Contents

Page

Safety Precautions.................................................2

1. Package Contents ......................................... 5

2. Specifications ................................................ 6

2-1. Product Specifications .........................6

2-2. External dimensions ............................6

2-3. Power supply function to the M-NET

transmission line ..................................7

3. Sample system configuration ........................8

3-1. System in which BAC-HD150 is

connected to the M-NET line ............... 8

3-2. Restrictions for using BAC-HD150 in

combination with AG-150A ..................9

3-3. System in which BAC-HD150 is

connected to the expansion

controller ............................................10

3-4. Restrictions for using BAC-HD150 in

combination with other

controllers .........................................11

3-5. Setting M-NET address for

various devices ..................................12

4. Installation ................................................... 14

4-1. Required parts ...................................14

4-2. M-NET transmission line length.........15

4-3. Installation.......................................... 16

5. Wiring connections......................................17

5-1. Installing and uninstalling

the cover ............................................17

5-2. Connecting the power cable and

protective earth cable ........................17

5-3. Connecting the M-NET transmission

lines ...................................................18

5-4. Connecting the LAN cable .................20

6. Making the initial settings ............................21

7. Test run .......................................................21

Air-conditioner Control System

BM ADAPTER

BAC-HD150 Installation Manual

BACnet

®

is a registered trade mark of ASHRAE

(American Society of Heating, Refrigerating, and

Air-Conditioning Engineers, Inc.).

gb02_WT05543X03_9.book Page 1 Friday, June 28, 2013 1:23 PM

- 2 -

Safety Precautions

• Thoroughly read this installation manual before use to ensure safety.

• Before installing the BAC-HD150, read the Safety Precautions section carefully to ensure proper installation.

• Observe these precautions carefully to ensure safety.

• After reading this manual, pass the manual on to the end user to retain for future reference.

• The users should keep this manual for future reference and refer to it as necessary. This manual should be made available to those

who repair or relocate the units. Make sure that the manual is passed on to any future air condition system users.

Electric work must be performed by an authorized technician.

Installation

Wire installation

WARNING

Indicates a risk of death or serious injury.

CAUTION

Indicates a risk of injury or structural damage.

WARNING

To reduce the risk of fire and electric shock, do not install

the units where they can get wet.

To reduce the risk of electric shock, fire, and malfunction,

do not install the unit in a steamy or condensing

environments.

Properly dispose of the packing materials.

Plastic bags can pose suffocation and choking hazards. Keep

out of the reach of children. Tear the plastics bags before

disposing of them.

Properly install the unit on a stable, load-bearing surface.

Unit installed on an unstable surface may fall and cause injury.

Units must be properly installed by your dealer or

authorized technician according to the instructions in the

Installation Manual.

Improper installation may result in electric shock or fire.

Properly secure the cables with clamps so that the weight

of the cables will not strain the connectors.

Improperly connected cables may break, produce heat, and

cause smoke or fire.

Electric work must be performed by an authorized

technician according to the local regulations and the

instructions detailed in this manual. Always use a

dedicated circuit.

Capacity shortage to the power supply circuit or improper

installation may result in electric shock, smoke, or fire.

Install all required covers.

Infiltration of dust or water may cause electric shock, smoke,

or fire.

Take appropriate measures against electrical noise

interference when installing the air conditioners in

hospitals or radio communication facilities.

• Inverter, power generators, or radio communication

equipment may interfere with the normal operation of the

unit.

• Subsequently, the device may also affect medical treatment,

image broadcasting by creating frequency noise.

Make sure that there is a main power switch and residual

current circuit breaker (RCCB) for each unit.

A ready accessible breaker for power source line helps reduce

the risk of electric shock. Installation of a breaker is mandatory

in some area.

To reduce the risk of electric leak, overheating, and fire,

only use standard cables with the proper current carrying

capacity.

Use properly rated breakers (residual current circuit

breaker (RCCB), main switch + fuse, circuit breaker).

The use of improperly rated breakers may result in

malfunctions or fire.

To reduce the risk of electric shock and malfunctions,

keep wire pieces and sheath shavings out of the terminal

block.

This appliance must be earthed.

Do not connect the protective earth cable to a gas pipe, water

pipe, lightning rod, or telephone earthing cable.

If the unit is not properly earthed, the unit may malfunction due

to electrical noise interference. It also poses a risk of electric

shock, smoke, or fire.

gb02_WT05543X03_9.book Page 2 Friday, June 28, 2013 1:23 PM

- 3 -

General caution

Relocating/Repairing units

Transporting units/Unit installation

Electric work

General caution

CAUTION

Do not install the unit in environments where large

amounts of oil (including machine) or acidic/alkaline

chemical sprays are present. These types of substances

may cause device performance to be reduced and cause

electrical shock, malfunction, smoke, or fire.

To reduce the risk of electric shock, fire, or malfunction,

do not wash the unit with water or other types of liquids.

Wear protective gloves.

A high voltage is applied to the terminals. To reduce the risk of

electric shock, wear protective gloves before touching the

electrical parts on the unit.

