Air separation plants

History and technological progress

in the course of time

Making our world more productive

N₂

O₂

Ar

Linde based his experiment on findings

discovered by J. P. Joule and W. Thomson

(1852). They found that compressed air

expanded in a valve cooled down by approx.

0.25°C with each bar of pressure drop. This

proved that real gases do not follow the

Boyle-Mariotte principle, according to which

no temperature decrease is to be expected

from expansion. An explanation for this effect

was given by J. K. van der Waals (1873), who

discovered that the molecules in compressed

gases are no longer freely movable and

the interaction among them leads to a

temperature decrease after decompression.

Carl von Linde in 1925.

History and technological progress of air separation 03

When and how did air separation start?

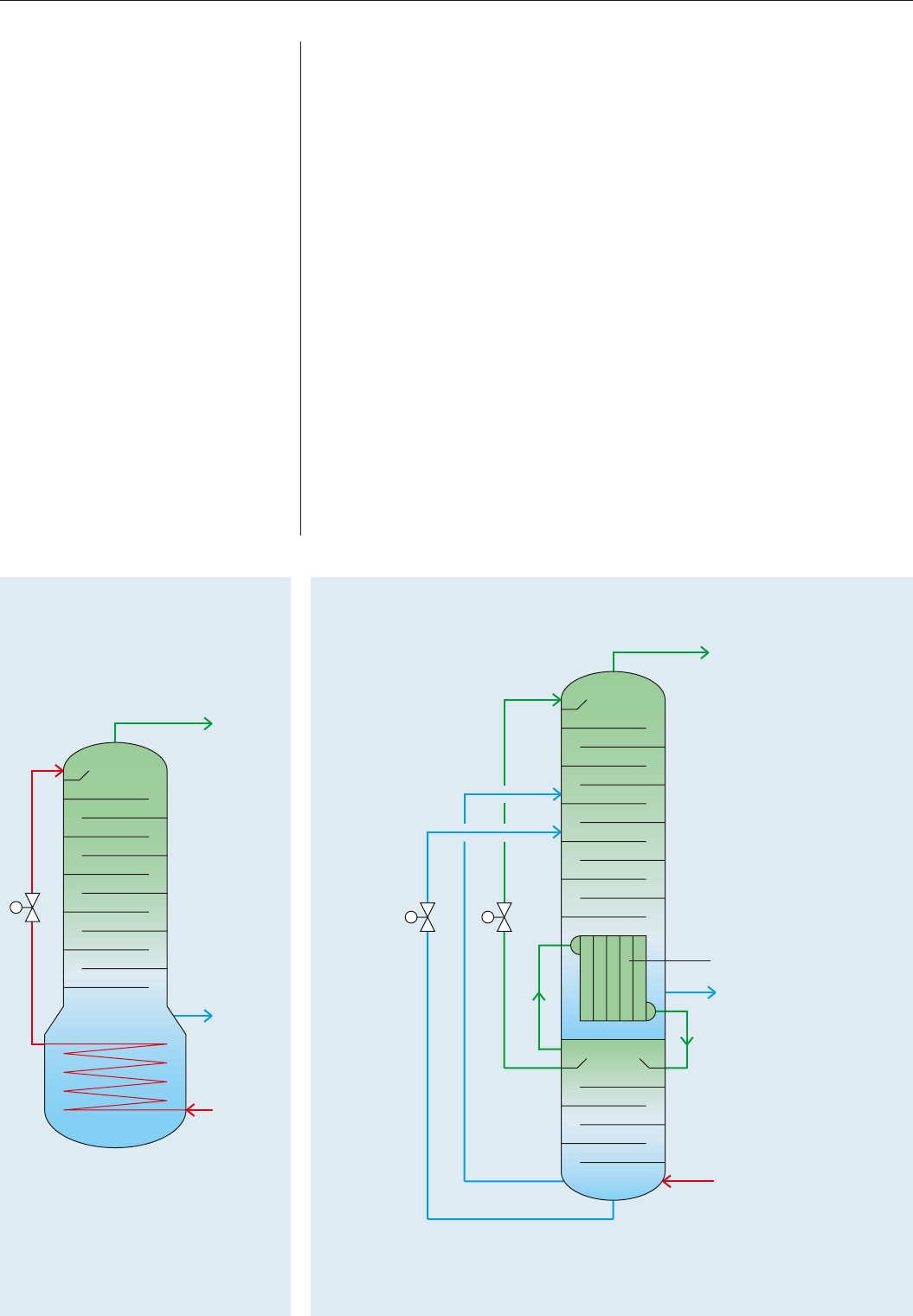

Liquefaction process of air separation

Water cooler

p₂t

5

p₁t₄

p₂t₁

p₁t

3

p₂t₂

t₃

For his experiment, air was compressed

from 20 bar [p₁] [t₄] to 60 bar [p₂] [t₅] in

the compressor and cooled in the water

cooler to ambient temperature [t₁]. The pre-

cooled air was fed into the countercurrent

heat exchanger, further cooled down [t₂]

and expanded in the expansion valve

(Joule-Thomson valve) [p₁] to liquefaction

temperature [t₃]. The gaseous content of the

air was then warmed up again [t₄] in the heat

exchanger and fed into the suction side of

the compressor [p₁]. The hourly yield from

this experiment was approx. three litres of

liquid air.

In May 1895, Carl von Linde performed an experiment in his laboratory in Munich that

led to his invention of the first continuous process for the liquefaction of air based on the

Joule-Thomson refrigeration effect and the principle of countercurrent heat exchange. This

marked the breakthrough for cryogenic air separation.

Nitrogen 78.08%

Oxygen 20.95%

Argon 0.93%

Neon 0.0018%

Helium 0.0005%

Krypton 0.00011%

Xenon 0.000009%

Composition of air

Separator

Expansion valve

Compressor

Liquid air

Heat exchanger

Gaseous air

04 History and technological progress of air separation

What are the physical properties of air

required for liquefaction?

To enable air to be separated into its

constituents by means of rectification – the

actual separation process – a large part

of the air volume used must be liquefied.

A gas can only be transformed into a

