Managerial Decision Modeling

with Spreadsheets

Balakrishnan Render Stair

Third Edition

Pearson Education Limited

Edinburgh Gate

Harlow

Essex CM20 2JE

England and Associated Companies throughout the world

Visit us on the World Wide Web at: www.pearsoned.co.uk

© Pearson Education Limited 2014

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted

in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without either the

prior written permission of the publisher or a licence permitting restricted copying in the United Kingdom

issued by the Copyright Licensing Agency Ltd, Saffron House, 6–10 Kirby Street, London EC1N 8TS.

All trademarks used herein are the property of their respective owners. The use of any trademark

in this text does not vest in the author or publisher any trademark ownership rights in such

trademarks, nor does the use of such trademarks imply any affi liation with or endorsement of this

book by such owners.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library

Printed in the United States of America

ISBN 10: 1-292-02419-4

ISBN 13: 978-1-292-02419-6

ISBN 10: 1-292-02419-4

ISBN 13: 978-1-292-02419-6

Table of Contents

PEARSON C U S T OM LIBRAR Y

I

1

. Introduction to Managerial Decision Modeling

1

1Nagraj Balakrishnan/Barry Render/Ralph M. Stair

2

. Linear Programming Models: Graphical and Computer Methods

19

19Nagraj Balakrishnan/Barry Render/Ralph M. Stair

3

. Linear Programming Modeling Applications with Computer Analyses in Excel

65

65Nagraj Balakrishnan/Barry Render/Ralph M. Stair

4

. Transportation, Assignment, and Network Models

119

119Nagraj Balakrishnan/Barry Render/Ralph M. Stair

5

. Integer, Goal, and Nonlinear Programming Models

169

169Nagraj Balakrishnan/Barry Render/Ralph M. Stair

6

. Project Management

225

225Nagraj Balakrishnan/Barry Render/Ralph M. Stair

7

. Decision Analysis

277

277Nagraj Balakrishnan/Barry Render/Ralph M. Stair

8

. Queuing Models

325

325Nagraj Balakrishnan/Barry Render/Ralph M. Stair

9

. Simulation Modeling

365

365Nagraj Balakrishnan/Barry Render/Ralph M. Stair

10

. Forecasting Models

433

433Nagraj Balakrishnan/Barry Render/Ralph M. Stair

Inventory Control Models

495

495Nagraj Balakrishnan/Barry Render/Ralph M. Stair

Appendix: Useful Excel 2010 Commands and Procedures for Installing ExcelModules

535

535Nagraj Balakrishnan/Barry Render/Ralph M. Stair

Appendix: Probability Concepts and Applications

549

549Nagraj Balakrishnan/Barry Render/Ralph M. Stair

II

Appendix: Areas Under the Normal Standard Curve

575

575Nagraj Balakrishnan/Barry Render/Ralph M. Stair

577

577Index

1 What Is Decision Modeling?

2 Types of Decision Models

3 Steps Involved in Decision Modeling

4 Spreadsheet Example of a Decision Model:

Tax Computation

5 Spreadsheet Example of a Decision Model:

Break-Even Analysis

6 Possible Problems in Developing Decision

Models

7 Implementation—Not Just the Final Step

After completing this chapter, students will be able to:

1. Define decision model and describe the impor-

tance of such models.

2. Understand the two types of decision models:

deterministic and probabilistic models.

3. Understand the steps involved in developing

decision models in practical situations.

4. Understand the use of spreadsheets in developing

decision models.

5. Discuss possible problems in developing decision

models.

CHAPTER OUTLINE

LEARNING OBJECTIVES

Introduction to Managerial

Decision Modeling

Summary • Glossary • Discussion Questions and Problems

The companion website for this text is www.pearsonhighered.com/balakrishnan.

From Chapter 1 of Managerial Decision Modeling with Spreadsheets, Third Edition. Nagraj Balakrishnan, Barry Render, Ralph M. Stair, Jr.

Copyright © 2013 by Pearson Education, Inc. All rights reserved.

1

INTRODUCTION TO MANAGERIAL DECISION MODELING

1 What Is Decision Modeling?

Although there are several definitions of decision modeling , we define it here as a scientific

approach to managerial decision making. Alternatively, we can define it as the development of

a model (usually mathematical) of a real-world problem scenario or environment. The resulting

model should typically be such that the decision-making process is not affected by personal bias,

whim, emotions, and guesswork. This model can then be used to provide insights into the solu-

tion of the managerial problem. Decision modeling is also commonly referred to as quantitative

analysis , management science , or operations research . In this text, we prefer the term deci-

sion modeling because we will discuss all modeling techniques in a managerial decision-making

context.

Organizations such as American Airlines, United Airlines, IBM, Google, UPS, FedEx, and

AT&T frequently use decision modeling to help solve complex problems. Although mathemati-

cal tools have been in existence for thousands of years, the formal study and application of quan-

titative (or mathematical) decision modeling techniques to practical decision making is largely

a product of the twentieth century. The decision modeling techniques studied here have been

applied successfully to an increasingly wide variety of complex problems in business, govern-

ment, health care, education, and many other areas. Many such successful uses are discussed

throughout this text.

It isn’t enough, though, just to know the mathematical details of how a particular decision

modeling technique can be set up and solved. It is equally important to be familiar with the

limitations, assumptions, and specific applicability of the model. The correct use of decision

modeling techniques usually results in solutions that are timely, accurate, flexible, economical,

reliable, easy to understand, and easy to use.

Decision modeling is a scientific

approach to decision making.

2 Types of Decision Models

Decision models can be broadly classified into two categories, based on the type and nature of

the decision-making problem environment under consideration: (1) deterministic models and

(2) probabilistic models. We define each of these types of models in the following sections.

Deterministic Models

Deterministic models assume that all the relevant input data values are known with certainty;

that is, they assume that all the information needed for modeling a decision-making problem

environment is available, with fixed and known values. An example of such a model is the

case of Dell Corporation, which makes several different types of PC products (e.g., desktops,

laptops), all of which compete for the same resources (e.g., labor, hard disks, chips, working

capital). Dell knows the specific amounts of each resource required to make one unit of each

type of PC, based on the PC’s design specifications. Further, based on the expected selling price

and cost prices of various resources, Dell knows the expected profit contribution per unit of

Deterministic means with

complete certainty .

Decision modeling has been in existence since the begin-

ning of recorded history, but it was Frederick W. Taylor who,

in the early 1900s, pioneered the principles of the scientific

approach to management. During World War II, many new

scientific and quantitative techniques were developed to assist

the military. These new developments were so successful that

after World War II, many companies started using similar tech-

niques in managerial decision making and planning. Today,

many organizations employ a staff of operations research or

management science personnel or consultants to apply the prin-

ciples of scientific management to problems and opportunities.

The terms management science , operations research , and quan-

titative analysis can be used interchangeably, though here we

use decision modeling .

The origins of many of the techniques discussed in this text

can be traced to individuals and organizations that have applied

the principles of scientific management first developed by Taylor;

they are discussed in History boxes scattered throughout the text.

HISTORY

The Origins of Decision Modeling

2

INTRODUCTION TO MANAGERIAL DECISION MODELING

each type of PC. In such an environment, if Dell decides on a specific production plan, it is a

simple task to compute the quantity required of each resource to satisfy that production plan. For

example, if Dell plans to ship 50,000 units of a specific laptop model, and each unit includes a

pair of 2.0GB SDRAM memory chips, then Dell will need 100,000 units of these memory chips.

Likewise, it is easy to compute the total profit that will be realized by this production plan

(assuming that Dell can sell all the laptops it makes).

Perhaps the most common and popular deterministic modeling technique is linear program-

ming (LP).

Probabilistic Models

In contrast to deterministic models, probabilistic models (also called stochastic models ) assume

that some input data values are not known with certainty. That is, they assume that the values of

some important variables will not be known before decisions are made. It is therefore important

to incorporate this “ignorance” into the model. An example of this type of model is the decision

of whether to start a new business venture. As we have seen with the high variability in the stock

market during the past several years, the success of such ventures is unsure. However, investors

(e.g., venture capitalists, founders) have to make decisions regarding this type of venture, based

on their expectations of future performance. Clearly, such expectations are not guaranteed to

occur. In recent years, we have seen several examples of firms that have yielded (or are likely

to yield) great rewards to their investors (e.g., Google, Facebook, Twitter) and others that have

either failed (e.g., eToys.com, Pets.com) or been much more modest in their returns.