Consult your dealer or an authorized technician when the

unit needs to be relocated or repaired.

Do not disassemble the unit or make any modifications/

alterations to the unit.

Improper repair, modification, or alteration may cause injury,

electric shock, or fire.

Do not install the unit where there is a risk of leaking

flammable gas.

If flammable gas accumulates around the unit, it may ignite

and cause a fire or explosion.

Take appropriate safety measures against earthquakes to

prevent the unit from toppling over.

Unit installed on an unstable surface may fall and cause injury.

To reduce the risk of fire and malfunctions and to keep the

unit from falling, do not install the unit where the unit may

receive vibration or mechanical shock.

Do not touch switches or other electrical parts with wet

hands.

Doing so poses a risk of fire or electric shock.

To reduce the risk of electric shock, turn off the power

before performing electric work.

When replacing fuses, only use fuses with adequate

breaking capacity.

The use of improperly rated fuses or a substitution of fuses

with steel or copper wire may result in fire.

To reduce the risk of injury, do not touch the edges of

parts.

To reduce the risk of injury from accidentally dropped

tools, check the surroundings before performing

installation, inspection, and repairs, and keep children

away from the site.

gb02_WT05543X03_9.book Page 3 Friday, June 28, 2013 1:23 PM

- 4 -

Important

To avoid deformation and malfunction, do not install the

unit in direct sunlight or where the ambient temperature

exceeds 55°C (131°F) or drops below -10°C (14°F).

Always use adequate tools for repair.

The use of unsuitable tools may result in failure to complete

the job properly and cause unit damage or injury.

When connecting to the Internet, manage the security of

the Internet.

To prevent unauthorized access, always use a security device

such as a VPN router when connecting to the Internet.

To avoid malfunctions, do not bundle the power cable and

signal transmission lines together, or put them in the

same conduit.

To avoid fire, malfunction, and damage, do not connect

the power cable to terminal block for signal cables.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety.

Children should be supervised to ensure that they do not

play with the appliance.

gb02_WT05543X03_9.book Page 4 Friday, June 28, 2013 1:23 PM

- 5 -

Check that the following parts are included in the package.

1 Package Contents

No. Item Usage Qty

①

BM ADAPTER (BAC-HD150) BAC-HD150 is a protocol converter that

enables the centralized control/operation of

CITY MULTI air conditioners. By connecting

this unit to the BACnet

®

building

management system, it can control up to 50

units.(*)

1

②

Installation Manual (this document) Describes how to install BAC-HD150. 1

③

Instructions Book

Explains how to make the initial settings for

BAC-HD150 and how to test run the

system.

1

④

Setting Tool CD

Contains the software to set up BAC-

HD150 and an Instruction Manual file. Use

them to initially set up the addresses for

BAC-HD150 and configure an air

conditioning system.

1

Note

* Expansion controllers (PAC-YG50ECA; separately sold) can be connected to BAC-HD150 to control up to

150 units. Up to 3 PAC-YG50ECA can be connected to each BAC-HD150.

Refer to section 3-3. "System in which BAC-HD150 is connected to the expansion controller" for details.

gb02_WT05543X03_9.book Page 5 Friday, June 28, 2013 1:23 PM

- 6 -

2-1. Product Specifications

2-2. External dimensions

2 Specifications

Items Specifications

Power source

Rated input 100-240 VAC ±10 % 0.4-0.3 A 50/60 Hz

Fuse 250 VAC 3.15 A Time-delay type (IEC127-2 S.S.5)

Interface

Rated output of the power supply

to M-NET transmission lines

22-30 VDC

LAN 1 (for BACnet

®

)

LAN 2 (for Expansion Controller)

10Base-T or 100Base-TX

Ambient

conditions

Temperature

Operating

temperature range

-10 ~ 55°C (14 ~ 131°F)

Storage

temperature range

-20 ~ 60°C (-4 ~ 140°F)

Humidity 30 ~ 90 %RH (Non-condensing)

Dimensions 266 (H) × 250 (W) × 97.2 (D) mm (10-

1

/2 (H) × 9-

7

/8 (W) × 3-

7

/8 (D) in.)

Weight 2.8 kg (6-

3

/16 lbs.)

Installation conditions Inside the metal control panel (indoor)

250(9-

7

/

8

)

155(6-

1

/

8

) 47.5(1-

7

/

8

)

97.2(3-

7

/

8

)

266(10-

1

/

2

)

253.5(10)

5(

3

/

16

)

M-NET Terminal

block (M3.5)

LAN

LAN1 LAN2

Power source 100-240 VAC

Terminal block (M3.5)

Terminal block (to be used in the future when functions of the BAC-HD150 are upgraded.)

Unit: mm (in.)

gb02_WT05543X03_9.book Page 6 Friday, June 28, 2013 1:23 PM

- 7 -

2-3. Power supply function to the M-NET transmission line

BAC-HD150 has a built-in function to supply power to the M-NET transmission line. (power supply coefficient: 6)

When power is supplied from BAC-HD150, the total power consumption coefficient of the system controller and M-NET

remote controller to which BAC-HD150 supplies power (See table 1) should not exceed the power supply coefficient of

BAC-HD150, which is six.