liquid state at temperature and pressure

conditions below those of its critical point.

The critical point of air is T

crit

= –140.7ºC

(132.5 K) and P

crit

= 37.7 bar. In other words,

air can be liquefied only at temperatures

below –140.7ºC (132.5 K).

The vapour pressure curve illustrates the

temperatures and pressures at which a gas

condenses or a liquid evaporates.

→ Air below atmospheric pressure (1 bar)

must be chilled to –192ºC (81.5 K) before it

starts to condense

→ Air below a pressure of 6 bar must be

chilled to –172ºC (101 K) before it starts to

condense

The boiling point and condensation conditions

of gas mixtures such as air are not identical.

A condensation line and a boiling point line

delineate the boiling point range.

Vapour pressure curves of atmospheric gases

Critical point V Start of evaporation K Start of condensation

0°C Water freezes

Boiling points

–107°C Xenon

–152°C Krypton

–183°C Oxygen

–186°C Argon

–196°C Nitrogen

–246°C Neon

–273°C Absolute zero

50

10

6

1

5

0.5

60 100 14080 160

Pressure in bar

Temperature in K

120

101

81.5

V K

Air

Vapour

Liquid

N₂

O₂

Ar

Rectification is synonymous with counter-

current distillation. This special distillation

separation process enables the individual

components of a mixture to be separated

with a high purity combined with a good

yield, even when their boiling points are

relatively close to each other.

As a result of the different vapour pressures

of the individual components (pN₂ > pO₂), the

composition of the vapour differs from that of

the liquid mixture.

The vapour produced from a boiling liquid

mixture of O₂/N₂ will thus have a higher N₂

concentration than the liquid mixture from

which it originates.

History and technological progress of air separation 05

What is rectification of air?

Liquid

Condensation

temperature

T

S

at P

S

= 1 bar

Boiling point

temperature

T

S

at P

S

= 1 bar

Vapour

77

0

Temperature in K

O₂ concentration in O₂/N₂ mixture % by volume

20 40 60 80 100

90

Boiling point diagram of O₂/N₂ mixtures

06

Process air

Nitrogen

with 7% O₂

Pure oxygen

Single column

Air separation by rectification in a single/double column

Using his air liquefaction principle as a basis, Carl von Linde constructed the first air separation

plant for oxygen production in 1902 using a single-column rectification system.

