CITY MULTI

MEES19K173

2. BC CONTROLLER

GENERAL LINE-UP

BC controller

CMB-M-V-J1(-TR) R32 R410A ...............................................................................................................2 - 1

CMB-M-V-JA1(-TR)

R32 R410A.............................................................................................................2 - 1

CMB-P-V-KA1(-TR)

R410A .......................................................................................................................2 - 1

CMB-M-V-KB1(-TR)

R32 R410A ............................................................................................................2 - 1

MEES19K173

GENERAL LINE-UP

GENERAL LINE-UP

I.GENERAL LINE-UP

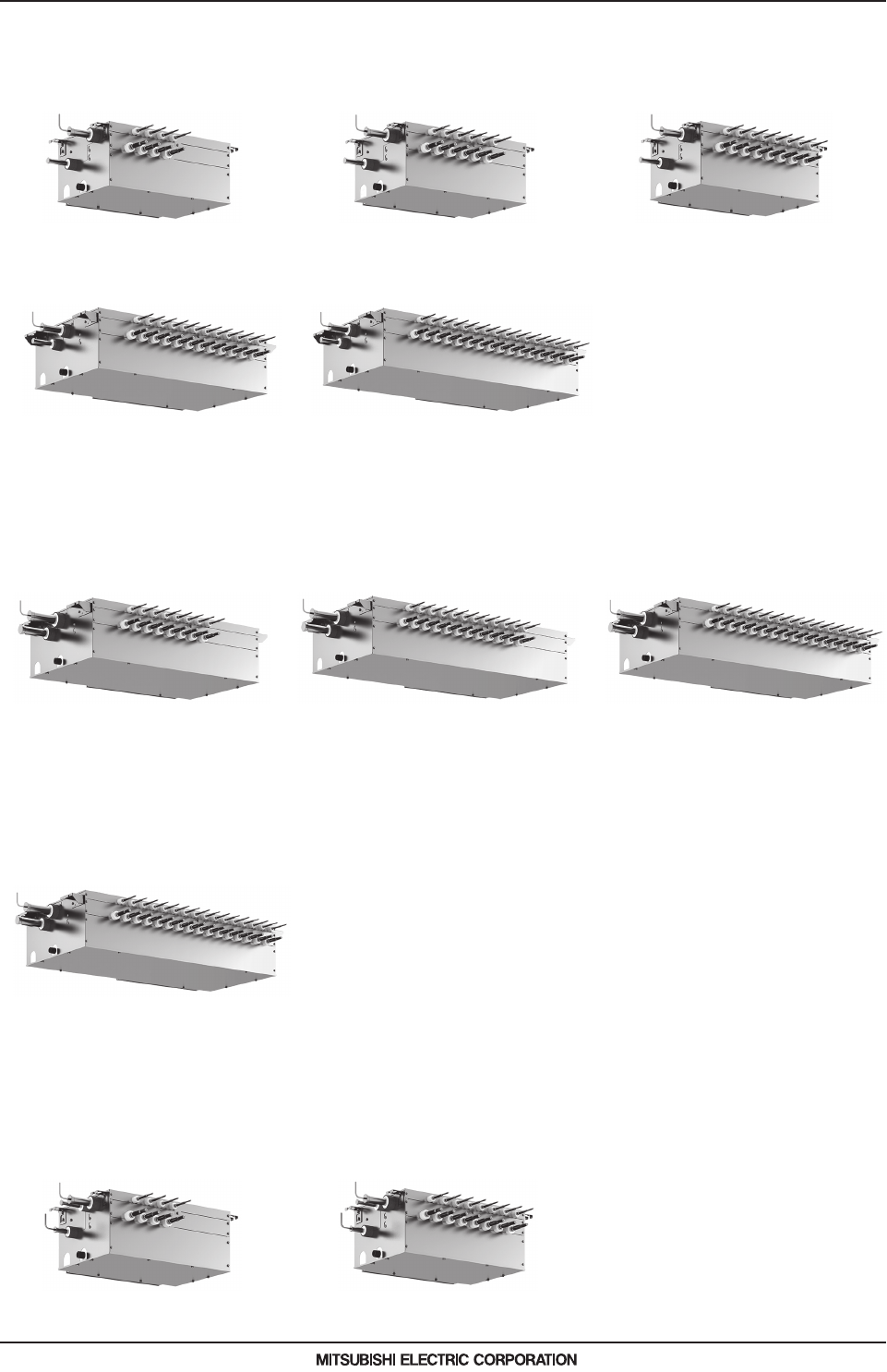

Main BC controller (J1 type)

CMB-M104V-J1 (-TR) CMB-M106V-J1 (-TR) CMB-M108V-J1 (-TR)

CMB-M1012V-J1 (-TR)

CMB-M1016V-J1 (-TR)

Main BC controller (JA1 type)

CMB-M108V-JA1 (-TR) CMB-M1012V-JA1 (-TR) CMB-M1016V-JA1 (-TR)

Main BC controller (KA1 type)

CMB-P1016V-KA1 (-TR)

Sub BC controller (KB1 type)

CMB-M104V-KB1 (-TR) CMB-M108V-KB1 (-TR)

CMB-M-V-J1(-TR), CMB-M-V-JA1(-TR), CMB-P-V-KA1(-TR), CMB-M-V-KB1(-TR)

MEES19K085

2 - 1

CONTENTS

BC controller

I.

BC controll er

1. SPECIFICATIONS .................................................................................................................................... 2 - 2

2. EXTERNAL DIMENSIONS ....................................................................................................................... 2 - 13

3. ELECTRICAL WIRING DIAGRAMS ......................................................................................................... 2 - 18

4. SOUND LEVELS ...................................................................................................................................... 2 - 27

4-1. Sound levels in cooling mode .......................................................................................................... 2 - 27

4-2. Sound levels in heating mode.......................................................................................................... 2 - 28

4-3. Sound levels in defrost mode .......................................................................................................... 2 - 29

5. ELECTRICAL CHARACTERISTICS......................................................................................................... 2 - 30

6. OPTIONAL PARTS................................................................................................................................... 2 - 31

6-1. JOINT and REDUCER..................................................................................................................... 2 - 31

6-2. JOINT KIT "CMY-R160-J1" FOR BC CONTROLLER ..................................................................... 2 - 36

7. INSTALLATION ........................................................................................................................................ 2 - 37

7-1. Installing BC controllers ................................................................................................................... 2 - 37

8. SYSTEM DESIGN .................................................................................................................................... 2 - 38

8-1. Compatibility .................................................................................................................................... 2 - 38

8-2. System examples ............................................................................................................................ 2 - 39

MEES19K085

BC controller

2 - 2

1. SPECIFICATIONS

BC controller

I.BC controll er1. SPECIFICATIONS

Model CMB-M104V-J1 (-TR)

Number of branch 4

Power source 1-phase 220-230-240 V

50Hz 60Hz

Power input Cooling kW 0.067/0.076/0.085 0.054/0.061/0.067

Heating kW 0.030/0.034/0.038 0.024/0.027/0.030

Current input Cooling A 0.31/0.34/0.36 0.25/0.27/0.28

Heating A 0.14/0.15/0.16 0.11/0.12/0.13

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit capacity P200 to P350/M200 to M300

Indoor unit capacity connectable to 1 branch *14

Model P/M80 or smaller

(Use optional joint pipe combining 2 branches when the total unit capacity exceeds P/M81.)

External dimension H x W x D mm 250 x 596 x 476

in. 9-7/8 x 23-1/2 x 18-3/4

Refrigerant To outdoor/heat source unit Connectable unit capacity High press. Pipe Low press. Pipe

piping mm (in.) O.D. P200/M200 15.88 (5/8) Brazed 19.05 (3/4) Brazed

diameter mm (in.) O.D. P250/P300 19.05 (3/4) Brazed 22.2 (7/8) Brazed

*15 mm (in.) O.D. P350

19.05 (3/4) Brazed or 22.2 (7/8)

Brazed

28.58 (1-1/8) Brazed

mm (in.) O.D. M250/M300 15.88 (5/8) Brazed 22.2 (7/8) Brazed

To indoor unit Liquid pipe Gas pipe

mm (in.) O.D.

Indoor unit Model 50 or smaller 6.35 (1/4) Brazed Indoor unit Model 50 or smaller 12.7 (1/2) Brazed

bigger than 50 9.52 (3/8) Brazed bigger than 50 15.88 (5/8) Brazed

(19.05 (3/4), 22.2 (7/8) with optional joint pipe used.)

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 26 (58)

Sound power level

Rated operation dB <A> 59

(measured in anechoic room)

Defrost dB <A> 71

Sound pressure level

Rated operation dB <A> 40

(measured in anechoic room)

*16 Defrost dB <A> 53

Accessories Drain Connection pipe, Washer, Tie band

Remarks

Notes:

1.Installation/foundation work, electrical connection work, insulation work, power source switch, and other items

shall be referred to the Installation Manual.

2.The equipment is for R410A or R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away

from any indoor units.)

4.Sound pressure/power level differs depending on the connected outdoor/heat source unit capacity or operation condition.

The sound pressure/power level at the rated operation is the value of the cooling mode.

5.The sound pressure/power level values were obtained in an anechoic room. Actual sound pressure level is usually

greater than that measured in anechoic room due to ambient noise and deflection sound.

6.The sound pressure level values were obtained at the location below 1.5m from the unit.

7.The solenoid valve switching sound is 56 dB (sound pressure level) regardless of the unit model.

8.Indoor units P/M100, P/M125, P/M140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

9.Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the

Installation Manual.

10.This unit is not designed for outside installations.

11.When blazing the pipes, be sure to blaze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

12.The ambient relative humidity of the BC controller needs to be kept below 80%.

13.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the DATA BOOK on installation restrictions.

14.Indoor unit capacity connectable to 1 branch is changed depending on the indoor unit type and connection

method. Please refer to the Installation Manual for more information.

15.For the refrigerant pipe size, refer to Installation Manual of outdoor units/heat source units.

16.The sound pressure level measured by the conventional method in JIS for reference purpose.

MEES19K085

BC controller

2 - 3

1. SPECIFICATIONS

BC controller

Model CMB-M106V-J1 (-TR)

Number of branch 6

Power source 1-phase 220-230-240 V

50Hz 60Hz

Power input Cooling kW 0.097/0.110/0.123 0.078/0.088/0.097

Heating kW 0.045/0.051/0.057 0.036/0.041/0.045

Current input Cooling A 0.45/0.48/0.52 0.36/0.39/0.41

Heating A 0.21/0.23/0.24 0.17/0.18/0.19

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit capacity P200 to P350/M200 to M300

Indoor unit capacity connectable to 1 branch *14

Model P/M80 or smaller

(Use optional joint pipe combining 2 branches when the total unit capacity exceeds P/M81.)