Table 1 Power consumption coefficient of the controller

Table 2 No. of connected units

Table 3 No. of connected units in systems with various combinations of remote controllers V: connectable

System controller M-NET remote controller

ON/OFF remote controller

System remote controller

Schedule timer

Group remote controller

ME remote controller

LOSSNAY remote

controller

1 0.5 0.25

System controller M-NET remote controller

ON/OFF remote controller

System remote controller

Schedule timer

Group remote controller

ME remote controller

LOSSNAY remote

controller

6 units 12 units 24 units

Total number of ON/OFF remote controllers

0123456

Total number of system remote controllers,

schedule timers, and group remote

controllers combined

0VVVVVVV

1VVVVVV

2VVVVVV

3VVVVV

4VVVVV

5VVVV

6VVVV

7VVV

8VVV

9VV

10 V V

11 V

12 V

gb02_WT05543X03_9.book Page 7 Friday, June 28, 2013 1:23 PM

- 8 -

3-1. System in which BAC-HD150 is connected to the M-NET line

The figure below only shows the transmission line connections. Power supply lines are omitted.

3 Sample system configuration

Note Use a switching HUB.

Provide “one-point grounding” for the M-NET transmission line (centralized control system) by grounding the

shield of the BAC-HD150.

Ground the indoor-outdoor transmission line in each outdoor unit refrigerant system.

Set the centralized control switch (SW2-1) on the outdoor units on the M-NET line to ON.

(Refer to the outdoor unit Installation Manual for the details of the dipswitch settings.)

TB7 TB3

ME

MA

K

TB7 TB3

MA

K

R2

TB7 TB3

MA MA

[000]

BM ADAPTER

Model: BAC-HD150

Model: PAC-SC25KAA

K-transmission converter

Building Management System

Mitsubishi Electric air conditioning system

[051]

[001] [002]

[006]

[057]

[056]

[007] [008] [009]

[010]

[003] [004] [005]

[106]

[11] [12]

[13]

[13]

[213]

[14] [15]

[15]

[16]

BACnet

®

HUB

HUB

LAN1

(LAN)

M-NET

Group 1 Group 2

Indoor unit

Local remote controller

BACnet

®

(LAN)

M-NET transmission line

K transmission line

MA remote controller line

The numbers in the [ ] indicate

the M-NET address No.

Group 3

Group 4 Group 5

Group 13 Group 15

M-NET

Outdoor unit

M-NET

M-NET adapter

Outdoor unit

K control

outdoor unit

Mr.Slim

Mr.Slim outdoor unit

outdoor unit

LOSSNAY

BC controller

gb02_WT05543X03_9.book Page 8 Friday, June 28, 2013 1:23 PM

- 9 -

3-2. Restrictions for using BAC-HD150 in combination with AG-150A

(When BAC-HD150 is connected to the M-NET line)

When AG-150A and BAC-HD150 are connected to the M-NET line, note that the number of connectable controllers and the

compatible software versions are limited.

If the software version is not compatible, update the software version of the controllers.

Unless AG-150A and/or PAC-YG50ECA support the dual set point function, BAC-HD150 is not also available for the dual set

point function (AV_xxxx24-28).

Refer to the Instruction Manual with regard to AV_xxxx24-28.

(1) Restrictions on the number of connectable units

Only one BAC-HD150 can be connected to the M-NET line.

Only one AG-150A can be connected to BAC-HD150.

(2) Compatible software versions and the number of connectable controllers

(3) Restrictions on the DB No.

None

(4) Miscellaneous restrictions

If a main system controller, such as AG-150A, is used in combination with a BAC-HD150, there will be many restrictions

on the settings, such as group settings. Please consult your dealer for more information.

