New York State Oil and Gas Sector:

Methane Emissions Inventory

Final Report | Report Number 22-38 | November 2022

NYSERDA’s Promise to New Yorkers:

NYSERDA provides resources, expertise,

and objective information so New Yorkers can

make confident, informed energy decisions.

Our Vision:

New York is a global climate leader building a healthier future with thriving communities; homes and

businesses powered by clean energy; and economic opportunities accessible to all New Yorkers.

Our Mission:

Advance clean energy innovation and investments to combat climate change, improving the health,

resiliency, and prosperity of New Yorkers and delivering benefits equitably to all.

New York State Oil and Gas Sector:

Methane Emissions Inventory

Final Report

Prepared for:

New York State Energy Research and Development Authority

Albany, NY

Macy Testani

Project Manager

James Wilcox

Senior Project Manager

Prepared by:

Abt Associates

Rockville

,

MD

Jonathan Dorn

Senior Associate

Hannah Derrick

Analyst

NYSERDA Report 22-38

NYSERDA Contract 30191

November 2022

ii

Notice

This report was prepared by Abt Associates in the course of performing work contracted for

and sponsored by the New York State Energy Research and Development Authority (hereafter

“NYSERDA”). The opinions expressed in this report do not necessarily reflect those of NYSERDA

or the State of New York, and reference to any specific product, service, process, or method does not

constitute an implied or expressed recommendation or endorsement of it. Further, NYSERDA, the State

of New York, and the contractor make no warranties or representations, expressed or implied, as to the

fitness for particular purpose or merchantability of any product, apparatus, or service, or the usefulness,

completeness, or accuracy of any processes, methods, or other information contained, described,

disclosed, or referred to in this report. NYSERDA, the State of New York, and the contractor make

no representation that the use of any product, apparatus, process, method, or other information will

not infringe privately owned rights and will assume no liability for any loss, injury, or damage resulting

from, or occurring in connection with, the use of information contained, described, disclosed, or

referred to in this report.

NYSERDA makes every effort to provide accurate information about copyright owners and related

matters in the reports we publish. Contractors are responsible for determining and satisfying copyright

or other use restrictions regarding the content of reports that they write, in compliance with NYSERDA’s

policies and federal law. If you are the copyright owner and believe a NYSERDA report has not properly

attributed your work to you or has used it without permission, please email prin[email protected]

Information contained in this document, such as web page addresses, are current at the time

of publication.

Preferred

Citation

New York State Energy Research and Development Authority (NYSERDA). 2022. “New York State Oil

and Gas Sector: Methane Emissions Inventory.” NYSERDA Report Number 22-38. Prepared by Abt

Associates, Rockville, MD. nyserda.ny.gov/publications

iii

Abstract

Methane (CH

4

) is a greenhouse gas that is second only to carbon dioxide (CO

2

) in its contribution

to global climate change. Fossil fuel production and consumption—including the extraction and

processing of natural gas as well as the distribution of natural gas to homes and businesses—is a

significant source of anthropogenic CH

4

emissions. The goal of this project was to support CH

4

emission reduction efforts in New York State by improving the State’s understanding of CH

4

emissions

and CH

4

emission-accounting methodologies for its oil and natural gas sector, including upstream,

midstream, and downstream sources within New York State. Informed by a literature review and guided

by identified best practices, a 1990–2020 geospatially resolved, bottom-up CH

4

emissions inventory

for the oil and natural gas sector was developed. In 2020, CH

4

emissions from oil and natural gas activity

in the State totaled 167,915 metric tons (MT) CH

4

, equivalent to 14,104,891 MTCO

2

e (AR5 GWP

20

).

Downstream emissions totaled 5.165 MMTCO

2

e in 2020 (36.6%), midstream emissions totaled 6.067

MMTCO

2

e (43%) and upstream sources emitted 2.873 MMTCO

2

e (20.4%). These results demonstrate

that the State is largely a consumer of natural gas and, as such, the midstream and downstream source

categories drive the majority of CH

4

emissions.

Keywords

Methane, oil, natural gas, emissions, inventory, greenhouse gas inventory, emission factors, methane

inventory, downstream emissions, upstream emissions, midstream emissions, natural gas emissions,

natural gas production, New York State methane inventory

Acknowledgments

The NYSERDA project team expresses its appreciation to the members of the Project Advisory

Committee during the first phase of the project and to the New York Department of Public Service

and the New York State Department of Environmental Conservation during the second phase of the

project for their guidance, expertise, and time.

iv

Table of Contents

Notice ........................................................................................................................................ ii

Preferred

Citation ..................................................................................................................... ii

Abstract ....................................................................................................................................iii

Keywords ..................................................................................................................................iii

Acknowledgments ...................................................................................................................iii

List of Figures .........................................................................................................................vii

List of Tables .......................................................................................................................... viii

Acronyms

and

Abbreviations

..................................................................................................ix

Summary ............................................................................................................................... S-1

1 Introduction ....................................................................................................................... 1

2 Characterization

of New York State’s Oil and Natural Gas Sector

.................................... 3

2.1 Oil and Gas Wells in New York State ............................................................................................ 3

2.2 New York State Oil and Natural Gas Production ........................................................................... 5

2.3 New York State Oil and Natural Gas Infrastructure ....................................................................... 9

3

Methane

Emissions

Inventory

Development

....................................................................11

3.1

Methane

Emissions

Literature

Review

......................................................................................... 11

3.1.1 Overview ............................................................................................................................. 11

3.1.2

Key

Terminology .................................................................................................................. 12

3.1.2.1 Oil and Natural Gas Supply Chain ...................................................................................... 12

3.1.2.2 Upstream Stages ................................................................................................................. 12

3.1.2.3 Midstream Stages................................................................................................................ 12

3.1.2.4 Downstream Stage .............................................................................................................. 13

3.1.2.5 Emission Source Categories ............................................................................................... 15

3.1.2.6 Bottom-Up versus Top-Down Methodologies ...................................................................... 15

3.1.3

Review of Existing Methane Inventory Approaches for Oil and

Natural Gas Systems ............ 16

3.1.3.1 EPA’s Greenhouse Gas Reporting Program Subpart W ..................................................... 16

3.1.3.2 EPA’s Facility-Level Information on Greenhouse Gas Tool ................................................ 18

3.1.3.3 EPA’s Greenhouse Gas Emissions Inventory ..................................................................... 18

3.1.3.4 Environmental Defense Fund’s 16 Study Series ................................................................. 19

3.1.3.5 European Union’s Greenhouse Gas Inventory ................................................................... 25

3.1.4

Emission

Factors, Spatial Variability, and High-Emitting Sources ....................................... 29

3.1.4.1 Emission Factors ................................................................................................................. 29

3.1.4.2 Spatial Variability ................................................................................................................. 31

v

3.1.4.3 Comparison across Historical Methane Loss Rates ............................................................ 31

3.1.4.4 High-Emitting Sources ......................................................................................................... 32

3.1.5 Conclusion ........................................................................................................................... 34

3.2 Methods and Data ....................................................................................................................... 35

3.2.1 Overview ............................................................................................................................. 35

3.2.2 Summary of Best Practices ................................................................................................. 36

3.2.3

Emissions

Factor

Confidence

................................................................................................ 38

3.2.3.1 Geography .......................................................................................................................... 39

3.2.3.2 Recency .............................................................................................................................. 39

3.2.3.3 Study Methodology ............................................................................................................. 39

3.2.3.4 Publication Status ................................................................................................................ 40

3.2.3.5 Summary Table ................................................................................................................... 40

3.2.4

Activity Data

Summary

.......................................................................................................... 46

3.2.5

Upstream

Stages ................................................................................................................. 49

3.2.5.1 Drill Rigs .............................................................................................................................. 49

3.2.5.2 Fugitive Drilling Emissions .................................................................................................. 51

3.2.5.3 Mud Degassing ................................................................................................................... 53

3.2.5.4 Well Completion .................................................................................................................. 56

3.2.5.5 Conventional Production ..................................................................................................... 58

3.2.5.6 Abandoned Wells ................................................................................................................ 60

3.2.6

Midstream

Stages ................................................................................................................ 63

3.2.6.1 Gathering Compressor Stations .......................................................................................... 63

3.2.6.2 Gathering Pipeline ............................................................................................................... 65

3.2.6.3 Truck Loading...................................................................................................................... 68

3.2.6.4 Gas Processing Plants ........................................................................................................ 71

3.2.6.5 Gas Transmission Pipelines ................................................................................................ 72

3.2.6.6 Gas Transmission Compressor Stations ............................................................................. 75

3.2.6.7 Gas Storage Compressor Stations ...................................................................................... 76

3.2.6.8 Storage Reservoir Fugitives ................................................................................................ 79

3.2.6.9 Liquified Natural Gas Storage Compressor Stations ........................................................... 79

3.2.6.10 LNG Terminal .................................................................................................................... 81

3.2.7

Downstream

Stages ............................................................................................................. 81

3.2.7.1 Distribution Pipelines ........................................................................................................... 81