External dimension H x W x D mm 250 x 596 x 476

in. 9-7/8 x 23-1/2 x 18-3/4

Refrigerant To outdoor/heat source unit Connectable unit capacity High press. Pipe Low press. Pipe

piping mm (in.) O.D. P200/M200 15.88 (5/8) Brazed 19.05 (3/4) Brazed

diameter mm (in.) O.D. P250/P300 19.05 (3/4) Brazed 22.2 (7/8) Brazed

*15 mm (in.) O.D. P350

19.05 (3/4) Brazed or 22.2 (7/8)

Brazed

28.58 (1-1/8) Brazed

mm (in.) O.D. M250/M300 15.88 (5/8) Brazed 22.2 (7/8) Brazed

To indoor unit Liquid pipe Gas pipe

mm (in.) O.D.

Indoor unit Model 50 or smaller 6.35 (1/4) Brazed Indoor unit Model 50 or smaller 12.7 (1/2) Brazed

bigger than 50 9.52 (3/8) Brazed bigger than 50 15.88 (5/8) Brazed

(19.05 (3/4), 22.2 (7/8) with optional joint pipe used.)

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 29 (64)

Sound power level

Rated operation dB <A> 59

(measured in anechoic room)

Defrost dB <A> 71

Sound pressure level

Rated operation dB <A> 40

(measured in anechoic room)

*16 Defrost dB <A> 53

Accessories Drain Connection pipe, Washer, Tie band

Remarks

Notes:

1.Installation/foundation work, electrical connection work, insulation work, power source switch, and other items

shall be referred to the Installation Manual.

2.The equipment is for R410A or R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away

from any indoor units.)

4.Sound pressure/power level differs depending on the connected outdoor/heat source unit capacity or operation condition.

The sound pressure/power level at the rated operation is the value of the cooling mode.

5.The sound pressure/power level values were obtained in an anechoic room. Actual sound pressure level is usually

greater than that measured in anechoic room due to ambient noise and deflection sound.

6.The sound pressure level values were obtained at the location below 1.5m from the unit.

7.The solenoid valve switching sound is 56 dB (sound pressure level) regardless of the unit model.

8.Indoor units P/M100, P/M125, P/M140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

9.Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the

Installation Manual.

10.This unit is not designed for outside installations.

11.When blazing the pipes, be sure to blaze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

12.The ambient relative humidity of the BC controller needs to be kept below 80%.

13.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the DATA BOOK on installation restrictions.

14.Indoor unit capacity connectable to 1 branch is changed depending on the indoor unit type and connection

method. Please refer to the Installation Manual for more information.

15.For the refrigerant pipe size, refer to Installation Manual of outdoor units/heat source units.

16.The sound pressure level measured by the conventional method in JIS for reference purpose.

MEES19K085

BC controller

2 - 4

1. SPECIFICATIONS

BC controller

Model CMB-M108V-J1 (-TR)

Number of branch 8

Power source 1-phase 220-230-240 V

50Hz 60Hz

Power input Cooling kW 0.127/0.144/0.161 0.102/0.115/0.127

Heating kW 0.060/0.068/0.076 0.048/0.054/0.060

Current input Cooling A 0.58/0.63/0.68 0.47/0.50/0.53

Heating A 0.28/0.30/0.32 0.22/0.24/0.25

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit capacity P200 to P350/M200 to M300

Indoor unit capacity connectable to 1 branch *14

Model P/M80 or smaller

(Use optional joint pipe combining 2 branches when the total unit capacity exceeds P/M81.)

External dimension H x W x D mm 250 x 596 x 476

in. 9-7/8 x 23-1/2 x 18-3/4

Refrigerant To outdoor/heat source unit Connectable unit capacity High press. Pipe Low press. Pipe

piping mm (in.) O.D. P200/M200 15.88 (5/8) Brazed 19.05 (3/4) Brazed

diameter mm (in.) O.D. P250/P300 19.05 (3/4) Brazed 22.2 (7/8) Brazed

*15 mm (in.) O.D. P350

19.05 (3/4) Brazed or 22.2 (7/8)

Brazed

28.58 (1-1/8) Brazed

mm (in.) O.D. M250/M300 15.88 (5/8) Brazed 22.2 (7/8) Brazed

To indoor unit Liquid pipe Gas pipe

mm (in.) O.D.

Indoor unit Model 50 or smaller 6.35 (1/4) Brazed Indoor unit Model 50 or smaller 12.7 (1/2) Brazed

bigger than 50 9.52 (3/8) Brazed bigger than 50 15.88 (5/8) Brazed

(19.05 (3/4), 22.2 (7/8) with optional joint pipe used.)

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 33 (73)

Sound power level

Rated operation dB <A> 59

(measured in anechoic room)

Defrost dB <A> 71

Sound pressure level

Rated operation dB <A> 40

(measured in anechoic room)

*16 Defrost dB <A> 53

Accessories Drain Connection pipe, Washer, Tie band

Remarks

Notes:

1.Installation/foundation work, electrical connection work, insulation work, power source switch, and other items

shall be referred to the Installation Manual.

2.The equipment is for R410A or R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away

from any indoor units.)

4.Sound pressure/power level differs depending on the connected outdoor/heat source unit capacity or operation condition.

The sound pressure/power level at the rated operation is the value of the cooling mode.

5.The sound pressure/power level values were obtained in an anechoic room. Actual sound pressure level is usually

greater than that measured in anechoic room due to ambient noise and deflection sound.

6.The sound pressure level values were obtained at the location below 1.5m from the unit.

7.The solenoid valve switching sound is 56 dB (sound pressure level) regardless of the unit model.

8.Indoor units P/M100, P/M125, P/M140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

9.Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the

Installation Manual.

10.This unit is not designed for outside installations.

11.When blazing the pipes, be sure to blaze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

12.The ambient relative humidity of the BC controller needs to be kept below 80%.

13.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the DATA BOOK on installation restrictions.

14.Indoor unit capacity connectable to 1 branch is changed depending on the indoor unit type and connection

method. Please refer to the Installation Manual for more information.

15.For the refrigerant pipe size, refer to Installation Manual of outdoor units/heat source units.

16.The sound pressure level measured by the conventional method in JIS for reference purpose.

MEES19K085

BC controller

2 - 5

1. SPECIFICATIONS

BC controller

Model CMB-M1012V-J1 (-TR)

Number of branch 12

Power source 1-phase 220-230-240 V

50Hz 60Hz

Power input Cooling kW 0.186/0.211/0.236 0.150/0.168/0.186

Heating kW 0.090/0.102/0.114 0.072/0.081/0.090

Current input Cooling A 0.85/0.92/0.99 0.69/0.74/0.78

Heating A 0.42/0.44/0.48 0.33/0.36/0.38

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit capacity P200 to P350/M200 to M300

Indoor unit capacity connectable to 1 branch *14

Model P/M80 or smaller

(Use optional joint pipe combining 2 branches when the total unit capacity exceeds P/M81.)

External dimension H x W x D mm 252 x 911 x 622

in. 9-15/16 x 35-7/8 x 24-1/2

Refrigerant To outdoor/heat source unit Connectable unit capacity High press. Pipe Low press. Pipe

piping mm (in.) O.D. P200/M200 15.88 (5/8) Brazed 19.05 (3/4) Brazed

diameter mm (in.) O.D. P250/P300 19.05 (3/4) Brazed 22.2 (7/8) Brazed

*15 mm (in.) O.D. P350

19.05 (3/4) Brazed or 22.2 (7/8)

Brazed

28.58 (1-1/8) Brazed

mm (in.) O.D. M250/M300 15.88 (5/8) Brazed 22.2 (7/8) Brazed

To indoor unit Liquid pipe Gas pipe

mm (in.) O.D.

Indoor unit Model 50 or smaller 6.35 (1/4) Brazed Indoor unit Model 50 or smaller 12.7 (1/2) Brazed

bigger than 50 9.52 (3/8) Brazed bigger than 50 15.88 (5/8) Brazed

(19.05 (3/4), 22.2 (7/8) with optional joint pipe used.)

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 49 (109)

Sound power level

Rated operation dB <A> 59

(measured in anechoic room)

Defrost dB <A> 71

Sound pressure level

Rated operation dB <A> 40

(measured in anechoic room)

*16 Defrost dB <A> 53

Accessories Drain Connection pipe, Washer, Tie band

Remarks

Notes:

1.Installation/foundation work, electrical connection work, insulation work, power source switch, and other items

shall be referred to the Installation Manual.

2.The equipment is for R410A or R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away

from any indoor units.)

4.Sound pressure/power level differs depending on the connected outdoor/heat source unit capacity or operation condition.

The sound pressure/power level at the rated operation is the value of the cooling mode.

5.The sound pressure/power level values were obtained in an anechoic room. Actual sound pressure level is usually

greater than that measured in anechoic room due to ambient noise and deflection sound.

6.The sound pressure level values were obtained at the location below 1.5m from the unit.

7.The solenoid valve switching sound is 56 dB (sound pressure level) regardless of the unit model.

8.Indoor units P/M100, P/M125, P/M140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

9.Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the

Installation Manual.

10.This unit is not designed for outside installations.

11.When blazing the pipes, be sure to blaze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

12.The ambient relative humidity of the BC controller needs to be kept below 80%.

13.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the DATA BOOK on installation restrictions.

14.Indoor unit capacity connectable to 1 branch is changed depending on the indoor unit type and connection

method. Please refer to the Installation Manual for more information.

15.For the refrigerant pipe size, refer to Installation Manual of outdoor units/heat source units.

16.The sound pressure level measured by the conventional method in JIS for reference purpose.

MEES19K085

BC controller

2 - 6

1. SPECIFICATIONS

BC controller

Model CMB-M1016V-J1 (-TR)

Number of branch 16

Power source 1-phase 220-230-240 V

50Hz 60Hz

Power input Cooling kW 0.246/0.279/0.312 0.198/0.222/0.246

Heating kW 0.119/0.135/0.151 0.096/0.108/0.119

Current input Cooling A 1.12/1.22/1.30 0.90/0.97/1.03

Heating A 0.55/0.59/0.63 0.44/0.47/0.50

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit capacity P200 to P350/M200 to M300

Indoor unit capacity connectable to 1 branch *14

Model P/M80 or smaller

(Use optional joint pipe combining 2 branches when the total unit capacity exceeds P/M81.)

External dimension H x W x D mm 252 x 1,135 x 622

in. 9-15/16 x 44-11/16 x 24-1/2

Refrigerant To outdoor/heat source unit Connectable unit capacity High press. Pipe Low press. Pipe

piping mm (in.) O.D. P200/M200 15.88 (5/8) Brazed 19.05 (3/4) Brazed

diameter mm (in.) O.D. P250/P300 19.05 (3/4) Brazed 22.2 (7/8) Brazed

*15 mm (in.) O.D. P350

19.05 (3/4) Brazed or 22.2 (7/8)

Brazed

28.58 (1-1/8) Brazed

mm (in.) O.D. M250/M300 15.88 (5/8) Brazed 22.2 (7/8) Brazed

To indoor unit Liquid pipe Gas pipe

mm (in.) O.D.