Another example of probabilistic modeling to which students may be able to relate easily

is their choice of a major when they enter college. Clearly, there is a great deal of uncertainty

regarding several issues in this decision-making problem: the student’s aptitude for a spe-

cific major, his or her actual performance in that major, the employment situation in that

major in four years, etc. Nevertheless, a student must choose a major early in his or her col-

lege career. Recollect your own situation. In all likelihood, you used your own assumptions

(or expectations) regarding the future to evaluate the various alternatives (i.e., you developed

a “model” of the decision-making problem). These assumptions may have been the result

of information from various sources, such as parents, friends, and guidance counselors. The

important point to note here is that none of this information is guaranteed, and no one can

predict with 100% accuracy what exactly will happen in the future. Therefore, decisions

made with this information, while well thought out and well intentioned, may still turn out to

not be the best choices. For example, how many of your friends have changed majors during

their college careers?

Because their results are not guaranteed, does this mean that probabilistic decision models

are of limited value? The answer is an emphatic no. Probabilistic modeling techniques provide

a structured approach for managers to incorporate uncertainty into their models and to evaluate

decisions under alternate expectations regarding this uncertainty. They do so by using probabili-

ties on the “random,” or unknown, variables. Probabilistic modeling techniques include decision

analysis, queuing, simulation, and forecasting. Two other techniques, project management and

inventory control, include aspects of both deterministic and probabilistic modeling. For each

modeling technique, we discuss what kinds of criteria can be used when there is uncertainty and

how to use these models to identify the preferred decisions.

Because uncertainty plays a vital role in probabilistic models, some knowledge of basic

probability and statistical concepts is useful.

The most commonly used

deterministic modeling technique

is linear programming.

Some input data are unknown

in probabilistic models.

Probabilistic models use

probabilities to incorporate

uncertainty.

3

INTRODUCTION TO MANAGERIAL DECISION MODELING

Quantitative versus Qualitative Data

Any decision modeling process starts with data. Like raw material for a factory, these data are

manipulated or processed into information that is valuable to people making decisions. This

processing and manipulating of raw data into meaningful information is the heart of decision

modeling.

In dealing with a decision-making problem, managers may have to consider both qualitative

and quantitative factors. For example, suppose we are considering several different investment

alternatives, such as certificates of deposit, the stock market, and real estate. We can use quan-

titative factors such as rates of return, financial ratios, and cash flows in our decision model to

guide our ultimate decision. In addition to these factors, however, we may also wish to consider

qualitative factors such as pending state and federal legislation, new technological breakthroughs,

and the outcome of an upcoming election. It can be difficult to quantify these qualitative factors.

Due to the presence (and relative importance) of qualitative factors, the role of quantitative

decision modeling in the decision-making process can vary. When there is a lack of qualitative

factors, and when the problem, model, and input data remain reasonably stable and steady over

time, the results of a decision model can automate the decision-making process. For example,

some companies use quantitative inventory models to determine automatically when to order

additional new materials and how much to order. In most cases, however, decision modeling

is an aid to the decision-making process. The results of decision modeling should be combined

with other (qualitative) information while making decisions in practice.

Using Spreadsheets in Decision Modeling

In keeping with the ever-increasing presence of technology in modern times, computers have

become an integral part of the decision modeling process in today’s business environments.

Until the early 1990s, many of the modeling techniques discussed here required specialized soft-

ware packages in order to be solved using a computer. However, spreadsheet packages such as

Microsoft Excel have become increasingly capable of setting up and solving most of the deci-

sion modeling techniques commonly used in practical situations. For this reason, the current

trend in many college courses on decision modeling focuses on spreadsheet-based instruction.

In keeping with this trend, we discuss the role and use of spreadsheets (specifically Microsoft

Excel) during our study of the different decision modeling techniques presented here.

In addition to discussing the use of some of Excel’s built-in functions and procedures

(e.g., Goal Seek , Data Table , Chart Wizard ), we also discuss several add-ins for Excel. The Data

Analysis and Solver add-ins come standard with Excel; others are included on the Companion

Website.

The decision modeling process

starts with data.

Both qualitative and quantitative

factors must be considered.

Spreadsheet packages are

capable of handling many

decision modeling techniques.

Several add-ins for Excel are

included on the Companion

Website for this text,

www.pearsonhighered.com/

balakrishnan .

IBM is a well-known multinational computer technology, software,

and services company with over 380,000 employees and revenue of

over $100 billion. A majority of IBM’s revenue comes from services,

including outsourcing, consulting, and systems integration. At the

end of 2007, IBM had approximately 40,000 employees in sales-

related roles.

Recognizing that improving the efficiency and productivity

of this large sales force can be an effective operational strategy

to drive revenue growth and manage expenses, IBM Research

developed two broad decision modeling initiatives to facilitate

this issue. The first initiative provides a set of analytical models

designed to identify new sales opportunities at existing IBM ac-

counts and at noncustomer companies. The second initiative allo-

cates sales resources optimally based on field-validated analytical

estimates of future revenue opportunities in market segments.

IBM estimates the revenue impact of these two initiatives to be in

the several hundreds of millions of dollars each year.

Source: Based on R. Lawrence et al. “Operations Research Improves Sales

Force Productivity at IBM,” Interfaces 40, 1 (January-February 2010): 33–46.

IN ACTION

IBM Uses Decision Modeling to Improve

the Productivity of Its Sales Force

4

INTRODUCTION TO MANAGERIAL DECISION MODELING

3 Steps Involved in Decision Modeling

Regardless of the size and complexity of the decision-making problem at hand, the decision

modeling process involves three distinct steps: (1) formulation, (2) solution, and (3) interpreta-

tion. Figure 1 provides a schematic overview of these steps, along with the components, or parts,

of each step. We discuss each of these steps in the following sections.

It is important to note that it is common to have an iterative process between these three

steps before the final solution is obtained. For example, testing the solution (see Figure 1 ) might

reveal that the model is incomplete or that some of the input data are being measured incor-

rectly. This means that the formulation needs to be revised. This, in turn, causes all the subse-

quent steps to be changed.

Step 1: Formulation

Formulation is the process by which each aspect of a problem scenario is translated and

expressed in terms of a mathematical model. This is perhaps the most important and challeng-

ing step in decision modeling because the results of a poorly formulated problem will almost

surely be incorrect. It is also in this step that the decision maker’s ability to analyze a problem

rationally comes into play. Even the most sophisticated software program will not automatically

formulate a problem. The aim in formulation is to ensure that the mathematical model completely

The decision modeling process

involves three steps.

It is common to iterate between

the three steps.

Formulation is the most

challenging step in decision

modeling.

FIGURE 1

The Decision Modeling

Approach

Formulation

Solution

Interpretation

Defining

the Problem

Developing

a Model

Acquiring

Input Data

Developing

a Solution

Testing the

Solution

Analyzing

the Results

and Sensitivity

Analysis

Implementing

the Results

5

INTRODUCTION TO MANAGERIAL DECISION MODELING

addresses all the issues relevant to the problem at hand. Formulation can be further classified into

three parts: (1) defining the problem, (2) developing a model, and (3) acquiring input data.

DEFINING THE PROBLEM The first part in formulation (and in decision modeling) is to develop

a clear, concise statement of the problem. This statement gives direction and meaning to all the

parts that follow it.

In many cases, defining the problem is perhaps the most important, and the most difficult,

part. It is essential to go beyond just the symptoms of the problem at hand and identify the true

causes behind it. One problem may be related to other problems, and solving a problem without

regard to its related problems may actually make the situation worse. Thus, it is important to

analyze how the solution to one problem affects other problems or the decision-making environ-

ment in general. Experience has shown that poor problem definition is a major reason for failure

of management science groups to serve their organizations well.

When a problem is difficult to quantify, it may be necessary to develop specific , measurable

objectives. For example, say a problem is defined as inadequate health care delivery in a hospi-

tal. The objectives might be to increase the number of beds, reduce the average number of days a

patient spends in the hospital, increase the physician-to-patient ratio, and so on. When objectives

are used, however, the real problem should be kept in mind. It is important to avoid obtaining

specific and measurable objectives that may not solve the real problem.

