information at the appropriate level

• is derived from the same management systems used by the contractor to manage

the contract

7.5.1 Basic EVM Description

The basic requirements for effective implementation of an EVMS include:

1. Defining and organizing all work necessary to complete the project. This typically

includes determining the scope of work required by the contract and organizing it into

a Work Breakdown Structure (WBS).

2. Planning the work elements of the WBS to determine the time and estimated costs

required to perform the work.

3. Developing a project network that integrates the scope of work, schedule, and cost

objectives into a time-phased baseline plan that spans the duration of the project.

4. Defining Earned Value Techniques (EVTs) for measuring the accomplishment of the

WBS work elements. A variety of different EVTs may be applied within the same

EVMS based on the nature of the work.

5. Periodically determining the project’s earned value by applying the EVTs to each

work element and summing the earned value of all work.

6. Comparing the earned value to the baseline plan to determine cost and schedule

variances.

7. Analyzing significant variances to determine their cause, to forecast impact, and to

determine appropriate corrective action.

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

12

Refer to Appendix 7-A for a depiction of an EVMS chart and the associated EVMS

terminology.

7.5.2 Components and Processes of an Earned Value Management System

Implementation of EVMS for large-scale projects, such as the construction of Navy surface

ships and submarines, requires considerable contractor effort and rigorous application of

EVMS guidelines and processes if it is to provide accurate information concerning contract

performance. The following sections describe the components and processes commonly

found in an EVMS supporting major DoD programs.

7.5.2.1 Statement of Work (SOW)

The SOW for the program should reflect all work to be performed. The SOW communicates

the work scope requirements for a program and should define the requirements to the fullest

extent practicable. It is a basic element of control used in the processes of work assignment

and establishment of program schedules and budgets.

7.5.2.2 Work Breakdown Structure (WBS)

The WBS is a direct representation of the work scope defined in the program SOW. It is an

essential element of an EVMS used to provide the structure for identifying and categorizing

the work to be performed. It is a hierarchal breakdown of the material, services, and

operations that must be obtained or completed, by both government and commercial

activities, to achieve the objectives of an acquisition program. It provides the framework for

program and technical planning, cost estimating, resource allocation, performance

measurement, technical assessment, status reporting, and EVMS data collection and

reporting.

A preliminary top-level WBS is developed by the PM and systems engineering staff early in

the planning phase of acquisition programs utilizing reference (o), MIL-STD-881E

, Work

Breakdown Structures for Defense Materiel Items. The program WBS is included as part of

the solicitation and used by the successful contractor to develop a more detailed Contract

Work Breakdown Structure (CWBS), when required by data item description DI-MGMT-

81334D, which includes all product elements (hardware, software, data, or services) for

which the contractor is responsible. The WBS is structured to best manage and report on

program performance. Cost collection requirements, such as Cost and Software Data

Reporting (CSDR), may require a different reporting structure than the WBS used in the

EVMS for program management.

7.5.2.3 Contractor Program Organization

It is important for the organization to be defined at the onset of the program so that work

assignments are identified and responsibilities are clear. A company will organize as

required for the optimal management of its business. This includes decisions such as the

use of work teams or functional organizations and staffing by direct (project-oriented) or

matrix management. This process includes identification and coordination of subcontracted

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

13

work as well as internal efforts. A program organization is dynamic and may change as the

program evolves. This program organizational structure, commonly referred to as an

Organizational Breakdown Structure (OBS), is hereinafter referred to as an organizational

structure.

The organizational structure reflects the way the program is organized. To assign work

responsibility to appropriate organizational elements, any WBS and organizational structure

must be interrelated; that is, organizational responsibility must be established for identified

units of work. The assignment of lower-level work segments to responsible lower-level

managers provides a key control point for management purposes and cost collection. This is

called the control account (CA). A CA thus represents a defined work scope (with the

associated charge number or numbers) given to a single organizational unit (and single

manager or team leader) for work performance. EVMS guidelines require that a control

account is assigned to a single Control Account Manager (CAM) or team leader with

responsibility for managing that account.

When effort is to be subcontracted out, the applicable subcontractor is identified and related

to, or integrated with, the appropriate WBS element(s) and organization charged with

acquiring the subcontracted item.

7.5.2.4 Program Schedule

The program schedule is the time-oriented plan for accomplishment of work scope

requirements on a program. Schedule planning and control, along with work scope

definition, are necessary prerequisites for basic program management and effective cost

control. The scheduling process begins during original program definition, and overall

schedule plans are typically established during the pre-planning for a program.