Indoor unit Model 50 or smaller 6.35 (1/4) Brazed Indoor unit Model 50 or smaller 12.7 (1/2) Brazed

bigger than 50 9.52 (3/8) Brazed bigger than 50 15.88 (5/8) Brazed

(19.05 (3/4), 22.2 (7/8) with optional joint pipe used.)

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 59 (131)

Sound power level

Rated operation dB <A> 59

(measured in anechoic room)

Defrost dB <A> 71

Sound pressure level

Rated operation dB <A> 40

(measured in anechoic room)

*16 Defrost dB <A> 53

Accessories Drain Connection pipe, Washer, Tie band

Remarks

Notes:

1.Installation/foundation work, electrical connection work, insulation work, power source switch, and other items

shall be referred to the Installation Manual.

2.The equipment is for R410A or R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away

from any indoor units.)

4.Sound pressure/power level differs depending on the connected outdoor/heat source unit capacity or operation condition.

The sound pressure/power level at the rated operation is the value of the cooling mode.

5.The sound pressure/power level values were obtained in an anechoic room. Actual sound pressure level is usually

greater than that measured in anechoic room due to ambient noise and deflection sound.

6.The sound pressure level values were obtained at the location below 1.5m from the unit.

7.The solenoid valve switching sound is 56 dB (sound pressure level) regardless of the unit model.

8.Indoor units P/M100, P/M125, P/M140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

9.Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the

Installation Manual.

10.This unit is not designed for outside installations.

11.When blazing the pipes, be sure to blaze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

12.The ambient relative humidity of the BC controller needs to be kept below 80%.

13.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the DATA BOOK on installation restrictions.

14.Indoor unit capacity connectable to 1 branch is changed depending on the indoor unit type and connection

method. Please refer to the Installation Manual for more information.

15.For the refrigerant pipe size, refer to Installation Manual of outdoor units/heat source units.

16.The sound pressure level measured by the conventional method in JIS for reference purpose.

MEES19K085

BC controller

2 - 7

1. SPECIFICATIONS

BC controller

Model CMB-M108V-JA1 (-TR)

Number of branch 8

Power source 1-phase 220-230-240 V

50Hz 60Hz

Power input Cooling kW 0.127/0.144/0.161 0.102/0.115/0.127

Heating kW 0.060/0.068/0.076 0.048/0.054/0.060

Current input Cooling A 0.58/0.63/0.68 0.47/0.50/0.53

Heating A 0.28/0.30/0.32 0.22/0.24/0.25

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit capacity P200 to P900/M200 to M300

Indoor unit capacity connectable to 1 branch *14

Model P/M80 or smaller

(Use optional joint pipe combining 2 branches when the total unit capacity exceeds P/M81.)

External dimension H x W x D mm 252 x 911 x 622

in. 9-15/16 x 35-7/8 x 24-1/2

Refrigerant To outdoor/heat source unit Connectable unit capacity High press. pipe Low press. pipe

piping mm (in.) O.D. P200/M200 15.88 (5/8) Brazed 19.05 (3/4) Brazed

diameter mm (in.) O.D. P250/P300 19.05 (3/4) Brazed 22.2 (7/8) Brazed

*15 mm (in.) O.D. P350

19.05 (3/4) Brazed or 22.2 (7/8)

Brazed

28.58 (1-1/8) Brazed

mm (in.) O.D. P400 to P500 22.2 (7/8) Brazed 28.58 (1-1/8) Brazed

*15 mm (in.) O.D. P550

22.2 (7/8) Brazed or 28.58 (1-1/8)

Brazed

28.58 (1-1/8) Brazed

*15 mm (in.) O.D. P600

22.2 (7/8) Brazed or 28.58 (1-1/8)

Brazed

28.58 (1-1/8) Brazed or 34.93 (1-3/8)

Brazed

mm (in.) O.D. P650 28.58 (1-1/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P700 to P800 28.58 (1-1/8) Brazed 34.93 (1-3/8) Brazed

mm (in.) O.D. P850 to P900 28.58 (1-1/8) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. M250/M300 15.88 (5/8) Brazed 22.2 (7/8) Brazed

To indoor unit Liquid pipe Gas pipe

mm (in.) O.D.

Indoor unit Model 50 or smaller 6.35 (1/4) Brazed Indoor unit Model 50 or smaller 12.7 (1/2) Brazed

bigger than 50 9.52 (3/8) Brazed bigger than 50 15.88 (5/8) Brazed

(19.05 (3/4), 22.2 (7/8) with optional joint pipe used.)

To other BC controller

Total down-stream Indoor

unit capacity

High press. pipe Liquid pipe Low press. pipe

mm (in.) O.D. to P200/M200 15.88 (5/8) Brazed 9.52 (3/8) Brazed 19.05 (3/4) Brazed

mm (in.) O.D. P201 to P300 19.05 (3/4) Brazed 9.52 (3/8) Brazed 22.2 (7/8) Brazed

mm (in.) O.D. P301 to P350 19.05 (3/4) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P351 to P400 22.2 (7/8) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P401 to P600 22.2 (7/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P601 to P650 28.58 (1-1/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P651 to P800 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 34.93 (1-3/8) Brazed

mm (in.) O.D. P801 to P1000 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. P1001 or above 34.93 (1-3/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. M201 to M300 15.88 (5/8) Brazed 9.52 (3/8) Brazed 22.2 (7/8) Brazed

mm (in.) O.D. M301 to M350 15.88 (5/8) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. M351 to M400 19.05 (3/4) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. M401 to M450 19.05 (3/4) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 48 (106)

Sound power level Rated operation

dB <A> 68

(measured in anechoic room)

Defrost dB <A> 74

Sound pressure level Rated operation

dB <A> 50

(measured in anechoic room)

*16 Defrost dB <A> 56

Accessories Drain Connection pipe, Washer, Tie band

Remarks

Notes:

1.Installation/foundation work, electrical connection work, insulation work, power source switch, and other items

shall be referred to the Installation Manual.

2.The equipment is for R410A or R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away

from any indoor units.)

4.Sound pressure/power level differs depending on the connected outdoor/heat source unit capacity or operation condition.

The sound pressure/power level at the rated operation is the value of the cooling mode.

5.The sound pressure/power level values were obtained in an anechoic room. Actual sound pressure level is usually

greater than that measured in anechoic room due to ambient noise and deflection sound.

6.The sound pressure level values were obtained at the location below 1.5m from the unit.

7.The solenoid valve switching sound is 56 dB (sound pressure level) regardless of the unit model.

8.Indoor units P/M100, P/M125, P/M140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

9.Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the

Installation Manual.

10.This unit is not designed for outside installations.

11.When blazing the pipes, be sure to blaze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

12.The ambient relative humidity of the BC controller needs to be kept below 80%.

13.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the DATA BOOK on installation restrictions.

14.Indoor unit capacity connectable to 1 branch is changed depending on the indoor unit type and connection

method. Please refer to the Installation Manual for more information.

15.For the refrigerant pipe size, refer to Installation Manual of outdoor units/heat source units.

16.The sound pressure level measured by the conventional method in JIS for reference purpose.

MEES19K085

BC controller

2 - 8

1. SPECIFICATIONS

BC controller

Model CMB-M1012V-JA1 (-TR)

Number of branch 12

Power source 1-phase 220-230-240 V

50Hz 60Hz

Power input Cooling kW 0.186/0.211/0.236 0.150/0.168/0.186

Heating kW 0.090/0.102/0.114 0.072/0.081/0.090

Current input Cooling A 0.85/0.92/0.99 0.69/0.74/0.78

Heating A 0.42/0.44/0.48 0.33/0.36/0.38

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit capacity P200 to P900/M200 to M300

Indoor unit capacity connectable to 1 branch *14

Model P/M80 or smaller

(Use optional joint pipe combining 2 branches when the total unit capacity exceeds P/M81.)

External dimension H x W x D mm 252 x 1,135 x 622

in. 9-15/16 x 44-11/16 x 24-1/2

Refrigerant To outdoor/heat source unit Connectable unit capacity High press. pipe Low press. pipe

piping mm (in.) O.D. P200/M200 15.88 (5/8) Brazed 19.05 (3/4) Brazed

diameter mm (in.) O.D. P250/P300 19.05 (3/4) Brazed 22.2 (7/8) Brazed

*15 mm (in.) O.D. P350

19.05 (3/4) Brazed or 22.2 (7/8)

Brazed

28.58 (1-1/8) Brazed

mm (in.) O.D. P400 to P500 22.2 (7/8) Brazed 28.58 (1-1/8) Brazed

*15 mm (in.) O.D. P550

22.2 (7/8) Brazed or 28.58 (1-1/8)

Brazed

28.58 (1-1/8) Brazed

*15 mm (in.) O.D. P600

22.2 (7/8) Brazed or 28.58 (1-1/8)

Brazed

28.58 (1-1/8) Brazed or 34.93 (1-3/8)

Brazed

mm (in.) O.D. P650 28.58 (1-1/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P700 to P800 28.58 (1-1/8) Brazed 34.93 (1-3/8) Brazed

mm (in.) O.D. P850 to P900 28.58 (1-1/8) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. M250/M300 15.88 (5/8) Brazed 22.2 (7/8) Brazed

To indoor unit Liquid pipe Gas pipe

mm (in.) O.D.

Indoor unit Model 50 or smaller 6.35 (1/4) Brazed Indoor unit Model 50 or smaller 12.7 (1/2) Brazed

bigger than 50 9.52 (3/8) Brazed bigger than 50 15.88 (5/8) Brazed

(19.05 (3/4), 22.2 (7/8) with optional joint pipe used.)

To other BC controller

Total down-stream Indoor

unit capacity

High press. pipe Liquid pipe Low press. pipe

mm (in.) O.D. to P200/M200 15.88 (5/8) Brazed 9.52 (3/8) Brazed 19.05 (3/4) Brazed

mm (in.) O.D. P201 to P300 19.05 (3/4) Brazed 9.52 (3/8) Brazed 22.2 (7/8) Brazed

mm (in.) O.D. P301 to P350 19.05 (3/4) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P351 to P400 22.2 (7/8) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P401 to P600 22.2 (7/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P601 to P650 28.58 (1-1/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P651 to P800 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 34.93 (1-3/8) Brazed

mm (in.) O.D. P801 to P1000 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. P1001 or above 34.93 (1-3/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. M201 to M300 15.88 (5/8) Brazed 9.52 (3/8) Brazed 22.2 (7/8) Brazed

mm (in.) O.D. M301 to M350 15.88 (5/8) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. M351 to M400 19.05 (3/4) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. M401 to M450 19.05 (3/4) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 60 (133)

Sound power level Rated operation

dB <A> 68

(measured in anechoic room)

Defrost dB <A> 74

Sound pressure level Rated operation

dB <A> 50

(measured in anechoic room)

*16 Defrost dB <A> 56

Accessories Drain Connection pipe, Washer, Tie band

Remarks

Notes:

1.Installation/foundation work, electrical connection work, insulation work, power source switch, and other items

shall be referred to the Installation Manual.