DEVELOPING A MODEL Once we select the problem to be analyzed, the next part is to develop

a decision model. Even though you might not be aware of it, you have been using models most

of your life. For example, you may have developed the following model about friendship:

Friendship is based on reciprocity, an exchange of favors. Hence, if you need a favor, such as a

small loan, your model would suggest that you ask a friend.

Of course, there are many other types of models. An architect may make a physical model

of a building he or she plans to construct. Engineers develop scale models of chemical plants,

called pilot plants. A schematic model is a picture or drawing of reality. Automobiles, lawn

mowers, circuit boards, typewriters, and numerous other devices have schematic models (draw-

ings and pictures) that reveal how these devices work.

What sets decision modeling apart from other modeling techniques is that the models we

develop here are mathematical. A mathematical model is a set of mathematical relationships.

In most cases, these relationships are expressed as equations and inequalities, as they are in a

spreadsheet model that computes sums, averages, or standard deviations.

Although there is considerable flexibility in the development of models, most of the models

presented here contain one or more variables and parameters. A variable , as the name implies,

is a measurable quantity that may vary or that is subject to change. Variables can be controllable

or uncontrollable. A controllable variable is also called a decision variable . An example is how

many inventory items to order. A problem parameter is a measurable quantity that is inherent

in the problem, such as the cost of placing an order for more inventory items. In most cases,

variables are unknown quantities, whereas parameters (or input data) are known quantities.

All models should be developed carefully. They should be solvable, realistic, and easy to

understand and modify, and the required input data should be obtainable. A model developer

has to be careful to include the appropriate amount of detail for the model to be solvable yet

realistic.

ACQUIRING INPUT DATA Once we have developed a model, we must obtain the input data to

be used in the model. Obtaining accurate data is essential because even if the model is a perfect

representation of reality, improper data will result in misleading results. This situation is called

garbage in, garbage out (GIGO). For larger problems, collecting accurate data can be one of the

most difficult aspects of decision modeling.

Several sources can be used in collecting data. In some cases, company reports and docu-

ments can be used to obtain the necessary data. Another source is interviews with employees

or other persons related to the firm. These individuals can sometimes provide excellent infor-

mation, and their experience and judgment can be invaluable. A production supervisor, for

example, might be able to tell you with a great degree of accuracy the amount of time that

it takes to manufacture a particular product. Sampling and direct measurement provide other

sources of data for the model. You may need to know how many pounds of a raw material are

Defining the problem can be

the most important part of

formulation.

The types of models include

physical, scale, schematic, and

mathematical models.

A parameter is a measurable

quantity that usually has a

known value.

A variable is a measurable

quantity that is subject to

change.

Garbage in, garbage out means

that improper data will result in

misleading results.

6

INTRODUCTION TO MANAGERIAL DECISION MODELING

used in producing a new photochemical product. This information can be obtained by going to

the plant and actually measuring the amount of raw material that is being used. In other cases,

statistical sampling procedures can be used to obtain data.

Step 2: Solution

The solution step is when the mathematical expressions resulting from the formulation process

are actually solved to identify the optimal solution. Until the mid-1990s, typical courses in deci-

sion modeling focused a significant portion of their attention on this step because it was the most

difficult aspect of studying the modeling process. As stated earlier, thanks to computer technol-

ogy, the focus today has shifted away from the detailed steps of the solution process and toward

the availability and use of software packages. The solution step can be further classified into two

parts: (1) developing a solution and (2) testing the solution.

DEVELOPING A SOLUTION Developing a solution involves manipulating the model to arrive

at the best (or optimal) solution to the problem. In some cases, this may require that a set of

mathematical expressions be solved to determine the best decision. In other cases, you can use

a trial-and-error method, trying various approaches and picking the one that results in the best

decision. For some problems, you may wish to try all possible values for the variables in the

model to arrive at the best decision; this is called complete enumeration . For problems that are

quite complex and difficult, you may be able to use an algorithm. An algorithm consists of a

series of steps or procedures that we repeat until we find the best solution. Regardless of the

approach used, the accuracy of the solution depends on the accuracy of the input data and the

decision model itself.

TESTING THE SOLUTION Before a solution can be analyzed and implemented, it must be tested

completely. Because the solution depends on the input data and the model, both require testing.

There are several ways to test input data. One is to collect additional data from a different source

and use statistical tests to compare these new data with the original data. If there are significant

differences, more effort is required to obtain accurate input data. If the data are accurate but the

results are inconsistent with the problem, the model itself may not be appropriate. In this case,

the model should be checked to make sure that it is logical and represents the real situation.

Step 3: Interpretation and Sensitivity Analysis

Assuming that the formulation is correct and has been successfully implemented and solved,

how does a manager use the results? Here again, the decision maker’s expertise is called upon

because it is up to him or her to recognize the implications of the results that are presented. We

discuss this step in two parts: (1) analyzing the results and sensitivity analysis and (2) imple-

menting the results.

ANALYZING THE RESULTS AND SENSITIVITY ANALYSIS Analyzing the results starts with

determining the implications of the solution. In most cases, a solution to a problem will result in

some kind of action or change in the way an organization is operating. The implications of these

actions or changes must be determined and analyzed before the results are implemented.

Because a model is only an approximation of reality, the sensitivity of the solution to

changes in the model and input data is an important part of analyzing the results. This type of

analysis is called sensitivity, postoptimality, or what-if analysis. Sensitivity analysis is used to

determine how much the solution will change if there are changes in the model or the input data.

When the optimal solution is very sensitive to changes in the input data and the model specifica-

tions, additional testing must be performed to make sure the model and input data are accurate

and valid.

The importance of sensitivity analysis cannot be overemphasized. Because input data may

not always be accurate or model assumptions may not be completely appropriate, sensitivity

analysis can become an important part of decision modeling.

IMPLEMENTING THE RESULTS The final part of interpretation is to implement the results. This

can be much more difficult than one might imagine. Even if the optimal solution will result in

millions of dollars in additional profits, if managers resist the new solution, the model is of no

value. Experience has shown that a large number of decision modeling teams have failed in their

efforts because they have failed to implement a good, workable solution properly.

In the solution step, we solve the

mathematical expressions in the

formulation.

A n algorithm is a series of steps

that are repeated.

The input data and model

determine the accuracy of the

solution.

Analysts test the data and model

before analyzing the results.

Sensitivity analysis determines

how the solutions will change

with a different model or

input data.

7

INTRODUCTION TO MANAGERIAL DECISION MODELING

After the solution has been implemented, it should be closely monitored. Over time, there

may be numerous changes that call for modifications of the original solution. A changing econ-

omy, fluctuating demand, and model enhancements requested by managers and decision makers

are a few examples of changes that might require an analysis to be modified.

The solution should be

closely monitored even after

implementation.

4 Spreadsheet Example of a Decision Model: Tax Computation

Now that we have discussed what a decision model is, let us develop a simple model for a real-

world situation that we all face each year: paying taxes. Sue and Robert Miller, a newly married

couple, will be filing a joint tax return for the first time this year. Because both work as inde-

pendent contractors (Sue is an interior decorator, and Rob is a painter), their projected income

is subject to some variability. However, because their earnings are not taxed at the source, they

know that they have to pay estimated income taxes on a quarterly basis, based on their esti-

mated taxable income for the year. To help calculate this tax, the Millers would like to set up a

spreadsheet-based decision model. Assume that they have the following information available:

Their only source of income is from their jobs.

They would like to put away 5% of their total income in a retirement account, up to a

maximum of $6,000. Any amount they put in that account can be deducted from their total

income for tax purposes.

They are entitled to a personal exemption of $3,700 each. This means that they can deduct

$7,400 ( 2 $3,700) from their total income for tax purposes.

The standard deduction for married couples filing taxes jointly this year is $11,600. This means

that $11,600 of their income is free from any taxes and can be deducted from their total income.

They do not anticipate having any other deductions from their income for tax purposes.

The tax brackets for this year are 10% for the first $17,000 of taxable income, 15%

between $17,001 and $69,000 and 25% between $69,001 and $139,350. The Millers don’t

believe that tax brackets beyond $139,350 are relevant for them this year.

Excel Notes

The Companion Website for this text, at www.pearsonhighered.com/balakrishnan, con-

tains the Excel file for each sample problem discussed here. The relevant file name is

shown in the margin next to each example.