For DoD acquisition programs, program scheduling takes the form of the Integrated Master

Plan (IMP) and the Integrated Master Schedule (IMS). The IMP and IMS provide a

systematic approach to program planning, scheduling, and execution. The primary purpose

of the IMP and its supporting detailed schedule, the IMS, is their use by the Government and

contractor team as day-to-day tools for planning, executing, and tracking program technical,

schedule, and cost status.

The IMP is an event-based plan consisting of a hierarchy of program events, with each event

being supported by specific accomplishments, and each accomplishment associated with

specific criteria to be satisfied for its completion. The IMP is normally part of the contract and

thus contractually binding. The IMP is a narrative explaining the overall management of the

program.

The IMS is an integrated, networked schedule containing all the detailed discrete work

packages and lower-level tasks or activities necessary to support the events,

accomplishments, and criteria of the IMP (if applicable). The events, accomplishments, and

criteria are duplicated in the IMS. Detailed tasks are added to depict the steps required to

satisfy the criterion. The IMS is directly traceable to the IMP and includes all the elements

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

14

associated with production, modification, and delivery of the end product. It must also be

traceable to the CWBS, the contract SOW, and the EVMS. Durations are entered for each

discrete work package and lower-level tasks, along with predecessor and successor

relationships for each schedule task. The result is a fully networked schedule that supports

critical path analysis.

During contract execution, the IMP and IMS provide a framework for insight into the

contractor’s performance. When properly integrated with EVMS, the IMP and IMS should

enable the Government and contractor to:

• identify and assess actual progress versus planned progress

• monitor the program critical path and help develop workarounds to problem areas

• assess program maturity

• assess the status of risk management activities based on the inclusion of the

program risk mitigation activities in the IMP and IMS

• assess the progress on selected Key Performance Parameters (KPPs) and

Technical Performance Measures (TPMs)

• provide an objective, quantitative basis for the contractor’s performance assessment

rating and award fee

• help develop and support “what-if” scenarios and to identify and assess candidate

problem workarounds

• provide better insight into potential follow-on efforts that were not part of the original

contract award, for example, the contractor should be able to more clearly define the

activities, new interfaces, and other clarifying information necessary for a potential

program increment or contract option

Refer to the

DoD Integrated Master Plan and Integrated Master Schedule Preparation and

Use Guide (21 Oct 2005), reference (p), for more detailed information on the IMP and IMS.

7.5.2.5 Budget Allocation and Resource Planning

Before work can proceed, scope and budget must be authorized to the responsible

organizations. The contractor’s PM is given an internal authorization to proceed with contract

work. Budgets and work scope then are divided among the program’s organizations via

formal work authorizations that communicate work assignments. All authorized work must

be associated with a corresponding budget. This provides a documented trail of work

authorization from the program office that clearly assigns program work requirements to the

responsible organizations.

The process of work authorization, the approvals necessary, and the form will vary based on

individual company policies and procedures. Work authorizations do not need to duplicate

the SOW or WBS dictionary and can refer to that document for work scope definition. Work

authorizations should describe the work to be performed in as much detail as needed for the

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

15

CAM to understand the work to be accomplished. The company will decide on the flow of

the work authorizations and the approvals that are needed. The authorizations may be

communicated electronically or on paper. Work authorizations must be issued, before work

is due to begin, for improved control and advance planning.

7.5.2.5.1 Establishing Control Accounts (CA) and Control Account Budgets

All CAs must contain a budget, schedule, and scope of work and should realistically

represent the manner in which work is assigned and budgeted to organizational units. A

resource plan must be developed for every CA and Summary Level Planning Package

(SLPP - see section below). The resource plan is the time-phased budget that is developed

in accordance with assigned work scope and schedule requirements.

Each CA is allocated a budget that reflects the resources necessary to complete the

assigned effort. Budgets established at the CA level must be planned by element of cost

and may be stated either in dollars, hours, or other measurable units. When units other than

dollars are used, the company must determine the appropriate point of responsibility in their

control system for rate application for financial analysis and reporting.

The rates used in determining budgets will also be used for computation of earned value

data. In general, the budget process should provide for:

• direct budgets allocated to organizations performing the planned work

• indirect budgets allocated to specific organizations having responsibility and authority

for controlling indirect costs

• identification of any Management Reserve (MR) or Undistributed Budget (UB)

7.5.2.5.2 Performance Measurement Baseline (PMB)

The assignment of budgets to scheduled segments of work produces a plan against which

actual performance can be measured. This is called the Performance Measurement

Baseline. The PMB is a time-phased summation of:

• all Control Accounts (CA)

• Summary Level Planning Packages (SLPP)

• applicable indirect budgets

• any Undistributed Budget (UB)

CAs may include both Work Packages (WP) and Planning Packages (PP). A work package

is simply a task, activity, or grouping of work that has been planned and budgeted. A

Planning Package is a budget holding account within a CA for future work for which it is not

yet practicable to plan the work at the work package level.