2.The equipment is for R410A or R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away

from any indoor units.)

4.Sound pressure/power level differs depending on the connected outdoor/heat source unit capacity or operation condition.

The sound pressure/power level at the rated operation is the value of the cooling mode.

5.The sound pressure/power level values were obtained in an anechoic room. Actual sound pressure level is usually

greater than that measured in anechoic room due to ambient noise and deflection sound.

6.The sound pressure level values were obtained at the location below 1.5m from the unit.

7.The solenoid valve switching sound is 56 dB (sound pressure level) regardless of the unit model.

8.Indoor units P/M100, P/M125, P/M140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

9.Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the

Installation Manual.

10.This unit is not designed for outside installations.

11.When blazing the pipes, be sure to blaze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

12.The ambient relative humidity of the BC controller needs to be kept below 80%.

13.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the DATA BOOK on installation restrictions.

14.Indoor unit capacity connectable to 1 branch is changed depending on the indoor unit type and connection

method. Please refer to the Installation Manual for more information.

15.For the refrigerant pipe size, refer to Installation Manual of outdoor units/heat source units.

16.The sound pressure level measured by the conventional method in JIS for reference purpose.

MEES19K085

BC controller

2 - 9

1. SPECIFICATIONS

BC controller

Model CMB-M1016V-JA1 (-TR)

Number of branch 16

Power source 1-phase 220-230-240 V

50Hz 60Hz

Power input Cooling kW 0.246/0.279/0.312 0.198/0.222/0.246

Heating kW 0.119/0.135/0.151 0.096/0.108/0.119

Current input Cooling A 1.12/1.22/1.30 0.90/0.97/1.03

Heating A 0.55/0.59/0.63 0.44/0.47/0.50

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit capacity P200 to P900/M200 to M300

Indoor unit capacity connectable to 1 branch *14

Model P/M80 or smaller

(Use optional joint pipe combining 2 branches when the total unit capacity exceeds P/M81.)

External dimension H x W x D mm 252 x 1,135 x 622

in. 9-15/16 x 44-11/16 x 24-1/2

Refrigerant To outdoor/heat source unit Connectable unit capacity High press. pipe Low press. pipe

piping mm (in.) O.D. P200/M200 15.88 (5/8) Brazed 19.05 (3/4) Brazed

diameter mm (in.) O.D. P250/P300 19.05 (3/4) Brazed 22.2 (7/8) Brazed

*15 mm (in.) O.D. P350

19.05 (3/4) Brazed or 22.2 (7/8)

Brazed

28.58 (1-1/8) Brazed

mm (in.) O.D. P400 to P500 22.2 (7/8) Brazed 28.58 (1-1/8) Brazed

*15 mm (in.) O.D. P550

22.2 (7/8) Brazed or 28.58 (1-1/8)

Brazed

28.58 (1-1/8) Brazed

*15 mm (in.) O.D. P600

22.2 (7/8) Brazed or 28.58 (1-1/8)

Brazed

28.58 (1-1/8) Brazed or 34.93 (1-3/8)

Brazed

mm (in.) O.D. P650 28.58 (1-1/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P700 to P800 28.58 (1-1/8) Brazed 34.93 (1-3/8) Brazed

mm (in.) O.D. P850 to P900 28.58 (1-1/8) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. M250/M300 15.88 (5/8) Brazed 22.2 (7/8) Brazed

To indoor unit Liquid pipe Gas pipe

mm (in.) O.D.

Indoor unit Model 50 or smaller 6.35 (1/4) Brazed Indoor unit Model 50 or smaller 12.7 (1/2) Brazed

bigger than 50 9.52 (3/8) Brazed bigger than 50 15.88 (5/8) Brazed

(19.05 (3/4), 22.2 (7/8) with optional joint pipe used.)

To other BC controller

Total down-stream Indoor

unit capacity

High press. pipe Liquid pipe Low press. pipe

mm (in.) O.D. to P200/M200 15.88 (5/8) Brazed 9.52 (3/8) Brazed 19.05 (3/4) Brazed

mm (in.) O.D. P201 to P300 19.05 (3/4) Brazed 9.52 (3/8) Brazed 22.2 (7/8) Brazed

mm (in.) O.D. P301 to P350 19.05 (3/4) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P351 to P400 22.2 (7/8) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P401 to P600 22.2 (7/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P601 to P650 28.58 (1-1/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P651 to P800 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 34.93 (1-3/8) Brazed

mm (in.) O.D. P801 to P1000 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. P1001 or above 34.93 (1-3/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. M201 to M300 15.88 (5/8) Brazed 9.52 (3/8) Brazed 22.2 (7/8) Brazed

mm (in.) O.D. M301 to M350 15.88 (5/8) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. M351 to M400 19.05 (3/4) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. M401 to M450 19.05 (3/4) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 68 (150)

Sound power level Rated operation

dB <A> 68

(measured in anechoic room)

Defrost dB <A> 74

Sound pressure level Rated operation

dB <A> 50

(measured in anechoic room)

*16 Defrost dB <A> 56

Accessories Drain Connection pipe, Washer, Tie band

Remarks

Notes:

1.Installation/foundation work, electrical connection work, insulation work, power source switch, and other items

shall be referred to the Installation Manual.

2.The equipment is for R410A or R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away

from any indoor units.)

4.Sound pressure/power level differs depending on the connected outdoor/heat source unit capacity or operation condition.

The sound pressure/power level at the rated operation is the value of the cooling mode.

5.The sound pressure/power level values were obtained in an anechoic room. Actual sound pressure level is usually

greater than that measured in anechoic room due to ambient noise and deflection sound.

6.The sound pressure level values were obtained at the location below 1.5m from the unit.

7.The solenoid valve switching sound is 56 dB (sound pressure level) regardless of the unit model.

8.Indoor units P/M100, P/M125, P/M140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

9.Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the

Installation Manual.

10.This unit is not designed for outside installations.

11.When blazing the pipes, be sure to blaze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

12.The ambient relative humidity of the BC controller needs to be kept below 80%.

13.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the DATA BOOK on installation restrictions.

14.Indoor unit capacity connectable to 1 branch is changed depending on the indoor unit type and connection

method. Please refer to the Installation Manual for more information.

15.For the refrigerant pipe size, refer to Installation Manual of outdoor units/heat source units.

16.The sound pressure level measured by the conventional method in JIS for reference purpose.

MEES19K085

BC controller

2 - 10

1. SPECIFICATIONS

BC controller

Model CMB-P1016V-KA1 (-TR)

Number of branch 16

Power source 1-phase 220-230-240 V

50Hz 60Hz

Power input Cooling kW 0.246/0.279/0.312 0.198/0.222/0.246

Heating kW 0.119/0.135/0.151 0.096/0.108/0.119

Current input Cooling A 1.12/1.22/1.30 0.90/0.97/1.03

Heating A 0.55/0.59/0.63 0.44/0.47/0.50

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit capacity P200 to P1100

Indoor unit capacity connectable to 1 branch *13

Model P80 or smaller

(Use optional joint pipe combining 2 branches when the total unit capacity exceeds P81.)

External dimension H x W x D mm 250 x 1,135 x 622

in. 9-7/8 x 44-11/16 x 24-1/2

Refrigerant To outdoor/heat source unit Connectable unit capacity High press. pipe Low press. Pipe

piping mm (in.) O.D. P200 15.88 (5/8) Brazed 19.05 (3/4) Brazed

diameter mm (in.) O.D. P250/P300 19.05 (3/4) Brazed 22.2 (7/8) Brazed

*14 mm (in.) O.D. P350

19.05 (3/4) Brazed or 22.2 (7/8)

Brazed

28.58 (1-1/8) Brazed

mm (in.) O.D. P400 to P500 22.2 (7/8) Brazed 28.58 (1-1/8) Brazed

*14 mm (in.) O.D. P550

22.2 (7/8) Brazed or 28.58 (1-1/8)

Brazed

28.58 (1-1/8) Brazed

*14 mm (in.) O.D. P600

22.2 (7/8) Brazed or 28.58 (1-1/8)

Brazed

28.58 (1-1/8) Brazed or 34.93 (1-3/8)

Brazed

mm (in.) O.D. P650 28.58 (1-1/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P700 to P800 28.58 (1-1/8) Brazed 34.93 (1-3/8) Brazed

mm (in.) O.D. P850 to P1000 28.58 (1-1/8) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. P1050 to P1100 34.93 (1-3/8) Brazed 41.28 (1-5/8) Brazed

To indoor unit Liquid pipe Gas pipe

mm (in.) O.D.

Indoor unit Model 50 or smaller 6.35 (1/4) Brazed Indoor unit Model 50 or smaller 12.7 (1/2) Brazed

bigger than 50 9.52 (3/8) Brazed bigger than 50 15.88 (5/8) Brazed

(19.05 (3/4), 22.2 (7/8) with optional joint pipe used.)

To other BC controller

Total down-stream Indoor

unit capacity

High press. pipe Liquid pipe Low press. pipe

mm (in.) O.D. to P200 15.88 (5/8) Brazed 9.52 (3/8) Brazed 19.05 (3/4) Brazed

mm (in.) O.D. P201 to P300 19.05 (3/4) Brazed 9.52 (3/8) Brazed 22.2 (7/8) Brazed

mm (in.) O.D. P301 to P350 19.05 (3/4) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P351 to P400 22.2 (7/8) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P401 to P600 22.2 (7/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P601 to P650 28.58 (1-1/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P651 to P800 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 34.93 (1-3/8) Brazed

mm (in.) O.D. P801 to P1000 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. P1001 or above 34.93 (1-3/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 69 (153)

Sound power level Rated operation

dB <A> 66 (measured in anechoic room)

Defrost dB <A> 73

Sound pressure level Rated operation

dB <A> 48 (measured in anechoic room)

*15 Defrost dB <A> 55

Accessories Drain Connection pipe, Washer, Tie band

Remarks

Notes:

1.Installation/foundation work, electrical connection work, insulation work, power source switch, and other items

shall be referred to the Installation Manual.

2.The equipment is for R410A refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away

from any indoor units.)

4.Sound pressure/power level differs depending on the connected outdoor/heat source unit capacity or operation condition.

The sound pressure/power level at the rated operation is the value of the cooling mode.

5.The sound pressure/power level values were obtained in an anechoic room. Actual sound pressure level is usually

greater than that measured in anechoic room due to ambient noise and deflection sound.

6.The sound pressure level values were obtained at the location below 1.5m from the unit.

7.The solenoid valve switching sound is 56 dB (sound pressure level) regardless of the unit model.

8.Indoor units P100, P125, P140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

9.Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the

Installation Manual.

10.This unit is not designed for outside installations.

11.When blazing the pipes, be sure to blaze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

12.The ambient relative humidity of the BC controller needs to be kept below 80%.

13.Indoor unit capacity connectable to 1 branch is changed depending on the indoor unit type and connection

method. Please refer to the Installation Manual for more information.