3.2.7.2 Service Meters .................................................................................................................... 84

3.2.7.3 Residential Appliances ........................................................................................................ 86

vi

3.2.7.4 Residential Buildings ........................................................................................................... 91

3.2.7.5 Commercial Buildings .......................................................................................................... 93

4 Results ..............................................................................................................................96

4.1 Inventory Updates ....................................................................................................................... 96

4.2 Emissions Time Series ................................................................................................................ 97

4.3 Total Emissions ......................................................................................................................... 101

4.4 Emissions in Year 2020 by Upstream, Midstream, and Downstream Stages .......................... 101

4.5 Emissions by Equipment Source Category in Year 2020 ......................................................... 104

4.6

Emissions by

County and

Economic Region in

Year

2020

.......................................................... 113

4.7 Summary

of

Source

Category

Comparison:

1990–2020

............................................................. 123

4.8

Emissions

Inventory

Validation

................................................................................................... 125

4.8.1 Comparison to the 2020 EPA GHG Inventory ................................................................... 125

4.8.2

Comparison

to Environmental Protection Agency’s Greenhouse Gas Reporting

Program Values ................................................................................................................................. 126

4.8.3 Comparison to Other State Inventories ............................................................................. 126

4.8.4 Comparison to Top-Down and Bottom-Up Studies ........................................................... 128

4.9 Uncertainty ................................................................................................................................ 129

4.9.1 Emission Inventory Uncertainty ......................................................................................... 130

4.10

Comparing

AR4

and

AR5

Emission

Estimates

............................................................................ 132

5 Future Improvements .................................................................................................... 134

6 Conclusions ................................................................................................................... 135

7 References ..................................................................................................................... 138

8 Glossary ......................................................................................................................... 149

Appendix A. Inventory Improvement

...................................................................................... A-1

Appendix

B.

Details

of

EPA

Subpart W

Methodology

........................................................... B-1

Appendix C. Supporting Tables from Literature

Review ........................................................ C-1

Endnotes ............................................................................................................................ EN-1

vii

List of Figures

Figure 1. Number of Open Hole and Plugged Wells in New York State in 2020 ......................... 3

Figure 2. Number of Oil and Natural Gas Wells Completed per Year in New York State ............ 4

Figure 3. Age Distribution of Gas Wells Producing in 2020 ........................................................ 5

Figure 4. Oil and Natural Gas Production in New York State ...................................................... 6

Figure 5. Relationship between Percent of Total Cumulative Oil and Natural Gas

Production in 2020 and the Number of Wells in New York State..................................... 7

Figure 6. Oil and Natural Gas Well Locations and Production in New York State in 2020 .......... 8

Figure 7. Locations of Oil and Natural Gas Wells, Natural Gas Processing Plants,

Natural Gas Pipelines, Natural Gas Underground Storage, and Shale Plays

in New York State and Surrounding States ..................................................................... 9

Figure 8. New York State Gas Utility Service Territories ...........................................................10

Figure 9. Oil and Natural Gas System Depicting the Upstream, Midstream, and

Downstream Grouping of Stages ...................................................................................14

Figure 10. Decision Tree for Determining Natural Gas System Fugitive CH

4

Emissions

Estimation Methodology ................................................................................................27

Figure 11. Decision Tree for Determining Oil System Fugitive CH

4

Emissions

Estimation Methodology ................................................................................................28

Figure 12. Total CH

4

Emissions in New York State from 1990–2020 (AR5 GWP

20

) ..................98

Figure 13. Upstream CH

4

Emissions in New York State from 1990–2017 (AR4 GWP

100

) ..........99

Figure 14. Midstream CH

4

Emissions in New York State from 1990–2020 (AR5 GWP

20

) ........ 100

Figure 15. Downstream CH

4

Emissions in New York State from 1990–2020 (AR5 GWP

20

)..... 101

Figure 16. Downstream, Midstream, and Upstream CH

4

Emissions in 2020 as

Percentages of Total Emissions .................................................................................. 102

Figure 17. CH

4

Emissions by Source Category and Grouped by Upstream, Midstream,

and Downstream Stages in New York State in 2020 (AR5 GWP

20

) ............................. 103

Figure 18. Percentage of CH

4

Emissions in the Top Five Emitting Source Categories ............ 104

Figure 19. Map of CH

4

Emissions by County in New York State in 2020 (AR5 GWP

20

) ........... 113

Figure 20. CH

4

Emissions by County in New York State in 2020 (AR5 GWP

20

)....................... 114

Figure 21. New York State Economic Regions as Identified by Empire State Development .... 121

Figure 22. CH

4

Emissions by Economic Region in New York State in 2020 (AR5 GWP

20

) ...... 122

Figure 23. Comparison of Source Category CH

4

Emissions from 1990 and 2020 in

New York State, Using AR5 GWP

20

Conversion Factors for CH

4

................................. 124

Figure 24. Reproduction of Figure ES-11 from (EPA 2022), Showing Time Series

Trends in Emissions from Energy and Other Sectors .................................................. 125

Figure 25. Total Emissions Including Best Estimate and Upper and Lower

Bounds (AR5 GWP

20

) .................................................................................................. 131

Figure 26. Upstream Emissions Including Upper and Lower Bounds (AR5 GWP

20

) ................ 131

Figure 27. Midstream Emissions Including Upper and Lower Bounds (AR5 GWP

20

) ............... 131

Figure 28. Downstream Emissions Including Upper and Lower Bounds (AR5 GWP

20

) ............ 132

viii

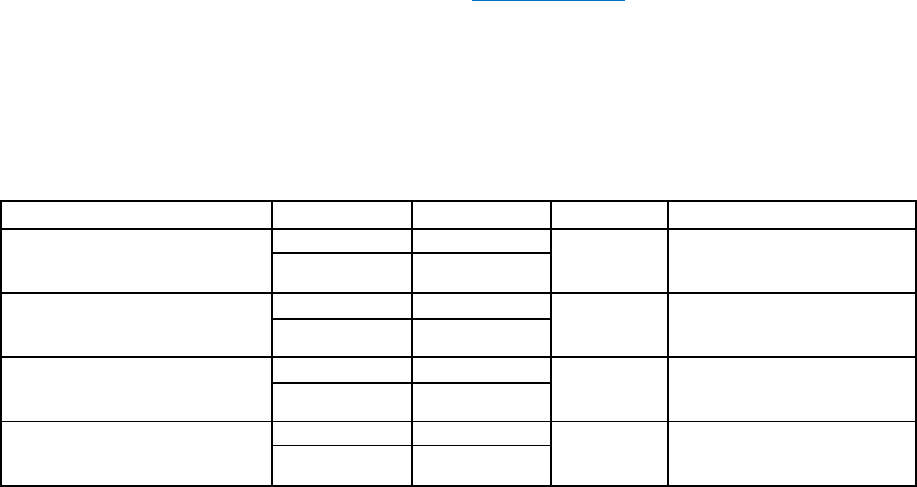

List of Tables

Table 1. List of Studies Included in Environmental Defense Fund’s 16 Study Series (2018) .....21

Table 2. Information on EFs (as a percentage loss) for Upstream, Downstream,

and Total Based on Data in Howarth (2014) ..................................................................30

Table 3. Example Cases of High-Emitting Sources from the Literature, Demonstrating

the Disproportionate Level of Emissions Coming from a Small Subset of the

Natural Gas Production Supply Chain ...........................................................................33

Table 4. Sources of CH

4

Emissions Included in the Improved New York State Inventory ..........36

Table 5. Summary of Best Practice Recommendations, Implementation of Best Practices,

and Areas for Future Inventory Improvements ...............................................................37

Table 6. Emission Factor Confidence Assessment for Emission Factors Used in the

Improved New York State Inventory ..............................................................................41

Table 7. Activity Data Summary for Activity Data Used in the Improved New York

State Inventory ..............................................................................................................46

Table 8. Number of Natural Gas Appliances in the Mid-Atlantic Region by Appliance Type ......88

Table 9. Fraction of Housing Units with Appliance Type by Appliance ......................................89

Table 10. Fraction of Units in Each Climate Zone by Housing Unit Type ...................................89

Table 11. Correction Factor to Account for Counties without Natural Gas Service ....................90