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

16

Indirect costs (or overhead) consist of those costs for common or joint objectives that are not

readily subject to treatment as direct costs. Indirect budgets are the budgeted indirect (or

overhead) costs associated with CAs, SLPP, and Undistributed budgets.

Summary Level Planning Packages are employed when it is impractical to plan authorized

work in CAs. An SLPP may be used to establish a high-level holding account for a budget

that is identified to some work scope, but which is not yet allocated to a CA. Budget and

work should be identified to higher WBS or organizational levels for subdivision into CAs at

the earliest opportunity, and certainly before the work actually begins. Because an SLPP is

associated with specific work scope, it should not be confused with a Management Reserve

(MR) or Undistributed Budget (UB).

It should be noted that PMB includes only the budgeted amount associated with specific

scope. For this reason, MR is not included in the PMB because it is an amount withheld

from the total budget for management control purposes and is not designated for the

accomplishment of specific work. UB is included because it is a temporary holding account

for specific work scope that has not yet been planned in detail at the CA or SLPP level.

An effective PMB possesses the following attributes:

• accurately represents all authorized work, and only authorized work, on the contract

• includes a realistic network schedule baseline

• includes a realistic time-phased distribution of budget/resources to the baseline

schedule

In addition to these attributes, an effective PMB requires a consistent commitment from both

the contractor and the Government to enforce proper baseline change procedures and

periodic review of the remaining baseline to ensure that it remains executable.

7.5.2.5.3 Integrated Baseline Review (IBR)

The IBR is a joint assessment led by the PM and supported by SUPSHIP and the contractor

to verify the realism and accuracy of the PMB. This involves verifying the technical content

of the baseline and assessing the realism and accuracy of the related resources. The IBR is

a tool that should be used as necessary throughout the life of the contract. Key benefits of

the IBR are:

• joint understanding of program risks

• management insight into the planning assumptions and the resource constraints of

the baseline

• comparison of expectations so that any differences can be addressed early in the

planning phase

• correction of baseline planning errors and omissions

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

17

• in-depth understanding of developing variances and improved early warning of

significant variances

• targeting of resources to address challenges and mitigate risks

• mutual commitment by the joint team to manage to the baseline

• more executable programs

7.5.2.5.3.1 IBR Policy and Guidance

Table 9 of DoDI 5000.02T

requires the PM and technical staff to conduct an IBR on any

contract requiring EVM compliance. FAR 34.202 also discusses IBRs. Occasions for the

government to require integrated baseline reviews include:

• as early as practicable, and no later than 180 days after contract award

• after the exercise of significant contract options

• with the incorporation of major modifications or as otherwise agreed upon

IBRs are also performed at the discretion of the PM or when major events occur within the

life of a program. These events may be a significant shift in the content and time-phasing of

the PMB. An IBR should also be conducted whenever an Over Target Baseline (OTB) or

Over Target Schedule (OTS) is implemented.

Refer to the DON EVMIG for more detailed information regarding the IBR. Additional

guidance is also contained in a guide prepared by a joint DoD/NDIA team, the

Program

Manager’s Guide to the Integrated Baseline Review Process (4 Jun 2003), reference (q).

While this is not a detailed how-to guide, it does describe the key attributes of the IBR and

establishes a framework for improving the consistency of the IBR across DoD.

7.5.2.6 Accounting Considerations

An EVMS itself is not an accounting system. It does, however, rely on actual cost data from

the contractor’s accounting system for accurate reporting of program costs and

measurement of contract performance. The establishment of work orders and other aspects

of the accounting process must be coordinated with the establishment of CAs and other

aspects of the budgeting process so that direct comparison and analysis can be performed.

The accounting system must be capable of accounting for all resource expenditures on an

"applied" basis (i.e., on an "as-used" or "as-consumed" basis). This requirement is fairly

straightforward in the categories of direct labor (where timecards or other time measurement

devices are used) or other direct charges (where services are typically charged on a per-unit

basis, such as per man-hour of direct effort).

Acceptable costing techniques should be used to fully account for all material purchased for

the program. To ensure effective performance measurement of material takes place, the

contractor’s accounting system should accurately accumulate material costs to the

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

18

appropriate CA. Where actual costs are not available in a timely manner, estimated costs

should be applied and adjustments made when actual costs are available.