In 1910, he established the basis for cryogenic air separation with the development of a double-

column rectification system. Now it was possible to produce pure oxygen and pure nitrogen

simultaneously.

This involves installing a pressure column below the low-pressure column. At the top of this

pressure column, pure nitrogen was drawn off, liquefied in a condenser and fed to the top

low-pressure column as reflux. At the top of the low-pressure column, pure gaseous nitrogen

was withdrawn, while liquid oxygen evaporated at the bottom of this column to deliver pure

gaseous oxygen. This principle of double-column rectification combining the condenser and

evaporator to form a heat exchanger unit is still used today.

History and technological progress of air separation

Liquid N₂

Pure nitrogen

Condenser

Pure

oxygen

Process air

Liquid with 35–40% O₂

Double column

What are the principles of air separation?

1.5 bar

5.6 bar

Low-pressure column

Pressure column

07

Condenser

1.5 bar

5.6 bar

History and technological progress of air separation

Condenser/reboiler

The principle of double-column rectification is characterised by the combination of condenser

and evaporator to form a common heat exchanger unit. This divides the rectification into two

separate areas with different pressures.

Condenser

N₂

1.0

70

Pressure in bar

Temperature in K

75 80 85 95 120

9.0

Vapour pressure of N₂ and O₂

0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

11511010510090

O₂

dT=1.4K

95.5

5.6

94.1

1.5

08

What happens inside a column?

Any tray of the rectification column follows

the same principle:

The O₂ concentration of the boiling O₂/N₂

liquid mixture F is greater than the O₂

concentration of the vapour D. A certain

volume of liquid corresponding to the same

volume of reflux constantly flows from the

tray above into the liquid mixture below with

an equivalent volume flowing down over a

weir onto the tray below.

The vapour D

u

coming from the bottom tray

penetrates the liquid mixture F and has a

higher O₂ content than the vapour mixture D.

The O₂ concentration of the vapour D

o

rising

from the upper tray is in turn less than that

of the vapour D. Thus a gas rich in nitrogen

is obtained in the head of the column and a

liquid rich in oxygen is obtained in the sump

of the column.

History and technological progress of air separation

Vapour

Liquid

D

O

F

O

D

F

D

U

F

U

Fabrication of sieve tray column.

Principle of sieve trays

09History and technological progress of air separation

Structured packings

1991

World’s largest

air separation plant with

packed columns

Packed column.

Significant progress in air separation

technology was made in the mid-1980s. For

the first time, structured packings were used

in cryogenic rectification. Packed columns

work in a similar way to sieve trays. The

intensive contact between liquid and vapour

required for the rectification takes place on

the huge surface area of the packing material.

Liquid flowing down becomes increasingly

richer in oxygen, whereby the ascending

vapour is enriched with nitrogen. The main

benefits of packed columns compared with

sieve trays are a lower pressure drop and

consequently a lower power consumption for

the air separation process. Another important

advantage of packed columns is the possible

loading range including a very high turn down

to nearly 30%. This also forms the basis for a

new process for argon separation.