In each of our Excel layouts, for clarity, we color code the cells as follows:

Variable input cells, in which we enter specific values for the variables in the

problem, are shaded yellow.

Output cells, which show the results of our analysis, are shaded green.

We have used callouts to annotate the screenshots in this text to highlight important

issues in the decision model.

Wherever necessary, many of these callouts are also included as comments in the Excel

files themselves, making it easier for you to understand the logic behind each model.

Screenshot 1A shows the formulas that we can use to develop a decision model for the

Millers. Just as we have done for this Excel model (and all other models in this text), we

strongly recommend that you get in the habit of using descriptive titles, labels, and comments

in any decision model that you create. The reason for this is very simple: In many real-world

settings, decision models that you create are likely to be passed on to others. In such cases,

the use of comments will help them understand your thought process. Perhaps an appropriate

question you should always ask yourself is “Will I understand this model a year or two after I

first write it?” If appropriate labels and comments are included in the model, the answer should

always be yes.

In Screenshot 1A , the known problem parameter values (i.e., constants) are shown in the

box labeled Known Parameters. Rather than use these known constant values directly in the

formulas, we recommend that you develop the habit of entering each known value in a cell and

then using that cell reference in the formulas. In addition to being more “elegant,” this way of

modeling has the advantage of making any future changes to these values easy.

A decision modeling example.

File: 1-1.xls, sheet: 1-1A

Wherever possible, titles,

labels, and comments should be

included in the model to make

them easier to understand.

Rather than use constants

directly in formulas, it is

preferable to make them cell

references.

8

INTRODUCTION TO MANAGERIAL DECISION MODELING

Cells B13 and B14 denote the only two variable data entries in this decision model:

Sue’s and Rob’s estimated incomes for this year. When we enter values for these two

variables, the results are computed in cells B17:B26 and presented in the box labeled Tax

Computation.

Cell B17 shows the total income. The MIN function is used in cell B18 to specify the

tax- deductible retirement contribution as the smaller value of 5% of total income and $6,000. Cells

B19 and B20 set the personal exemptions and the standard deduction, respectively. The net tax-

able income is shown in cell B21, and the MAX function is used here to ensure that this amount is

never below zero. The taxes payable at the 10%, 15%, and 25% rates are then calculated in cells

B22, B23, and B24, respectively. In each of these cells, the MIN function is used to ensure that

only the incremental taxable income is taxed at a given rate. (For example, in cell B23, only the

portion of taxable income above $17,000 is taxed at the 15% rate, up to an upper limit of $69,000.)

The IF function is used in cells B23 and B24 to check whether the taxable income exceeds the

lower limit for the 15% and 25% tax rates, respectively. If the taxable income does not exceed the

relevant lower limit, the IF function sets the tax payable at that rate to zero. Finally, the total tax

payable is computed in cell B25, and the estimated quarterly tax is computed in cell B26.

Now that we have developed this decision model, how can the Millers actually use it? Sup-

pose Sue estimates her income this year at $55,000 and Rob estimates his at $50,000. We enter

these values in cells B13 and B14, respectively. The decision model immediately lets us know

that the Millers have a taxable income of $80,750 and that they should pay estimated taxes

of $3,109.38 each quarter. These input values, and the resulting computations, are shown in

Screenshot 1B . We can use this decision model in a similar fashion with any other estimated

income values for Sue and Rob.

Observe that the decision model we have developed for the Millers’ example does not

optimize the decision in any way. That is, the model simply computes the estimated taxes for a

given income level. It does not, for example, determine whether these taxes can be reduced in

some way through better tax planning.

Excel’s MAX, MIN, and IF

functions have been used in this

decision model.

File: 1-1.xls, sheet: 1-1B

This box shows all

the known input

parameter values.

This box shows the

two input variables.

Maximum of (0,

taxable income)

Minimum of (5% of

total income, $6,000)

25% tax between $69,001 and $139,350.

This tax is calculated only if taxable

income exceeds $69,000.

15% tax between

$17,001 and $69,000.

This tax is calculated

only if taxable income

exceeds $17,000.

10% tax up to $17,000

SCREENSHOT 1A

Formula View of Excel

Layout for the Millers’

Tax Computation

9

INTRODUCTION TO MANAGERIAL DECISION MODELING

SCREENSHOT 1B

Excel Decision Model

for the Millers’ Tax

Computation

Total income of $105,000 has

been reduced to taxable

income of only $80,750.

The Millers should pay

$3,109.38 in estimated

taxes each quarter.

Estimated income

Hepatitis B is a vaccine-preventable viral disease that is a major

public health problem, particularly among Asian populations. Left

untreated, it can lead to death from cirrhosis and liver cancer. Over

350 million people are chronically infected with the hepatitis B virus

(HBV) worldwide. In the United States (US), although about 10%

of Asian and Pacific Islanders are chronically infected, about two

thirds of them are unaware of their infection. In China, HBV infec-

tion is a leading cause of death.

During several years of work conducted at the Asian Liver

Center at Stanford University, the authors used combinations of

decision modeling techniques to analyze the cost effectiveness of

various intervention schemes to combat the spread of the disease in

the US and China. The results of these analyses have helped change

US public health policy on hepatitis B screening, and have helped

encourage China to enact legislation to provide free vaccination for

millions of children.

These policies are an important step in eliminating health

disparities and ensuring that millions of people can now receive the

hepatitis B vaccination they need. The Global Health Coordinator

of the Asian Liver Center states that this research “has been

incredibly important to accelerating policy changes to improve

health related to HBV.”

Source: Based on D. W. Hutton, M. L. Brandeau, and S. K. So. “Doing

Good with Good OR: Supporting Cost-Effective Hepatitis B Interventions,”

Interfaces 41, 3 (May-June 2011): 289–300.

IN ACTION

Using Decision Modeling to Combat Spread of

Hepatitis B Virus in the United States and China

5 Spreadsheet Example of a Decision Model: Break-Even Analysis

Let us now develop another decision model—this one to compute the total profit for a firm as

well as the associated break-even point. We know that profit is simply the difference between

revenue and expense. In most cases, we can express revenue as the selling price per unit multi-

plied by the number of units sold. Likewise, we can express expense as the sum of the total fixed

and variable costs. In turn, the total variable cost is the variable cost per unit multiplied by the

number of units sold. Thus, we can express profit using the following mathematical expression:

Profit (Selling price per unit) (Number of units) (Fixed cost)

(Variable cost per unit) (Number of units) (1)

Expenses include fixed and

variable costs.

10

INTRODUCTION TO MANAGERIAL DECISION MODELING

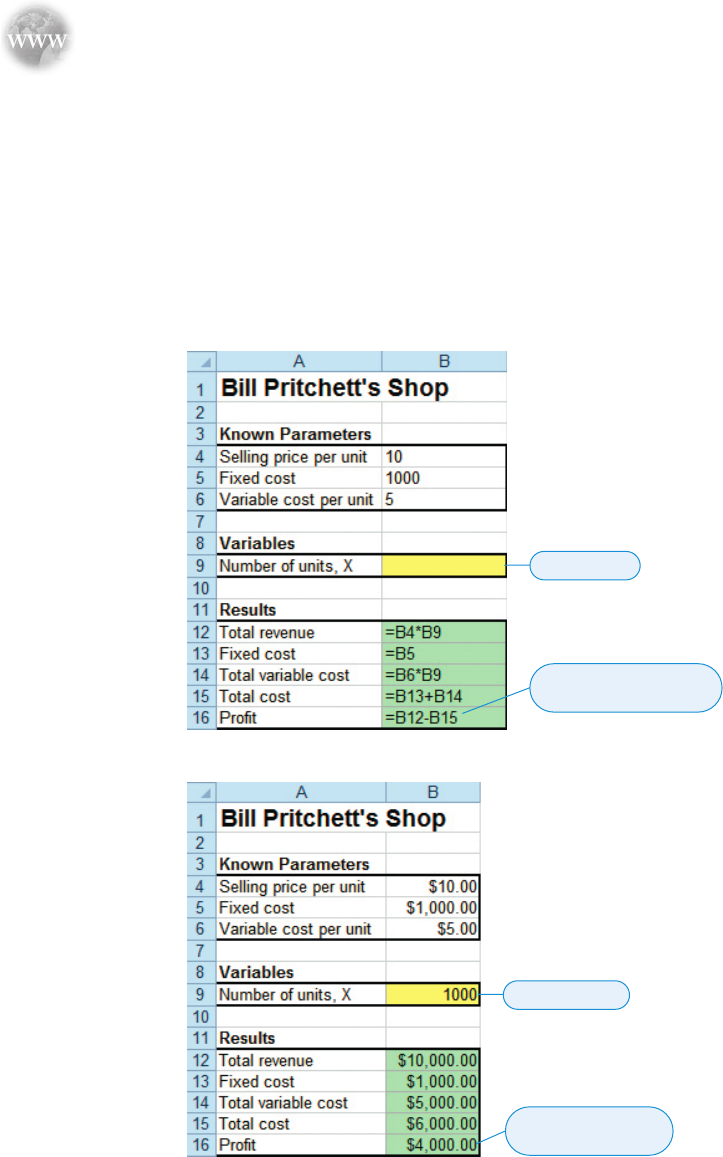

Let’s use Bill Pritchett’s clock repair shop as an example to demonstrate the creation of a

decision model to calculate profit and the associated break-even point. Bill’s company, Pritchett’s