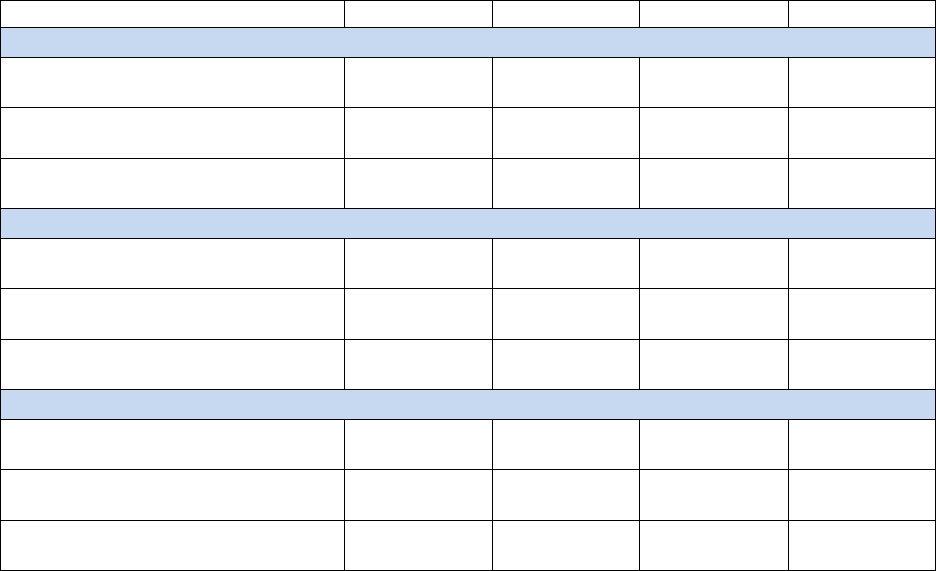

Table 12. Comparison of Emissions Across Key Inventory Years with AR4 and

AR5 GWP

100

and GWP

20

Values Applied from the Three Inventories ............................97

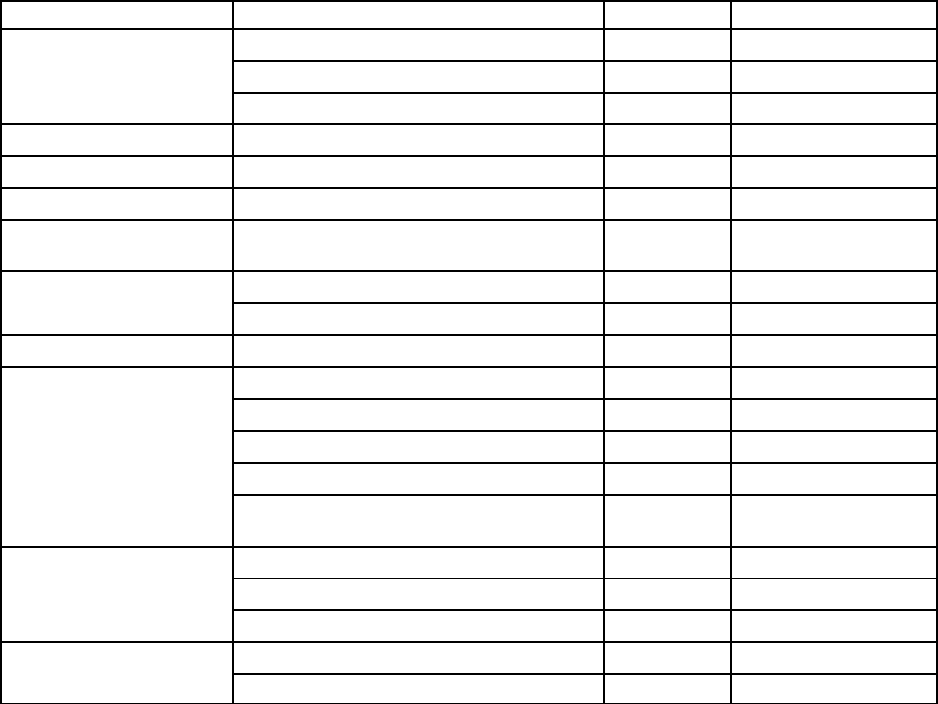

Table 13. CH

4

Emissions by Source Category in New York State from 1990–2000

(MTCO

2

e; AR5 GWP

20

) ............................................................................................... 105

Table 14. CH

4

Emissions by Source Category in New York State from 2001–2011

(MTCO

2

e; AR5 GWP

20

) ............................................................................................... 108

Table 15. CH

4

Emissions by Source Category in New York State from 2012–2020

(MTCO

2

e; AR5 GWP

20

) ............................................................................................... 111

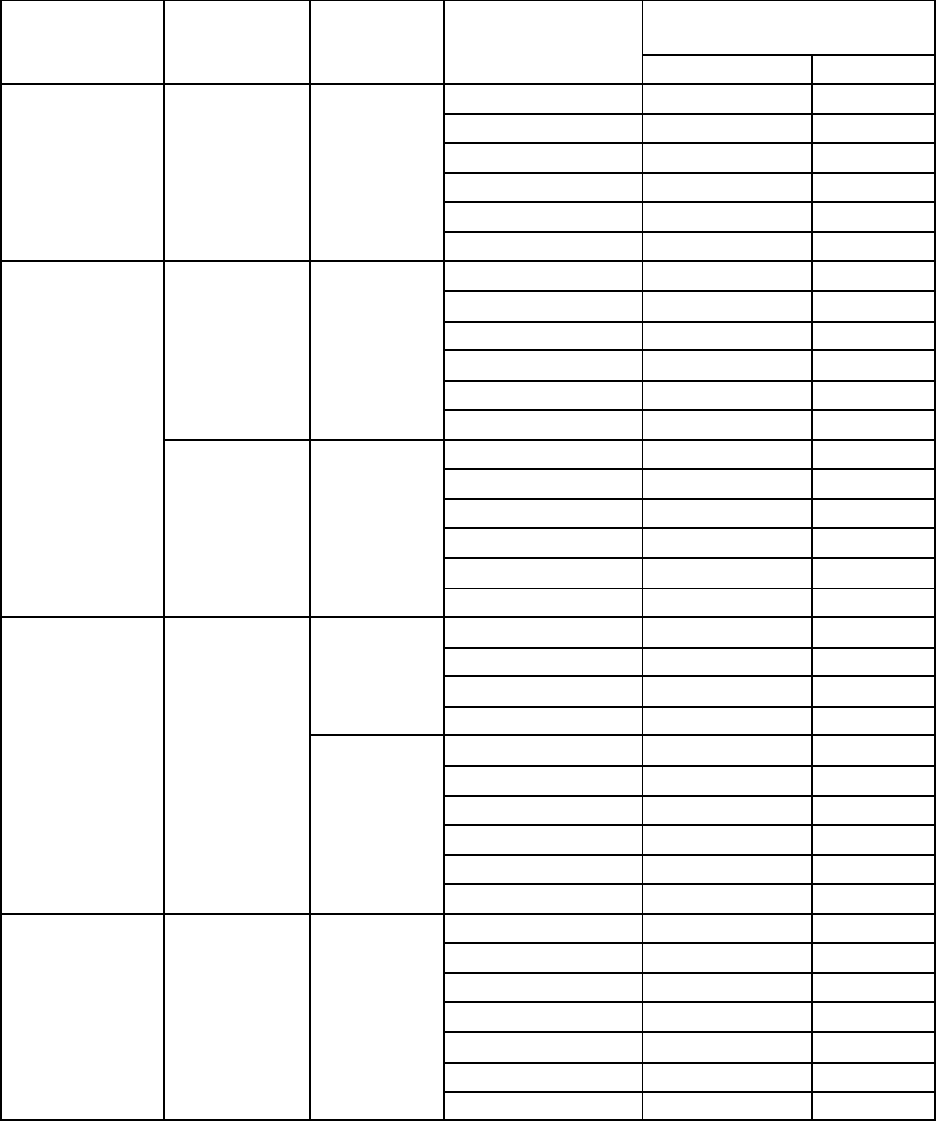

Table 16. CH

4

Emissions by County in New York State from 1990–2000

(MTCO

2

e; AR5 GWP

20

) ............................................................................................... 115

Table 17. CH

4

Emissions by County in New York State from 2001–2010

(MTCO

2

e, AR5 GWP

20

) ............................................................................................... 117

Table 18. CH

4

Emissions by County in New York State from 2011–2020

(MTCO

2

e, AR5 GWP

20

) ............................................................................................... 119

Table 19. CH

4

Emissions by Economic Region in New York State in 2020 .............................. 122

Table 20. Comparison of This Inventory to the Most Recent Year of Adjacent

State Inventories ......................................................................................................... 128

Table 21. Comparison of AR4 and AR5 GWP

100

and GWP

20

Values Applied to

the 2020 Oil and Gas Systems CH

4

Emissions in New York State (MMTCO

2

e) ........... 133

Table 22. Summary of Best Practice Recommendations, Implementation of Best

Practices and Areas for Future Inventory Improvements ............................................. 135

ix

Acronyms

and

Abbreviations

AR4 Fourth Assessment Report of the IPCC (2007)

AR5 Fifth Assessment Report of the IPCC (2014)

bbl barrels. 1 oil barrel = 42 U.S. gallons

Bcf billion cubic feet

BHFS Bacharach Hi Flow® Sampler

BOE barrels of oil equivalent

BOEM Bureau of Ocean Energy Management

Bscf billion standard cubic feet

Btu British thermal unit

BU bottom-up

CAP criteria air pollutants

CBM coal-bed methane

CenSARA Central States Air Resource Agencies

cf cubic feet

CFR Code of Federal Regulation

CH

4

methane

CI confidence interval

CO

2

carbon dioxide

CO

2

e carbon dioxide equivalent

CS compressor station

D-J Denver-Julesburg

EDF Environmental Defense Fund

EF emissions factor

EIA Energy Information Administration

EPA United States Environmental Protection Agency

ESOGIS Empire State Organized Geologic Information System

EU European Union

EU Inventory Annual European Union Greenhouse Gas Inventory 1990-2016 and

Inventory Report 2018

FLIGHT Facility Level Information on GreenHouse gases Tool

g gram

Gg gigagram

GHG greenhouse gas

GHGRP Greenhouse Gas Reporting Program

x

GRI Gas Research Institute

GWP global warming potential

GWP

20

global warming potential (20 year)