The number of

connectable controllers

AG-150A None 1 unit

BAC-HD150 1 unit 1 unit

Software

version

AG-150A - Ver. 2.30 or later

BAC-HD150 Ver. 1.00 or later Ver. 2.00 or later

gb02_WT05543X03_9.book Page 9 Friday, June 28, 2013 1:23 PM

- 10 -

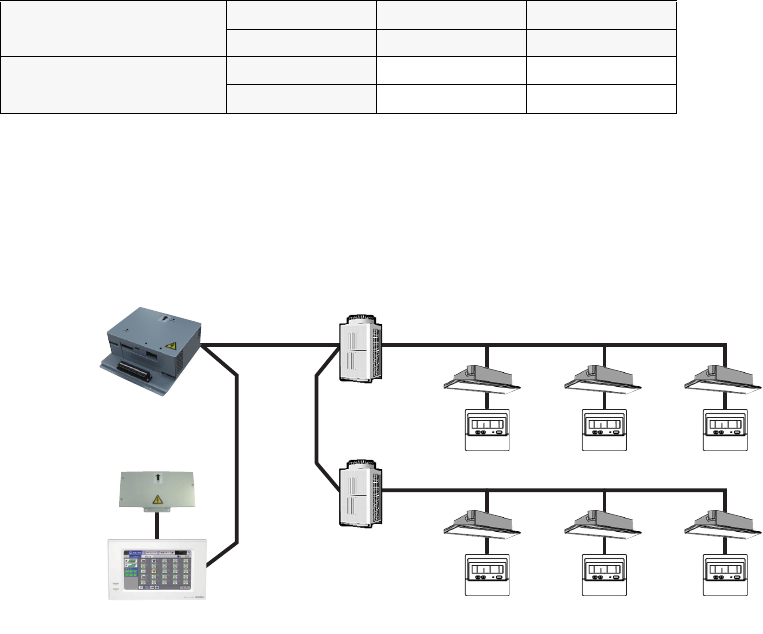

3-3. System in which BAC-HD150 is connected to the expansion controller

The figure below only shows the transmission line connections. Power supply lines are omitted.

• Refer to the PAC-YG50ECA Installation/Instructions Manual for how to set the IP address.

• The same M-NET address cannot be used twice in the same M-NET system that connects to the same PAC-YG50ECA.

NOTES

* The BAC-HD150 and the type of controllers that connect to the expansion controller via the LAN (e.g., AG-150A) each have a DB No.

This 2-digit number is indicated on the package box and the controller. ([DB No.:**])

Controllers with different DB No. cannot be connected to each other. Be sure to check the DB No. of each controller to be connected.

Connection of two or more controllers that have different DB No. requires a controller software version update. Consult your dealer for

how to update the software.

* Use a switching HUB.

* Provide “one-point grounding” for the M-NET transmission line (centralized control system) by grounding the shield of each

expansion controller.

Ground the indoor-outdoor transmission line in each outdoor unit refrigerant system.

* Set the centralized control switch (SW2-1) on the outdoor units on the M-NET line to ON.

(Refer to the outdoor unit Installation Manual for the details of the dipswitch settings.)

HUB

HUB

HUB

LAN1

LAN2

M-NET

Outdoor unit

M-NET

M-NET

M-NET

M-NET

Outdoor unit

M-NET

Outdoor unit

M-NET

Outdoor unit

LAN

LAN

LAN

LAN

LAN

(LAN)

TB7 TB3

ME

R2

TB7 TB3

ME ME

[051]

TB7 TB3

ME ME

TB7 TB3

ME ME

[001]

[101] [103]

[101] [103]

[101] [103]

[106]

[002]

[006] [007] [008] [009]

[010]

[003]

[004] [005]

[001] [002] [003]

[004]

[005]

[001] [002] [003]

[004]

[005]

[056]

[057]

[051]

[051]

[000]

[000]

[000]

Building Management System

192.168.1.100

Group 1-1

Group 1-3

Group 2-1

Group 3-1 Group 3-2

Group 2-2

BC controller

LOSSNAY

LOSSNAY

LOSSNAY

Group 1-2

Mitsubishi Electric air conditioning system

Indoor unit

Local remote

controller

LAN

M-NET

transmission line

Figures in indicate IP address.

Figures in [ ] indicate M-NET address.

BACnet

®

BM ADAPTER

Model: BAC-HD150

192.168.1.254 (LAN1)

192.168.200.212 (LAN2)

Expansion controller

Model:

PAC-YG50ECA

192.168.200.213

Expansion controller

Model:

PAC-YG50ECA

192.168.200.214

Centralized controller

Model:

AG-150A

192.168.200.201

Expansion controller

Model:

PAC-YG50ECA

192.168.200.215

Label contents

DB No. appears here.

gb02_WT05543X03_9.book Page 10 Friday, June 28, 2013 1:23 PM

- 11 -

3-4. Restrictions for using BAC-HD150 in combination with other controllers

(When BAC-HD150 is connected to the expansion controller)

After AG-150A or other controllers are connected to an air conditioning system, each controller can control the system.

Note that the number of connectable controllers and compatible software versions are limited

.

If the software version is not compatible, update the software version of the controllers.

Unless AG-150A and/or PAC-YG50ECA support the dual set point function, BAC-HD150 is not also available for the dual set

point function (AV_xxxx24-28).

Refer to the Instruction Manual with regard to AV_xxxx24-28.

(1)Restrictions on the number of connectable units

Only one BAC-HD150 can be connected to the M-NET line.

Note that the BAC-HD150 cannot be connected to the expansion controller unless the AG-150A is also connected to the

expansion controller.

The total number of AG-150A and BAC-HD150 units must be three or less

.

Up to three expansion controllers can be connected to one BAC-HD150 unit.

(2)Compatible software versions and the number of connectable controllers

(3)Restrictions on the DB No.

Controllers with different DB No. cannot be connected to each other.

When DB No. on the controllers is different, update the software version of the controllers.

(4)Miscellaneous restrictions

Use AG-150A to make group settings and interlocked ventilation settings.

Consult your dealer for details.