Precious Time Pieces, buys, sells, and repairs old clocks and clock parts. Bill sells rebuilt springs

for a unit price of $10. The fixed cost of the equipment to build the springs is $1,000. The vari-

able cost per unit is $5 for spring material. If we represent the number of springs (units) sold as

the variable X , we can restate the profit as follows:

Profit $10X $1,000 $5X

Screenshot 2A shows the formulas used in developing the decision model for Bill Pritchett’s

example. Cells B4, B5, and B6 show the known problem parameter values—namely, revenue

per unit, fixed cost, and variable cost per unit, respectively. Cell B9 is the lone variable in the

model, and it represents the number of units sold (i.e., X ). Using these entries, the total revenue,

total variable cost, total cost, and profit are computed in cells B12, B14, B15, and B16, respec-

tively. For example, if we enter a value of 1,000 units for X in cell B9, the profit is calculated as

$4,000 in cell B16, as shown in Screenshot 2B .

In addition to computing the profit, decision makers are often interested in the break-even

point (BEP) . The BEP is the number of units sold that will result in total revenue equaling total

costs (i.e., profit is $0). We can determine the BEP analytically by setting profit equal to $0 and

solving for X in Bill Pritchett’s profit expression. That is

File: 1-2.xls, sheets: 1-2A and 1-2B

The BEP results in $0 profit.

SCREENSHOT 2A

Formula View of Excel

Layout for Pritchett’s

Precious Time Pieces

Prot is revenue – xed

cost – variable cost.

Input variable

SCREENSHOT 2B

Excel Decision Model for

Pritchett’s Precious Time

Pieces

Prot is $4,000 if

1,000 units are sold.

1,000 units sold

11

INTRODUCTION TO MANAGERIAL DECISION MODELING

0 (Selling price per unit) (Number of units) (Fixed cost)

(Variable cost per unit) (Number of units)

which can be mathematically rewritten as

Break even point (BEP) Fixed cost ⁄ (Selling price per unit

Variable cost per unit) (2)

For Bill Pritchett’s example, we can compute the BEP as $1,000/($10 − $5) = 200 springs.

The BEP in dollars (which we denote as BEP

$

) can then be computed as

B E P

$

Fixed cost Variable costs BEP (3)

For Bill Pritchett’s example, we can compute BEP

$

as $1,000 + $5 × 200 = $2,000.

Using Goal Seek to Find the Break-Even Point

While the preceding analytical computations for BEP and BEP

$

are fairly simple, an advantage

of using computer-based models is that many of these results can be calculated automatically.

For example, we can use a procedure in Excel called Goal Seek to calculate the BEP and BEP

$

values in the decision model shown in Screenshot 2B . The Goal Seek procedure allows us to

specify a desired value for a target cell . This target cell should contain a formula that involves a

different cell, called the changing cell . Once we specify the target cell, its desired value, and the

changing cell in Goal Seek , the procedure automatically manipulates the changing cell value to

try and make the target cell achieve its desired value.

In our case, we want to manipulate the value of the number of units X (in cell B9 of Screen-

shot 2B ) such that the profit (in cell B16 of Screenshot 2B ) takes on a value of zero. That is, cell

B16 is the target cell, its desired value is zero, and cell B9 is the changing cell. Observe that the

formula of profit in cell B16 is a function of the value of X in cell B9 (see Screenshot 2A ).

Screenshot 2C shows how the

Goal Seek procedure is implemented in Excel. As shown

in Screenshot 2C (a), we invoke Goal Seek by clicking the Data tab on Excel’s main menu bar,

followed by the What-If Analysis button (found in the Data Tools group within the Data tab),

and then finally on Goal Seek . The window shown in Screenshot 2C (b) is displayed. We specify

cell B16 in the Set cell box, a desired value of zero for this cell in the To value box, and cell B9

in the By changing cell box. When we now click OK , the Goal Seek Status window shown in

Screenshot 2C (c) is displayed, indicating that the target of $0 profit has been achieved. Cell B9

shows the resulting BEP value of 200 units. The corresponding BEP

$

value of $2,000 is shown

in cell B15.

Observe that we can use Goal Seek to compute the sales level needed to obtain any

desired profit. For example, see if you can verify that in order to get a profit of $10,000, Bill

Pritchett would have to sell 2,200 springs.

Excel’s Goal Seek can be used to

automatically find the BEP.

File: 1-2.xls, sheet: 1-2C

To provide meaningful assistance to Merrill Lynch, the man-

agement science group has concentrated on mathematical

models that focus on client satisfaction. What are the keys to

continued success for the management science group? Although

skill and technical expertise in decision modeling are essential,

the management science group has identified the following four

critical success factors: (1) objective analysis, (2) focus on busi-

ness impact and implementation, (3) teamwork, and (4) adopting

a disciplined consultative approach.

Source: From R. Nigam et al. “Bullish on Management Science,” OR/MS

Today, Vol. 27, No. 3 (June 2000): 48-51. Reprinted with permission.

Management science groups at corporations can make a

huge difference in reducing costs and increasing profits. At Merrill

Lynch, the management science group was established in 1986.

Its overall mission is to provide high-quality quantitative (or math-

ematical) analysis, modeling, and decision support. The group

analyzes a variety of problems and opportunities related to client

services, products, and the marketplace. In the past, this group

has helped Merrill Lynch develop asset allocation models, mutual

fund portfolio optimization solutions, investment strategy devel-

opment and research tools, financial planning models, and cross-

selling approaches.

IN ACTION

The Management Science Group Is

Bullish at Merrill Lynch

12

INTRODUCTION TO MANAGERIAL DECISION MODELING

Goal Seek

result window

Cell denoting prot.

Set prot to 0.

BEP is 200 units.

BEP

$

is $2,000.

Cell denoting number of units.

Prot target of $0

has been achieved.

(a)

(b)

(c)

Data tab in Excel

Goal Seek is part of What-If

Analysis in the Data Tools group.

SCREENSHOT 2C

Using Excel’s Goal Seek

to Compute the Break-

Even Point for Pritchett’s

Precious Time Pieces

6 Possible Problems in Developing Decision Models

We present the decision modeling approach as a logical and systematic means of tackling

decision-making problems. Even when these steps are followed carefully, however, many dif-

ficulties can hurt the chances of implementing solutions to real-world problems. We now look

at problems that can occur during each of the steps of the decision modeling approach.

Defining the Problem

In the worlds of business, government, and education, problems are, unfortunately, not easily

identified. Decision analysts typically face four roadblocks in defining a problem. We use an

application, inventory analysis, throughout this section as an example.

CONFLICTING VIEWPOINTS Analysts may often have to consider conflicting viewpoints in

defining a problem. For example, in inventory problems, financial managers usually feel that

inventory is too high because inventory represents cash not available for other investments. In

contrast, sales managers often feel that inventory is too low because high levels of inventory

may be needed to fill unexpected orders. If analysts adopt either of these views as the problem

definition, they have essentially accepted one manager’s perception. They can, therefore, expect

resistance from the other manager when the “solution” emerges. So it’s important to consider

both points of view before stating the problem.

Real-world problems are not

easily identifiable.

The problem needs to be

examined from several

viewpoints.