GWP

100

global warming potential (100 year)

H

2

S hydrogen sulfide

HAP hazardous air pollutants

hp horsepower

hr hour

HVHF high-volume hydraulic fracturing

IPCC Intergovernmental Panel on Climate Change

ITRC Interstate Technology and Regulatory Council

Kg kilogram

lb pound

LAUF lost and unaccounted for

LNG liquefied natural gas

Mcf thousand cubic feet

Mg megagram

MMBTU million British thermal unit

MMcf million cubic feet

MMT million metric ton (1 MMT = 1 teragram)

M&R metering and regulating

MT metric ton

NAICS North American Industry Classification System

N

2

O nitrous oxide

NG natural gas

NEI National Emissions Inventory

NSPS New Source Performance Standards

NYS New York State

DEC New York State Department of Environmental Conservation

Oil and Gas Tool Nonpoint Oil and Gas Emission Estimation Tool

PAC Project Advisory Committee

PHMSA Pipeline and Hazardous Materials Safety Administration

psi pounds per square inch

psig pounds per square inch gauge

xi

SCC Source Classification Code

scf standard cubic foot

scfd standard cubic feet per day

SCFM standard cubic foot per minute (1 SCFM = 19.2 gCH

4

.min

-1

)

SEDS State Energy Data System

SIT State Inventory Tool

SNCR selective non-catalytic reduction

TD top-down

UNFCCC United Nations Framework Convention on Climate Change

VOC volatile organic compound

S-1

Summary

Methane (CH

4

) is a greenhouse gas that is second only to carbon dioxide (CO

2

) in its contribution to

global climate change. Driven by human activity, CH

4

emissions are increasing in the atmosphere.

CH

4

is particularly problematic because its impact on climate change is 84 times greater than CO

2

over a 20-year period, according to the Fifth Assessment Report (AR

5

) of the Intergovernmental

Panel on Climate Change (IPCC). Fossil fuel production and consumption, including the extraction

and processing of natural gas and the distribution of natural gas to homes and businesses, is a

significant source of anthropogenic CH

4

emissions.

In 2019, New York State passed the Climate Leadership and Community Protection Act (the Climate

Act). The Climate Act is among the most ambitious climate laws in the world and requires the State to

reduce economy-wide greenhouse gas emissions 40% by 2030 and no less than 85% by 2050 from 1990

levels. The goal of this project is to support CH

4

emission reduction efforts in New York State, as well

as achievement of the Climate Act goals, by improving the State’s understanding of CH

4

emissions

and CH

4

emission-accounting methodologies for the oil and natural gas sector. The use of improved

accounting methodologies to develop an activity-driven, site-level, CH

4

emissions inventory for upstream,

midstream, and downstream sources is needed to inform mitigation strategies and measure progress on

fugitive CH

4

emissions reductions from the oil and natural gas sector as the State moves toward its

ambitious climate goals.

The inventory developed under this project occurred in two phases. The project’s first phase incorporated

findings from empirical research and utilized the most accurate, current, and inventory-appropriate

available data sources at the time. The application of state-of-the-art practices and emissions factors (EFs)

represented a significant methodological advancement over other available tools, since those tools are

often based on out-of-date EFs that do not reflect the modern oil and natural gas sector. By applying

established best practices based on a thorough review of the literature and expert consultation, the

inventory established a rigorous and robust CH

4

emissions baseline in New York State. The development

of this inventory focused on the following best practices: (1) the use of appropriately scaled activity data,

(2) inclusion of state-of-the-science emission factors (EFs), (3) geospatial resolution of activities and

emissions, and (4) application and reporting of uncertainty factors, including high-emitting sources. The

original phase of this project sought to update the New York State Greenhouse Gas Inventory 1990–2015

and implement these best practices to improve and develop an activity-driven, geospatially-resolved,

CH

4

emissions inventory for the oil and natural gas sector. To ensure project rigor, a six-member Project

S-2

Advisory Committee (PAC) comprised of experts with knowledge on air pollutant emissions from the

oil and natural gas sector was established to provide technical oversight and peer review throughout the

duration of the first phase of this project. The original report for the initial phase was published in 2019

and included data years 1990–2017.

Following the best practices established during the first phase of the project, the second phase focused on

updating activity data and emissions factors to the latest found in the literature and extending the latest

year to 2020. During the second phase, additional source categories were also added to the inventory to

begin addressing identified gaps in the inventory. These inventory results provide important resources for

supporting rulemaking and regulations to reduce CH

4

emissions from the oil and natural gas sector. This

inventory lays the foundation for a geospatially refined inventory that can capture the impacts of future

mitigation strategies for CH

4

emissions from the oil and natural gas sector as well as the impacts of

current regulations, such as EPA’s proposed changes to the 2016 New Source Performance Standards for

the oil and gas industry or EPA’s 2022 Inflation Reduction Act. In addition, the inventory provides New

York State with the flexibility to revise the current inventory, or generate future inventories, by updating

activity data and EFs as improved data become available and as future advancements in the industry lead

to technological changes.

The current report represents the second phase of this project, where updates were made to the

new inventory to bring the data through the year 2020 and make improvements to emissions factors

and additional sources based on more recent data information and scientific studies. In addition, the

Climate Act requires the State to report emissions in CO

2

equivalents (CO

2

e) using the most recent

IPCC Assessment Report (AR5) 20-year global warming potential (20-year GWP, GWP

20

) rather

than AR4 100-year global warming potential (GWP

100

) values, which are typically used in national

and state inventories and was used in the first phase of the project. Using GWP

20

further emphasizes

the contribution of methane to global climate change.

Table S-1 below compares emissions from key inventory years from the first New York State

Greenhouse Gas Inventory (1990–2015) to the first iteration of the New York State Oil and Gas Sector

Methane Emissions Inventory (1990–2017) and the second iteration of the New York State Oil and Gas

Sector Methane Emissions Inventory (1990–2020). In the first iteration of the project, CH

4

emissions

in 2015 totaled 112,870 metric tons (MT) CH

4

or approximately 2.82 million metric tons (MMT) CO

2

e

(AR4 GWP

100

). Results of the first iteration estimated CH

4

emissions to be 27% higher than previous

estimates of CH

4

emissions from natural gas systems (2.22 MMT CO

2

e, AR4, GWP

100

in 2015), based

S-3

on prior inventories developed by the State and using 2015 as the most recent common year. In the first

iteration of the NYS Oil and Gas Methane Emissions Inventory 2017 emissions totaled 2.66 MMTCO

2

e

(AR4 GWP

100

), or 8.951 MMTCO

2

e (AR5 GWP

20

). The second iteration of the inventory estimates

emissions to total 14.7 MMTCO

2

e (AR5 GWP

20

) in 2017. Thus, the improvements made to the inventory

between the first and second iteration resulted in an emissions increase of 64%. The increase is due to

the addition of beyond-the-meter sources and updates to distribution emission factors and conventional

production emission factors. The current, second iteration of the inventory estimates emissions to be

approximately 113.5% higher than estimates from the original, 2015 inventory, when estimates from

the 2015 inventory are converted to AR5 GWP

20

and using 2015 as the most recent common year.

Table S-1. Comparison of Emissions Across Key Inventory Years with AR4 and AR5 GWP

100

and

GWP

20

Values Applied from the Three Inventories

Inventory

AR4 GWP

100

AR4 GWP

20

AR5 GWP

100

AR5 GWP

20

1990

New York State Greenhouse Gas

Inventory, 1990–2015

2.8 8.06 3.14 9.41

New York State Oil and Gas Methane

Emissions Inventory, 1990–2017

2.74 7.88 3.07 9.21

New York State Oil and Gas Methane

Emissions Inventory, 1990–2020

5.17 14.89 5.80 17.40

2005

New York State Greenhouse Gas

Inventory, 1990–2015

3.5 10.07 3.93

11.76

New York State Oil and Gas Methane

Emissions Inventory, 1990–2017

3.52 10.12 3.95

11.83

New York State Oil and Gas Methane

Emissions Inventory, 1990–2020

6.15 17.72 6.93

20.73

2015

New York State Greenhouse Gas

Inventory, 1990–2015

2.22

6.39

2.49

7.46

New York State Oil and Gas Methane

Emissions Inventory, 1990– 2017

2.82 8.12 3.16 9.48

New York State Oil and Gas Methane

Emissions Inventory, 1990– 2020

4.74 13.65 5.31

15.92

S-4

CH

4

emissions from oil and natural gas activity in New York State in 2020 totaled 167,915 metric tons

MTCH

4

, equivalent to 14.1 MMTCO

2

e (AR5 GWP

20

). Figure S-1 shows CH

4

emissions by source

category broken out by upstream, midstream, and downstream source categories using AR5 GWP

20

units. Downstream emissions totaled 5.165 MMTCO

2

e in 2020, accounting for 36.6% of total CH

4

emissions. Cast iron steel mains are the largest single-source category, followed by unprotected steel

mains and services and residential buildings. Midstream emissions totaled 6.067 MMTCO

2

e, accounting

for 43% of emissions, with compressors (storage and transmission) comprising the largest source

categories in the inventory. In fact, storage and transmission compressor stations are two of the largest

single-source categories identified in New York State. Upstream sources, dominated by conventional

gas wells, emitted 2.873 MMTCO

2

e, accounting for 20.4% of total CH

4

emissions. These results reflect

the fact that the State is largely a consumer of natural gas and, as such, the midstream and downstream

source categories drive the majority of CH

4

emissions.