7.5.2.7 Earned Value Techniques

There are several basic earned value techniques applicable to discrete work package efforts

(efforts with definable scope and objectives that can be scheduled and on which progress

can be objectively measured). Three basic techniques are:

• weighted milestones

• standard hours

• management assessments (only when these objective techniques are not feasible)

There are many variations and combinations of these techniques. Also, quantitative

formulas may be used to compute earned value for cases such as work in progress or

inventory materials. These formulas, such as the Program Evaluation Review Technique

(PERT) method for material, can cause data distortions, e.g., overstated Budgeted Cost for

Work Performed (BCWP), if not properly maintained. While this technique may be

appropriate for small value consumables, it is not an acceptable technique for performance

measurement of high-value material that can be treated as discrete material items.

The valued milestone technique involves the assignment of budget to specific work

objectives (milestones). That value is earned as the milestones are completed. It is

important for the milestones to be natural and meaningful points of accomplishment.

The use of standard hours technique (“equivalent units” is a similar process) is common in

manufacturing accounts. Budget is time-phased in relation to the standard hour plan and

should reflect the actual physical accomplishment of tasks within the work package. Earned

value is accrued in proportion to the standard hour status as earned standards are

sold/credited in the shops.

Management assessment may be used to determine the percentage of work completed for a

task or group of tasks only when an objective technique to determine the percentage is not

feasible. Earned value is then calculated by applying that percentage to the total budget for

the work. Management assessment may include the use of metrics for work measurement.

Durations for these work packages should be kept short to minimize any distortions caused

by their subjective nature.

The objective earned value techniques (valued milestones or standard hours) are always

preferred, but each technique has its own merits, and a company should use the most

objective techniques that best suit its management needs.

For short duration work packages (i.e., those of two months duration or less), other earned

value techniques are acceptable, such as 0/100 and 50/50. In the 0/100 technique, 100% of

the budget may be reported as earned when the work package is closed. In the 50/50

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

19

technique, 50% of the budget is earned when the work package is started, and the remaining

50% is earned when the WP is closed.

7.5.2.7.1 Planning and Control of Level of Effort Activities

Level of Effort (LOE) is work scope of a general or supportive nature for which performance

cannot be measured or is impractical to measure. Resource requirements are represented

by a time-phased budget scheduled in accordance with the time the support will likely be

needed. For discrete WPs, accomplishment can be measured based on the completed

pieces of work, but LOE is "measured"' through the passage of time. Since the earned value

for LOE is equal to the budget for the same time period, the performance data provided is

simply a comparison of budgeted to actual cost.

LOE activity should be separately identified from discrete work packaged effort to avoid

distorting that which is measurable. Some general guidelines for LOE are:

• The amount of LOE activity will vary among performing organizations, but it should

be held to the lowest practical level.

• LOE budgets should be separately substantiated and planned as direct labor,

material/subcontract, or other direct costs. LOE activity should be budgeted on a

time-phased basis for control and reporting purposes.

• When LOE and discrete effort are mixed within the same CA, the CAM must ensure

visibility into the performance of the discrete effort.

• LOE may be replanned if the work will not occur when planned or will slip past

planned (not contract) milestones. This avoids artificial cost variances.

7.5.2.8 Performance Measurement and Analysis

Earned value is a direct measurement of the quantity of work accomplished. Earned value is

a value-added metric that is computed based on the resources consumed compared to the

accomplished work scope.

Earned value analysis evaluates program performance and facilitates problem identification

for more effective management action. It also permits segregating schedule and cost

problems for early and improved visibility of program performance. Management actions will

typically involve lower-level analysis of problems and implementation of corrective actions to

restore or improve contract performance. Continued EV analysis permits analysis of these

corrective actions to assess their effectiveness.

See Appendix 7-A

for a graphical representation of EVMS terms and performance

measurements.

7.5.2.8.1 Significant Variances

Reasonable selection criteria should be established to ensure proper analysis of significant

problems and not cause an excessive burden on the CAM and mid-level managers. The

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

20

selection criteria should ensure all significant variances are analyzed, and any external

reporting requirements are supported. Although the frequency and nature of external reports

are dictated by the contract, the frequency and style of reports for internal management is a

company option. Unless otherwise specified in contracts, standardized reports and formats

may be used for customer reports on subcontracts or Government contracts per mutual

agreement, provided that the applicable IPMR, IPMDAR, and CPR formats are submitted

using the applicable DoD-approved XML or JSON data formats to the

EVM Central

Repository (EVM-CR).

7.5.2.8.1.1 Schedule Variance (SV)

Comparing the earned value (the budgeted value of work accomplished) during a given

period to the planned value (the budgeted value of work scheduled) during the same period

provides a valuable indication of schedule status in terms of the dollar value of work

accomplished. It represents the quantity, i.e., the value, of the work that is ahead of or

behind schedule. In essence, it is an “accomplishment” variance.

