Comfort Sync A3

Ultra Smart Thermostat

Installation and Setup Guide

508026-01 10/2021

Copyright 2021

©

Allied Air Enterprises, Inc.

West Columbia, SC, USA

2

Table of Contents

Shipping and Packing List ........................................................................................3

Operating and Storage Environment, Electrical and Dimensions ........................3

Installation Recommendations ................................................................................3

Smart Hub Installation, External Components, LEDs and Terminals ...................3

Smart Hub Installation ............................................................................................3

Smart Hub External Components ..........................................................................4

Smart Hub Push Button Functions .........................................................................4

Smart Hub LED Indicators .....................................................................................5

Smart Hub Terminals and Wiring Requirements ....................................................6

HD Display Installation, External Components and Terminals ............................6

HD Display Attachment ..........................................................................................7

HD Display External Components..........................................................................7

HD Display Terminals .............................................................................................8

Connecting Low Voltage Wiring ...............................................................................8

Control Wiring Requirements .................................................................................8

Discharge Air Temperature Sensor (DATS) (Optional for Indoor Unit) ...................8

Outdoor Air Temperature Sensor (OATS) .............................................................8

Reducing Electrical Noise on Communication Bus - Indoor, outdoor, HD

Display and Smart Hub. .........................................................................................8

Wiring Diagrams .....................................................................................................9

Electric Heat Conguration for Communicating Air Handlers ............................13

Commissioning ........................................................................................................13

Commissioning and Service (Using the Mobile Setup Application) .....................13

Mobile Device Operating System Requirements ........................................................... 14

Establishing a Direct Wireless Connection to the Smart Hub ....................................... 14

Service .......................................................................................................................... 14

Alternative Method ........................................................................................................ 15

Multiple Smart Hub(s) - Group ID .................................................................................. 15

Restarting Smart Hub .................................................................................................... 15

Commissioning (Using the HD Display) ...............................................................15

Boot-up Screen ............................................................................................................. 15

Low Battery Status ........................................................................................................ 15

Dealer Info and Language Selection ............................................................................. 15

Warning Screen ............................................................................................................. 15

General Information ....................................................................................................... 16

Equipment Found Screen .............................................................................................. 16

Non-Communicating Equipment ................................................................................... 16

Reminders ..................................................................................................................... 16

Comfort Sync

®

Zoning .................................................................................................. 16

Setup Airow Per Zone .................................................................................................. 17

Commissioning Completion ........................................................................................... 17

Dealer Control Center .............................................................................................17

Equipment Parameters ........................................................................................18

Tests .....................................................................................................................41

Diagnostics...........................................................................................................41

Installation Report ................................................................................................41

Information ...........................................................................................................41

Dehumidication Settings ......................................................................................42

Dehumidication Setting Options .........................................................................42

Overcooling ..........................................................................................................42

Dehumidication Set Point ...................................................................................42

Advanced Dehumidication Descriptions .............................................................42

Displaying Outdoor Temperature (Sensor) and Indoor Humidity on the

Home Screen............................................................................................................44

Displaying the Outdoor Sensor Temperature on the Home Screen .....................44

Displaying the Indoor Humidity on the Home Screen ..........................................44

Comfort Sync® Zoning ..........................................................................................44

Ventilation (ERV, HRV and Fresh Air Damper) ......................................................45

Ventilation Rates ..................................................................................................45

Energy Recovery Ventilator (ERV) .......................................................................45

Heat Recovery Ventilator (HRV) ..........................................................................45

Fresh Air Damper .................................................................................................45

Zoning Application ......................................................................................................... 45

Operation of Fresh Air Dampers with Environmental Overrides .................................... 45

Ventilation Control Modes ....................................................................................45

Wi-Fi Connection .....................................................................................................46

Performance Reports ..............................................................................................47

Notications .............................................................................................................48

Alert Code Types ..................................................................................................48

Service Notication Codes ...................................................................................48

Alert Codes ..........................................................................................................48

Electrical Troubleshooting .....................................................................................49

Overview ..............................................................................................................49

Denitions ............................................................................................................49

Testing ..................................................................................................................49

Technical Support ...................................................................................................49

Index .........................................................................................................................90

3

Shipping and Packing List

Quantity Description

1

Comfort Sync

®

A3 ultra smart thermostat includes a Smart Hub

and HD Display

4 Mounting screws (#6 X 1.25” pan head)

4 Wall anchors (alligator anged solid wall anchors)

1 Installation and setup guide

1 User guide

1 Warranty certicate

NOTE: Due to Allied Air’s ongoing commitment to quality, features and options

are subject to change without notice and without incurring liability.

Improper installation, adjustment, alteration, service or maintenance

can cause property damage or personal injury. Installation and service

must be performed by a qualied installer and servicing agency.

Operating and Storage Environment, Electrical and Dimensions

• Operating Temperature is 32°F to 104°F (0 to 40°C)

• Shipping and storage temperature range is -4°F to 140°F (-20°C to 60°C)

• Operating humidity range is 10% to 90% non-condensing at 104°F (40°C)

• Storage humidity range is 5% to 95% non-condensing at 104°F (40°C)

• Comfort Sync

®

A3 Smart Hub Power Input: 24VAC, 1AMP at 60Hz.

• Comfort Sync

®

A3 Smart Hub DC Power Output: 12VDC (to HD Display)

• Dimensions (H x W x D):

» HD Display: 7-1/4” x 5” x 1” (184 x 122.5 x 23 mm)

» Comfort Sync

®

A3 Smart Hub: 4-1/2 x 4-/2 x 1-1/2” (114 x 114 x 38 mm)

- antenna length is 7-1/4” (184 mm)

Installation Recommendations

WARNING

Improper installation, adjustment, alteration, ser vice or maintenance can

cause property damage, personal injury or loss of life.