The number of

connectable controllers

PAC-YG50ECA 3 units or less

AG-150A 1 or 2 units

BAC-HD150 1 unit

Software

version

PAC-YG50ECA Ver. 1.30 or later

AG-150A Ver. 2.30 or later

BAC-HD150 Ver. 2.00 or later

gb02_WT05543X03_9.book Page 11 Friday, June 28, 2013 1:23 PM

- 12 -

3-5. Setting M-NET address for various devices

The same address cannot be used more than once within a M-NET system. (The address overlap between K-control unit and

K-control remote controller is excluded.)

Address setting method

M-NET

address

Indoor unit

Assign the lowest address to the main indoor unit in the group, and assign sequential

addresses to the rest of the indoor units in the same group.

1 ~ 50

Outdoor unit Assign an address that equals the lowest indoor unit address in the group plus 50. 51 ~ 100

Auxiliary outdoor unit

(BC controller)

Assign an address that equals the address of the outdoor unit in the same refrigerant

system plus 1.

52 ~ 100

OA processing unit/

LOSSNAY

Assign an arbitrary but unused address to each of LOSSNAY units after assigning an

address to all indoor units.

1 ~ 50

Mr.Slim outdoor unit

(A-control)

Set the address in the same way as with the indoor units. An M-NET adapter (sold

separately) is required.

1 ~ 50

Air To Water Booster unit/

Air To Water HEX unit

Set the address in the same way as with the indoor units. 1 ~ 50

M-NET remote controller

Assign an address that equals the address of the main indoor unit with the lowest

address in the group plus 100.

Add 150 in stead of 100 to set a sub remote controller.

101 ~ 200

MA remote controller

Address setting is not required.

Connection of two remote controllers requires the main/sub setting for each

controller to be made.

–

Sub system controller Assign an address that equals the lowest number of the group to be controlled +200. 201 ~ 250

K-control indoor unit

Assign an address to all M-NET indoor units (incl. LOSSNAY units) first, and then assign

addresses to the K-control indoor unit, starting with the address after the last address.

1 ~ 50

K-control remote

controller

Assign the same address as the lowest main K-control indoor unit address within the

same group.

1 ~ 50

K-transmission converter Assign an address that equals the lowest address of the K-control indoor units +200. 201 ~ 250

Important Note the following when using a K-transmission converter (Model: PAC-SC25KAA) to control the K-control model units.

Refer to the K-transmission converter Installation manual for details.

① Be sure to set the BAC-HD150 address to "000."

② Be sure to set the K-control air conditioning unit connection setting on the BAC-HD150 to Yes (set via the

Setting Tool).

When the above setting is made, enter the K-transmission converter address.

③ Assign addresses to the K-control air conditioners so that they are larger than the addresses that are

assigned to the M-control indoor units.

④ When making the group settings for the K-control units, make the group number and the lowest address of

the indoor units within the group the same.

⑤ If the K-control Y series units and other types of units (K-control Mr. Slim) are used in combination, a relay

board is required. The K- control Y series units cannot be connected to the same transmission lines as the

other types of units.

⑥ Depending on the number of K-control units and transmission line length, a relay board may be required.

Refer to the System Design/Manual (control version) for details.

⑦ LOSSNAY units cannot be connected if they are connected to the K-control kit.

⑧ Remote controller addresses do not need to be included in the group setting for the K-control units.

Note A-control jet burner models cannot be controlled.

Some models of units (e.g., DIDO, PI, and AI controller) cannot be controlled.

Each PAC-YG50ECA can control up to 50 units.

Main system controllers (e.g., BAC-HD150) cannot be connected to an M-NET system that is controlled by the

expansion controller.

gb02_WT05543X03_9.book Page 12 Friday, June 28, 2013 1:23 PM

- 13 -

* Main and sub system controllers (M-NET)

BAC-HD150 can only be used as the main system controller, but not as a sub system controller.

Main system controller (Main SC)

Main SC refers to a controller that controls all other system controllers including the units they control. If a given system

has only one system controller, that controller becomes the main SC. Group settings and interlock settings can only be

made from a main SC.

Sub system controller (Sub SC)

Sub SC refers to a system controller that is controlled (including the units it controls) by a main SC.

Note

The system cannot be configured in the following way.

Groups that are not under the control of a main SC cannot be controlled from a sub SC.

Each group cannot be under the control of two or more main SC.

Sub SC cannot be under the control of two or more main SC.

BAC-HD150, AG-150A etc.

Main SC’s control range

(M-NET)

Sub SC’s

control range

Group Group

Group

BAC-HD150 is exclusively for use as a main SC. It cannot be used as a sub SC

or controlled from a main SC.

Group Group Group

Main SC Sub SC

Group Group Group

Main SC 1 Main SC 2

GroupGroup Group Group

Main SC 1 Sub SC Main SC 2

gb02_WT05543X03_9.book Page 13 Friday, June 28, 2013 1:23 PM

- 14 -

4-1. Required parts

The following parts are required to install the unit.

4 Installation

Required parts Specification

Power cable/

Protective earth cable

Power supply cable of appliances shall not be lighter than design 245 IEC 57 or 227 IEC 57.