Although the SV metric provides early insight into detail schedule conditions and overall

schedule performance, it should not be the sole source for determining the contractor’s

performance to schedule. Schedule variance does not clearly indicate whether scheduled

milestones are being met since some work may have been performed out of sequence or

ahead of schedule. Neither does SV indicate whether a completed activity is a critical event

or if delays in an activity's completion will affect the completion date of the contract. A formal

time-phased scheduling system, therefore, must be used to provide the means of

determining the status of specific activities, milestones, and critical events. Additionally,

other techniques, such as critical path analysis, may be better indicators of long-range time

projections. However, a trend analysis of the changes in the SV metric can provide a valid

and useful indication of current performance and near-term projections, as well as early

identification of incipient cost problems.

7.5.2.8.1.2 Cost Variance (CV)

Cost performance is determined by comparing the actual cost of the work accomplished to

the earned value for the same work scope, i.e., the budgeted cost of the work accomplished.

The resultant metric is the Cost Variance (CV). The CV is a true measure of cost

performance as it compares the actual cost incurred to the value of work accomplished. It

thus eliminates the distortions inherent in a simple comparison of actual costs to a total

budget.

Analysis of this difference reveals the factors contributing to the variances. These may

include:

• poor initial estimate for the task

• technical difficulties that require additional resources

• cost of labor or materials different than planned

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

21

• differences between planned and actual rates

• incorrect or inadequate selection of the earned value technique

• personnel efficiency different than planned (rate analysis and analysis of prime costs,

i.e., labor hours, may be segregated to isolate rate changes and efficiency factors)

Variance At Completion (VAC) represents the amount of expected overrun (negative VAC) or

under-run for the contract. It can be determined by taking the difference between the Budget

At Completion (BAC) and the EAC [VAC = BAC – EAC]. Because it can be calculated at the

CA level, in addition to the total contract level, it can serve as a useful metric for focusing

management attention on the sources of cost performance problems. While this

performance analysis involves examination of what has occurred, the focus should be on the

control of current actions and assessment of future plans. The assessment of future plans

should project when the remedial actions will be completed and its impact on schedule and

EAC.

7.5.2.9 Estimates at Completion (EAC)

An EAC is determined by estimating the cost of the remaining work, or Estimate To

Complete (ETC), and adding it to total costs incurred to date. A comprehensive EAC should

be periodically developed at the CA level using all available information to arrive at the best

possible estimate. This is done by:

• evaluating the efficiency achieved by performing organizations for completed work

and comparing it to remaining budgets

• establishing a schedule forecast that reflects the expected timeframe for completing

the remaining work

• considering all remaining risk areas on the program versus cost avoidance

possibilities

• ensuring the most current direct and indirect rate structure is used to value the

projected resources

• applying this analysis to future efforts to derive the most accurate estimate

The EAC should be the most likely estimate of the total costs for all authorized program

efforts and should be time-phased in accordance with the expected completion dates on

program schedules. The basis for the EAC and the reasons for changes from the last

estimate should be identified.

Comparisons of this estimate to budgets for the associated effort must be made frequently

enough for management to ensure program performance and resource availability will not be

adversely impacted. Monthly maintenance of the CA level EAC by the CAM ensures that the

EAC continuously reflects a valid projection of program costs.

The schedule for establishment and maintenance of EAC data depends on program

management needs and overall company or corporate financial review requirements. A

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

22

company should conduct periodic comprehensive EAC reassessments at least annually.

Alternatively, a company should establish an ongoing process of EAC review and

maintenance. In either case, significant EAC changes should be incorporated whenever

they are identified.

7.5.2.10 Revisions and Data Maintenance

Changes in major programs are inevitable. This discussion addresses the controlled

process whereby programs incorporate formal changes, conduct internal replanning, and

adjust past, present, and future information to accommodate changes. The key is timeliness

and control. The budget will change as contract changes are authorized and incorporated or

as internal replanning actions are taken. Rate changes and economic price adjustments

may also be made as appropriate. Changes to budgets in the current or past accounting

periods should only be made for the correction of errors or the effects of contract negotiation.

Revisions to program plans must be carefully controlled. The PMB should reflect the current

program management plan for accomplishment of program objectives. It must be up-to-date

and should include all authorized changes. It is equally important that unauthorized changes

are not introduced. Incorporating changes should not precipitate the elimination of existing

cost and schedule variances (sometimes referred to as “single point adjustments”). If the

maintenance of baseline plans is compromised, the value of information on management

reports will be degraded.