Principle of structured packings

Downflow of liquid O₂

Rising N

2

gas

10

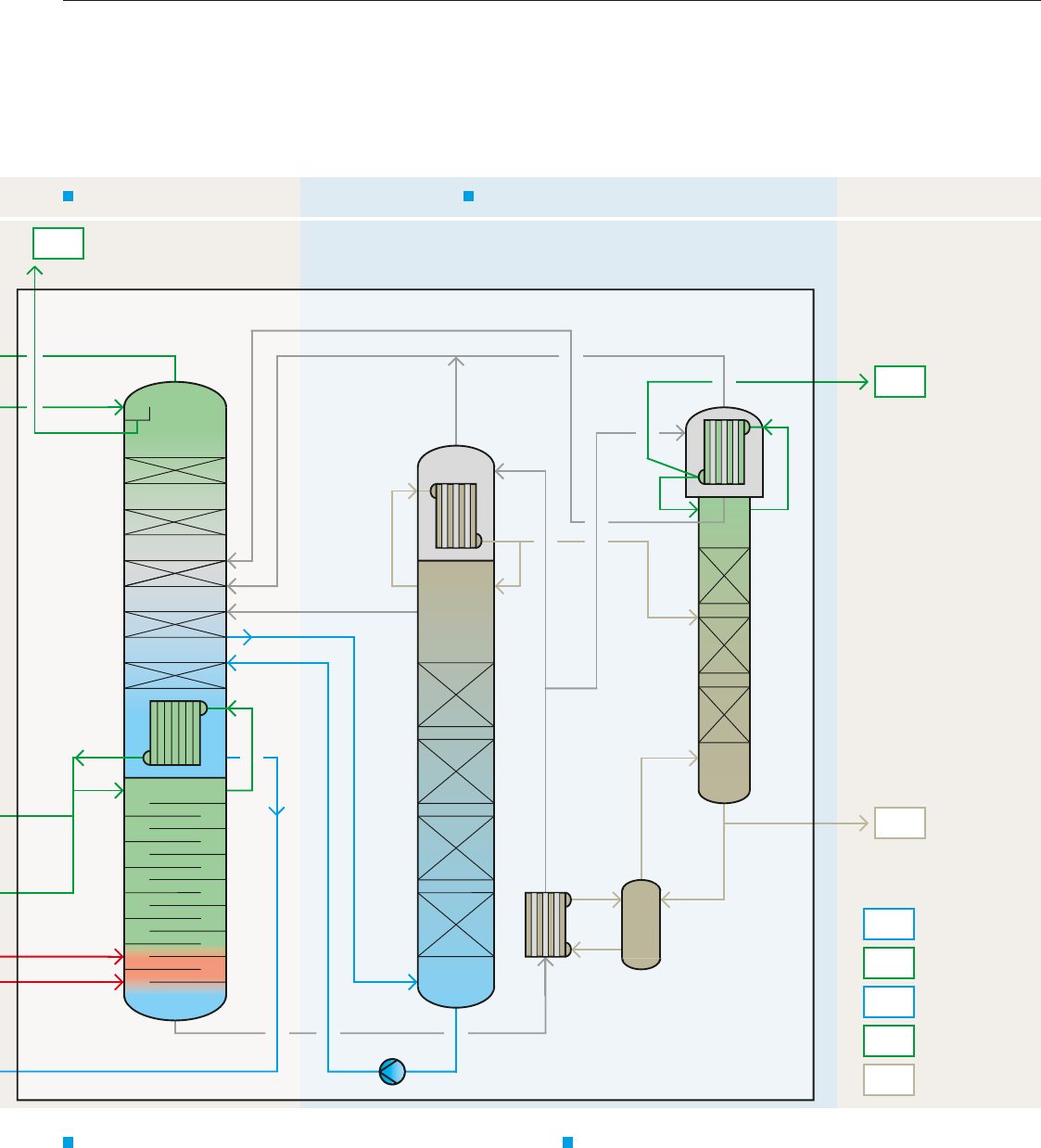

What does a typical cryogenic air separation process look like?

GOX GAN LOX

AIR

Air compression

Air compressor

Molecular sieve

unit

Direct

contact

cooler

Evaporation cooler

Water pump

Air booster

compressor

Coldbox

Expansion

turbine

Heat

exchanger

Sub-

cooler

Cryo pump for

int. compression

Cryo pump for

int. compression

1

Air cooling and purification

2

Cold production and internal product compression

3

1

Air compression

→ Compression of ambient air by a multi-stage turbo compressor with

intercoolers at a supply pressure of approx. 6 bar.

→ Removal of dust particles by a mechanical air filter at the inlet of

the compressor.

2

Air cooling and purification

→ Cooling of process air with water in a direct contact cooler and

removal of water soluble air impurities.

→ Chilling of cooling water in an evaporation cooler against dry

nitrogen waste gas from the rectification process.

→ Removal of CO₂, water and hydrocarbons from the process air in

periodically loaded/regenerated molecular sieve adsorbers.

3

Cold production and internal product compression

→ Cooling of process air in heat exchangers down to nearly

liquefaction temperature by means of countercurrent with gas

streams from the rectification process.

→ Further compression of a sidestream of process air by an air booster

compressor. Expansion and cold production of the boosted air

stream in an expansion turbine.

→ Expansion and liquefaction of a sidestream of the boosted air in a

liquid separator.