Installation and service must be performed by a li censed professional HVAC

installer (or equivalent) or a service agency.

Before beginning installation, note the type of equipment, number of stages,

and any accessories being installed.

Do

• Read this entire document, noting which procedures pertain to your specic

equipment and system requirements.

• Make sure that all wiring conforms to local and national building and electrical

codes and ordinances.

Do Not

• Install on voltages higher than 30VAC.

• Short (jumper) across terminals on the gas valve or at the system controls

to test installation. This will damage the thermostat and void the warranty.

• Exceed 300 feet (91 meters) run when using 18AWG or 22AWG thermostat

wire or larger (shielded or unshielded).

• Allow power load from any thermostat connection to be more than 1 AMP.

Smart Hub Installation, External Components, LEDs and Terminals

Smart Hub InStallatIon

1. Things to consider when installing the Smart Hub:

• Install near the indoor unit such that there is a direct path to the

approximate location of the home Wi-Fi access point (the signal is not

blocked by the indoor unit or duct work, for example).

• Can be attached to a vertical surface such as a wall stud or roof truss

web, or to a horizontal surface such as a oor or ceiling joist, or a roof

rafter.

• Smart Hub antenna should be positioned such that it is roughly vertical,

no matter the orientation of the Smart Hub itself.

• Do not install the Smart Hub on the indoor unit, duct work, or other

equipment that could induce vibration in the Smart Hub.

• Do not install the Smart Hub on or near large metal objects. This could

adversely affect the range and directional coverage of the Smart Hub

Wi-Fi signal.

• If the Smart Hub MUST be installed on a metal object, orientate the

antenna perpendicular to the metal surface.

• In all cases, the Smart Hub antenna orientation may need to be

adjusted to obtain best Wi-Fi results.

2. Use the procedure outlined in “Figure 1. Smart Hub Installation” on page

4 to install the Smart Hub controller.

4

1/4”

STRIP 1/4” INSULATION FROM

END OF EACH CONTROL WIRE

A

B

D

USE SMART HUB AS TEMPLATE TO MARK DESIRED MOUNTING

LOCATIONS ON WALL OR STUD.

CAUTION: DO NOT OVERTIGHTEN LOWER MOUNTING SCREW, MAY

DAMAGE SMART HUB.

SECURE SMART-HUB TO

WALL WITH

FIELD-PROVIDED

FASTENERS

RAER

TNORF

KEYHOLE

THROUGH-HOLE

C

MAKE CONNECTIONS TO SMART HUB

SCREW TERMINALS USING WIRING

DIAGRAMS PROVIDED

TERMINALS

(screw type)

+

-

COMMBUS

A B

R i+ I- C

ACC1 ACC2

+

-

COMMBUS

A B

R i+ I- C

ACC1 ACC2

Figure 1. Smart Hub Installation

3. For low voltage wiring connections use diagrams in section titled

“Connecting Low Voltage Wiring” on page 8.

IMPORTANT

Do not install smart hub in location were direct exposure to condensation or

dripping water is possible.

Smart Hub ExtErnal ComponEntS

System Status LED

System Commissioning

Status LED

USB Port

Manual Reboot Button

Terminal Connection Access Cover

Antenna

Figure 2. Smart Hub Indicators and External Components

Smart Hub puSH button FunCtIonS

The Smart Hub push button is for rebooting. Press and hold the button for ve

seconds to reboot the Smart Hub.

The push button has a LED associated with it that indicates the status of the

Smart Hub commissioning state (see “Table 1. System Status LED Indicators”).

5

Smart Hub lED InDICatorS

When alarms are present, you may review alarm(s) listed either on the homeowner notication screen or the menu / settings > advanced settings > dealer

control center > notications screen.

Alert codes which require manual clearing can only be done under the dealer control center > notication screen.