14.For the refrigerant pipe size, refer to Installation Manual of outdoor units/heat source units.

15.The sound pressure level measured by the conventional method in JIS for reference purpose.

MEES19K085

BC controller

2 - 11

1. SPECIFICATIONS

BC controller

Model CMB-M104V-KB1 (-TR)

Number of branch 4

Power source 1-phase 220-230-240 V

50Hz 60Hz

Power input Cooling kW 0.060/0.068/0.076 0.048/0.054/0.060

Heating kW 0.030/0.034/0.038 0.024/0.027/0.030

Current input Cooling A 0.28/0.30/0.32 0.22/0.24/0.25

Heating A 0.14/0.15/0.16 0.11/0.12/0.13

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable Main BC controller CMB-M108/1012/1016V-JA1 (-TR), CMB-P1016V-KA1 (-TR)

The maximum number of connectable Sub BC controllers 11

The maximum connectable capacity of indoor units P/M350 for each

External dimension H x W x D mm 250 x 596 x 476

in. 9-7/8 x 23-1/2 x 18-3/4

Refrigerant To outdoor/heat source unit Connectable unit capacity High press. pipe Low press. pipe

piping mm (in.) O.D. - - -

diameter To indoor unit Liquid pipe Gas pipe

mm (in.) O.D.

Indoor unit Model 50 or smaller 6.35 (1/4) Brazed Indoor unit Model 50 or smaller 12.7 (1/2) Brazed

bigger than 50 9.52 (3/8) Brazed bigger than 50 15.88 (5/8) Brazed

(19.05 (3/4), 22.2 (7/8) with optional joint pipe used.)

To other BC controller

Total down-stream Indoor

unit capacity

High press. pipe Liquid pipe Low press. pipe

mm (in.) O.D. to P200/M200 15.88 (5/8) Brazed 9.52 (3/8) Brazed 19.05 (3/4) Brazed

mm (in.) O.D. P201 to P300 19.05 (3/4) Brazed 9.52 (3/8) Brazed 22.2 (7/8) Brazed

mm (in.) O.D. P301 to P350 19.05 (3/4) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P351 to P400 22.2 (7/8) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P401 to P600 22.2 (7/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P601 to P650 28.58 (1-1/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P651 to P800 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 34.93 (1-3/8) Brazed

mm (in.) O.D. P801 to P1000 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. P1001 or above 34.93 (1-3/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. M201 to M300 15.88 (5/8) Brazed 9.52 (3/8) Brazed 22.2 (7/8) Brazed

mm (in.) O.D. M301 to M350 15.88 (5/8) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. M351 to M400 19.05 (3/4) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. M401 to M450 19.05 (3/4) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 23 (51)

Sound power level Rated operation

dB <A> 59 (measured in anechoic room)

Defrost dB <A> 71

Sound pressure level Rated operation

dB <A> 40 (measured in anechoic room)

*15 Defrost dB <A> 53

Accessories Drain Connection pipe, Washer, Tie band

Remarks

Notes:

1.Installation/foundation work, electrical connection work, insulation work, power source switch, and other items

shall be referred to the Installation Manual.

2.The equipment is for R410A or R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away

from any indoor units.)

4.Sound pressure/power level differs depending on the connected outdoor/heat source unit capacity or operation condition.

The sound pressure/power level at the rated operation is the value of the cooling mode.

5.The sound pressure/power level values were obtained in an anechoic room. Actual sound pressure level is usually

greater than that measured in anechoic room due to ambient noise and deflection sound.

6.The sound pressure level values were obtained at the location below 1.5m from the unit.

7.The solenoid valve switching sound is 56 dB (sound pressure level) regardless of the unit model.

8.Indoor units P/M100, P/M125, P/M140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

9.Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the

Installation Manual.

10.This unit is not designed for outside installations.

11.When blazing the pipes, be sure to blaze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

12.Can't use singleness. (MAIN BC CONTROLLER is necessary)

13.The ambient relative humidity of the BC controller needs to be kept below 80%.

14.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the DATA BOOK on installation restrictions.

15.The sound pressure level measured by the conventional method in JIS for reference purpose.

MEES19K085

BC controller

2 - 12

1. SPECIFICATIONS

BC controller

Model CMB-M108V-KB1 (-TR)

Number of branch 8

Power source 1-phase 220-230-240 V

50Hz 60Hz

Power input Cooling kW 0.119/0.135/0.151 0.096/0.108/0.119

Heating kW 0.060/0.068/0.076 0.048/0.054/0.060

Current input Cooling A 0.55/0.59/0.63 0.44/0.47/0.50

Heating A 0.28/0.30/0.32 0.22/0.24/0.25

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable Main BC controller CMB-M108/1012/1016V-JA1 (-TR), CMB-P1016V-KA1 (-TR)

The maximum number of connectable Sub BC controllers 11

The maximum connectable capacity of indoor units P/M350 for each

External dimension H x W x D mm 250 x 596 x 476

in. 9-7/8 x 23-1/2 x 18-3/4

Refrigerant To outdoor/heat source unit Connectable unit capacity High press. pipe Low press. pipe

piping mm (in.) O.D. - - -

diameter To indoor unit Liquid pipe Gas pipe

mm (in.) O.D.

Indoor unit Model 50 or smaller 6.35 (1/4) Brazed Indoor unit Model 50 or smaller 12.7 (1/2) Brazed

bigger than 50 9.52 (3/8) Brazed bigger than 50 15.88 (5/8) Brazed

(19.05 (3/4), 22.2 (7/8) with optional joint pipe used.)

To other BC controller

Total down-stream Indoor

unit capacity

High press. pipe Liquid pipe Low press. pipe

mm (in.) O.D. to P200/M200 15.88 (5/8) Brazed 9.52 (3/8) Brazed 19.05 (3/4) Brazed

mm (in.) O.D. P201 to P300 19.05 (3/4) Brazed 9.52 (3/8) Brazed 22.2 (7/8) Brazed

mm (in.) O.D. P301 to P350 19.05 (3/4) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P351 to P400 22.2 (7/8) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P401 to P600 22.2 (7/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P601 to P650 28.58 (1-1/8) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. P651 to P800 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 34.93 (1-3/8) Brazed

mm (in.) O.D. P801 to P1000 28.58 (1-1/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. P1001 or above 34.93 (1-3/8) Brazed 19.05 (3/4) Brazed 41.28 (1-5/8) Brazed

mm (in.) O.D. M201 to M300 15.88 (5/8) Brazed 9.52 (3/8) Brazed 22.2 (7/8) Brazed

mm (in.) O.D. M301 to M350 15.88 (5/8) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. M351 to M400 19.05 (3/4) Brazed 12.7 (1/2) Brazed 28.58 (1-1/8) Brazed

mm (in.) O.D. M401 to M450 19.05 (3/4) Brazed 15.88 (5/8) Brazed 28.58 (1-1/8) Brazed

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 31 (69)

Sound power level Rated operation

dB <A> 59 (measured in anechoic room)

Defrost dB <A> 71

Sound pressure level Rated operation

dB <A> 40 (measured in anechoic room)

*15 Defrost dB <A> 53

Accessories Drain Connection pipe, Washer, Tie band

Remarks

Notes:

1.Installation/foundation work, electrical connection work, insulation work, power source switch, and other items

shall be referred to the Installation Manual.

2.The equipment is for R410A or R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away

from any indoor units.)

4.Sound pressure/power level differs depending on the connected outdoor/heat source unit capacity or operation condition.

The sound pressure/power level at the rated operation is the value of the cooling mode.

5.The sound pressure/power level values were obtained in an anechoic room. Actual sound pressure level is usually

greater than that measured in anechoic room due to ambient noise and deflection sound.

6.The sound pressure level values were obtained at the location below 1.5m from the unit.

7.The solenoid valve switching sound is 56 dB (sound pressure level) regardless of the unit model.

8.Indoor units P/M100, P/M125, P/M140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

9.Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the

Installation Manual.

10.This unit is not designed for outside installations.

11.When blazing the pipes, be sure to blaze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

12.Can't use singleness. (MAIN BC CONTROLLER is necessary)

13.The ambient relative humidity of the BC controller needs to be kept below 80%.

14.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the DATA BOOK on installation restrictions.

15.The sound pressure level measured by the conventional method in JIS for reference purpose.