→ Evaporation and warming to ambient temperature of the pumped

oxygen and nitrogen product in high-pressure heat exchangers.

History and technological progress of air separation

11

LIN

ATM

LAR

Cryogenic rectification of air Cryogenic rectification of argon

GOX

GAN

LOX

LIN

LAR

gaseous oxygen

gaseous nitrogen

liquid oxygen

liquid nitrogen

liquid argon

Pressure

column

Condenser/

reboiler

Low-pressure

column

Crude argon

column

Pure argon

column

4 5

4

Cryogenic rectification of air

→ Pre-separation of the cooled and liquefied air within the pressure

column into oxygen-enriched liquid in the column sump and pure

nitrogen gas at the column top.

→ Liquefaction of the pure nitrogen gas in the condenser/reboiler

against boiling oxygen in the sump of the low-pressure column.

Liquefied nitrogen provides the reflux for the pressure column and

(after sub-cooling) for the low-pressure column.

→ Different types of condenser are described in detail on page 16.

→ Further separation of the oxygen-enriched liquid within the low-

pressure column into pure oxygen in the sump and nitrogen waste

gas at the top.

5

Cryogenic rectification of argon

→ Argon-enriched gas from the low-pressure column is transformed

into oxygen-free crude argon by means of separation within the

crude argon column.

→ Pumping back liquid oxygen from the crude argon column sump into

the low-pressure column. Removal of the remaining nitrogen in the

pure argon column.

History and technological progress of air separation

Coldbox

Milestones in air separation.

12

1902

1904

1910

1930

1950

World’s first air separation

unit (ASU) for oxygen production

World’s first air separation plant for

the recovery of nitrogen

World’s first air separation plant

using the double-column rectification

process

Development of the Linde-Fränkl

process for air separation

First Linde-Fränkl oxygen plant

without pressure recycling and stone-

filled reactors

1954

1968

1981

1984

World’s first air separation plant with

air purification by means of adsorbers

Introduction of the molecular sieve

technology for pre-purification of air

Introduction of the elevated pressure

process

World’s largest VAROX air separation

plant with variable oxygen flow

adjustment

History and technological progress of air separation

1978

Internal compression of oxygen applied

to tonnage air separation plants, p. 14

1988

First columns with structured packings

13

1997

Largest air separation plant built for

N₂ with capacity of 5 x 10,000 tpd,

fifth train added in 2004, p. 18–19

2012

2015

2016

2017

Flexible high air pressure process,

p. 14

Simple filling of dual-bed radial

adsorber

Optimised fins for high-pressure

PFHEs in ASUs

Trouble-free start-up of largest ASU

complex in the world

6 x 3,600 tpd of oxygen , p. 22–23

Start-up of world’s largest

air separation plant

5 x 5,250 tpd of oxygen, p. 24–25

History and technological progress of air separation

1990

1991

1992

1993

Linde introduced argon

production by rectification, p. 15

World’s first remotely controlled air

separation plant with unmanned operation

World’s largest air separation plant

with packed columns

Ultra-pure gases production in

air separation plants

First world-scale radial adsorbers in

large air separation plants

2006

2008

2010

2011

Largest EPC contract in history

of air separation with

8 x 3,800 tpd O₂, p. 20–21

Reflux condenser in crude argon

column, p. 16

Advanced cryogenic process,

efficiency optimised for

CCS application (oxyfuel, IGCC)

Argon production without

pure argon system, p. 15

2000

Development of the advanced

multi-stage bath-type condenser, p. 16

14

Internal compression

The internal compression (or liquid pumping)

process allows for oxygen, nitrogen as well as

argon to be compressed within the coldbox by

means of liquid pumps, to be evaporated and

warmed up in heat exchangers, and finally to

be supplied to the end user at the required

pressure.

In order to evaporate and warm up the

compressed liquid, a countercurrent stream

of air with a higher pressure than the liquid is

required for thermodynamic reasons.

For plants that produce pressurised nitrogen,

the booster and/or recycle nitrogen

compressor also provide the countercurrent

stream for evaporation. With this method,

complex external oxygen compression is no

longer required, thus plant operation and

maintenance have become considerably

easier and more reliable. Furthermore, the risk

of dangerous hydrocarbon enrichment in the

condenser is avoided because liquid oxygen is

continuously withdrawn from the condenser

and pumped into the heat exchanger, where

it evaporates. Compared with the external

compression system, a considerably higher

level of safety has been achieved.