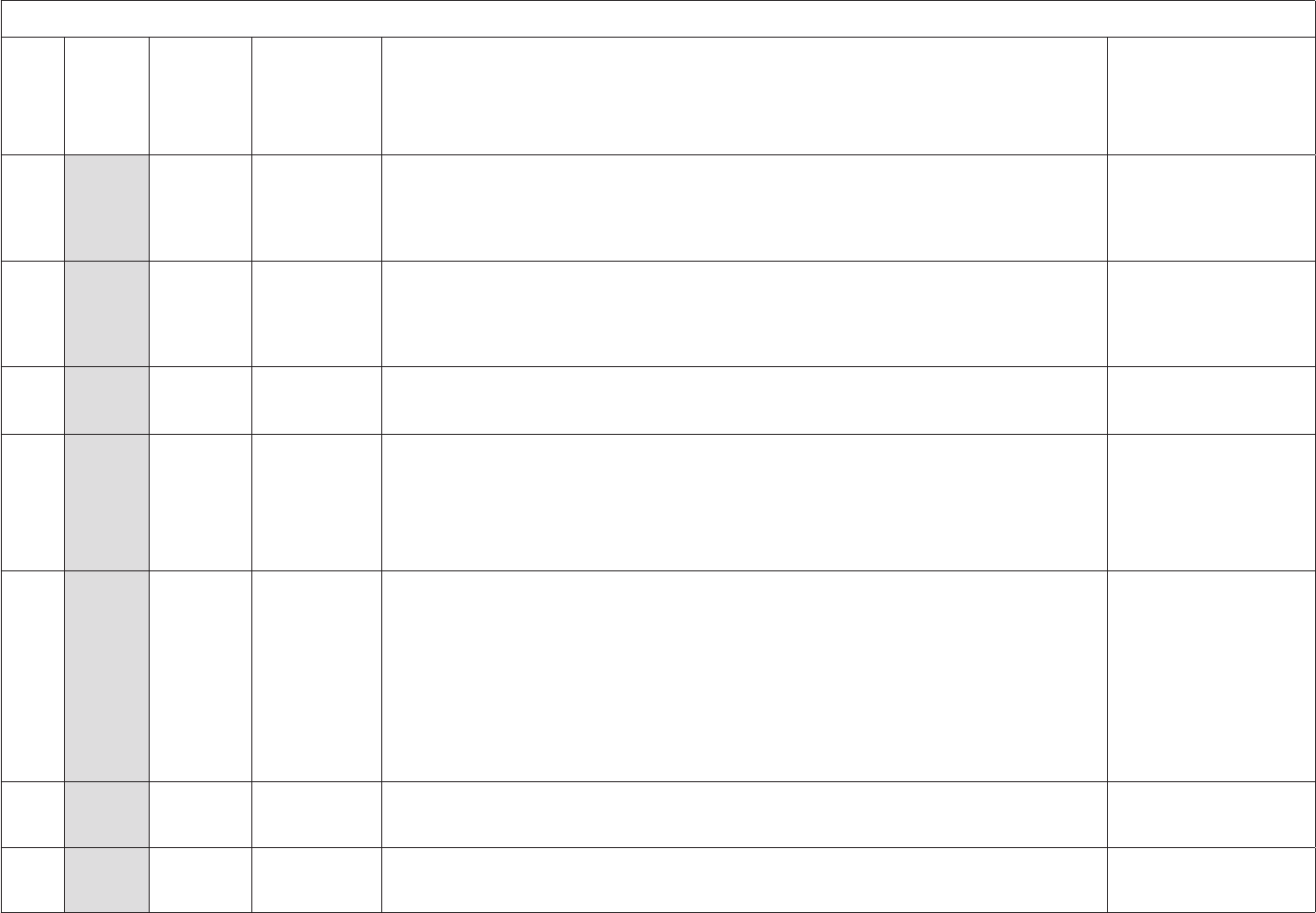

Table 1. System Status LED Indicators

System Status LED

System Commissioning

Status LED

Smart Hub

+

-

COMMBUS

A B

R i+ I- C

ACC1 ACC2

System Status LED

LED

Color

Status Description

Green

System is

normal

A solid green LED indicates no system errors are detected. System

operating as designed.

Red

HVAC

Fault

System has critical alert which needs attention.

Amber Wi-Fi Error

Blinking amber LED indicates either Wi-Fi is not connected, no Wi-Fi is

within range, or and Wi-Fi hardware error. Could also indicate intermittent

Wi-Fi connection.

Magenta

Thermostat

Error

Blinking magenta LED indicates HD display not connected. (see “Table 2.

Communication Error Troubleshooting

(HD Display to Smart Hub)” on page 6)

Cyan

HVAC

Error

Indoor unit is not connected or unable to communicate.

Commissioning Status LED

Blue

System is

normal

No mobile device is directly connected using Wi-Fi to the Smart Hub.

Green

Blinking green LED indicates the commissioning button has been activated and the Smart

Hub is waiting for a connection with a mobile device.

Green A solid green LED indicates a mobile device is connected to the Smart Hub.

• If multiple errors are present, the system status LED will display each active error for one second on and

one second off and then display the next error if present.

• The system will continue to cycle through all active errors.

• System status errors are displayed in the following priority: HVAC, thermostat and then Wi-Fi.