MEES19K085

BC controller

2 - 13

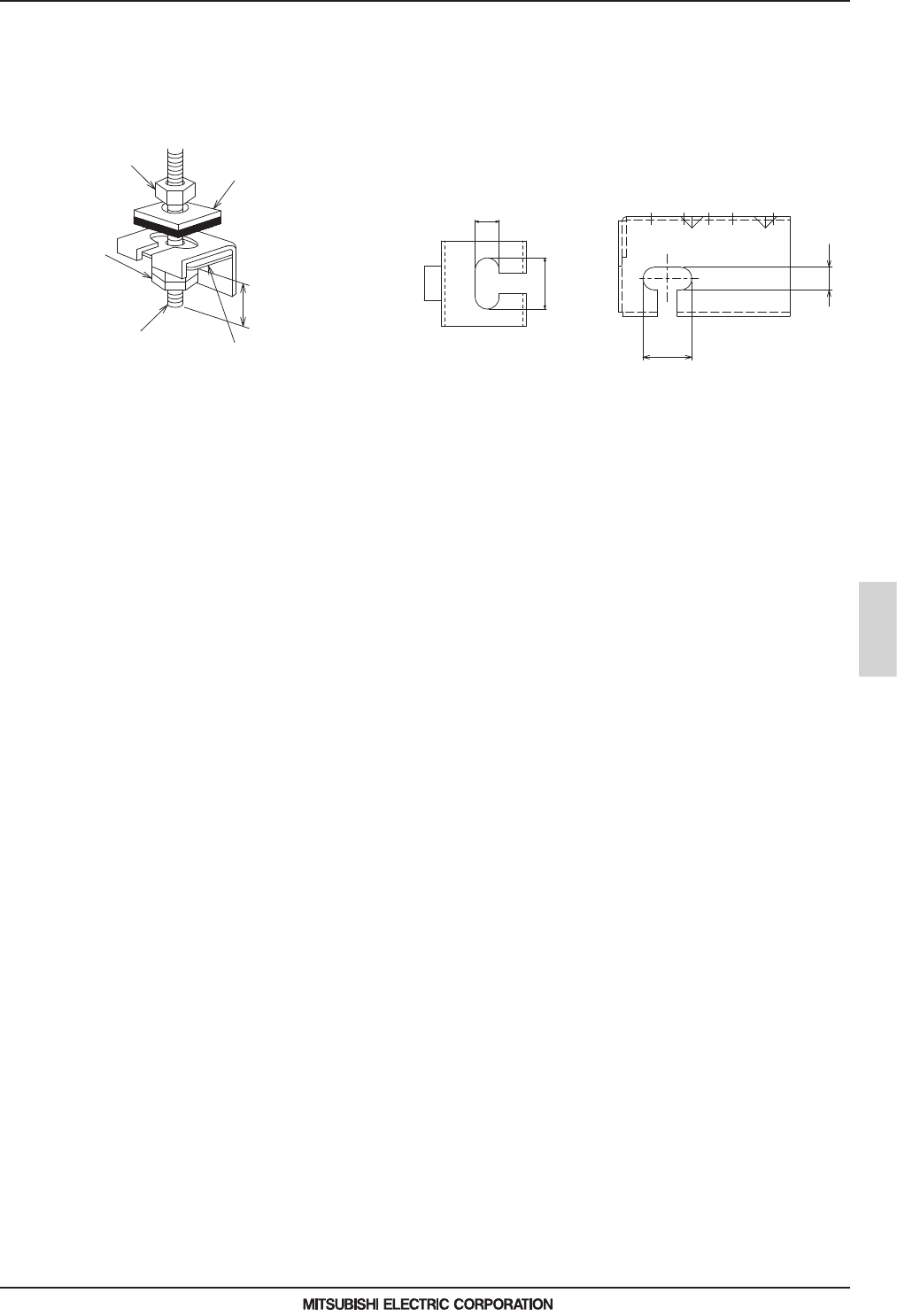

2. EXTERNAL DIMENSIONS

BC controller

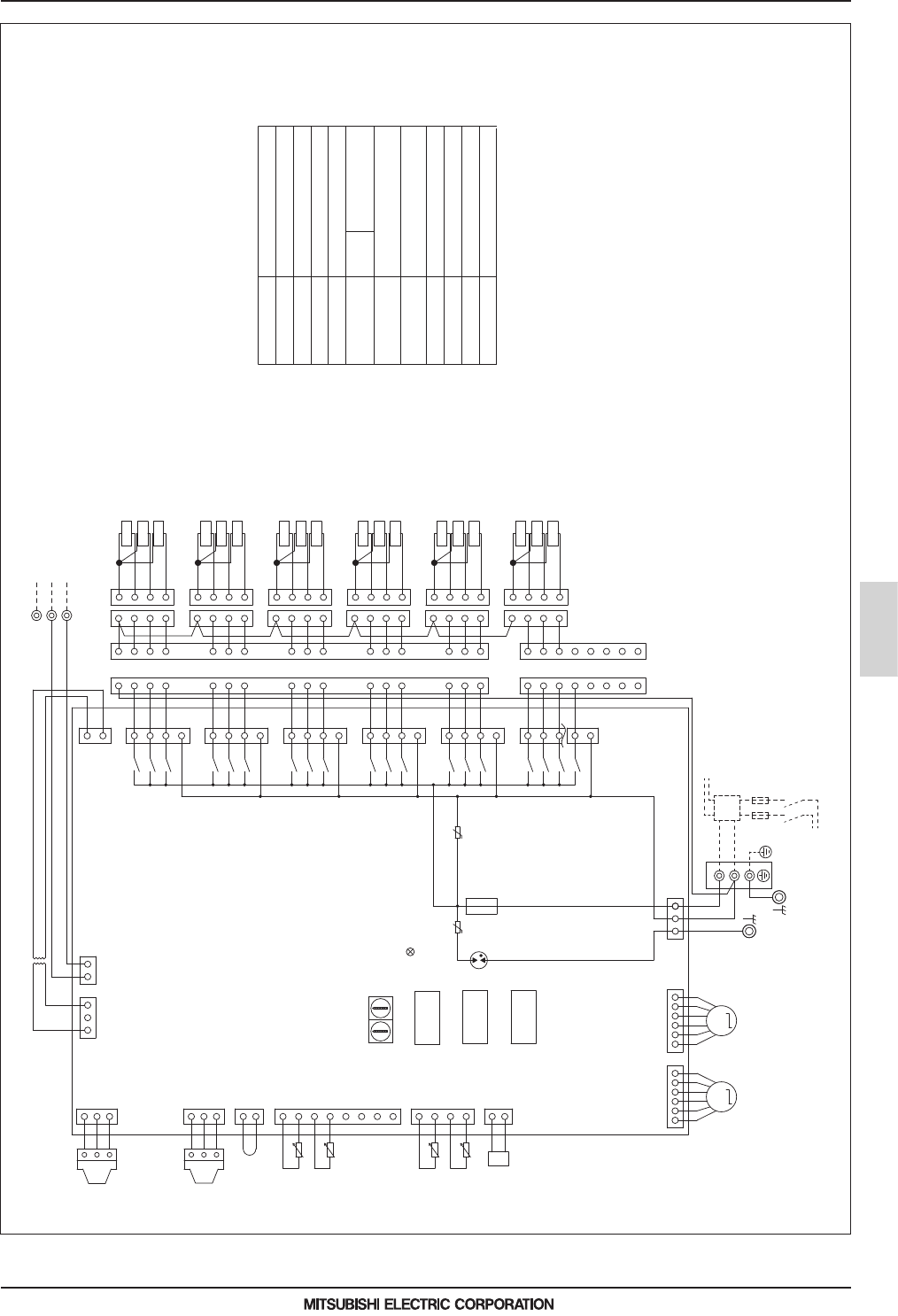

2. EXTERNAL DIMENSIONS

CMB-M104, 106, 108V-J1(-TR)

Unit: mm

Service

space

Service

space

Control box

(Lifting bolt pitch)

(Lifting bolt pitch)

8

7

6

5

4

3

2

1

Indoor unit model (Note 4)

P/M50 or less:ø6.35<Brazed>

P/M50 over :ø9.52<Brazed>

Indoor unit model (Note 4)

P/M50 or less:ø12.7<Brazed>

P/M50 over :ø15.88<Brazed>

ø19.05 (Note 5)

ø28.58 (Note 5)

(Note 2)

Access

door

Detail of X section

Detail of Y section

(Indoor unit Model:P/M50 over)

(Indoor unit Model:P/M50 or less)

Drain Piping

Note 1. Suspension bolt(ø10) and nut(M10) prepare in the field.

2. Take notice of service space as shown.

(Please give attention not to occupy service space by letting ducts

and pipes through.)

3. Install this product in a location where noise (refrigerant noise)

emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise,position

the BC CONTROLLER at least 5m away from any indoor units.)

4. Refer to the Installation Manual for refrigerant piping diameter size

when connecting plural indoor units with 1 branch.

5. Refer to the Table-1 for connection pipe of outdoor unit diameter

size.

6. Refer to the Installation Manual for insulation of connection pipe and

drain piping.

7. Do not place the BC controller directly on the floor.

<Accessories>

· Drain hose I.D.32 ···························· 1pc.

· Tie band ········································ 3pcs.

· Square washer (with cushion) ············ 4pcs.

· Square washer ······························· 4pcs.

AB

CMB-M104V-J1(-TR)

3180

CMB-M106V-J1(-TR)

5300

CMB-M108V-J1(-TR)

7420

35

78

130

25

199

121

60×A=B118

60

60×A=B

60

88

120

11

68

38

101

596

648

323

398

267

250

221

20

450

250

(250)

(100)

(200)

450

73

(700)

14

12

30

20

50

20

Y

X

Connection pipe of outdoor unit

(High pressure)

Connection pipe of outdoor unit

(Low pressure)

Connection pipe of

indoor unit (Liquid)

Connection pipe of

indoor unit (Gas)

Drain pipe O.D.32

Cutting point

Cutting point

Drain hose I.D.32

(Accessory)

Connectable

unit capacity

High press. Pipe Low press. Pipe

P200

ø15.88

ø19.05

P250, P300

ø19.05 ø22.2

P350

ø19.05 or ø22.2

ø28.58

M200

ø15.88

ø19.05

M250, M300

ø15.88

ø22.2

Table-1. To outdoor/heat source unit (Note.5)

*For the refrigerant pipe size, refer to Installation Manual of outdoor units/heat

source units.

*

MEES19K085

BC controller

2 - 14

2. EXTERNAL DIMENSIONS

BC controller

CMB-M1012, 1016V-J1(-TR)

Unit: mm

Access

door

12345678 910111213141516

Control box

(Lifting bolt pitch)

(Lifting bolt pitch)

ø28.58 (Note 5)

ø19.05 (Note 5)

Indoor unit model (Note 4)

P/M50 or less:ø6.35<Brazed>

P/M50 over :ø9.52<Brazed>

Indoor unit model (Note 4)

P/M50 or less:ø12.7<Brazed>

P/M50 over :ø15.88<Brazed>

(Note 2)

(Indoor unit Model : P/M50 over)

Detail of Y section

(Indoor unit Model : P/M50 or less)

Detail of X section

Drain Piping

<Accessories>

· Drain hose I.D.32 ···························· 1pc.

· Tie band ········································ 3pcs.

· Square washer (with cushion) ············ 4pcs.

· Square washer ······························· 4pcs.

Note 1. Suspension bolt(ø10) and nut(M10) prepare in the field.

2. Take notice of service space as shown.

(Please give attention not to occupy service space by letting ducts

and pipes through.)

3. Install this product in a location where noise (refrigerant noise)

emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise,position

the BC CONTROLLER at least 5m away from any indoor units.)

4. Refer to the Installation Manual for refrigerant piping diameter size

when connecting plural indoor units with 1 branch.

5. Refer to the Table-1 for connection pipe of outdoor unit

diameter size.

6. Refer to the Installation Manual for insulation of connection pipe and

drain piping.

7. Do not place the BC controller directly on the floor.

ABCDE

CMB-M1012V-J1(-TR)

911

983 11 660 231

CMB-M1016V-J1(-TR)

1135 1207 15 900 343

B

A

130

41

77

47

91

158

60

60×C=D

120

22

188

60

60×C=D

2568

273

264

342

545

252

221

463

20

E

(250)

250 450

(100)

(200)

450

(700)

20

50

14

12

30

20

Connection pipe of outdoor unit

(Low pressure)

Connection pipe of outdoor unit

(High pressure)

Connection pipe of

indoor unit (Liquid)

Connection pipe of

indoor unit (Gas)

Y

X

Drain pipe O.D.32

Service

space

Service

space

Cutting point

Cutting point

Drain hose I.D.32

(Accessory)

Connectable

unit capacity

High press. Pipe Low press. Pipe

P200

ø15.88

ø19.05

P250, P300

ø19.05 ø22.2

P350

ø19.05 or ø22.2 ø28.58

M200 ø15.88 ø19.05

M250, M300

ø15.88 ø22.2

Table-1. To outdoor/heat source unit (Note.5)

*For the refrigerant pipe size, refer to Installation Manual of outdoor

units/heat source units.