1978

Internal compression

of oxygen

History and technological progress of air separation

Booster compressor

75 bar

Heat exchanger

HPGAN 100 bar

HPGOX 100 bar

Rectification column

Oxygen pump

Nitrogen

pump

The ambient air is compressed by a state-of-

the-art multi-stage turbo compressor with

intercoolers at a supply pressure of approx.

20 bar. A booster air compressor is no longer

required with this process design, leading

to a reduction of investment cost. A further

advantage is the improved energy efficiency

of the main air compressor for small plants.

High air pressure process

2012

Flexible high air pressure

process used in ASUs

15History and technological progress of air separation

Conventional process

The area in the low-pressure column where

the argon concentration is at a maximum

(approx. 10%) is known as the argon belly.

From there, the gas stream is fed into the

raw argon column for further rectification.

The remaining oxygen in this gas stream

is completely removed in the packed raw

argon column. Due to the very low pressure

drop in the packings, it is possible to install

a sufficient number of “theoretical trays”

required for the rectification. In the adjoining

pure argon column, the remaining nitrogen is

removed by rectification and the pure argon is

liquefied.

Pure liquid

argon (LAR)

1ppm nitrogen

1ppm oxygen

Pure argon production by rectification

1990

Pure argon production

by rectification

Cost-optimised process for small- and

medium-sized air separation plants

As in the conventional process, a gas stream

from the low-pressure column is fed into

the raw argon system. Due to optimised

packing types, the gas stream is already free

of nitrogen. Therefore, only the remaining

oxygen needs to be removed in the argon

system.

The argon purity and recovery can be kept at

the same level as in the conventional process.

The additional pure argon column is no longer

required.

Pure liquid

argon (LAR)

1ppm nitrogen

1ppm oxygen

2011

Pure argon production

by rectification

without pure argon system

16

2000

Development of

cascade condenser

2008

Reflux condenser

for argon rectification

History and technological progress of air separation

2006

Forced flow condenser

Condenser

Forced flow condenser

→ No condenser vessel required

→ Less space necessary

→ Specially designed for total evaporation

→ Energy-saving solution

Cascade condenser

→ Multi-stage bath-type condenser

→ Suitable for medium-sized and large ASUs

→ Suitable for ASUs with internal oxygen

compression

→ Integration of large heat transfer area

into low-pressure column compared to

conventional bath-type condenser

→ No oxygen pipework

→ Energy-saving solution

→ Safe operation

Reflux condenser

→ Used instead of conventional bath-type

condenser

→ No oxygen and no nitrogen pipework

necessary

→ Space-saving design compared to

bath-type condenser

→ Very simple and stable mode of operation

→ Cost-efficient design

Low-pressure column

Liquid oxygen

Gaseous nitrogen

Pressure column

Gaseous

nitrogen

Liquid oxygen

Low-pressure column

Liquid oxygen

Gaseous nitrogen

Pressure column

1

st

stage

2

nd

stage

17History and technological progress of air separation

Condenser fabrication.

18 History and technological progress of air separation

Air separation units in Cantarell, Mexico.

5 ⨯ 10,000 t

N

2

per day for

Cantarell, Mexico

19History and technological progress of air separation

1997

Largest ASU

for nitrogen

production

20

2006

Largest EPC

contract in the

history of

air separation

History and technological progress of air separation

21

Air separation units at the Pearl GTL complex in Ras Laffan, Qatar.

History and technological progress of air separation

8 ⨯ 3,800 t

O

2

per day in

Ras Laffan, Qatar

22

Air separation units near Yinchuan, China.

History and technological progress of air separation

6 ⨯ 3,600 t

O

2

per day for a plant

near Yinchuan City, China

23History and technological progress of air separation

2016

Engineering

masterpiece

in China

24

2017

Start-up of

largest ASU

in the world

History and technological progress of air separation

25

Delivery of world’s largest coldbox weighing 800 tonnes for Jamnagar, India.