S-5

Figure S-1. CH

4

Emissions by Source Category and Grouped by Upstream, Midstream, and Downstream Stages in New York

State in 2020

S-6

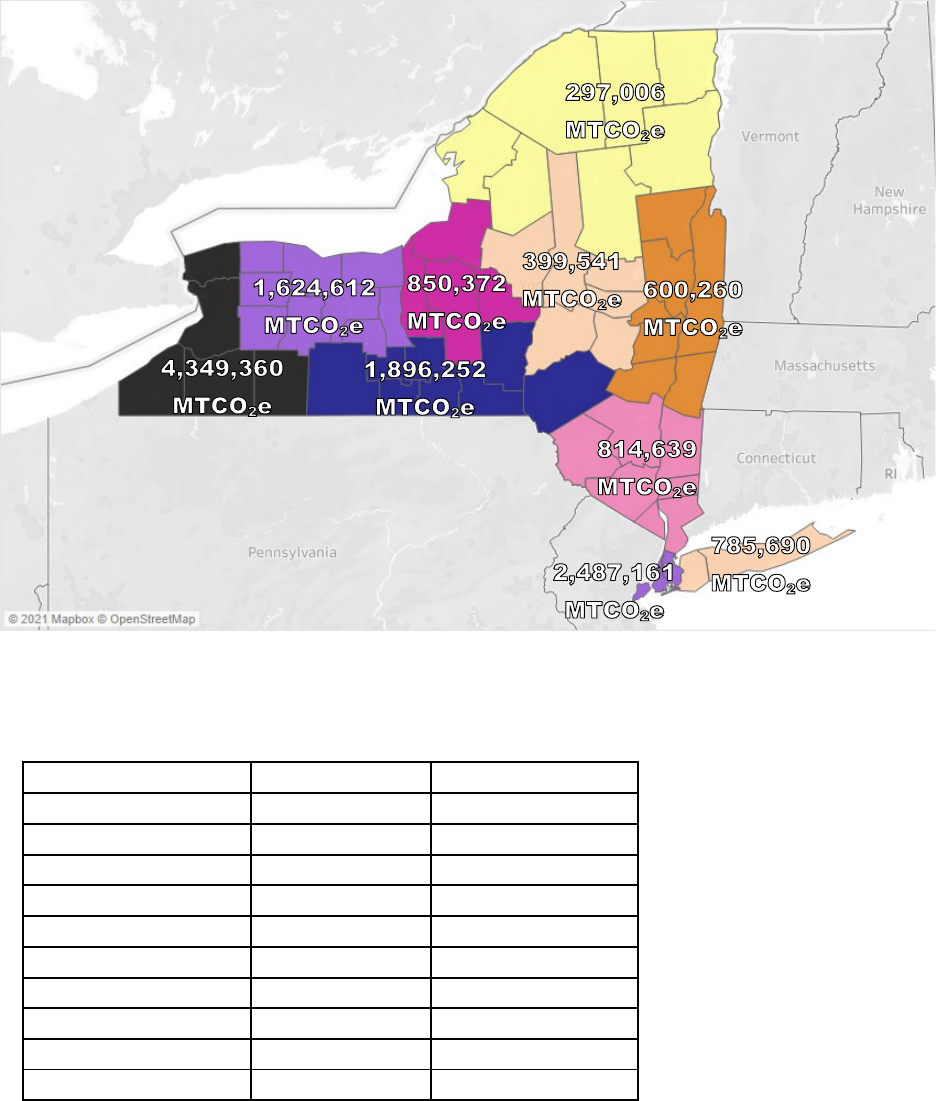

Figure S-2 shows the distribution of emissions by county. The counties with the largest emissions

correspond to the high oil and natural gas exploration and production areas in Western New York

and to areas of high population, gas services, and consumption around New York City and Long Island.

Downstream emissions in counties that correspond to New York City and Long Island (New York, Kings,

Bronx, Richmond, Queens, Nassau, and Suffolk) total 2.82 MMTCO

2

e, which is approximately 54.5% of

total downstream emissions. As shown in Figure S-2, Erie County had the highest total CH

4

emissions

in 2020, accounting for 11% of statewide CH

4

emissions from the oil and natural gas sector, followed

by Chautauqua (10%). Erie County had the second-highest conventional gas production from high

producing wells in New York State, as well as the largest miles of transmission pipeline (378 miles)

and second-highest number of compressor stations (five gas transmission compressor stations and six

gas storage compressor stations), resulting in high-midstream emissions. Chautauqua County ranked

highest in gathering and processing and in conventional gas production resulting in high upstream and

midstream emissions. The top five counties (Erie, Chautauqua, Steuben, Kings, and Queens) accounted

for 40.6% of statewide CH

4

emissions in 2020.

Figure S-2. Map of CH

4

Emissions by County in New York State in 2020 (AR5 GWP

20

)

S-7

Figure S-3 shows that total CH

4

emissions in New York State from 1990–2020 followed a generally

increasing trend from 1990 until peaking at 20.725 MMTCO

2

e in 2005. Since 2005 CH

4

emissions

have decreased each year with the exception of a small increase in 2019. Total CH

4

emissions

decreased 31.9% since their peak in 2005.

Figure S-3. Total CH

4

Emissions in New York State from 1990–2020 (AR5 GWP

20

)

Upstream CH

4

emissions (Figure S-4), though smaller in magnitude than midstream and downstream

emissions, have shown greater variation over time, more closely mirroring the cyclical nature of oil and

gas exploration and well completions in the State. Upstream CH

4

emissions peaked at 7.431 MMTCO

2

e

in 2007, corresponding with the observed peak in natural gas prices and production and well completions.

Since 2007, well completions have fallen to near zero and natural gas production is around one-fifth

of the peak production, resulting in an overall decline in emissions associated with upstream source

categories. Overall upstream emissions decreased 22.4% from 1990–2020, and by 61.3% from

2007–2020.

S-8

Figure S-4. Upstream CH

4

Emissions in New York State (AR5 GWP

20

)

Midstream CH

4

emissions (Figure S-5) increased from 1990–2020 by 15.4%. Midstream emissions are

largely a function of transmission and storage compressor stations and transmission pipelines. New York

State Department of Environmental Conservation (DEC) data, used to verify compressor station counts in

this inventory, show increasing compressor counts and transmission pipeline miles, resulting in increasing

midstream CH

4

emissions. Although natural gas production in New York State has declined since 2006,

natural gas consumption in the State has risen by 17%, from 1,080 Bcf in 2005 to 1,264 Bcf in 2020.

Correspondingly, midstream emissions peaked in 2008 from the addition of transmission compressor

stations and transmission pipelines but have declined by 6.1% since then as a result of declining natural

gas production and subsequent natural gas gathering in the State.

S-9

Figure S-5. Midstream CH

4

Emissions in New York State (AR5 GWP

20

)

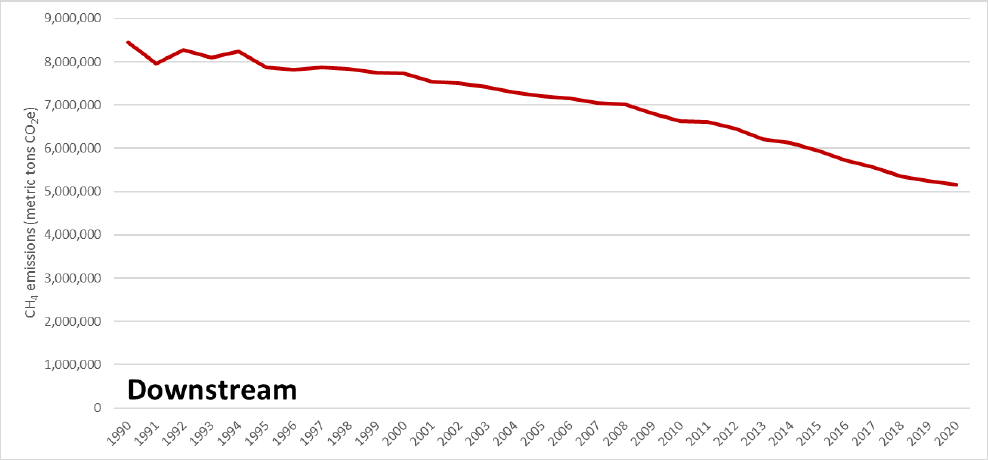

Downstream CH

4

emissions (Figure S-6) decreased by 38.8% from 1990–2020. The two largest source

categories in downstream emissions, cast-iron and unprotected steel distribution main pipelines, have

both decreased since 1990, since they have largely been replaced with plastic distribution mains. Plastic

mains have much lower leak rates and therefore a lower emissions factor, resulting in the downward

trend observed in Figure S-6. Though increasing consumption in New York State has driven increases

in the number of residential services and meters, any increase in emissions from these components is

outweighed by the transition from cast-iron and unprotected steel distribution lines to plastic.

