installation instructions

Smart Slide Door

Contents

Page No.

Introduction……………………………………………………………….1

Important Instructions…………………………………………………….1

Materials and Tools Required…………………………………………....2

Rough Openings………………………………………………………….. 2

Terminology……………………………………………………………….3

Sealant Joint Placement………………………………………………….. 4

Smart-Slide Door Install- Fixed Sash Jamb - Outside …...........….….. 7

Smart-Slide Door Install - Fixed Sash Sill - Outside ………..………... 8

Protective Film Handling………………………….…………………….. 5

EUROLINE

Windows

1

© EuroLine Windows Inc

Instructions Rev. 3 2022

Important

Leaving tightly spaced

windows/doors in the sun can result

in overheating of the sealed units and

extrusions, which may result in

damage. Ensure that product is

secured to a wall to prevent any

damage

Important

Improper installation may void all

warranties expressed or implied.

Installation Instructions are also

available on our website.

Contact Information

EuroLine Windows Inc.

7620 MacDonald Road,

Delta BC V4G 1N2

Telephone: 604-940-8485

Fax: 604-940-8486

Toll-Free: 1-800-337-8604

Web Site: 1-800-337-8604

Introduction

Important Instructions

Please read before you start installation

RECEIVING:

Carefully inspect all windows and doors at the time you receive them and

again at the time you install them. Any visible defects with the product must

be reported to EuroLine before installation begins.

HANDLING:

Window and door units are to be handled carefully to avoid damage. They

must be moved in the vertical position. If the product is supplied with a

flange it must rest on shipping blocks that are temporarily attached.

COLD WEATHER CAUTION: Use special care when handling or

installing below 5° C (40°F). Avoid any impact to frames, sash, or glazing

beads.

STORAGE:

Store the units at a slight lean against a wall on a flat, level area, undercover.

Allow adequate spacing between the products for ventilation.

BUILDING CODES:

It is the responsibility of the owner, architect, or builder to select and install

products in compliance with applicable laws, regulations, and building

codes.

BUILDING ENVELOPE:

To minimize the danger of leakage at window openings, various other items,

such as properly configured head flashings, perimeter penetration flashings,

sealant joints, building wraps, and similar components, are of critical

importance. Typically, some of these components need to be installed prior

to the window installation, while others must follow the window installation.

The specific configurations of such flashings and similar components are

dependent on the specific wall construction and assembly and should be

determined by the project architect, a building envelope specialist, or a

similar design professional. This manual does not address such items, and

EuroLine is not responsible for the proper design or installation of these.

INSTALLATION:

Proper installation is necessary for this window or door to perform as

designed and rated for water and air resistance. EuroLine products must be

installed plumb, level, and square.

SHOP DRAWINGS:

If you have EuroLine shop drawings, refer to these for specific installation

instructions.

EUROLINE

Windows

2

© EuroLine Windows Inc

Instructions Rev. 3 2022

CARE AND MAINTENANCE:

Protect windows/doors from welding splatter, grinding sparks, concrete,

mortar, stucco, paint, and other harmful construction materials. To clean

vinyl, use a mild soap and water solution. To clean the glass, use a soft, grit-

free cloth and glass cleaner. On all operable windows and doors, keep the

channel at sill free of debris and protect sills from traffic damage. Keep all

weep holes open for proper drainage. The protective film must be removed

on completion of installation. Clean and lubricate all hardware after

construction. Ongoing maintenance and adjustments are described in our

maintenance manual, available by contacting our sales office or visiting our

website.

PERFORMANCE DATA:

Our products are tested to ASTM test standards, CSA A440 Standards, and

are NFRC certified for thermal performance. Data is available upon request.

Materials and tools

Tools Materials

- Spirit level - Shims: use non-deteriorating,

- Framing hammer non-swelling, hard plastic (4"x1 ½ ")

- Screwdriver/screw gun of several thicknesses to suit. Shims

- Tape measure may be purchased from Euro-Line

- 11 mm wrench Windows in thickness of 2,3,4,5, and

- 4 mm Allen key 6 mm.