6

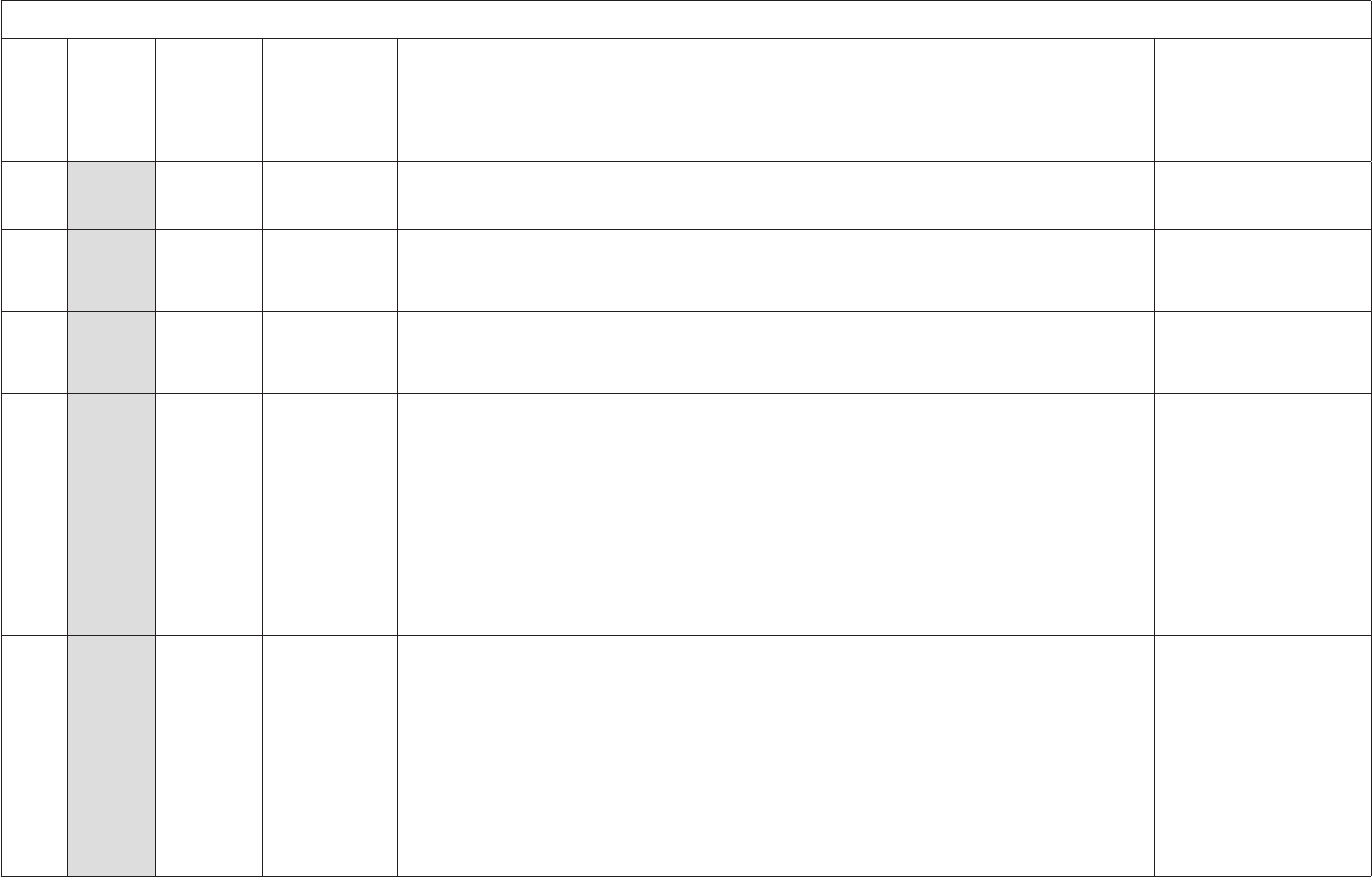

Table 2. Communication Error Troubleshooting

(HD Display to Smart Hub)

Possible Connection Issues

Comfort Sync

®

A3 Smart

Hub - System Status LED

One communication wire at the Smart

Hub COMM BUS A or B terminals is

disconnected.

Flashing Magenta LED

Both communication wires – at

the Smart Hub COMM BUS A or B

terminals are reversed.

Flashing Magenta LED

Power wires at Smart Hub 12VDC +

and - terminals are disconnected.

Flashing Magenta LED

If terminals are connected correctly,

then check HD Display mounting to

subbase. HD Display may not be

secured correctly to subbase.

Flashing Magenta LED.

HD Display screen may be

either blank or a message

indicating Comfort Sync

®

A3

cannot communicate with the

equipment.

Smart Hub tErmInalS anD WIrIng rEquIrEmEntS

Table 3. Smart Hub Terminal Designations, Order and Wiring

Requirements

Terminal

Designation

Description Thermostat Wiring

R 24VAC input 18AWG unshielded

I+ RS-BUS I+

22AWG shielded

(recommended)

(2-pair conductor only)

I- RS-BUS I-

C 24VAC return 18AWG unshielded

ACC1 Accessory 1 and 2 (typically

can be used for 1 or 2

speed ventilators and fresh

air dampers)

18AWG unshielded

ACC2

12+ 12VDC output 18AWG unshielded

A Communications bus A 22AWG shielded

(recommended)

(2-pair conductor only)

B Communications bus B

12- 12VDC return 18AWG unshielded

IMPORTANT

Use 2-pair, 18AWG unshielded thermostat cable (eld-provided) for power

terminals (R, C, 12+ AND 12-). Recommend using 2-pair 22AWG shielded

thermostat cable for communications terminals (I+, I-, A and B) which will

help eliminate any noise interference.

HD Display Installation, External Components and Terminals

Use the following procedure for installation of the subbase where existing

thermostat wiring does not exist:

1. Unpack the HD Display and subbase.

2. Determine the best location to install either the subbase. Ideal location

should be located away from outside wall, direct sunlight or discharge air

vents.

3. Cut or drill a small hole for thermostat wiring.

3/8” (10 mm)

Diameter Hole

4. Pull about three inches (75mm) of thermostat wire through the opening

and remove the outer thermostat wire jacket.

Seal wire hole in wall to prevent

cold or hot air from affecting temperature

sensor in display.

IMPORTANT

Seal wire hole in wall to prevent cold or hot air from affecting temperature

sensor in HD Display.

5. Strip 1/4” (6 mm) insulation from end of each wire.

1/4”

7

6. Use a level to align either the subbase on wall horizontally.

7. Use the subbase as a template to mark the desired mounting hole locations

on the wall.

Use the subbase as a template to

mark the desired mounting hole

locations on the wall.

HD Display Subbase

(Rear View)

8. Drill 3/16” (5 mm) holes at marked locations on the wall for anchors. Then

insert wall anchors into holes until ush with the wall.

Drill Holes

Insert in hole until flush with wall.

WARNING

DO NOT over-tighten mounting screws. Doing so my distort the subbase

plastic housing and cause connection issues when attaching the HD display.

9. Secure subbase with provided #6 x 1.25” pan-head screws (4).

10. Connect thermostat wiring to subbase screw terminals referencing

provided wiring diagrams in this guide.

HD DISplay attaCHmEnt

1. Hold the HD Display by the edges, line it up with the subbase (horizontal

position), and move the HD Display toward the subbase.

2. Center the cavity on the back of the display over the subbase.

3. Gently press on the edges of the HD Display until you hear the mounting

snaps engage. Be careful not to apply force directly on the glass.

NOTE: Once the HD Display is connected, it may take up to 45 seconds for it

to power up.