13

INTRODUCTION TO MANAGERIAL DECISION MODELING

IMPACT ON OTHER DEPARTMENTS Problems do not exist in isolation and are not owned by

just one department of a firm. For example, inventory is closely tied with cash flows and various

production problems. A change in ordering policy can affect cash flows and upset production

schedules to the point that savings on inventory are exceeded by increased financial and

production costs. The problem statement should therefore be as broad as possible and include

inputs from all concerned departments.

BEGINNING ASSUMPTIONS People often have a tendency to state problems in terms of

solutions. For example, the statement that inventory is too low implies a solution: that its

levels should be raised. An analyst who starts off with this assumption will likely find that

inventory should be raised! From an implementation perspective, a “good” solution to the

right problem is much better than an “optimal” solution to the wrong problem.

SOLUTION OUTDATED Even if a problem has been specified correctly at present, it can change

during the development of the model. In today’s rapidly changing business environment,

especially with the amazing pace of technological advances, it is not unusual for problems to

change virtually overnight. The analyst who presents solutions to problems that no longer exist

can’t expect credit for providing timely help.

Developing a Model

Even with a well-defined problem statement, a decision analyst may have to overcome hurdles

while developing decision models for real-world situations. Some of these hurdles are discussed

in the following sections.

FITTING THE TEXTBOOK MODELS A manager’s perception of a problem does not always

match the textbook approach. For example, most textbook inventory models involve minimizing

the sum of holding and ordering costs. Some managers view these costs as unimportant; instead,

they see the problem in terms of cash flow, turnover, and levels of customer satisfaction. The

results of a model based on holding and ordering costs are probably not acceptable to such

managers.

UNDERSTANDING A MODEL Most managers simply do not use the results of a model they

do not understand. Complex problems, though, require complex models. One trade-off is to

simplify assumptions in order to make a model easier to understand. The model loses some

of its reality but gains some management acceptance. For example, a popular simplifying

assumption in inventory modeling is that demand is known and constant. This allows analysts

to build simple, easy-to-understand models. Demand, however, is rarely known and constant, so

these models lack some reality. Introducing probability distributions provides more realism but

may put comprehension beyond all but the most mathematically sophisticated managers. In such

cases, one approach is for the decision analyst to start with the simple model and make sure that

it is completely understood. More complex models can then be introduced slowly as managers

gain more confidence in using these models.

Acquiring Input Data

Gathering the data to be used in the decision modeling approach to problem solving is often not

a simple task. Often, the data are buried in several different databases and documents, making it

very difficult for a decision analyst to gain access to the data.

USING ACCOUNTING DATA One problem is that most data generated in a firm come from

basic accounting reports. The accounting department collects its inventory data, for example, in

terms of cash flows and turnover. But decision analysts tackling an inventory problem need to

collect data on holding costs and ordering costs. If they ask for such data, they may be shocked

to find that the data were simply never collected for those specified costs.

Professor Gene Woolsey tells a story of a young decision analyst sent down to accounting

to get “the inventory holding cost per item per day for part 23456/AZ.” The accountant asked

the young man if he wanted the first-in, first-out figure; the last-in, first-out figure; the lower of

cost or market figure; or the “how-we-do-it” figure. The young man replied that the inventory

model required only one number. The accountant at the next desk said, “Heck, Joe, give the kid

a number.” The analyst was given a number and departed.

All inputs must be considered.

Managers do not use the

results of a model they do not

understand.

14

INTRODUCTION TO MANAGERIAL DECISION MODELING

VALIDITY OF DATA A lack of “good, clean data” means that whatever data are available

must often be distilled and manipulated (we call it “fudging”) before being used in a model.

Unfortunately, the validity of the results of a model is no better than the validity of the data that

go into the model. You cannot blame a manager for resisting a model’s “scientific” results when

he or she knows that questionable data were used as input.

Developing a Solution

An analyst may have to face two potential pitfalls while developing solutions to a decision

model. These are discussed in the following sections.

HARD-TO-UNDERSTAND MATHEMATICS The first concern in developing solutions is that

although the mathematical models we use may be complex and powerful, they may not be

completely understood. The aura of mathematics often causes managers to remain silent when

they should be critical. The well-known management scientist C. W. Churchman once cautioned

that “because mathematics has been so revered a discipline in recent years, it tends to lull the

unsuspecting into believing that he who thinks elaborately thinks well.”

1

THE LIMITATION OF ONLY ONE ANSWER The second problem in developing a solution is that

decision models usually give just one answer to a problem. Most managers would like to have

a range of options and not be put in a take-it-or-leave-it position. A more appropriate strategy

is for an analyst to present a range of options, indicating the effect that each solution has on the

objective function. This gives managers a choice as well as information on how much it will

cost to deviate from the optimal solution. It also allows problems to be viewed from a broader

perspective because it means that qualitative factors can also be considered.

Testing the Solution

The results of decision modeling often take the form of predictions of how things will work in

the future if certain changes are made in the present. To get a preview of how well solutions will

really work, managers are often asked how good a solution looks to them. The problem is that

complex models tend to give solutions that are not intuitively obvious. And such solutions tend to

be rejected by managers. Then a decision analyst must work through the model and the assump-

tions with the manager in an effort to convince the manager of the validity of the results. In the

process of convincing the manager, the analyst has to review every assumption that went into the

model. If there are errors, they may be revealed during this review. In addition, the manager casts

a critical eye on everything that went into the model, and if he or she can be convinced that the

model is valid, there is a good chance that the solution results are also valid.

Analyzing the Results

Once a solution has been tested, the results must be analyzed in terms of how they will affect the

total organization. You should be aware that even small changes in organizations are often diffi-

cult to bring about. If results suggest large changes in organizational policy, the decision analyst

can expect resistance. In analyzing the results, the analyst should ascertain who must change and

by how much, if the people who must change will be better or worse off, and who has the power

to direct the change.

The results of a model are only as

good as the input data used.

Hard-to-understand mathematics

and having only one answer

can be problems in developing

a solution.

Assumptions should be reviewed.

1

Churchman, C. W. “Reliability of Models in the Social Sciences,” Interfaces 4, 1 (November 1973): 1–12.

7 Implementation—Not Just the Final Step

We have just presented some of the many problems that can affect the ultimate acceptance of

decision modeling in practice. It should be clear now that implementation isn’t just another

step that takes place after the modeling process is over. Each of these steps greatly affects the

chances of implementing the results of a decision model.

Even though many business decisions can be made intuitively, based on hunches and

experience, there are more and more situations in which decision models can assist. Some

managers, however, fear that the use of a formal analytical process will reduce their

15

INTRODUCTION TO MANAGERIAL DECISION MODELING

decision-making power. Others fear that it may expose some previous intuitive decisions as

inadequate. Still others feel uncomfortable about having to reverse their thinking patterns with

formal decision making. These managers often argue against the use of decision modeling.

Many action-oriented managers do not like the lengthy formal decision-making process and

prefer to get things done quickly. They prefer “quick and dirty” techniques that can yield imme-

diate results. However, once managers see some quick results that have a substantial payoff, the

stage is set for convincing them that decision modeling is a beneficial tool.

We have known for some time that management support and user involvement are critical to

the successful implementation of decision modeling processes. A Swedish study found that only

40% of projects suggested by decision analysts were ever implemented. But 70% of the modeling

projects initiated by users, and fully 98% of projects suggested by top managers, were implemented.

Management support and user

involvement are important.

Summary

Decision modeling is a scientific approach to decision mak-

ing in practical situations faced by managers. Decision mod-

els can be broadly classified into two categories, based on

the type and nature of the problem environment under con-

sideration: (1) deterministic models and (2) probabilistic

models. Deterministic models assume that all the relevant

input data and parameters are known with certainty. In con-

trast, probabilistic models assume that some input data are

not known with certainty. The decision modeling approach

includes three major steps: (1) formulation, (2) solution, and

(3) interpretation. It is important to note that it is common

to iterate between these three steps before the final solution

is obtained. Spreadsheets are commonly used to develop

decision models.

In using the decision modeling approach, however, there

can be potential problems, such as conflicting viewpoints,

disregard of the impact of the model on other departments,

outdated solutions, misunderstanding of the model, difficulty

acquiring good input data, and hard-to-understand mathemat-

ics. In using decision models, implementation is not the final

step. There can be a lack of commitment to the approach and

resistance to change.