Cable size:0.75mm² to 2mm²

M-NET transmission line

Shielded cable

• CPEVS: 1.2mm to 1.6mm

• CVVS: 1.25mm² to 2mm²

Ring terminal (with a

sleeve)

M3.5 terminal (used with the power cable (L/L1, N/L2), M-NET transmission line (A, B, S))

M4 ring terminal (used with the protective earth cable)

Screw Have four M4 screws ready to install the unit.

LAN cable 10Base-T or 100Base-TX (category 5 or above) straight cable (Maximum 100m (328 ft))

HUB Switching HUB (communication speed: 10 Mbps or 100 Mbps)

Overcurrent breaker and

Residual Current Circuit

Breaker (RCCB)

Install an overcurrent breaker and a residual current circuit breaker (RCCB) for each BAC-

HD150 unit.

*1 Use a circuit breaker and a residual current circuit breaker (RCCB) of bipolar type (2P2E).

Use a breaker with the minimum contact distance of 3 mm (

1

/

8

in.).

*2 When using a fuse, use it in combination with a main switch (Rated current: 3A).

Overcurrent breaker

Residual Current Circuit Breaker

(RCCB)

*1

Fuse Circuit breaker

*1

Rated current: 3A

Rated sensitivity current: 30mA

Maximum operation time:

0.1 sec or less

Rated current: 3A

*2

Rated current:3A

gb02_WT05543X03_9.book Page 14 Friday, June 28, 2013 1:23 PM

- 15 -

4-2. M-NET transmission line length

• Connect the BAC-HD150 to the transmission line for centralized control (TB7 on the outdoor unit).

• There should only be one power supply source within a single transmission circuit. The factory setting is that power is not

supplied from the BAC-HD150.

• Connect the shield of the M-NET transmission line for centralized control to the S terminal of TB3.

Provide an earth for the indoor-outdoor transmission lines at one single outdoor unit.

• Maximum line distance Maximum 500 m/1,640 ft*

1

• Maximum power supply distance Maximum 200 m/656 ft*

1

(1) Maximum line distance

L1 + L2 + 5 + 1 + 2 ( 3) 500 m/1,640 ft

L1 + L2 + 5 + 4 500 m/1,640 ft

L1 + L3 + 6 + 7 ( 8) 500 m/1,640 ft

2 ( 3) + 1 + 5 + L2 + L3 + 6 + 7 ( 8) 500 m/1,640 ft

4 + 5 + L2 + L3 + 6 + 7 ( 8) 500 m/1,640 ft

(2) Power supply distance for the indoor-outdoor transmission lines

5 + 1 + 2 ( 3) 200 m/656 ft

5 + 4 200 m/656 ft

6 + 7 ( 8) 200 m/656 ft

(3) Power supply distance for the centralized control transmission lines

L1 + L2 + L4 200 m/656 ft

L1 + L3 + L4 200 m/656 ft

Maximum power supply distance is the distance in which a power supply unit (or an outdoor unit designated as a power

supply unit) is capable of supplying power to other units on the receiving end, such as remote controllers and indoor units.

Note

*1 The ME remote controller wiring length ( 3, 8) should be 10 m (32 ft) or less.

The length that exceeds 10 m (32 ft) needs to be included in the maximum distance to the farthest unit (500 m/1,640 ft) and

the maximum power supply distance (200 m/656 ft).

If the ME remote controller wiring length ( 3, 8) is 10 m (32 ft) or less, it does not need to be included in the distance to the

farthest unit or the power supply distance.

L1

BM ADAPTER

(BAC-HD150)

AG-150A, etc.

BACnet

®

(LAN)

M-NET

(For centralized control)

M-NET (For indoor-outdoor transmission line)

M-NET transmission line

(centralized control)

M-NET transmission line

(indoor-outdoor)

BACnet

®

(LAN)

ME remote controller

ME remote controller

Outdoor

unit

Indoor unit Indoor unit Indoor unit

Indoor unit Indoor unit Indoor unit

Indoor unit Indoor unit Indoor unit

Outdoor

unit

Outdoor

unit

Outdoor

unit

1

2

3

4

6

7

8

L2L3

L4

5

Sample wiring connection

CN40 CN41

outdoor unit

* To supply power from the BAC-HD150,

check that the power jumper is

connected to CN41 on the outdoor unit.

Refer to section 5-3 for details.

gb02_WT05543X03_9.book Page 15 Friday, June 28, 2013 1:23 PM

- 16 -

4-3. Installation

• Leave enough space around the unit to allow for an installation/uninstallation of the cover. (The amount of space needed is

shown in the figure below.)

• Screw down the cover with M4 screws as shown in the figure below.

Be sure to fix the four corners to prevent it from falling.

• Install on the metal control panel (indoors) with an effective depth of at least 105mm (4-

3

/

16

in.).

* Refer to section for the product dimensions and weight.

2 Specifications

Unit: mm (in.)

20(

13

/

16

)

50(2)

20(

13

/

16

) 20(

13

/

16

)

Properly install the unit on a stable, load-bearing surface.