4. To remove the HD Display from the subbase, grasp the left and right edges

of the HD Display and gently pull towards yourself.

NOTE: If the HD Display is removed from the subbase base, the HD Display

will shut down and will not be able to communicate with the system.

System can be controlled from mobile devices or consumer web

portals once registration has been completed.

5. Do not remove the label covering the HD Display screen until after power

is applied to the system.

HD DISplay ExtErnal ComponEntS

• Proximity sensor - Detects a person approaching the HD Display. If the

HD Display is in Screen Saver mode and the Proximity Sensor setting is

enabled, the proximity sensor takes the HD Display out of screen saver mode

automatically and returns to the home screen when someone approaches.

• Humidity sensor - This is the intake location for the humidity sensor. Do not

block.

• Power button - Turns off the HD Display when pressed and held for about

ve (5) seconds.

• microSD card slot - Not functional, for future use.

• Micro USB connector - Not functional, for future use.

Proximity and Ambient Light Sensors

microSD slot

micro USB port

power button

humidity sensor

air intake

humidity sensor

air discharge

temperatur sensor

Subbase attached

Figure 3. HD Display Components

8

HD DISplay tErmInalS

Table 4. Smart Hub Terminal Designations and Order

Terminal Designation Description

12+ 12VDC output

A Communications bus A

B Communications bus B

12- 12VDC return

Connecting Low Voltage Wiring

The following diagrams in this section illustrates the basic Allied Air control

wiring for all compatible components.

Control WIrIng rEquIrEmEntS

The following is the wiring specication requirements for installation of this

system.

• Comfort Sync

®

A3 wiring size is 18# AWG.

• Maximum total length of all connections combined is 1500 feet (457 meters).

• Maximum length between components is 300 feet (90 meters).

DISCHargE aIr tEmpEraturE SEnSor (DatS) (optIonal For InDoor unIt)

Installation of discharge air temperature sensor (DATS) (88K38) must comply

with the following requirements:

• Installed downstream of the heat exchanger or electric heat elements.

• It must be placed in free airow, where other accessories (such as humidiers,

UV lights, etc.) will not interfere with its accuracy.

• Wiring distance between the integrated furnace and air handler controls or

damper control module and the discharge air sensor must not exceed 10 feet

(3 meters) when wired with 18# AWG thermostat wire.

• DATS is highly recommended for all systems that include a variable capacity

outdoor unit in order to provided more precise dehumidication operation.

outDoor aIr tEmpEraturE SEnSor (oatS)

The optional outdoor air (temperature) sensor (OAS) (X2658) wiring distance to

the Comfort Sync

®

A3 should not exceed 150 feet (45 meters) when wired with

minimum 22 #AWG (recommend 18 #AWG) dedicated 2-conductor thermostat

cable or two wire shielded. Installation of OAS must comply with the following

requirements:

• Sensor wiring must be run to avoid touching or being close to high voltage

wiring and light ballast.

• Choose a protected outdoor location away from direct sunlight or other heat

sources (usually on the north side of the building).

• Ensure that water will neither collect on, nor wash over the sensor.

• Do not locate the sensor near driveways or similar heat-absorbing masses

which may reect stored heat energy onto the sensor and send inaccurate

information to the thermostat.

• Locate the sensor away from attic and soft vents, or furnace venting pipes.

• Do not locate the sensor directly above an air conditioner or heat pump.

rEDuCIng ElECtrICal noISE on CommunICatIon buS - InDoor, outDoor, HD DIS-

play anD Smart Hub.

Communicating systems requires four thermostat wires between the HD

Display and Smart Hub. Four wires are also used between the Smart Hub and

indoor/outdoor units as well. When a thermostat cable with more than four

wires is used, the extra wires must be properly connected to avoid electrical

noise. The wires must not be left disconnected.

• Use wire nuts to bundle the unused wires at each end of the cable. A single

wire should then be connected to the indoor unit end of the wire bundle

and attached to the “C” terminals as shown in “Figure 4. Thermostat Wire

Termination in Communicating Systems (Electrical Noise)”.

• Keep all communication wiring as far away from the house electrical wiring

and large electrical appliances as possible. Recommended minimal distance

is 15 feet (4.6 meters).

Unused wires

Unused wires

Single wire

to bundle

wire to indoor

terminal “C”.

Single wire

to indoor unit

terminal “C”.

Unused wires

Single wire

to terminal “C”.

Indoor Unit Controller

Outdoor Unit

+12V A B

HD Display

Subbase

-12V

12VDC

12+

COMBUS

A B

Smart Hub

R i+ I- C

ACC1 ACC2

12-

Figure 4. Wire Termination in Communicating Systems

(Electrical Noise) - Typical

IMPORTANT

It is recommended to use 2-pair, 18AWG unshielded thermostat cable (eld-

provided) for power terminals (R, C, 12+ AND 12-). Recommend using 2-pair

22AWG shielded thermostat cable for communications terminals (I+, I-, A

and B) which will help eliminate any noise interference. See “Table 3. Smart

Hub Terminal Designations, Order and Wiring Requirements” on page 6

for further details.

9

WIrIng DIagramS

The following diagrams are typical low voltage wiring connections for various

system congurations.