- 2” Gal

vanized Roofing Nails (10 ½

ga.)

-1 ½” #

10 Pan Head Tapping Screws

(cad plate

d)

Rough Openings

Make sure that the rough openings are square, and that they have a level sill

and plumb (vertical) jambs. Make sure that the outside face of the wall is

straight and plumb. If a rough opening is out-of-square, adjust the thickness of

the shim blocks as necessary to make sure that you install the window or door

frame in a square, level and plumb way.

If you see any rough openings that are not acceptable for frame installation,

tell the general contractor or the party responsible for the construction. Get

written authorization from the general contractor or from the responsible

party before you install frames in unacceptable openings.

EUROLINE

Windows

3

© EuroLine Windows Inc

Instructions Rev. 3 2022

Make sure that the general contractor corrects the rough opening if you find the

rough opening does not allow you to install the frame perfectly level, square,

straight in every direction and plumb, and does not provide a minimum of 3/8"

(10 mm) and no larger than 1/2" (12 mm) clearance between the top of the

frame and the top of the rough opening.

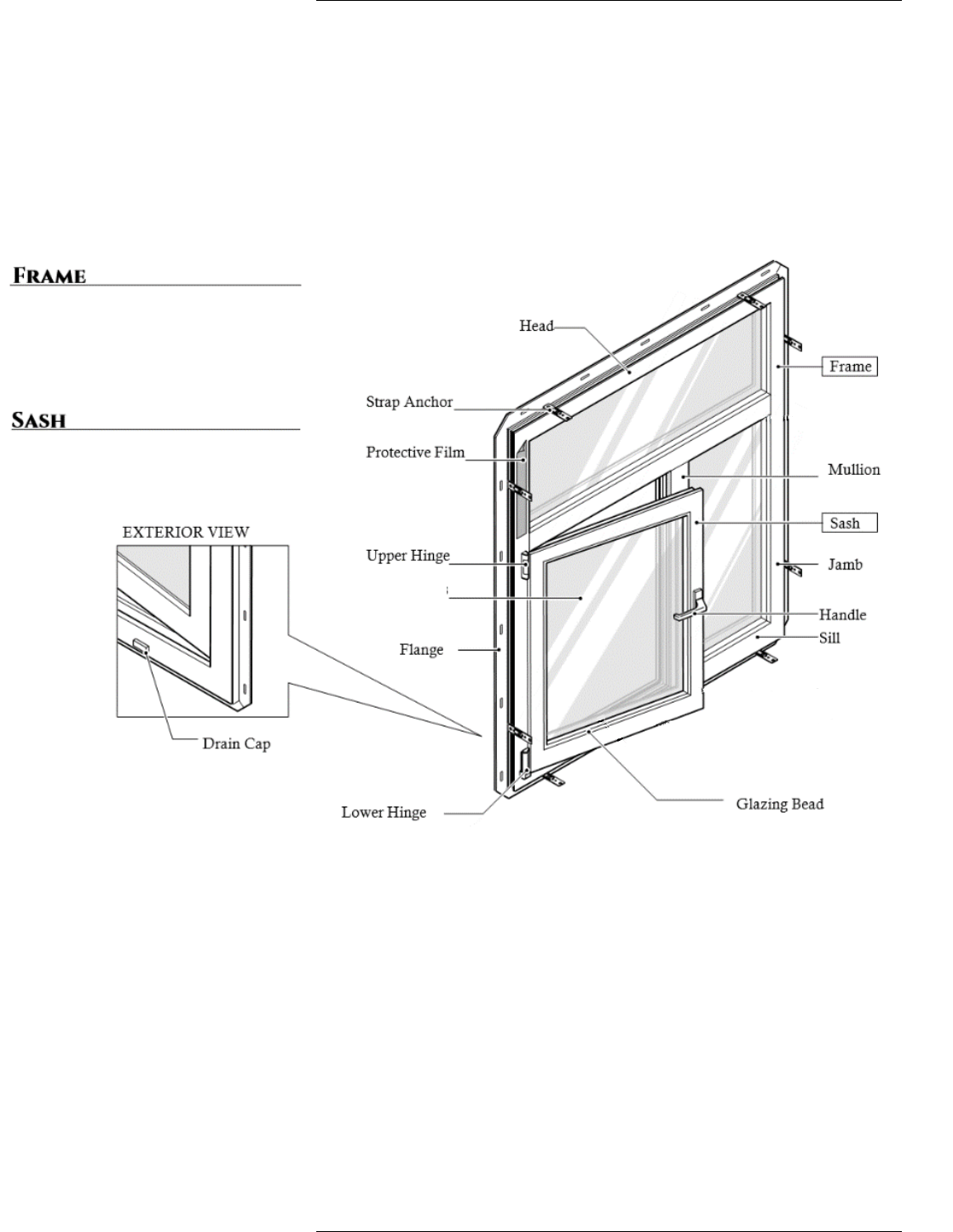

turn window

The fixed parts of the window or door.

The frame includes the head, jambs, sill,

and mullions. The frame does not include

the sash.

The movable part of the window or door.

Sealed Unit

Terminology of tilt & turn window

EUROLINE

Windows

4

© EuroLine Windows Inc Instructions Rev. 3 2022

Sealant Joint Placement

Sealants – Important Notes

Design of sealant joints and the selection of sealants are not the responsibility

of Euroline Windows. Sealants must be compatible with the window

materials to which they adhere. Check with your sealant supplier that the

sealant is compatible with the uPVC, the laminate covering the uPVC, metal

surfaces, caulked surfaces, or any other material of the window system to

which you plan to have a sealant joint.

If you are unsure as to the material composition of the window, contact

EuroLine Windows for more information.

The placement of the sealant joint must be located as shown on the cross-

sections below (location “A”). Care must be taken not to bridge the closeout

strip, or impede water exiting the drains on the face of the frame at the sill.

The same practice applies to other frames that are not included below.

CAUTION:

The close-out strip is not designed for air and water tightness.

To ensure an air and water seal, joint placement is as shown in

one or more of the locations shown “A”.

The sealant joint must be 7/8” (22mm) below drain caps on the

sill.

EUROLINE

Windows

5

© EuroLine Windows Inc Instructions Rev. 3 2022

Considerations

PFG Protective Film has been tested for

resistance to chemicals commonly found in

building and window manufacturing. These

include, but was not limited to:

- Resistance to water and air based

stains

- Paints and varnishes

- Adhesives

- Sealants

- Cement

- Stucco and brick wash solution

(muriatic acid) 20 to 1 dilution

Note

The above list is not an exhaustive. The

chemical makeup of products can be

reformulated over time. If in doubt, test for

exposure compatibility. Exposure to any

chemicals should be kept to a minimum.

Buckling of film may occur if environmental

or situational temperatures exceed 60ºC.

Protective Film Removal

PFG Protective Film protects glass surfaces against damage during shipping,

handling, and damage caused by other trades during construction. This clear

protective film can be applied to the outboard surface #1 or in combination with

surface #4 of dual IGUs, or surface #6 for triple IGUs.

Timeline for Removal

PFG Protective Film applied to the outboard surface #1 should be removed

within 9 months of delivery for best results. The film should be removed at a glass

temperature between 0º and 60ºF (-17 Cº and 15Cº). Typically, as the film is

exposed to UV, humidity and heat, the adhesion of the film to glass will increase.

In addition, as the temperature at removal decreases, the adhesion of the film to

glass will typically increase. Under normal circumstances, removing the film

within 9 months will help ensure easy removal with little to none of the film

adhesive remaining on the glass.

Use of high absorption coatings, tints, or Cardinal i89 Low-E on surfaces #4 or

#6, may affect adhesion. As such, it is advised to remove the film a few months

less than the allotted 9 months.

PFG Protective Film is applied in horizontal lengths overlapping from edge to

edge. To facilitate removal, start from one edge of the overlapping regions and

pull away from each strip of film. A plastic scraper or plastic putty knife can be

used to help where removal requires assistance. Do not use knives, razors, or any

sharp metal blades.