*

MEES19K085

BC controller

2 - 15

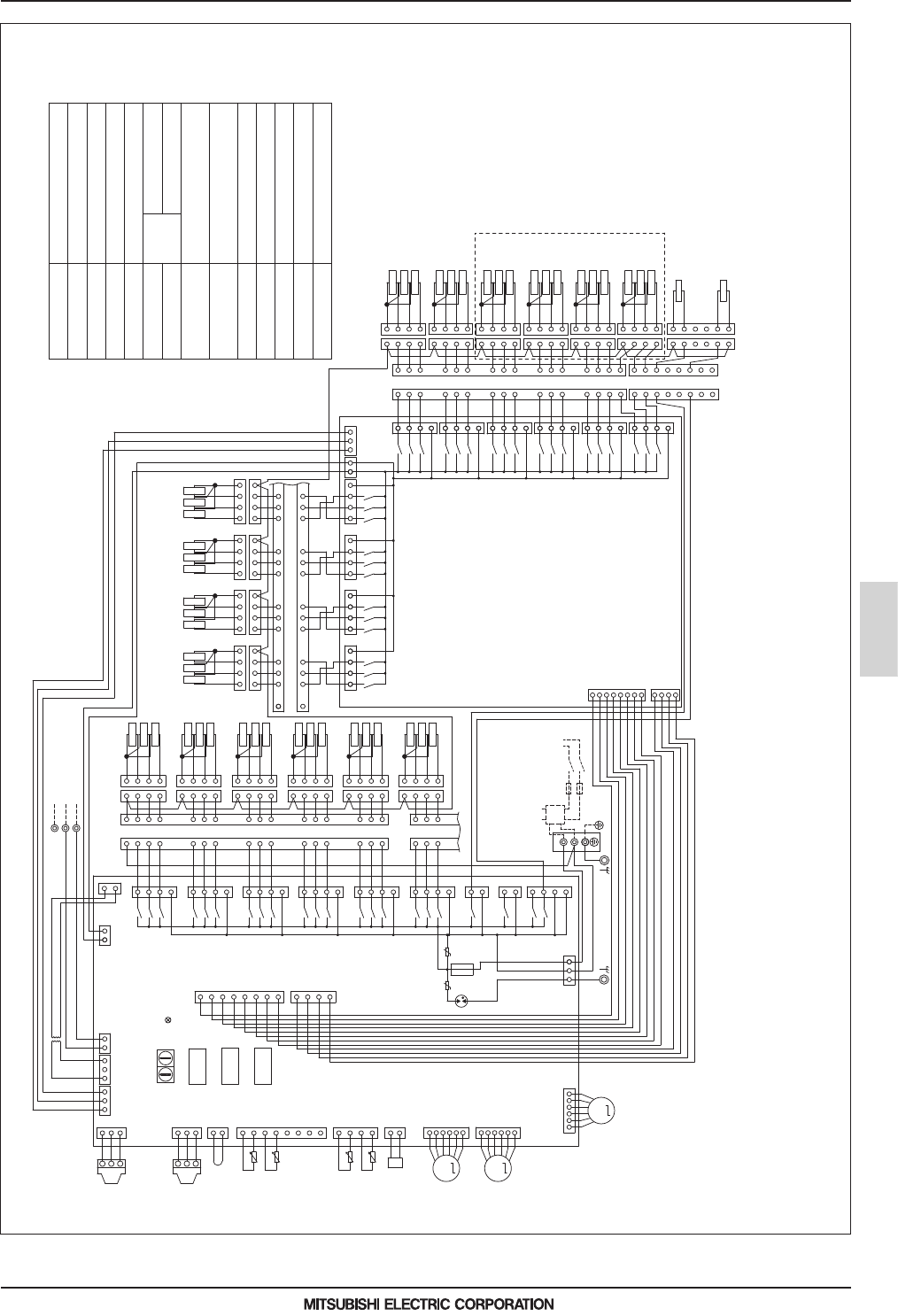

2. EXTERNAL DIMENSIONS

BC controller

CMB-M108, 1012, 1016V-JA1(-TR)

Unit: mm

123456789101112131415

16

(Lifting bolt pitch)

(Lifting bolt pitch)

ø38.1 (Note 6)

ø34.93 (Note 6)

Indoor unit model (Note 5)

P/M50 or less:ø6.35<Brazed>

P/M50 over :ø9.52<Brazed>

Indoor unit model (Note 5)

P/M50 or less:ø12.7<Brazed>

P/M50 over :ø15.88<Brazed>

ø28.58 (Note 6)

ø19.05 (Note 6)

ø38.1 (Note 6)

Control box

(Indoor unit Model : P/M50 over)

Detail of Y section

(Indoor unit Model : P/M50 or less)

Detail of X section

Drain Piping

Access

door

ABCD

E

CMB-M108V-JA1(-TR)

911

983 7 420 231

CMB-M1012V-JA1(-TR)

1135

1207 11 660 343

CMB-M1016V-JA1(-TR)

1135

1207 15 900 343

<Accessories>

· Drain hose I.D.32 ···························· 1pc.

· Tie band ········································ 3pcs.

· Square washer (with cushion) ············ 4pcs.

· Square washer ······························· 4pcs.

41

77130

A

B

47

91

47

97

155 188

60

60×C=D

158

60

60×C=D

22

80

155

25

273

264

342

252

264

325

379

68

463

545

221

20

20

50

14

12

30

20

(100)

(200)

250

(700)

250

(300)

450 E

450

Y

Connection pipe of outdoor unit

(Low pressure)

Connection pipe of outdoor unit

(High pressure)

Connection pipe of

indoor unit (Liquid)

Connection pipe of

indoor unit (Gas)

Connection pipe of

SUB BC CONTROLLER

(High pressure)

Connection pipe of

SUB BC CONTROLLER

(Liquid)

Connection pipe of

SUB BC CONTROLLER

(Low pressure)

X

Drain pipe O.D.32

Cutting point

Cutting point

Drain hose I.D.32

(Accessory)

Service space

Service

space

Note 1. Suspension bolt(ø10) and nut(M10) prepare in the field.

2. Take notice of service space as shown.

(Please give attention not to occupy service

space by letting ducts and pipes through.)

3. Please take service space for connection pipe of SUB BC CONTROLLER.

4. Install this product in a location where noise (refrigerant noise)

emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position

the BC CONTROLLER at least 5m away from any indoor units.)

5. Refer to the Installation Manual for refrigerant piping diameter size

when connecting plural indoor units with 1 branch.

6. Refer to the Table-1,2 connection pipe of outdoor unit

or SUB BC CONTROLLER diameter size.

7. Refer to the Installation Manual for insulation of connection pipe and

drain piping.

8. Do not place the BC controller directly on the floor.

Connectable

unit capacity

High press. Pipe Low press. Pipe

P200

ø15.88

ø19.05

P250, P300

ø19.05 ø22.2

P350

ø19.05 or ø22.2

ø28.58

P400 to P500 ø22.2 ø28.58

P550 ø22.2 or ø28.58 ø28.58

P600

ø22.2 or ø28.58 ø28.58 or ø34.93

P650

ø28.58

ø34.93

P700 to P800

ø28.58 ø34.93

P850, P900

ø28.58

ø41.28

M200 ø15.88

ø19.05

M250, M300

ø15.88

ø22.2

Table-1. To outdoor/heat source unit (Note.6)

Total downstream

Indoor unit capacity

High press. Pipe

Liquid Pipe Low press. Pipe

~P200 ø15.88 ø9.52 ø19.05

P201~300 ø19.05 ø9.52 ø22.2

P301~350 ø19.05 ø12.7 ø28.58

P351~400 ø22.2 ø12.7 ø28.58

P401~600 ø22.2 ø15.88 ø28.58

P601~650 ø28.58 ø15.88 ø28.58

P651~800 ø28.58 ø19.05 ø34.93

P801~1000 ø28.58 ø19.05 ø41.28

P1001~ ø34.93 ø19.05

ø41.28

~M200

ø15.88 ø9.52

ø19.05

M201~300

ø15.88 ø9.52

ø22.2

M301~350

ø15.88 ø12.7

ø28.58

M351~400

ø19.05 ø12.7

ø28.58

M401~450

ø19.05 ø15.88

ø28.58

Table-2. To other BC controller (Note.6)

*For the refrigerant pipe size, refer to Installation Manual of outdoor units/heat

source units.

*

*

*

MEES19K085

BC controller

2 - 16

2. EXTERNAL DIMENSIONS

BC controller

CMB-P1016V-KA1(-TR)

Unit: mm

1 2 3 4 5 6 7 8 9 10111213141516

(Lifting bolt pitch)

(Lifting bolt pitch)

ø38.1 (Note 7)

ø34.93 (Note 7)

Indoor unit model (Note 6)

P50 or less:ø6.35<Brazed>

P50 over :ø9.52<Brazed>

Indoor unit model (Note 6)

P50 or less:ø12.7<Brazed>

P50 over :ø15.88<Brazed>

ø34.93 (Note 7)

ø19.05 (Note 7)

ø38.1 (Note 7)

Control box

(Indoor unit Model : P50 over)

Detail of Y section

(Indoor unit Model : P50 or less)

Detail of X section

Drain Piping

Access

door

<Accessories>

· Drain hose I.D.32 ···························· 1pc.

· Tie band ········································ 3pcs.

· Square washer (with cushion) ············ 4pcs.

· Square washer ······························· 4pcs.

41

77130

47

91

47

97

155 188

60

60×15=900

158

60

60×15=900

22

80

155

25

221

273

264

342

252

379

325

264

545

68

463

1135

1207

20

20

50

14

12

30

20

(100)

(200)

250 450

250343450

(300)

(700)

Y

Connection pipe of outdoor unit

(Low pressure)

Connection pipe of outdoor unit

(High pressure)

Connection pipe of

indoor unit (Liquid)

Connection pipe of

indoor unit (Gas)

Connection pipe of

SUB BC CONTROLLER

(High pressure)

Connection pipe of

SUB BC CONTROLLER

(Liquid)

Connection pipe of

SUB BC CONTROLLER

(Low pressure)

X

Drain pipe O.D.32

Cutting point

Cutting point

Drain hose I.D.32

(Accessory)

Service space

Service

space

Connectable

unit capacity

High press. Pipe Low press. Pipe

P200

ø15.88

ø19.05

P250, P300

ø19.05 ø22.2

P350

ø19.05 or ø22.2

ø28.58

P400 to P500

ø22.2 ø28.58

P550

ø22.2 or ø28.58 ø28.58

P600

ø22.2 or ø28.58 ø28.58 or ø34.93

P650

ø28.58

ø34.93

P700 to P800

ø28.58 ø34.93

P850 to P1000

ø28.58

ø41.28

P1050 to P1100

ø34.93 ø41.28

Table-1. To outdoor/heat source unit (Note.7)

Total downstream

Indoor unit capacity

High press. Pipe Liquid Pipe Low press. Pipe

~P200

ø15.88 ø9.52 ø19.05

P201~300 ø19.05 ø9.52 ø22.2

P301~350 ø19.05 ø12.7 ø28.58

P351~400 ø22.2 ø12.7 ø28.58

P401~600 ø22.2 ø15.88 ø28.58

P601~650 ø28.58 ø15.88 ø28.58

P651~800 ø28.58 ø19.05 ø34.93

P801~1000 ø28.58 ø19.05 ø41.28

P1001~ ø34.93 ø19.05

ø41.28

Table-2. To other BC controller (Note.7)

*For the refrigerant pipe size, refer to Installation Manual of

outdoor units/heat source units.