Communicating

Indoor Unit

Smart Hub

C

i+

i-

R

HD

Display

Subbase

-

COMMBUS

A B

ACC1 ACC2

Communicating

Outdoor Unit

OATS (Optional)

DATS (Optional)

+

B

A

+

-

Figure 5. Comfort Sync

®

A3 with Allied Air Communicating Indoor and

Outdoor Units

24VAC 1- or 2-Stage

Heat Pump

SETUP NOTES:

CUT Y1-Y2 ON-BOARD

MUNICATING)

CUT R-O ON-BOARD LINK

FOR OUTDOOR HEAT

MUNICATING)

ACC1

ACC2

DATS (Optional)

OATS (Optional)

Smart Hub

Communicating

Air Handler Unit

-

COMMBUS

A B

+

HD

Display

Subbase

B

A

+

-

Figure 6. Comfort Sync

®

A3, Allied Air Communicating Air Handler

with 24VAC 1 or 2-Stage Heat Pump

24VAC Outdoor Unit

(1 - or 2-Stage

Air Conditioner)

SETUP NOTE:

CUT Y1-Y2 ON-BOARD LINK FOR

2-STAGE OUTDOOR UNITS

(NON-COMMUNICATING)

ACC1

ACC2

DATS (Optional)

OATS (Optional)

Smart Hub

Communicating

Indoor Unit

-

COMMBUS

A B

+

HD

Display

Subbase

B

A

+

-

Figure 7. Comfort Sync

®

A3, Allied Air Communicating Indoor Unit

with 24VAC Air Conditioner

24VAC

1- or 2-Stage

Non-Communicating

Indoor Unit

If jumber is present between

R and W2 on indoor unit terminals then

removed it. Installed jumper

may cause erroneous Alert Code 125.

ACC1

ACC2

Smart Hub

Equipment

Interface Module

Communicating

Outdoor Unit

-

COMMBUS

A B

+

HD

Display

Subbase

B

A

+

-

Figure 8. Comfort Sync

®

A3 with Equipment Interface Module (EIM),

24VAC Indoor Unit and Allied Air Communicating Outdoor Unit

10

DATS

(Required)

OATS (Optional)

Zone

Sensors

PWR

D+

D-

C

PWR

D+

D-

C

PWR

D+

D-

C

See ComfortSync Zoning Installation instruction for damper connection information.

INDOOR

DOOR” ON DAMPER CONTROL MODULE TO

CONNECT TO THE INDOOR UNIT.

PWR

D+

D-

C

TS

TS

T

T

A

A

T

T

COMFORTSYNC ZONING

SYSTEM

To indoor unit

To ComfortSync

Zoning

If unable to connect two wires

to indoor unit terminals then

pigtail wiring as exampled

here.

DATS

Up to three zone

sensors are supported.

ACC1

ACC2

If TSTAT terminal is present,

DO NOT use.

Smart Hub

-

COMMBUS

A B

+

Communicating

Indoor Unit

Communicating

Outdoor Unit

HD

Display

Subbase

B

A

+

-

Figure 9. Comfort Sync

®

A3, Allied Air Communicating Indoor and Outdoor Units, Comfort Sync

®

Zoning (Damper Control Module) and Zone

Sensors

11

FURNACE (IFC) OR AIR

HANDLER (AHC)

COMMUNICATING

FURNACE

48G96 Relay

GND

IN

120VAC<-------HUMIDIFIER CONNECTIONS------> 24VAC

CHARGE AIR SENSOR

(SEE DAS NOTES)

OPTIONAL OUTDOOR

AIR SENSOR (SEE OAS

NOTES)

ACC1

ACC2

ERV / HRV

24VAC UV Light Applications: In any Allied communicating system, the indoor unit will

NOT have adequate power to to run the 24VAC UV light application. An additional transformer

will be required. UV light wiring connections are independent of the HVAC system operation

(refer to UV light installation instruction.

Humidity Control Applications: The Comfort Sync A3 thermostat can sense humidity and controls

both 24VAC “H” and 120VAC “H” outputs to cycle humdifier based on demand. No other

control or humidistat is required. Optional outdoor air temperature sensor for use with humidifier

(if not already in the system for other function and are typically built into all Allied communicating

outdoor units

Smart

Hub

-

COMMBUS

A B

+

Communicating

Outdoor Unit

HD

Display

Wall-Mount

Smart

Hub

B A

-12V

+12V

-

COMMBUS

A B

+

HD

Display

Subbase

B

A

+

-

Figure 10. Comfort Sync

®

A3 with Humidier Accessory

12

HEPA BYPASS FILTER X2680 HEPA

INTERLOCK KIT

TOR COMMON WIRE

THROUGH CURRENT LOOP.

SEE HEPA INTERLOCK KIT

FOR INSTALLAT ION DETAILS

(POWER COMPANY INTERRUPTION

SYSTEMS ARE WIRED SAME AS

OVERFLOW SWITCH)

CUT

R-DS

W914

DS

R

COMMUNICATING

OUTDOOR UNIT

COMMUNICATING

INDOOR UNIT

COMMUNICATING

THERMOSTAT OR DAMPER

CONTROL MODULE

CONVENTIONAL TERMINALS

FLOAT

SWITCH

FLOAT

SWITCH

COMMUNICATING

INDOOR UNIT

COMMUNICATING

INDOOR UNIT

COMMUNICATING

INDOOR UNIT

CONVENTIONAL

OUTDOOR UNIT

(1 OR 2 STAGE)

COMMUNICATING

OUTDOOR UNIT

COMMUNICATING

FURNACE UNIT

(2 STAGE)

C

C

MAY NEED TO WRAP WIRE MULIPLE TIMES TO

GET AMP DRAW HIGHER (1 AMP) TO MAKE

SENSOR WORK CORRECTLY.

Figure 11. Installing Comfort Sync

®

A3, Communicating Indoor Unit, Float Switch, HEPA Bypass Filter Interlock Kit, Humidier, Relay and

FreezeStat

13

ACC1

ACC2

Communicating

Indoor Unit

Wire Jumper required between ON and RED terminals.