S-10

Figure S-6. Downstream CH

4

Emissions in New York State (AR5 GWP

20

)

The identified activity patterns correspond to national trends in CH

4

emissions. To validate this

emission inventory, comparisons were made with EPA’s nationwide inventory and with adjacent

state inventories. Comparison to the national inventory shows New York State CH

4

emissions to

be equivalent to 6.87% of the total national oil and natural gas inventory. Comparison with inventories

from adjacent states shows New York State oil and gas emissions to be approximately one-third of

emissions from the same source categories in Pennsylvania, which has much higher upstream

production and similar downstream consumption.

1

1 Introduction

In 2019, New York State passed the Climate Leadership and Community Protection Act (the Climate

Act). The Climate Act is among the most ambitious climate laws in the world and requires the State to

reduce economy-wide greenhouse gas (GHG) emissions 40% by 2030 and no less than 85% by 2050

from 1990 levels. The goal of this project is to support CH

4

emission reduction efforts in New York

State (NYS), and achievement of the Climate Act goals, by improving the State’s understanding of CH

4

emissions and CH

4

emissions-accounting methodologies for the oil and natural gas sector. The use of

improved accounting methodologies to develop an activity-driven, site-level, CH

4

emissions inventory

for upstream, midstream, and downstream sources is needed to inform mitigation strategies and measure

progress on fugitive CH

4

emission reductions from the oil and natural gas sector as the State moves

toward its ambitious climate goals. Consequently, the inventory developed under this project incorporates

findings from the most current empirical research and utilizes the most accurate, current, and inventory-

appropriate available data sources to develop an activity-driven, site-level, CH

4

emissions inventory.

The inventory developed under this project occurred in two phases. The project’s original phase sought

to update the New York State Greenhouse Gas (NYS GHG) Inventory 1990–2015 and implement the

following best practices to improve and develop an activity-driven, geospatially-resolved, CH

4

emissions

inventory for the oil and natural gas sector: (1) the use of appropriately scaled activity data, (2) inclusion

of state-of-the-science emission factors (EFs), (3) geospatial resolution of activities and emissions, and

(4) application and reporting of uncertainty factors, including high-emitting sources. To ensure project

rigor, a six-member Project Advisory Committee (PAC) comprised of experts with knowledge on air

pollutant emissions from the oil and natural gas sector was established to provide technical oversight and

peer review throughout the duration of the first phase of this project. The report for the initial phase was

published in 2019 and included data years 1990–2017. The current report represents the second phase of

this project, where updates were made to the new inventory to bring the data up to date through 2020 and

make improvements to emissions factors and additional sources.

Specific objectives of first phase of this project, completed in 2019, included (1) assessing the

State’s previous oil and natural gas sector CH

4

emissions inventory (NYSERDA and DEC 2018),

(2) performing a literature review of CH

4

emission-accounting methodologies and associated analyses

and studies, (3) developing an improved CH

4

emission-accounting methodology, and (4) implementing

the methodology to create an improved CH

4

emissions inventory for the oil and natural gas sector in

the State.

2

For Phase 2, further updates were made after the initial assessment and development of the NYS oil

and gas methane inventory. In addition to bringing the activity data up to date through 2020, additional

objectives during the second phase of the project included (1) assessing NYS’s 2017 oil and natural gas

sector CH

4

emissions inventory for areas of improvement, (2) performing a literature review of latest

data on fugitive oil and gas methane emissions in NYS, and (3) incorporating the latest data to create

an updated CH

4

emissions inventory for the oil and natural gas sector in NYS through 2020.

3

2 Characterization of New York State’s Oil and

Natural Gas Sector

The following section begins with a characterization of oil and gas wells, then moves into a discussion

of oil and gas production and concludes with an overview of associated oil and gas infrastructure.

2.1 Oil and Gas Wells in New York State

In 2020, New York State had 8,019 unplugged natural gas wells and 6,311 unplugged oil wells

(DEC 2021). In addition, the State had 9,637 plugged oil wells, 4,264 plugged gas wells (Figure 1),

825 unplugged storage wells, and 130 plugged storage wells. (Plugged wells are wells that are no

longer in use and the borehole has been plugged with cement or another impermeable substance to

isolate and prevent the underlying hydrocarbon formation from contaminating the environment.)

Figure 1. Number of Open Hole and Plugged Wells in New York State in 2020

Source: New York State Department of Environmental Conservation (DEC) downloadable well data.

4

Gas well development in New York State increased significantly in the 1970s, reaching a peak in

1982 when 611 wells were drilled and put into production, followed by a decline in activity until

the mid-2000s. There was a secondary spike in installations from 2006–2008 (Figure 2). After 2008,

natural gas well completions fell to fewer than 10 per year. High-volume hydraulic fracturing (HVHF),

or fracking, was banned in the State in 2014. Oil well completions also followed a cyclical pattern, with

increased activity from 1973–1985 and again from 2006–2014. Oil well completion activity follows oil

and natural gas price patterns, with higher activity during periods of high-fuel prices, and lower activity

during periods of low-fuel prices. The deregulation of oil and natural gas markets also played a role in

increasing production and consumption of natural gas while reducing prices.

Figure 2. Number of Oil and Natural Gas Wells Completed per Year in New York State

The age distribution of natural gas wells producing in New York State in 2020 (Figure 3) followed

a similar bimodal pattern to that seen in Figure 2. Well count data for 2020 show a primary peak of

wells aged around 12 and 13 years old, and a secondary peak of wells aged between 37 and 38 years

old. Comparing Figure 2 and Figure 3, age and completions follow a similar bimodal pattern, with peaks

in age corresponding to peaks in completions, indicating that older wells can remain in production for a

long time. Well age data showed that, although there were far more completions in the 1970s and 1980s,

14.7% of currently operational wells were completed in the last 15 years, with 88.4% of wells under

45 years old.

5

Figure 3. Age Distribution of Gas Wells Producing in 2020

2.2 New York State Oil and Natural Gas Production

Natural gas production far outweighs oil production in New York State as shown in Figure 4. Natural

gas production peaked at 55.34 billion cubic feet (Bcf) or 9.78 million barrels of oil equivalent (BOE) in

2006 (1 BOE = 5.65853 thousand cubic feet, Mcf), while oil production peaked at 386,192 barrels (bbl) in

2008. Natural gas production declined from 55.34 Bcf in 2006 to 10.70 Bcf, or 1.89 million BOE in 2020.

Oil production has also declined in the State from the 2008 peak to 146,861 bbl in 2020. Since there are

no in-state oil refineries, all the oil produced is refined out of State, primarily in Pennsylvania

(DEC 2006).

As shown in Figure 5, 157 out of 7,495 wells (2.09%) accounted for 50% of natural gas production in

New York State in 2020, 17.95% of the wells accounted for 75% of natural gas production, and almost

all (99%) of natural gas production came from 5,172 (69%) of wells. These data demonstrate that a

comparatively small number of wells produce the majority of natural gas, and that production is not

evenly distributed across those wells. Oil wells also showed a similarly skewed distribution, with

411 out of 4,963 (8.2 %) wells accounting for 50% of production, 864 (17.4%) wells accounting

for 75% of production, and 2,350 (47.4%) wells accounting for 99% of production in 2020.

7

Figure 5. Relationship between Percent of Total Cumulative Oil and Natural Gas Production in

2020 and the Number of Wells in New York State

As shown in Figure 6, oil and natural gas production occur largely in Western New York, west of the

line delineating the eastern boundary of Broome, Chenango, Madison, Oneida, and Lewis counties.

Oil production is concentrated in the far west of New York State, in Allegany, Cattaraugus, Chautauqua,

Erie, and Steuben counties.

8

Figure 6. Oil and Natural Gas Well Locations and Production in New York State in 2020

(Oil): *There are no oil producing wells located outside of western New York.

(Natural

Gas)

9

2.3 New York State Oil and Natural Gas Infrastructure

As shown in Figure 7, oil and natural gas activities are concentrated in the western portion of the State.