*

*

*

Note 1. Suspension bolt(ø10) and nut(M10) prepare in the field.

2. Take notice of service space as shown.

(Please give attention not to occupy service

space by letting ducts and pipes through.)

3. Please take service space for connection pipe of SUB BC CONTROLLER.

4. When using an outdoor unit-38HP(P950) or more, use this product.

5. Install this product in a location where noise (refrigerant noise)

emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position

the BC CONTROLLER at least 5m away from any indoor units.)

6. Refer to the Installation Manual for refrigerant piping diameter size

when connecting plural indoor units with 1 branch.

7. Refer to the Table-1,2 for connection pipe of outdoor unit or

SUB BC CONTROLLER diameter size.

8. Refer to the Installation Manual for insulation of connection pipe and

drain piping.

9. Do not place the BC controller directly on the floor.

MEES19K085

BC controller

2 - 17

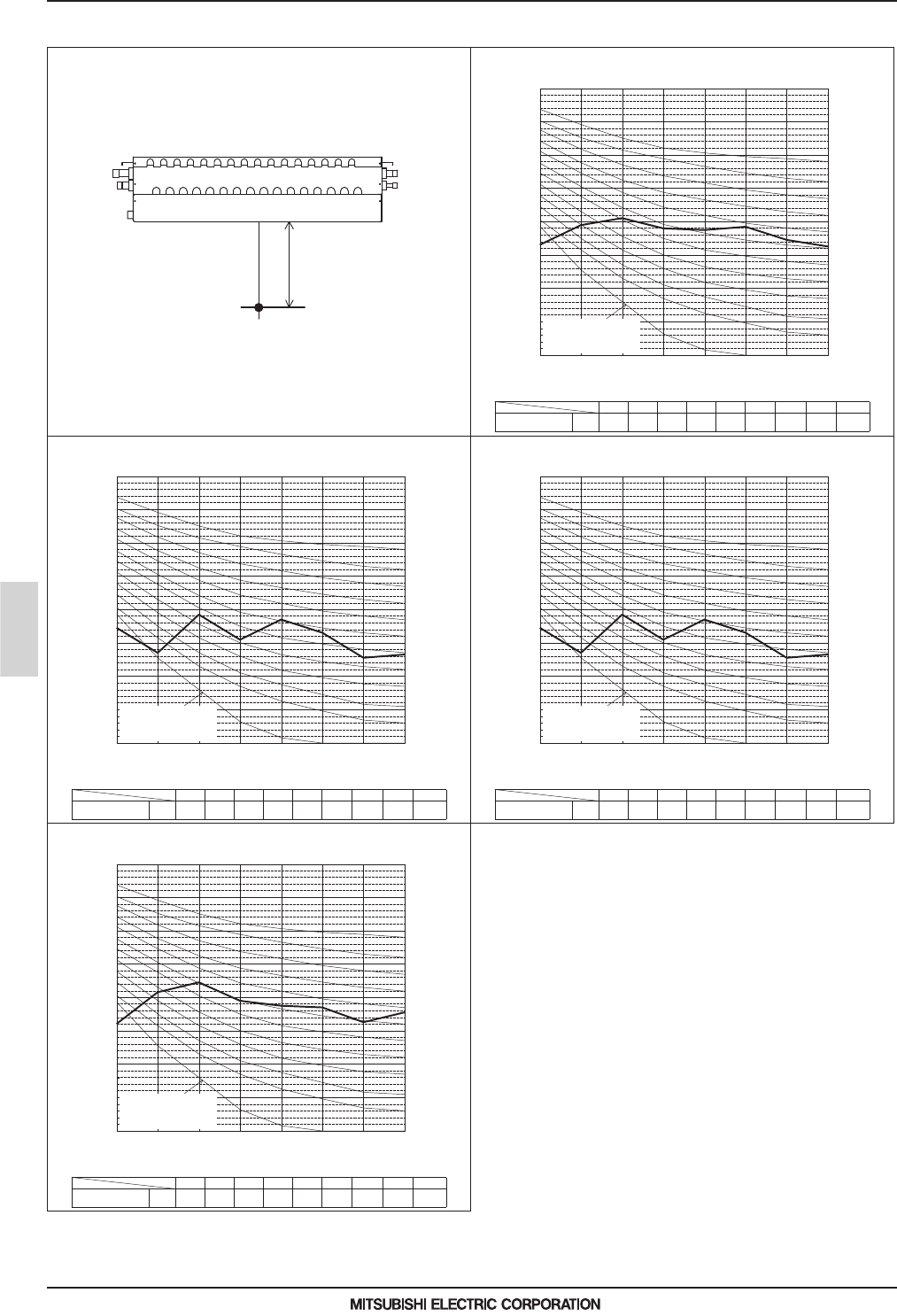

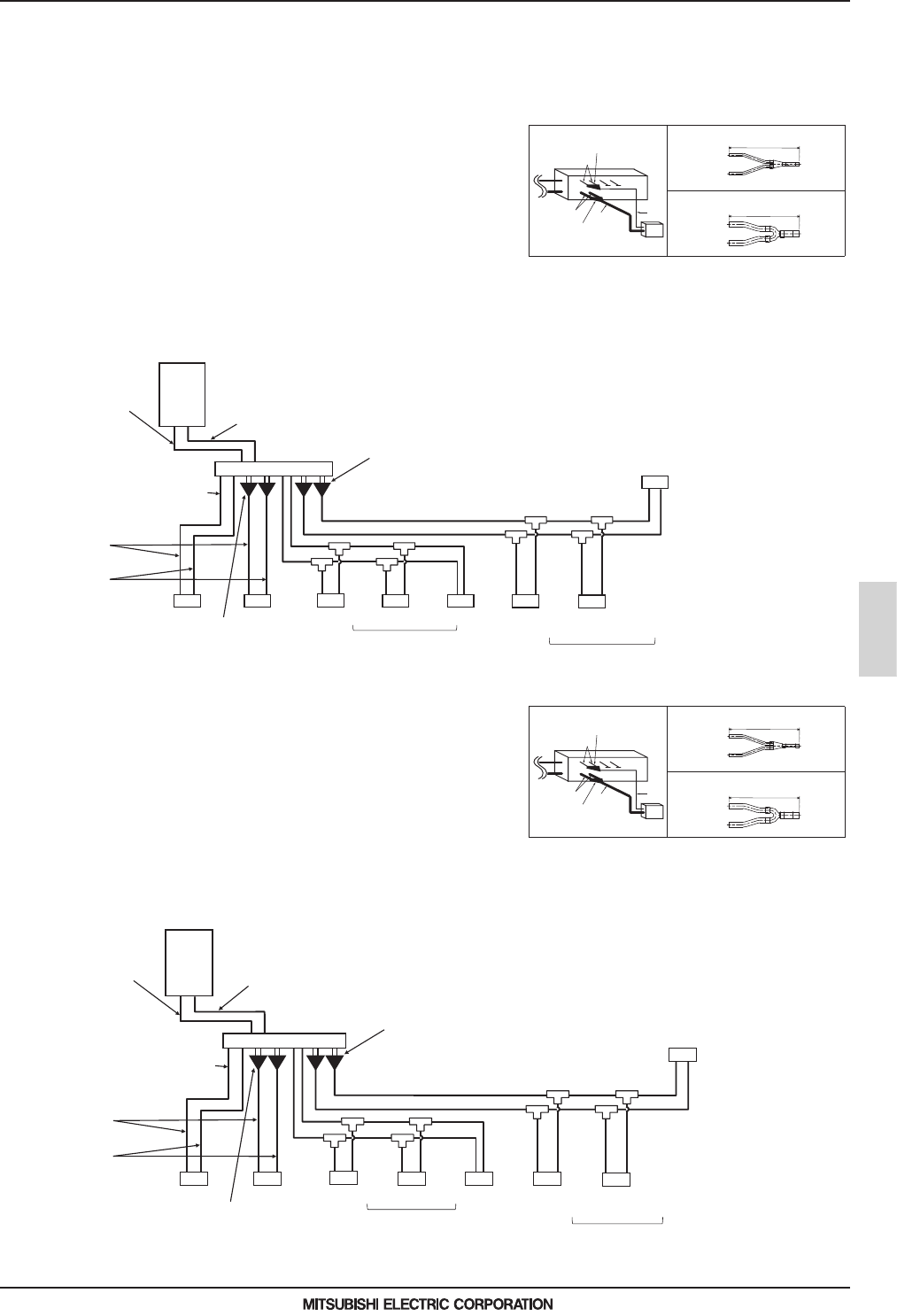

2. EXTERNAL DIMENSIONS

BC controller

CMB-M104, 108V-KB1(-TR)

Unit: mm

11

120

88 60×A=B

118

60

60×A=B

89

60

101

166

121

38

25

130

35

78

199

267

648

596

398

250

68

323

20

221

20

14

12

30

50

20

250

73

(250)

(100)

(200)

450

450

(700)

1

2

34

5

6

78

(Lifting bolt pitch)

Control box

(Lifting bolt pitch)

Indoor unit model (Note 5)

P/M50 or less :ø6.35<Brazed>

P/M50 over :ø9.52<Brazed>

Indoor unit model (Note 5)

P/M50 or less :ø12.7<Brazed>

P/M50 over :ø15.88<Brazed>

ø19.05 (Note 6)

ø15.88 (Note 6)

ø28.58 (Note 6)

(Indoor unit Model : P/M50 over)

Detail of Y section

(Indoor unit Model : P/M50 or less)

Detail of X section

Drain Piping

(Note 2)

Access

door

Note 1. Suspension bolt(ø10) and nut(M10) prepare in the field.

2. Take notice of service space as shown.

(Please give attention not to occupy service space by letting ducts and

pipes through.)

3. Can't use singleness. (MAIN BC CONTROLLER is necessary.)

4. Install this product in a location where noise (refrigerant noise)

emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position

the BC CONTROLLER at least 5m away from any indoor units.)

5. Refer to the Installation Manual for refrigerant piping diameter size

when connecting plural indoor units with 1 branch.

6. Refer to the Table-1 for connection pipe of MAIN BC CONTROLLER.

7. Refer to the Installation Manual for insulation of connection pipe and drain piping.

8. Do not place the BC controller directly on the floor.

<Accessories>

· Drain hose I.D.32 ···························· 1pc.

· Tie band ········································ 3pcs.

· Square washer (with cushion) ············ 4pcs.

· Square washer ······························· 4pcs.

AB

CMB-M104V-KB1(-TR)

3180

CMB-M108V-KB1(-TR)

7420

Connection pipe of

indoor unit (Liquid)

Connection pipe of

indoor unit (Gas)

Drain pipe O.D.32

Connection pipe of MAIN BC CONTROLLER

(High pressure)

Connection pipe of MAIN BC CONTROLLER

(Low pressure)

Connection pipe of MAIN BC CONTROLLER

(Liquid)

X