7.5.2.10.1 Customer-Directed Changes

Customer-directed changes to the program can impact virtually all aspects of the internal

planning and control system, such as organization structures, work authorizations, budgets,

schedules, and EACs. The incorporation of authorized changes should be made in a timely

manner and strictly controlled. This will ensure the PMB can be accurately maintained.

7.5.2.10.2 Traceability to Previous Budgets

The original budget established for the program should constitute a traceable basis against

which program growth can be measured. The starting point or base on which these original

budgets are built is the program target cost. This value increases or decreases only as a

result of authorized changes. For definitized changes, the program target cost changes by

the negotiated amount. For authorized work that has not been negotiated, or authorized

unpriced work (AUW), the program target cost increases by the amount of cost estimated for

that effort. After negotiations, the program target cost is adjusted to reflect the negotiation

results. Adequate records of all changes should be maintained to provide the basis for

reconciliation back to the original budgets assigned during the baselining process.

7.5.2.10.3 Control Internal Changes to the PMB

Future plans may significantly vary from the original baseline, and the PM may choose to

realign scope, schedule, or budget. Some examples of when it may be appropriate to do

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

23

internal replanning, i.e., within the program target cost or approved Total Allocated Budget

(TAB), include:

• changes resulting from a Preliminary Design Review (PDR) or a Critical Design

Review (CDR) that modify future requirements

• a major shift in the resource profile to accomplish the remaining effort

• funding restrictions or modifications that affect future resource availability

• rate changes that are significant enough to warrant replanning

Internal replanning is intended for in-scope changes to future budgets. The objective of

internal replanning is to reflect a revised program plan. Changes to near-term effort

(scheduled to start in the next accounting period) must be minimized.

Changes in the funding projections for a program may affect both the schedule and the cost

for a program. The movement of budget to meet a new funding profile requires a

reassessment of the schedule for the associated work. There may also be cost impact due

to rate differences in the affected time periods.

7.5.2.10.4 Over Target Baseline (OTB) and Over Target Schedules (OTS)

During contract execution, the contractor may conclude that the budget or schedule for

performing the remaining work is decidedly insufficient and no longer represents a realistic

plan. At this point the contractor should prepare and submit a request to implement an OTB

or OTS.

An OTB is a PMB that has been formally reprogrammed to include additional performance

management budget in excess of the contract’s negotiated cost. An OTB increases the

performance budget without modifying the work scope or other constraints of the contract.

An OTS condition is created when the contractor re-plans the schedule to one that exceeds

the contract milestones or delivery dates. This new schedule also becomes the basis for the

performance budgets. While it is possible to have an OTS without a corresponding increase

in cost, normally an OTS is accompanied by increased costs and therefore by an OTB.

Implementing an OTB or OTS is a major management decision for the contractor and

requires government approval at the start of the process. Consequently, the PM should fully

understand the concepts and processes. The PM should consider the factors discussed in

section 2.5.2.4 of the DON EVMIG

when considering whether an OTB or OTS is appropriate

for the contract and when evaluating the contractor’s request.

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

24

7.6 Contract Requirements

7.6.1 Evaluation

Evaluation of the contractor proposed EVMS is normally undertaken as part of the proposal

evaluation process. This evaluation is an assessment to determine if the contractor’s system

meets the EIA-748 guidelines.

7.6.2 Contract Award

The contract award phase is primarily a Procuring Contracting Officer (PCO)/Program Office

function that would include SUPSHIPs upon request. DFARS 252.234-7001

is the provision

that provides Notice of EVMS and is included in the RFP for contracts that meet EVM

application requirements. The offeror will either assert that the ACO has determined their

EVMS to be acceptable or will provide a comprehensive plan for compliance with the EIA-

748 guidelines. In accordance with

DFARS PGI 234.201(2), the PCO shall obtain the

assistance of the ACO in determining the adequacy of an EVMS plan that an offeror

proposes for compliance with the EIA-748.

When EVM is required in a contract, the following sections of the contract will include EVM

related requirements:

• Section C - Includes EVM in Statement of Work

• Section I - Includes EVMS FAR and DFARS Clauses

• Section J - Includes EVMS Data Items

o Integrated Program Management Report (IPMR)

o Integrated Program Management Data Analysis Report (IPMDAR)

o Contract Performance Report (CPR)

o Contract Work Breakdown Structure (CWBS)

• Section L - Includes EVMS descriptions in proposal

• Section M - Includes EVMS as an evaluation factor

The SOW tasks, FAR/DFARS contract clauses, and the CDRL items require the contractor

to:

• use and maintain an EVMS that meets the EIA-748 guidelines

• notify the Government of any EVMS changes

• provide the Government with access to EVMS pertinent records and data

• require EVMS on selected subcontractors

• support a Government – Contractor IBR

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

25

7.6.3 Post-Contract Award

Although the DON EVMIG describes a variety of post-contract award activities, including

functions associated with contract administration, delivery, and contract closeout, the five

primary EVM elements associated with post-contract award are:

• Contract Award Review/Contract Implementation Review

• EVM System Validation

• EVM System Surveillance

• Integrated Baseline Review

• Program Management Reviews

7.6.3.1 EVMS System Validation

DoD policy requires EVMS validation for all DoD EVM contracts of $100 million or greater.