Western NY has the greatest density of wells and underground natural gas storage facilities. Storage

fields are located in former solution salt caverns and depleted reservoirs. The Energy Information

Administration (EIA) data lists no natural gas processing plants in New York State, with the closest

processing plants located in northwestern Pennsylvania. The greatest density of interstate and intrastate

natural gas transmission pipelines, as identified by EIA, is in Western New York near the production and

storage wells for removal and delivery. Transmission pipelines are well-connected to Pennsylvania and

have linkages to Canada in the west and north. Two main pipeline trunks extend east-west across the

State, with one along the southern Pennsylvania border, connecting to pipelines in the New York City

Metropolitan Area and the other connecting farther north to pipelines in the Albany and Buffalo regions.

Figure 7. Locations of Oil and Natural Gas Wells, Natural Gas Processing Plants, Natural

Gas Pipelines, Natural Gas Underground Storage, and Shale Plays in New York State and

Surrounding States

10

New York State has 17 natural gas utility service territories (Figure 8). These service territories cover

around 94% of the households identified by the United States (U.S.) Census Bureau. According to the

Census, 54% of households inside natural gas utility service areas use natural gas as their primary home

heating source. In addition, EIA data

2

show 422,542 commercial and industrial end users of natural gas

in the State. Based on census data, which show 537,369 registered businesses in 2020 with 96.9% of

businesses within natural gas utility service areas, 81.1% of businesses inside natural gas utility

service areas use natural gas.

Figure 8. New York State Gas Utility Service Territories

11

3

Methane

Emissions

Inventory

Development

3.1

Methane

Emissions

Literature

Review

3.1.1 Overview

The following section provides the results of a literature review, primarily conducted during Phase 1

of the project, aimed at uncovering best practices for CH

4

inventory development and inputs to inform

improvements in the State’s inventory models in the future.

As part of Phase 1, a literature review was conducted that included peer-reviewed articles, reports,

and tools describing state-of-the-art CH

4

inventory development in the United States and internationally,

with a focus on emissions in the oil and natural gas sector. While over 100 documents on oil and natural

gas emissions were carefully reviewed, specific attention was paid to three sources of information:

(1) EPA’s GHGRP (Greenhouse Gas Reporting Program) Subpart W, (2) EPA’s FLIGHT (Facility

Level Information on GreenHouse gases Tool), and (3) the Environmental Defense Fund’s (EDF)

16 Study Series. The European Union’s (EU) most recent inventory report (European Environment

Agency 2018) was also reviewed to explore differences between international and U.S.-centric

inventory methodologies.

The literature review highlights the

rapid advancement of state-of-the-art CH

4

inventory development.

In just the last decade, new data now allow for more geographic-specific inventory development and

greater certainty of emissions, ranging from routine leaks to episodic releases. The literature has also

advanced on identifying the role of high-emitting sources, which have previously been ignored in

conventional CH

4

inventories, but which can play an important part in a region’s overall emission

levels. The literature review was used to inform the first iteration of the New York State Oil and

Gas Methane Emissions Inventory (NYSERDA 2019).

Section 3.1.2 presents key terminology so that readers may better understand subsequent sections.

Section 3.1.3 reviews existing methane inventory approaches for oil and natural gas systems. Section

3.1.4 discusses key findings on emission factors, spatial variability, and high-emitting sources. Section

3.2 provides a review of the methods and data used to develop this inventory including a summary of best

practices, assessment of emissions factor confidence, an activity data summary, and a review of emission

factor development for the upstream stages, midstream stages, and downstream stages.

12

3.1.2

Key

Terminology

3.1.2.1 Oil and Natural Gas Supply Chain

The U.S. oil and natural gas supply chain can be broken into nine main segments. For oil development,

CH

4

emissions occur across the following four stages: (1) exploration, (2) production, (3) gathering and

boosting, and (4) transmission. For natural gas development, CH

4

emissions occur across the following

nine stages: (1) exploration, (2) production, (3) gathering and boosting, (4) processing, (5) transmission,

(6) underground storage, (7) LNG import and export terminals, (8) LNG storage, and (9) distribution,

as shown in Figure 9 (Howarth 2014; Harrison et al. 1997a). These stages are divided into three major

groups: (1) upstream, (2) midstream, and (3) downstream stages.

3.1.2.2 Upstream Stages

• Exploration includes well drilling, testing, and completions. The predominant sources of

emissions from exploration are well completions and testing.

• Production involves taking crude oil or raw natural gas from underground formations, whether

using conventional drilling or unconventional drilling techniques. Sources of emissions during

the oil production stage typically include leaks, pneumatic devises, storage tanks, and flaring

of associated gases. Sources of emissions during the natural gas production stage depend

on the technologies employed for gas extraction, but typically include leaks, pneumatic

controllers, unloading liquids from wells, storage tanks, dehydrators, and compressors.

Many wells co-produce oil and natural gas; therefore, the distinction between oil

production and gas production is not always clear.

• Gathering and boosting stations receive natural gas from production sites/wells and via

gathering pipelines, and then transfer the gas to transmission pipelines and/or processing

facilities and distribution systems. Compression, dehydration, and sweetening (removal

of foul-smelling sulfur containing compounds) occur in this segment. Sources of emissions

in this segment include gathering stations, pneumatic controllers, natural gas engines,

gathering pipelines, liquids unloading, and flaring.

3.1.2.3 Midstream Stages

• Natural gas processing includes the process of removing impurities and other hydrocarbons,

including liquids, from raw natural gas, resulting in pipeline grade natural gas. Emissions from

the processing stage originate from reciprocating and centrifugal compressors, blowdowns,

venting, and leaks.

13

• The transmission and compression stage is the transfer of natural gas from gathering lines and

processing plants to the city gate or to high-volume industrial users through main transmission

lines. Compressor stations located along the pipelines maintain high pressure and move the gas

throughout the system. Sources of emissions in this segment include compressor stations,

venting from pneumatic controllers, uncombusted engine exhaust, unburned and

pipeline venting.

• Underground storage involves injecting natural gas into underground formations during

periods of low demand; and the natural gas is withdrawn, processed, and redistributed during

periods of high demand. Compressors and dehydrators are the primary emission sources from

the storage segment.

• LNG import/export terminal activities involve the receipt and delivery of LNG for storage

and ultimately delivery.

• LNG storage involves the storage of LNG while it awaits final distribution.

3.1.2.4 Downstream Stage

• The distribution stage represents the delivery of natural gas to end users through distribution

mains and service pipelines. Distribution pipelines receive high-pressure gas from the

transmission pipelines at city gate stations, where the pressure is reduced, and the gas is

distributed through predominantly underground main and service pipelines to the customer’s

meter, where the downstream stage ends. Primary sources of emissions from the distribution

segment are leaks from pipes and metering and regulating (M&R) stations. Fugitive emissions

after the customer meter are not considered here since those emissions should be accounted

for in the residential or commercial sector inventory.

• Beyond-the-meter end use sources are those downstream of meters, and account for end-uses

such as natural gas appliances and commercial and residential buildings. Discrepancies between

top-down and bottom-up methodologies (see section 3.1.2.6) suggest that beyond-the-meter

sources are a significant contribution to methane emissions.

14

Figure 9. Oil and Natural Gas System Depicting the Upstream, Midstream, and Downstream

Grouping of Stages

The fraction of emissions is based on the 2014 EPA U.S. GHG Inventory.

Source: McCabe et al. 2015.

15

3.1.2.5 Emission Source Categories

Emissions from oil and natural gas production systems fall into three main categories: fugitive

emissions, vented emissions, and combustion emissions (Kirchgessner 1997). Definitions of

these categories are as follows:

• Fugitive emissions represent unintended emissions from equipment leaks (such as those from

compressor stations, meters, pressure regulating stations, malfunctioning pneumatic controllers,

and various parts of the production process) and pipeline leaks due to deteriorating pipelines

or poor pipeline connectors.

• Vented emissions represent purposeful releases (i.e., by design) of CH

4

(e.g., through

pneumatics, dehydrator vents, regular maintenance, and chemical injection pumps).

• Combustion emissions represent unburned CH

4

emitted during any fossil fuel combustion

component of the production process (e.g., compressor exhaust emissions or flares).

These different types of emissions are discussed in the context of inventory development in the

following sections.

3.1.2.6 Bottom-Up versus Top-Down Methodologies

CH

4

emissions from the oil and natural gas sector are typically quantified using either top-down (TD)

or bottom-up (BU) methodologies. Definitions of these methodologies are as follows:

• TD studies calculate CH

4

emission levels using observational techniques, including

airborne measurements, satellites, mobile measurement devices, and stationary sensors.

These approaches estimate aggregate CH

4

emissions from all sources in a given region, and

then attempt to apportion those emissions to different source categories. Allen (2014) notes

that the challenges of estimating emissions using TD methods include separating anthropogenic

emissions from natural emissions, and identifying legacy emission sources such as abandoned

wells and nonoperational infrastructure. TD estimates are typically generated at the area-level.