ACC1 is always low-stage for single- and two-stage ventilators.

LOW

ON

RED

YEL

GRN

HI

COM

NO

NC

BLK

HRV/ERV

Terminal Block

Smart Hub

-

COMMBUS

A B

+

HD

Display

Subbase

B

A

+

-

Figure 12. Comfort Sync

®

A3 with Ventilation

(Fresh Air Damper, ERV and HRV)

Electric Heat Conguration for Communicating Air Handlers

OUTDOOR

AIR SENSOR

HEAT

1234

COOL

1234

DELAY

12 34

ADJUST

NORM + −

HUMIDIFICATION

SMART AUTO

1234

BLOWER

ONLY CFM

100

11 5

130

85

Y1−Y2

2−STAGE

COMPR

R−O

HEAT

PUMP

R−DS

DEHUM

C

W1

W2

G

Y2

Y1

C

R

DH

H

L

O

DS

W3

FUSE3 AMP

XFMR 24V

24 VAC

COM

3

6

9

1

4

7

XFMR LINE

G

2

5

8

P8

L1

L2

L2 L1

INDOOR

BLOWER

POWER

EARTH

INDOOR BLOWER

SIGNAL

45 6

12 3

A92

INTEGRATED

CONTROL

OUTDOOR UNIT

LINK

I +

I −

I +I −RC

I +I −RC

THERMOSTAT

DH

DISCHARGE

AIR SENSOR

PUSHBUTTON LED

Figure 13. Air Handler Control

IMPORTANT

After electric heat strips are installed, but prior to running the thermostat

installer setup, electric heat must be manually congured to detect the

number of electric heat sections.

This procedure is for conguring the heat strips so that they will be detected

by the thermostat:

• Power must be applied to the air handler but NOT to the Smart Hub.

• Disconnect any communication wiring between the Smart Hub and indoor

unit prior to electric heat discovery.

• The air handler control must be in idle mode (decimal blinks at 1 Hertz—0.5

second ON, 0.5 second OFF to use the following procedure.

1. Select eld test mode—press and hold the push button until solid “–”

appears; release button. Display will blink.

2. Push and hold button and wait for the display LED to show “H” (capital H),

then release the button.

3. The air handler control cycles the indoor blower motor “on” to the selected

heat speed and stages the electric heat relays “on” and “off” to automatically

detect the number of electric heat sections. The air handler control stores

the number of electric heat sections, then automatically exits “Field Test

Mode”.

4. The thermostat will now detect the heat strip information stored in the air

handler control.

5. Turn off power and connect all low voltage wiring (power and communication

to and from the Smart Hub).

6. After completing the commissioning of the system then check to see if you

have electric heat or emergency heat.

Commissioning

CommISSIonIng anD SErvICE (uSIng tHE mobIlE SEtup applICatIon)

This application tool is used by dealers to commission a Comfort Sync

®

A3

ultra smart thermostat using a Wi-Fi enabled mobile device.

A temporary Smart Hub local network provides a means for a mobile device

using the Comfort Sync

®

dealer mobile app application to directly communicate

with the Smart Hub.

NOTE: The Comfort Sync

®

dealer mobile app running on a mobile device

cannot connect to the Smart Hub through the Internet or home Wi-Fi

network.

To use the Comfort Sync

®

dealer mobile app, the mobile device must be:

• Wi-Fi capable

• Located in the home near the Smart Hub

14

NOTE: A router with Bonjour capabilities is required for this function. Check

the router features if the Smart Hub does not connect. Apple Bonjour

®

is an implementation of Zero-conguration networking (Zeroconf),

a group of technologies that includes service discovery, address

assignment, and host name resolution.

Mobile Device Operating System Requirements

The Comfort Sync

®

dealer mobile app is available for both IOS 6.0 and higher

(App Store) and Android 4.1 and higher (Google Play).

Establishing a Direct Wireless Connection to the Smart Hub

IMPORTANT

If the connection between the Comfort Sync

®

dealer mobile app and Smart

Hub is idle for three (3) minutes, the Smart Hub will auto-disconnect from the

mobile device. Repeat procedures to reconnect.

1. Download and install the Comfort Sync

®

dealer mobile app

2. Apply power to the system.

NOTE: At this point, it is recommended that when using the Comfort Sync

®

Mobile Setup application to commission the system, remove the HD

Display from the subbase before starting.

NOTE: Once commissioning is completed you may reattach the HD Display

to the subbase.

3. Go to the Smart Hub and press the commissioning button located on

the side of the unit (see “Figure 2. Smart Hub Indicators and External

Components” on page 4 for location of button).

4. The commissioning status LED will start blinking green for two minutes.

During this time the Smart Hub will broadcast its Wi-Fi identier (SSID).

5. Go to your mobile device’s Wi-Fi connection tool and locate the Smart

Hub Wi-Fi broadcast identier. A typical example of a identier (SSID) is

DIRECT-XY12-3456.

NOTE: Refer to your mobile device’s owners manual on how to use your Wi-Fi

Connection tool.

6. Connect to the Smart Hub by using the last eight digits of the Smart Hub

SSID as the password. In this example, it would be XY123456).

7. Once the mobile device is connected to the Smart Hub, the commissioning

Status LED will turn solid green.

8. Start the Comfort Sync

®

dealer mobile app and make sure you are

connected to the correct Smart Hub by checking the serial number.

9. Touch the remote-in tab on the Comfort Sync

®

dealer mobile app home

screen. This will take you to the commissioning screen.

10. You can use the information provided in “Commissioning (Using the HD

Display)” on page 15 to complete the commissioning process using the

Comfort Sync

®

dealer mobile app.