Unit installed on an unstable surface may fall and cause injury.

This product is not water-proof. Be sure to install the unit

inside the metal control panel (indoors).

To reduce the risk of wire shorting, fire, electric shock,

and malfunction, do not install the unit in a condensing

environment, and keep the unit out of water and other

sources of water.

gb02_WT05543X03_9.book Page 16 Friday, June 28, 2013 1:23 PM

- 17 -

5-1. Installing and uninstalling the cover

Unscrew the three screws on the cover to remove it as shown in the figure below.

Reinstall the cover using the three screws that were unscrewed.

5-2. Connecting the power cable and protective earth cable

• Connect the power cable and the protective earth cable as shown in the figure below.

Use an M3.5 ring terminal to the power cable, and connect an M4 ring terminal to the protective earth cable before

connecting them to their corresponding terminals (power supply terminal block or protective earth terminal).

• Be sure to connect the N/L2 phase of the power cable to the N/L2 side of the power supply terminal block (TB1).

• Secure cables with cable clamps.

5 Wiring connections

WARNING • Electric work must be performed by an authorized technician. Improper wiring work may result in electric

shock or fire.

• Turn off the power supply before performing wiring work.

CAUTION • To avoid damage to the terminal block, do not connect an AC power supply (100-240 VAC) to the M-NET

transmission line terminal block.

CAUTION • Install an overcurrent breaker and a residual current circuit breaker for the power wire to each BAC-HD150 unit.

Use a bipolar breaker (2P2E) with a minimum contact distance of 3 mm (

1

/

8

in.).

• Install a breaker for each BAC-HD150 so that turning off the power to one BAC-HD150 will not affect the rest of

the devices in the system.

• When using a fuse instead of an overcurrent breaker, use it in combination with a main switch (Rated current: 3 A).

B

B

A

A

Power supply

100-240 VAC

50 Hz/60 Hz

Residual current

circuit breaker

Overcurrent breaker

Earth

Protective earth cable

Power cable

Power

cable

Protective

earth terminal

Protective

earth cable

Cable

clamps

Power supply

terminal block

L/L1 N/L2

TB1

gb02_WT05543X03_9.book Page 17 Friday, June 28, 2013 1:23 PM

- 18 -

5-3. Connecting the M-NET transmission lines

(1) System in which BAC-HD150 is connected to the M-NET line

Connect the M-NET transmission lines and the power jumper as shown in the figure below.

To supply power to the M-NET transmission line from the BAC-HD150

To not supply power to the M-NET transmission line from the BAC-HD150

CAUTION • In an air conditioner system has more than 1 Outdoor units, System controller receiving transmission power

through TB7 on one of the Outdoor unit would have a risk that the connected Outdoor units failure would stop

power supply to System controller, and disrupt the whole system.

M-NET

TB7

TB3

CN40 CN41

CN41

CN41

CN41

CN40CN40

OFF

ONON

TB3

ABS

BM ADAPTER

(BAC-HD150)

Outdoor unit

M-NET

transmission line

(non-polarized)

Shield

Cable

clamps

CAUTION • Connect the shield to the S terminal of TB3.

• Insulate the cables with vinyl tape, except the part

that connects to the ring terminal.

• Connect the power jumper of BAC-HD150 to

CN40 (supplies power).

Connect the power jumper of the outdoor unit

to CN41 (does not supply power).

• Use the type of transmission lines specified, and

connect them to the appropriate terminals. Secure

the cables to keep undue force from being applied.

Improper connections or failure to properly secure

cables may result in overheating and fire.

M-NET

TB7

TB3

CN40

CN40

CN40

TB3

ABS

CN41

CN40CN40

OFF

ONON

BM ADAPTER

(BAC-HD150)

Outdoor unit

Power supply unit (PAC-SC51KUA...etc)

CN41

CN41

CN41

M-NET

transmission line

(non-polarized)

Shield

Cable

clamps

CAUTION • Connect the shield to the S terminal of TB3.

• Insulate the cables with vinyl tape, except the part

that connects to the ring terminal.

• Connect the power jumper of BAC-HD150 to

CN41 (does not supply power at factory setting).

Connect the power jumper of the outdoor unit

to CN41 (does not supply power).

• Use the type of transmission lines specified, and

connect them to the appropriate terminals. Secure

the cables to keep undue force from being applied.

Improper connections or failure to properly secure

cables may result in overheating and fire.

gb02_WT05543X03_9.book Page 18 Friday, June 28, 2013 1:23 PM

- 19 -

(2) System in which BAC-HD150 is connected to the expansion controller (PAC-YG50ECA)(system in which BAC-HD150

is not connected to the M-NET)

It is not necessary to connect the M-NET transmission line to the TB3 on BAC-HD150. Connect the power jumper as shown in

the figure below.

Refer to section 5-4. "Connecting the LAN cable" for how to connect PAC-YG50ECA.

TB3

TB3

CN41

CN40CN40

OFF

ONON

BM ADAPTER

(BAC-HD150)

CAUTION • Leave the power jumper of BAC-HD150

connected to CN41 (Does not supply power at

factory setting).