For shipbuilding contracts, this responsibility would typically fall on DCMA. Once a

contractor’s EVM system is validated, it may be applied to other contracts with EVMS

requirements. EVMS validation determines that the EVMS:

• meets the intent of the EIA-748 guidelines

• is being used appropriately on the contract

7.6.3.2 Integrated Baseline Review (IBR)

The IBR is a joint risk assessment of the EVM PMB conducted by the Government PM,

SUPSHIP, and the contractor. DoD acquisition policy and NAVSEAINST 7000.4H

** require

PMs to conduct IBRs on EVM contracts:

• within six months of contract award

• upon exercise of significant contract options

• upon incorporation of major modifications

• as otherwise agreed

7.6.4 Deficiencies in Validated EVM Systems

Deficiencies may be uncovered either in the EVM system processes or in the consistency

and discipline of the validated processes. These deficiencies may be discovered during

routine surveillance or during analysis of performance data. SUPSHIP should notify and

consult with the PCO and EVMSS (SEA05C) if major deficiencies are identified.

DON

EVMIG, section 2.3.6, provides additional information regarding the process for correcting

deficiencies and restoring compliance. This process is designed to provide the contractor an

opportunity to correct deficiencies prior to formal withdrawal of the company’s EVMS

validation.

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

26

The contractor's EVMS is considered to be a contractor business system as defined by

DFARS. Qualifying contracts should include clauses 252.234-7002

Earned Value

Management System and 252.242-7005 Contractor Business System. These clauses require

the contractor to establish and maintain acceptable business systems in accordance with the

terms and conditions of the contract. If a business system is found to have a significant

deficiency, these clauses permit the withholding of contract payments. See SOM section

3.18 for more information.

Refer to NAVSEA letter Ser 022/007 - Contractor Business Systems Guidance of 28 Nov

2018** (NAVSEA Fusion access required), reference (r), and the NAVSEA SUPSHIP EVMS

Surveillance Operating Procedure (May 2020)** (NAVSEA Fusion access required) for more

information on SUPSHIP oversight of contractor EVM systems. Note that per reference (q),

DCMA is the Cognizant Federal Agencies (CFAs) with audit responsibilities for contractor

EVM systems.

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

27

Appendix 7-A: Graphical Representation of EVMS Terms

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

28

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

29

Appendix 7-B: Glossary

Actual Cost – The costs incurred and recorded in accomplishing work performed.

Actual Date - The date on which a milestone or scheduled work task is completed.

Apportioned Effort – Effort that by itself is not readily measured or divisible into discrete work

packages, but which is related in direct proportion to the planning and performance on other

measured effort.

Authorized Unpriced Work – The value of authorized work on the contract that has not yet

been definitized.

Authorized Work – Effort (work scope) on contract or assigned by management.

Budget At Completion (BAC) – The total authorized budget for accomplishing the program

scope of work. It is equal to the sum of all allocated budgets plus any undistributed budget.

Management Reserve is not included. The BAC will form the Performance Measurement

Baseline as it is allocated and time-phased in accordance with program schedule

requirements.

Contract Budget Base (CBB) – The Negotiated Contract Cost (NCC) plus the cost of any

authorized unpriced work.

Control Account – A management control point at which budgets (resource plans) and actual

costs are accumulated and compared to earned value for management control purposes. A

control account is a natural management point for planning and control since it represents

the work assigned to one responsible organizational element on one program work

breakdown structure element.

Cost Variance – A metric for the cost performance on a program. It is the algebraic

difference between earned value and actual cost (Cost Variance = Earned Value – Actual

Cost). A positive value indicates a favorable position and a negative value indicates an

unfavorable condition.

Critical Path – In a schedule network, the sequence of discrete work packages, planning

packages, and lower-level tasks and activities in the network that has the longest total

duration through to a milestone (e.g., critical path to undocking) or to project completion.

Direct Costs – The costs of resources expended in the accomplishment of work which are

directly charged to the affected program.