History and technological progress of air separation

5 ⨯ 5,250 t

O

2

per day for

Jamnagar, India

26 History and technological progress of air separation

Linde Engineering.

Facts and figures.

… World’s first air separation

unit for oxygen production

… Linde introduced argon

production by rectification.

1990

Our air separation business.

1902

Number of patents

150

new air

separation

patents in last

5 years

5,250 tpd

oxygen

World‘s largest single train

air separation unit built by

400

air separation

units owned and

operated by The

Linde Group

3,000+

air separation

plants have

been built

by Linde

Composition of air

O₂ 20.95 −183.0 °C

N₂ 78.08 −195.8 °C

Ar 0.93 −185.9 °C

Ne 0.0018 −246.1 °C

He 0.0005 −268.9 °C

Kr 0.00011 −153.2 °C

Xe 0.000009 −108.0 °C

Vol % Boiling point

N₂

O₂

27History and technological progress of air separation

Biggest

prefabricated coldbox:

Height 70 m

Weight 800 t

Number of patents

1,700 m ²/m³

Heat exchanger

max. surface

−15%

average power consumption

of our ASUs over the last

10 years

Linde air separation units

built in more than

90

countries

Read more:

linde-engineering.com/air_separation_plants

19%

TCO

(Total Cost of

Ownership)

savings in past

10

YEARS

Published by:

Linde Aktiengesellschaft

Engineering Division, Dr.-Carl-von-Linde-Strasse 6–14

82049 Pullach, Germany

Phone +49 89 7445-0, Fax +49 89 7445-4908

info@linde-le.com, www.linde-engineering.com

Plant engineering

→ Air separation plants

→ LNG and natural gas processing plants

→ Petrochemical plants

→ Hydrogen and synthesis gas plants

→ Adsorption plants

→ Cryogenic plants

→ Carbon capture and utilization plants

→ Furnaces, fired heaters, incinerators

Component manufacturing

→ Coldboxes and modules

→ Coil-wound heat exchangers

→ Plate-fin heat exchangers

→ Cryogenic columns

→ Cryogenic storage tanks

→ Liquefied helium tanks and containers

→ Air-heated vaporizers

→ Water bath vaporizers

→ Spiral-welded aluminum pipes

Your partner for the production and

processing of gases

Delivering reliable process plants for maximum capital efficiency

Linde has been optimizing gas processing technologies for 140 years, successfully delivering more than 4,000 plant

engineering projects around the globe. Favoring trusted, lasting business relationships, the company collaborates closely

with customers to enhance plant lifecycle productivity and innovate process flows. The company’s proven gas processing

expertise plays an indispensable role in the success of customers across multiple industries – from natural gas and oil

refining through petrochemicals and fertilizers to electronics and metal processing.

Operational excellence along the entire plant lifecycle

We work closely with our customers to gain an in-depth understanding of individual needs. Building on the unique

synergies of Linde as an integrated plant operator and engineering company, Linde offers innovative process technologies

and services to exceed our customers’ reliability and profitability expectations. This commitment to innovation extends

along the entire plant lifecycle. The LINDE PLANTSERV® service team supports customers every step of the way – from

maintenance and repairs to full revamps. Leveraging the latest digital technologies to offer on-site and remote operational

and support services, we consistently take asset performance to the next level.

Making the impossible possible

From the desert to the Arctic, from small- to world-scale, from standardized to customized designs, Linde’s engineering

specialists develop solutions that operate under all conditions. The company covers every step in the design, project

management and construction of gas processing plants and components. Customers can always rely on Linde to deliver the

plants, components and services that fit their needs best – anywhere in the world.

Discover how we can contribute to your success at www.linde-engineering.com

Get in touch with our air separation plant team:

Phone +49 89 7445-3526, inquiry: www.linde-engineering.com/contact

Core competencies at a glance

Services

→ Revamps and plant modifications

→ Plant relocations

→ Spare parts

→ Operational support, troubleshooting

and immediate repairs

→ Long-term service contracts

→ Expert reviews for plants, operations

and spare part inventory

→ Operator training

41273_LCS_0719

Linde is a company name used by Linde plc and its affiliates. The Linde logo, the Linde word and LINDE PLANTSERV are trademarks or registered trademarks of Linde plc or its affiliates. Copyright © 2019. Linde plc.