Refer to the PAC-YG50ECA Installation/

Instructions Manual for where to connect the power

jumper of the expansion controllers and outdoor

units.

gb02_WT05543X03_9.book Page 19 Friday, June 28, 2013 1:23 PM

- 20 -

5-4. Connecting the LAN cable

• Make sure that the LAN cable is long enough to reach the LAN1 and LAN2 connectors on the BAC-HD150. Leave the LAN

cable disconnected until all the initial settings for the BAC-HD150 (IP address setting etc.) have been completed.

• Connect the BAC-HD150 (LAN1) and the Building Management System via a HUB.

• Expansion controllers (PAC-YG50ECA), when used, must be connected to the LAN2 of BAC-HD150 via a HUB.

• The maximum distance between the HUB and BAC-HD150 is 100 m (328 ft).

CAUTION Connect the BACnet

®

building management system to LAN1 port and the expansion controllers (PAC-

YG50ECA) to LAN2 port, and be careful not to mix them up.

LAN1 LAN2

LAN1 LAN2

Building Management

System

BM ADAPTER

(BAC-HD150)

LAN1 LAN2

HUB

M-NET

BACnet

®

(LAN)

BACnet

®

(LAN)

*

* LAN2 of BAC-HD150 will not be used.

(1) LAN connection example of a system in which BAC-HD150 is connected to the M-NET line

(2) LAN connection example of a system in which BAC-HD150 is connected to the expansion controller (PAC-YG50ECA)

Building Management

System

Building Management

System

BM ADAPTER

(BAC-HD150)

LAN1 LAN2

HUB

BACnet

®

(LAN)

BACnet

®

(LAN)

LAN

Building Management

System

HUB

LAN

Expansion Controller

(PAC-YG50ECA)

Expansion Controller

(PAC-YG50ECA)

Expansion Controller

(PAC-YG50ECA)

M-NET

M-NET

M-NET

Centralized Controller

(AG-150A)

gb02_WT05543X03_9.book Page 20 Friday, June 28, 2013 1:23 PM

- 21 -

1. Turning on the power

Disconnect the LAN cable for connection to the BACnet

®

before turning the power on for the first time.

There is a possibility that the IP address of the unit is already used by another device that is connected to the BACnet

®

.

2. Initial settings

Make the initial setting using the Setting Tool after turning on the power to the BAC-HD150.

Some of the items that require initial settings include BAC-HD150 address and air conditioning system related items.

• IP address of BAC-HD150 (The factory setting for LAN1 is "192.168.1.254." The factory LAN2 setting is "192.168.200.212".)

• M-NET address of BAC-HD150 (The factory setting is "0.")

• Group configuration for the air conditioning system

Refer to the BAC-HD150 Instructions Book and the Setting Tool Instructions Book for detailed instructions for how to make the

initial settings.

Refer to the Installation Manuals that came with the air conditioning units for how to perform a test run.

Perform a test run for the Mitsubishi Electric air conditioning system and confirm proper operation before connecting to the

building management system and performing a test run. (Refer to the BAC-HD150 Instructions Book for details.)

CAUTION • Install the LAN cable before installing the unit, and route the cable in the same way as the M-NET transmission

lines.

• Connect the BAC-HD150 to a private network. Use a security device such as a VPN router when connecting to

the Internet. (Without a proper security measure in place, the air conditioning system is vulnerable to access

from unauthorized users.)

6 Making the initial settings

Note

Refer to the BAC-HD150 Instructions Book and the Setting Tool Instructions Book for how to make the initial

settings for the BAC-HD150.

Refer to the PAC-YG50ECA Installation/Instructions Manual for how to use the expansion controller.

7 Test run

Note

Refer to the BAC-HD150 Instructions Book and the Installation Manuals that came with the air conditioning units for

how to perform a test run for the BAC-HD150.

gb02_WT05543X03_9.book Page 21 Friday, June 28, 2013 1:23 PM

- 22 -

NOTE:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide resonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more

of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio / TV technician for help.

gb02_WT05543X03_9.book Page 22 Friday, June 28, 2013 1:23 PM

gb02_WT05543X03_9.book Page 23 Friday, June 28, 2013 1:23 PM

HEAD OFFICE: TOKYO BLDG. , 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Authorized representative in EU: MITSUBISHI ELECTRIC EUROPE B.V.

HARMAN HOUSE, 1 GEORGE STREET, UXBRIDGE, MIDDLESEX UB8 1QQ, U.K.

WT05543X03

Printed in Japan

Recycled Paper

Please be sure to put the contact address/telephone number on

this manual before handing it to the customer.

This product is designed and intended for use in the residential,

commercial and light-industrial environment.

The product at hand is

based on the following

EU regulations:

• Low Voltage Directive 2006/95/EC

• Electromagnetic Compatibility Directive,

2004/108/EC

• Restriction of Hazardous Substances

2011/65/EU

gb02_WT05543X03_9.book Page 24 Friday, June 28, 2013 1:23 PM