Any remaining adhesive can be removed using a citrus-based cleaner. Any

residual lines left behind that are visible during wet conditions are similar to those

of suction cup marks. They are not classified as defects.

Should you have any questions, please contact your EuroLine Windows Design

Representative.

Removing the film may result in static

discharge. To help reduce the chances of

static discharge, consider wetting the film

and/or reducing the speed of removal. Do

not remove film in the presence of flammable

or explosive chemicals. Including materials

or substances that come in contact with these

chemicals.

Caution

EUROLINE

Windows

6

© EuroLine Windows Inc Instructions Rev. 3 2022

Handling

IGUs with PFG Protective Film can be handled using suction cups. Some air may

become trapped under the film. This air will typically dissipate with time. Center

the cups over the overlapping layers of film for best results.

Location Key

1. Suction cup completely on upper layer --- Recommended Placement

2. Suction cup partially on overlap area, partially on upper layer--- Not

Recommended Suction cup on completely on overlap --- Recommended Placement

3. Suction cup partially on the overlap and partially on lower layer --- Not

Recommended Suction cup completely on lower layer --- Recommended

Placement

4. Suction cup over any edge of protected area --- Not Recommended

DO NOT pressure wash the film as it may

cause the film to lose adhesion.

Note

Fixed Sash Jamb - Outside

Series 3800 Smart-Slide Door Install - OX & XO Configurations

Drawing #:3800-DR-SSD-FS-JAMB-INSTALL-OX-R2

Date: 18 SEPT. 2020

Scale: 1:2

Fastening Through External Perimeter Frame

(Denoted by F )

Applies to all perimeter frame sides (Head, Sill & Jambs)

- Pre-drill 5mm (3/16") diameter hole through both

sides of uPVC frame and galvanized steel tube

- Drill 10mm (13/32") diameter hole though first inner

uPVC frame wall and first layer of galvanized steel tube

wall

- Ensure proper shimming at each fastener location

- Fasten through hole using #10 x 3-1/2" Panhead

corrosion resistant fastener

(Do

not over torque as this may distort the frame)

- Plug hole in uPVC frame using 10mm PVC plug

(black or white color)

F

ELEVATION VIEW

(EXTERIOR SIDE)

31

ACB

42

PLAN VIEW

(EXTERIOR SIDE)

F

F

F

F

F

F F

F

F

F

F

FASTENER LOCATIONS

ELEVATION VIEW

F

B

Left cross section:

Fixed door sash jamb - outside

1-2

Finishing 1/2" (13mm) PVC Plug

for

13/32" (10mm) to 7/16" (11mm) hole

(Black or white color)

7

© EuroLine Windows Inc Instructions Rev. 3 2022

Fixed Sash Sill - Outside

Series 3800 Smart-Slide Door Install - OX & XO Configurations

SILL

2

PLAN VIEW

EXTERIOR SIDE

ELEVATION VIEW

EXTERIOR SIDE

31

ACB

42

Drawing #:3800-DR-SSD-FS-SILL-INSTALL-OX-R2

Date: 18 SEPT. 2020

Scale: 1:2

SHIM LOCATIONS

ELEVATION VIEW

F

S

S

S

S

S

S

S

S

S

S S S S S

X

X

Finishing 1/2" (13mm) PVC Plug

for

13/32" (10mm) to 7/16" (11mm) hole

(Black or white color)

8

©

EuroLine Windows Inc

Instructions Rev. 3 2022

EUROLINE

Windows

© EuroLine Windows Inc Instructions Rev. 3 2022

For more information on these quality products

please contact:

EuroLine Windows Inc.

7620 MacDonald Road

Delta, BC. CanadaV4G1N2

T. 604.940.8485

F. 604.940.8486

E.

service@euroline-windows.com

W. www.euroline-windows.com

Toll Free: 1 800 337.8604

Other publications available from EuroLine Windows Inc. can be

found on our website (www.euroline-windows.com).

Do not reproduce this manual without prior written permission from Euroline Windows Inc.