Glossary

Break-Even Point (BEP) The number of units sold that

will result in total revenue equaling total costs (i.e., profit

is $0).

Break-Even Point in Dollars (BEP

$

) The sum of fixed and

total variable cost if the number of units sold equals the

break-even point.

Decision Analyst An individual who is responsible for

developing a decision model.

Decision Modeling A scientific approach that uses quantitative

(mathematical) techniques as a tool in managerial decision

making. Also known as quantitative analysis , management

science , and operations research .

Deterministic Model A model which assumes that all the

relevant input data and parameters are known with certainty.

Formulation The process by which each aspect of a prob-

lem scenario is translated and expressed in terms of a

mathematical model.

Goal Seek A feature in Excel that allows users to specify a

goal or target for a specific cell and automatically manipu-

late another cell to achieve that target.

Input Data Data that are used in a model in arriving at the

final solution.

Model A representation (usually mathematical) of a practical

problem scenario or environment.

Probabilistic Model A model which assumes that some input

data are not known with certainty.

Problem Parameter A measurable quantity that is inherent

in a problem. It typically has a fixed and known value (i.e.,

a constant).

Sensitivity Analysis A process that involves determining

how sensitive a solution is to changes in the formulation

of a problem.

Variable A measurable quantity that may vary or that is sub-

ject to change.

Discussion Questions and Problems

Discussion Questions

1 Define decision modeling . What are some of the organi-

zations that support the use of the scientific approach?

2 What is the difference between deterministic and

probabilistic models? Give several examples of each

type of model.

3 What are the differences between quantitative and qualita-

tive factors that may be present in a decision model?

4 Why might it be difficult to quantify some qualitative

factors in developing decision models?

5 What steps are involved in the decision modeling

process? Give several examples of this process.

16

INTRODUCTION TO MANAGERIAL DECISION MODELING

6 Why is it important to have an iterative process

between the steps of the decision modeling approach?

7 Briefly trace the history of decision modeling. What

happened to the development of decision modeling

during World War II?

8 What different types of models are mentioned in this

chapter? Give examples of each.

9 List some sources of input data.

10 Define decision variable . Give some examples of

variables in a decision model.

11 What is a problem parameter? Give some examples

of parameters in a decision model.

12 List some advantages of using spreadsheets for deci-

sion modeling.

13 What is implementation, and why is it important?

14 Describe the use of sensitivity analysis, or postopti-

mality analysis, in analyzing the results of decision

models.

15 Managers are quick to claim that decision modelers

talk to them in a jargon that does not sound like Eng-

lish. List four terms that might not be understood by

a manager. Then explain in nontechnical terms what

each of them means.

16 Why do you think many decision analysts don’t like

to participate in the implementation process? What

could be done to change this attitude?

17 Should people who will be using the results of a new

modeling approach become involved in the techni-

cal aspects of the problem-solving procedure?

18 C. W. Churchman once said that “mathematics tends

to lull the unsuspecting into believing that he who

thinks elaborately thinks well.” Do you think that

the best decision models are the ones that are most

elaborate and complex mathematically? Why?

Problems

19 A Website has a fixed cost $15,000 per day. The

revenue is $0.06 each time the Website is accessed.

The variable cost of responding to each hit is $0.02.

(a) How many times must this Website be accessed

each day to break even?

(b) What is the break-even point, in dollars?

20 An electronics firm is currently manufacturing

an item that has a variable cost of $0.60 per unit

and selling price of $1.10 per unit. Fixed costs are

$15,500. Current volume is 32,000 units. The firm

can substantially improve the product quality by

adding a new piece of equipment at an additional

fixed cost of $8,000. Variable cost would increase

to $0.70, but volume is expected to jump to 50,000

units due to the higher quality of the product.

(a) Should the company buy the new equipment?

(b) Compute the profit with the current equipment

and the expected profit with the new equipment.

21 A manufacturer is evaluating options regarding

his production equipment. He is trying to decide

whether he should refurbish his old equipment for

$70,000, make major modifications to the produc-

tion line for $135,000, or purchase new equipment

for $230,000. The product sells for $10, but the

variable costs to make the product are expected to

vary widely, depending on the decision that is to

be made regarding the equipment. If the manufac-

turer refurbishes, the variable costs will be $7.20 per

unit. If he modifies or purchases new equipment, the

variable costs are expected to be $5.25 and $4.75,

respectively.

(a) Which alternative should the manufacturer

choose if it the demand is expected to be between

30,000 and 40,000 units?

(b) What will be the manufacturer’s profit if the

demand is 38,000 units?

22 St. Joseph’s School has 1,200 students, each of

whom currently pays $8,000 per year to attend. In

addition to revenues from tuition, the school receives

an appropriation from the church to sustain its activ-

ity. The budget for the upcoming year is $15 million,

and the church appropriation will be $4.8 million.

By how much will the school have to raise tuition

per student to keep from having a shortfall in the

upcoming year?

23 Refer to Problem 22. Sensing resistance to the idea

of raising tuition from members of St. Joseph’s

Church, one of the board members suggested that

the 960 children of church members could pay

$8,000 as usual. Children of nonmembers would pay

more. What would the nonmember tuition per year

be if St. Joseph’s wanted to continue to plan for a

$15 million budget?

24 Refer to Problems 22 and 23. Another board mem-

ber believes that if church members pay $8,000 in

tuition, the most St. Joseph’s can increase nonmem-

ber tuition is $1,000 per year. She suggests that an-

other solution might be to cap nonmember tuition

at $9,000 and attempt to recruit more nonmember

students to make up the shortfall. Under this plan,

how many new nonmember students will need to be

recruited?

25 Great Lakes Automotive is considering producing,

in-house, a gear assembly that it currently purchases

from Delta Supply for $6 per unit. Great Lakes esti-

mates that if it chooses to manufacture the gear as-

sembly, it will cost $23,000 to set up the process and

then $3.82 per unit for labor and materials. At what

volume would these options cost Great Lakes the

same amount of money?

26 A start-up publishing company estimates that the

fixed costs of its first major project will be $190,000,

the variable cost will be $18, and the selling price

per book will be $34.

17

INTRODUCTION TO MANAGERIAL DECISION MODELING

19 (a) 375,000. (b) $22,500.

21 (a) Make major modifications. (b) $45,500.

23 $10,500.

25 10,550 units.

27 Yes. The profit will increase by $1,000.

29 (a) BEP

A

= 6,250. BEP

B

= 7,750. (b) Choose A.

(c) 3,250 widgets, but both machines lose money at

this production level.

(a) How many books must be sold for this project to

break even?

(b) Suppose the publishers wish to take a total of

$40,000 in salary for this project. How many

books must be sold to break even, and what is

the break-even point, in dollars?

27 The electronics firm in Problem 20 is now consid-

ering purchasing the new equipment and increas-

ing the selling price of its product to $1.20 per

unit. Even with the price increase, the new volume

is expected to be 50,000 units. Under these cir-

cumstances, should the company purchase the new

equipment and increase the selling price?

28 A distributer of prewashed shredded lettuce is

opening a new plant and considering whether to

use a mechanized process or a manual process to

prepare the product. The manual process will have

a fixed cost of $43,400 per month and a variable

cost of $1.80 per 5-pound bag. The mechanized

process would have a fixed cost of $84,600 per

month and a variable cost of $1.30 per bag. The

company expects to sell each bag of shredded let-

tuce for $2.50.

(a) Find the break-even point for each process.

(b) What is the monthly profit or loss if the company

chooses the manual process and sells 70,000

bags per month?

29 A fabrication company must replace its widget

machine and is evaluating the capabilities of two avail-

able machines. Machine A would cost the company

$75,000 in fixed costs for the first year. Each widget

produced using Machine A would have a variable cost

of $16. Machine B would have a first-year fixed cost

of $62,000, and widgets made on this machine would

have a variable cost of $20. Machine A would have

the capacity to make 18,000 widgets per year, which is

approximately double the capacity for Machine B.

(a) If widgets sell for $28 each, find the break-even

point for each machine. Consider first-year costs

only.

(b) If the fabrication company estimates a demand

of 6,500 units in the next year, which machine

should be selected?

(c) At what level of production do the two produc-

tion machines cost the same?