Discrete Effort – Tasks that are related to the completion of specific end products or services

and can be directly planned and measured. (May also be known as work packaged effort.)

Due Date – The date by which a milestone or task is scheduled to be completed.

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

30

Earned Value – The value of completed work expressed in terms of the budget assigned to

that work.

Estimate At Completion (EAC) – The current estimated total cost for program authorized

work. It equals the actual cost to a point in time plus the estimated costs to completion

(Estimate To Complete).

Estimate To Complete (ETC) – Estimate of costs to complete all work from a point in time to

the end of the program.

Estimated Completion Date (ECD) – The date on which a scheduled milestone or task is

currently expected to complete.

Estimated Cost – An anticipated cost for specified work scope.

Indirect Cost – The cost for common or joint objectives that cannot be identified specifically

with a particular program or activity. Also referred to as overhead cost or burden.

Internal Replanning – Replanning actions for remaining work scope. A normal program

control process accomplished within scope, schedule, and cost objectives of the program.

Level of Effort – Unmeasured effort of a general or supportive nature usually without a

deliverable end product. Examples are supervision and program administration.

Management Reserve – An amount of the total budget withheld for management control

purposes rather than being designated for the accomplishment of a specific task or set of

tasks.

Milestone – A schedule event marking the due date for accomplishment of a specified effort

(work scope) or objective. A milestone may mark the start, an interim step, or the end of one

or more activities.

Near Critical Path – In a schedule network, a sequence of lowest float or slack paths of

discrete work packages, planning packages, and lower level tasks and activities that has the

longest total duration nearest to the critical path.

Network or Network Schedule – A schedule format in which the activities and milestones are

represented along with interdependencies between activities. It expresses the logic of how

the program will be accomplished. Network schedules are the basis for critical path analysis,

a method for identification and assessment of schedule priorities and impacts.

Organizational Structure – The hierarchal arrangement for the management organization for

a program, graphically depicting the reporting relationships. The organizational structure will

be by work team, function, or whatever organization units are used by the company.

Other Direct Costs – Usually the remaining direct costs, other than labor and material, such

as travel and computer costs.

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

31

Over Target Baseline (OTB) - Replanning actions involving the establishment of cost or

schedule objectives that exceed the desired or contractual objectives of the program. An

OTB is a recovery plan, a new baseline for management when the original objectives cannot

be met and new goals are needed for management purposes.

Over Targe Schedule (OTS) - A replanned schedule baseline that extends beyond the

contract milestones or delivery dates. An OTS is usually accompanied by an increase in

budgets resulting in a corresponding Over Target Baseline (OTB).

Performance Measurement Baseline – The total time-phased budget plan against which

program performance is measured. It is the schedule for expenditure of the resources

allocated to accomplish program scope and schedule objectives and is formed by the budget

assigned to control accounts and applicable indirect budgets. The Performance

Measurement Baseline also includes budget for future effort assigned to higher work

breakdown structure levels (summary level planning packages) plus any undistributed

budget. Management Reserve is not included in the baseline as it is not yet designated for

specific work scope.

Performing Organization – The organization unit that applies resources to accomplish

assigned work.

Planned Value – The budgeted value of the scheduled work.

Planning Package – A logical aggregation of work, usually future efforts that can be identified

and budgeted, but which is not yet planned in detail at the work package or task level.

Program Budget – The total budget for the program including all allocated budget,

management reserve, and undistributed budget.

Program Target Cost – The program cost objective based on the negotiated contract costs,

or the management goal value of the authorized work, plus the estimated cost of authorized

unpriced work.

Resource Plan – The time-phased budget which is the schedule for the planned expenditure

of program resources for the accomplishment of program work scope.

Responsible Organization – The organizational unit responsible for the accomplishment of

assigned work scope.

Schedule – A plan that defines when specified work must be done to accomplish program

objectives on time.

Schedule Traceability – Compatibility among schedule due dates, status, and work scope

requirements at all levels of schedule detail (vertical traceability) and between schedules at

the same level of detail (horizontal traceability).

S0300-B2-MAN-010 Rev 2, Chg 32 Chapter 7, 14 January, 2021

SUPSHIP Operations Manual (SOM) EVM Conference & CBS Changes

** Denotes hyperlink requiring CAC/NMCI access

7

-

32

Schedule Variance – A metric for the schedule performance of a program. It is the algebraic

difference between earned value and planned value (Schedule Variance = Earned Value –

Planned Value). A positive value is a favorable condition while a negative value is

unfavorable.

Statement of Work (SOW) – The document that defines the work scope requirements for a

program.

Total Allocated Budget – The Contract Budget Base (CBB) plus any amount of OTB that has