• BU studies generate emission estimates by applying EFs to different activities in the oil and

natural gas sector. The generation of EFs can be challenging and usually involve laboratory

or in situ measurements of emissions that are then extrapolated and applied broadly to develop

overall emission inventories. As Allen (2014, 2016) notes, one of the primary challenges with

BU studies is obtaining a representative sample of a large, geographically dispersed, and diverse

population of equipment and activities. Other uncertainties are due to inaccurate activity data,

malfunctioning equipment, or poorly operated equipment (Allen 2016). Furthermore, emissions

from various sources are not normally distributed, and so the use of an “average” EF may lead

to both overestimation and underestimation (Littlefield et al. 2017). BU inventories are typically

estimated at the component or site level. BU estimates are particularly challenging when

estimating emissions from high-emitting sources, as an accurate estimate requires either

prior understanding of which sources are likely to be high-emitting sources; or obtaining a

statistically representative sample, which is itself not easily determined without a large

16

sample size. Lastly, because BU methods calculated at the component level only capture

source emissions for known and well-defined sources, they typically underestimate actual

emissions, which include emissions from unknown or ill-defined sources (Heath et al. 2015;

Adam R Brandt, Heath, and Cooley 2016; A R Brandt et al. 2014; Miller et al. 2013;

Alvarez et al. 2018).

• Site-level estimates use a similar methodology to TD estimates, often estimating emissions

from atmospheric concentrations, but then apply those estimates in a BU approach. Site-level

estimates are generated for each site (e.g., well head, compressor station) and are at a smaller

geographic scale than TD estimates—and at a greater scale than component-level BU estimates.

In both BU and TD approaches, uncertainty exists and the literature suggests that CH

4

inventories at

the national level are likely under representing actual emissions by 50% or more (Miller et al. 2013;

A R Brandt et al. 2014). At a regional level, Miller et al. (2013) suggest that fossil fuel extraction and

processing emissions could be three to seven times higher than reported. Zavala-Araiza et al. (2015a)

also show that CH

4

emissions from oil and gas production are almost twice as large as reported by the

EPA and represent approximately 1.5% of natural gas production. This 1.5% may also be on the low

range; other authors have observed regional losses of 2–12% or more in the Natural Gas sector, implying

CH

4

emissions nationally could be three times higher than the EPA reports (Pétron et al. 2012; A.

Karion et al. 2013; Caulton et al. 2014). The ceiling for fugitive emissions can be considered as the

delta between aggregated meter readings in the distribution segment and the input of gas into the

system from production and gathering.

3.1.3

Review of Existing Methane Inventory Approaches for Oil and

Natural

Gas Systems

3.1.3.1 EPA’s Greenhouse Gas Reporting Program Subpart W

EPA’s GHGRP [codified at 40 Code of Federal Regulation (CFR) Part 98] requires large emitters

of GHGs to report their emissions through a centralized database accessible by the public (EPA n.d.).

Data collection began in 2011 and covers sources emitting over 25,000 MT of CO

2

e per year, using

the GWP

100

from AR4 (IPCC 2006) for converting CH

4

and other GHGs to CO

2

e. These facilities

self-identify and report annually. The owners and operators of these facilities are tasked with

calculating CO

2

e emissions, filing their results with the EPA, and maintaining records.

17

Subpart W of the GHGRP is focused specifically on facilities operating in oil or gas sectors (EPA 2018a).

This includes emission sources in the following segments of the oil and natural gas system. Subpart W

facility definitions differ across segments and are defined in parentheses.

• Onshore Oil and Natural Gas Production (Company or Basin)

• Offshore Oil and Natural Gas Production (Company or Basin)

• Natural Gas Gathering and Boosting (Company or Basin)

• Natural Gas Processing (Site)

• Natural Gas Transmission Compression (Site)

• Natural Gas Transmission Pipeline (Site)

• Underground Natural Gas Storage (Site)

• LNG Import/Export (Site)

• LNG Storage (Site)

• Natural Gas Distribution (Company or State)

In 2016, 2,248 Subpart W facilities reported emissions totaling 282.9 MMTCO

2

e, of which

186.7 MMTCO

2

e was CO

2

, 96.0 MMTCO

2

e was CH

4

, and 0.2 MMTCO

2

e nitrous oxide (N

2

O).

Note that although the GHGRP data and the U.S. national GHG Inventory are not directly comparable,

total emissions in the U.S. for all sectors in 2016 was 6,511 MMTCO

2

e (EPA 2018a), so the Subpart W

emitters contributed about 4.3% of total emissions nationally.

GHGRP facilities are required to report emissions greater than 25,000 MTCO

2

e for specific source

categories. Facilities report emissions data to the EPA through an electronic submission. A review

of the spreadsheet tool used by the EPA for this purpose, herein called the “Subpart W Tool,” was

conducted. The Subpart W Tool is a BU approach that captures emissions of different components

of the oil and natural gas system. The Subpart W forms are embedded in a Microsoft Excel spreadsheet

and require facilities to provide input on equipment at an operational level. For example, Subpart W

forms ask for input on the quantity of oil and natural gas produced, the quantity of oil and natural gas

stored, the number and type of pneumatic devices and pumps, the number and types of dehydrators,

the amount of well venting for liquids unloading, blowdown vent stacks, well completions, atmospheric

storage units, flare stacks, and estimates of non-planned emission leaks.

The value of the Subpart W form for inventory development is its library of EFs, which provide

specific values for a host of equipment and operations. For example, onshore production facilities

that use natural gas pneumatic devices will find EFs (standard cubic feet/hour/device) for high-bleed

pneumatic devices, intermittent-bleed pneumatic devices, and low-bleed pneumatic devices of 37.9,

13.5, and 1.39, respectively. This level of detail is useful for others constructing BU emission inventories.

18

3.1.3.2 EPA’s Facility-Level Information on Greenhouse Gas Tool

EPA’s FLIGHT provides access to GHG data reported to the EPA through the previously mentioned

Subpart W reporting system and other GHGRP subparts. Aside from providing data access in geospatial,

graphical, and tabular formats, FLIGHT does not provide any additional advancements with respect to

inventory methodology.

3

Data included in FLIGHT are submitted to the EPA periodically under the GHGRP (typically in

March following the reporting year), as reported by over 8,000 facilities, including Subpart W and

non-Subpart W facilities. These data are submitted by large emitters (> 25,000 MMTCO

2

e.yr

-1

) and

cover an estimated 85–90% of total GHG emissions in many sectors in the U.S., including power

plants and landfills, but less than 50% of the oil and natural gas sector. GHGRP data are available

at the national, state, local, sector, and facility levels (EPA 2018c).

Emission sources available in FLIGHT relevant to CH

4

inventory accounting include point sources,

onshore oil and gas production, onshore oil and gas gathering and boosting, local distribution, and

onshore gas transmission pipelines. Sectors available in FLIGHT are power plants, petroleum and

natural gas systems, refineries, chemicals, other, minerals, waste, metals, and pulp and paper.

EPA’s Envirofacts, which draws on data from EPA’s GHGRP and provides an alternate path to

accessing FLIGHT data, shows that CH

4

emissions from all sources in New York State in 2016 totaled

3,082,129 MTCO

2

e (using IPCC AR4 GWP

100

values), of which 1,334,090 MTCO

2

e of CH

4

were

emitted from the oil and natural gas sector, and 1,716,960 MTCO

2

e were emitted from waste facilities,

primarily landfills (the agriculture sector was not included). Together, these two sectors account for

98.98% of non-agriculture based CH

4

emissions reported in the State (43.28% and 55.70%, respectively).

3.1.3.3 EPA’s Greenhouse Gas Emissions Inventory

EPA’s Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2016 provides an overview

of U.S. GHG emissions, including CH

4

emissions from oil and natural gas systems (EPA 2018a).

The approach for calculating emissions for natural gas systems generally involves the application

of EFs to activity data. For most sources, the approach uses technology specific EFs or EFs that vary

over time and consider changes to technologies and practices, which are used to calculate net emissions

directly. For others, the approach uses what are considered “potential methane factors” and reduction

data to calculate net emissions.

19

Key references for EFs for CH

4

emissions from the U.S. oil and natural gas sector include a 1996

study published by the Gas Research Institute (GRI) and the EPA (EPA/GRI 1996). The EPA/GRI

study developed over 80 CH

4

EFs to characterize emissions from the various components within the

operating stages of the U.S. natural gas system. The EPA/GRI study was based on a combination of

process engineering studies, a collection of activity data, and measurements at representative gas

facilities conducted in the early 1990s.

In the production segment, EPA’s GHGRP data (EPA 2017) were used to develop EFs used for all years

for well testing, gas well completions and workovers with and without hydraulic fracturing, pneumatic

controllers and chemical injection pumps, condensate tanks, liquids unloading, and miscellaneous flaring.

In the processing segment, for recent years of the times series, GHGRP data were used to develop EFs

for fugitives, compressors, flares, dehydrators, and blowdowns/venting. In the transmission and storage

segment, for recent years of the times series, GHGRP data were used to develop factors for pneumatic

controllers. Other data sources used for CH

4