30 Bismarck Manufacturing intends to increase capac-

ity through the addition of new equipment. Two

vendors have presented proposals. The fixed cost for

proposal A is $65,000, and for proposal B, $34,000.

The variable cost for A is $10, and for B, $14. The

revenue generated by each unit is $18.

(a) What is the break-even point for each proposal?

(b) If the expected volume is 8,300 units, which

alternative should be chosen?

Brief Solutions to Odd-Numbered End-of-Chapter Problems

18

1 Introduction

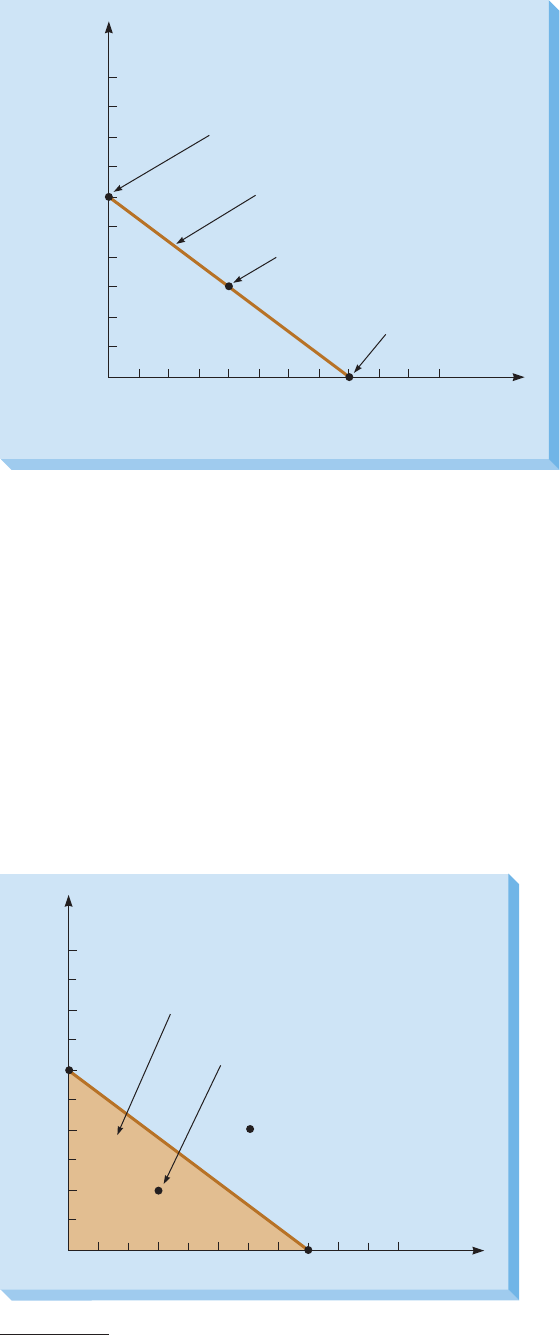

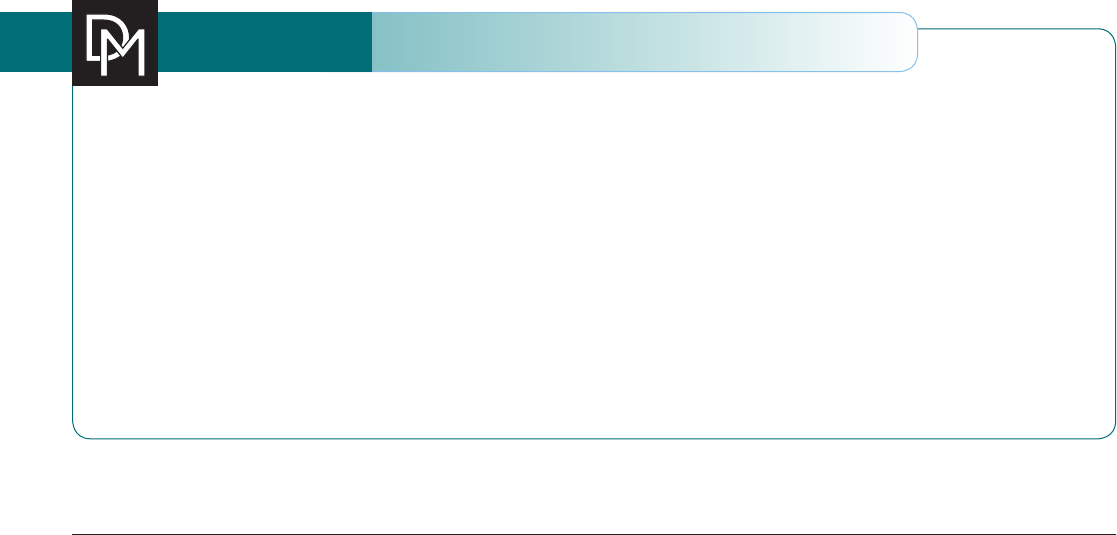

2 Developing a Linear Programming Model

3 Formulating a Linear Programming Problem

4 Graphical Solution of a Linear Programming

Problem with Two Variables

5 A Minimization Linear Programming Problem

6 Special Situations in Solving Linear Programming

Problems

7 Setting Up and Solving Linear Programming

Problems Using Excel’s Solver

8 Algorithmic Solution Procedures for Linear

Programming Problems

After completing this chapter, students will be able to:

1. Understand the basic assumptions and properties

of linear programming (LP).

2. Use graphical procedures to solve LP problems

with only two variables to understand how LP

problems are solved.

3. Understand special situations such as

redundancy, infeasibility, unboundedness, and

alternate optimal solutions in LP problems.

4. Understand how to set up LP problems on a

spreadsheet and solve them using Excel’s Solver.

CHAPTER OUTLINE

Summary • Glossary • Solved Problems • Discussion Questions and Problems • Case Study: Mexicana Wire

Winding, Inc. • Case Study: Golding Landscaping and Plants, Inc. • Internet Case Studies

LEARNING OBJECTIVES

Linear Programming

Models: Graphical and

Computer Methods

The companion website for this text is www.pearsonhighered.com/balakrishnan.

From Chapter 2 of Managerial Decision Modeling with Spreadsheets, Third Edition. Nagraj Balakrishnan, Barry Render, Ralph M. Stair, Jr.

Copyright © 2013 by Pearson Education, Inc. All rights reserved.

19

LINEAR PROGRAMMING MODELS: GRAPHICAL AND COMPUTER METHODS

Management decisions in many organizations involve trying to make the most effective use of

resources. Resources typically include machinery, labor, money, time, warehouse space, and

raw materials. These resources can be used to manufacture products (e.g., computers, automo-

biles, furniture, clothing) or provide services (e.g., package delivery, health services, advertising

policies, investment decisions).

In all resource allocation situations, the manager must sift through several thousand decision

choices or alternatives to identify the best, or optimal, choice. The most widely used decision

modeling technique designed to help managers in this process is called mathematical program-

ming . The term mathematical programming is somewhat misleading because this modeling

technique requires no advanced mathematical ability (it uses just basic algebra) and has nothing

whatsoever to do with computer software programming! In the world of decision modeling,

programming refers to setting up and solving a problem mathematically.

Within the broad topic of mathematical programming, the most widely used modeling tech-

nique designed to help managers in planning and decision making is linear programming (LP) .

When developing LP (and other mathematical programming)–based decision models, we

assume that all the relevant input data and parameters are known with certainty. For this reason,

these types of decision modeling techniques are classified as deterministic models.

Computers have, of course, played an important role in the advancement and use of LP.

Real-world LP problems are too cumbersome to solve by hand or with a calculator, and com-

puters have become an integral part of setting up and solving LP models in today’s business

environments. Over the past decade, spreadsheet packages such as Microsoft Excel have be-

come increasingly capable of handling many of the decision modeling techniques (including

LP and other mathematical programming models) that are commonly encountered in practical

situations.

Linear programming helps in

resource allocation decisions.

We focus on using Excel to set

up and solve LP models.

L inear programming was conceptually developed before World

War II by the outstanding Soviet mathematician A. N. Kolmogorov.

Another Russian, Leonid Kantorovich, won the Nobel Prize in Eco-

nomics for advancing the concepts of optimal planning. An early

application of linear programming, by George Stigler in 1945,

was in the area we today call “diet problems.”

Major progress in the field, however, took place in 1947 and