11. If the system has not been commissioned it will go to commissioning

screen automatically. If the system has already been commissioned it will

go to dealer control center.

12. Once the commissioning is completed, exit the Comfort Sync

®

dealer

mobile app.

13. Go to the mobile device’s Wi-Fi tool and manually disconnect from the

Smart Hub.

14. Once disconnected, the Smart Hub commissioning LED will change to

solid blue.

15. Reinstall the HD Display on the subbase.

Service

To use Comfort Sync

®

dealer mobile app as a service tool, the commissioning

of the system must have already been completed.

NOTE: Currently there is a default timer for 30 minutes to complete any service

procedures before the Smart Hub will automatically log you out. The

duration of the timer cannot be adjusted.

1. Download and install the Comfort Sync

®

dealer mobile app if not already

installed.

2. Go to the Smart Hub and press the commissioning button once.

3. The LED will start blinking green for two minutes. During this time the

Smart Hub will broadcast its Wi-Fi identier (SSID).

4. If this is the rst time connecting to the target Smart Hub then go to your

mobile device’s Wi-Fi connection tool and locate the Smart Hub Wi-Fi

broadcast identier. A typical example of a identier (SSID) is DIRECT-

XY12-3456.

5. If your mobile device had already connected previously to the target Smart

Hub, then touch the applicable Smart Hub SSID on the list and skip to step

7.

NOTE: Refer to your mobile device’s owners manual on how to use our Wi-Fi

Connection tool.

6. Connect to the Smart Hub by using the last eight digits of the Smart Hub

SSID as the password (XY123456) for example.

7. Once connected to the mobile device the Smart Hub commissioning LED

will turn solid green.

8. Start the Comfort Sync

®

dealer mobile app and make sure you are

connected to the correct Smart Hub by checking the serial number.

15

9. Touch the remote-in tab on the Comfort Sync

®

dealer mobile app home

screen.

10. If the system has not been commissioned it will launch the commissioning

screen. If the system has already been commissioned it will go to dealer

control center.

11. Once servicing is completed, exit the Comfort Sync

®

dealer mobile app.

12. Go to the mobile device’s Wi-Fi tool and manually disconnect from the

Smart Hub.

13. Once disconnected the Smart Hub LED will change to a solid blue.

Alternative Method

From the home screen, go to menu > settings > advanced settings > pair

Smart Hub to Comfort Sync

®

dealer mobile app selection. It will auto connect

to dealer application and start you at the dealer control center screen. The

following screen will appear and show the status of the connection. Once

connected the screen will automatically disappear.

view dealer dashboard

restart

pair Smart Hub to icomfort dealer mobile app

advanced settings

wi-fi local

smart away on

off

auto

Feels Like

fan

heat & cool

humidity

iHarmony zoning

notifications

general

display

account

settings

home info

a

d

vance

d

sett

i

n

g

s

wi-

fi

local

smart

F

ee

l

s

f

a

n

heat

&

h

um

id

iHarm

o

noti

f

ic

a

gener

a

displa

y

accou

nt

s

ett

i

n

g

s

home in

fo

vi

vi

ew

ew

d

d

ea

ea

le

le

r

r

da

da

sh

sh

bo

bo

ar

ar

d

d

aw

w

a

ay

y

Li

k

ke

e

&

c

c

oo

l

i

ty

y

o

n

ny

y

z

z

o

a

ti

i

ons

al

y

Connect to the Smart Hub from

the dealer Comfort Sync mobile app

now broadcasting...

stop

Figure 14. Pairing

Multiple Smart Hub(s) - Group ID

Multiple Smart Hubs in a home can be assigned to a group (up to nine groups

with up to ve (5) Smart Hubs in each group). All Smart Hubs in a group can

communicate with other Smart Hubs in the same group over the home Wi-Fi

network.

Default Group ID 1. Range is 1 to 9.

NOTE: If a Smart Hub is set to Group 0, then there is no connectivity with

another Smart Hub.

Group IDs can be changed by going to menu > settings > advanced settings

> view > dealer control center > equipment > smart hub.

Restarting Smart Hub

Pressing the Smart Hub button for more than ve seconds will reboot the

Smart Hub.

CommISSIonIng (uSIng tHE HD DISplay)

The following procedures are written for commissioning the system using the

HD display interface.

When power is rst applied to the system all Comfort Sync

®

devices attached

to the system (air handler or furnace, outdoor unit or zoning control) will

automatically be congured using optimal factory default settings based on

system type, capacity and other conguration considerations.

Boot-up Screen

When power is applied to the system, the HD Display will display a welcome

screen.

If there is an issue with communication between any components attached to

the thermostat, a critical alert message will appear on the screen. The alert

message will provide detail information concerning the possible cause. Once

the issue is corrected and power is restored to the system the rst screen in

the initial commissioning sequence will appear.

Low Battery Status

If a critical low battery screen is displayed, the system will automatically start

charging the HD Display internal battery. On the screen the word “charging”

will appear. Once “charging” disappears (typically 3 to 10 minutes) then the

display will automatically start-up.

Dealer Info and Language Selection

The rst screen in the commissioning sequence is the dealer information

screen and language selection tool. Supported languages are English, French

and Spanish. The drop-down selection tool is located in the upper right-hand

corner of the screen.

Dealer information and/or phone number can be added. Once the system

is connected to the Internet, the remaining information will be populated

automatically by the Allied Air server based on the dealer information or phone

number entered. All information can be entered manually if desired however.

Information that can be manually entered is name, email website, dealer

address which includes address 1, address 2, city, state and zip/postal code.

Once completed touch continue.

Warning Screen

If either the Dealer Information or phone number is NOT provided, a warning

screen will appear. The warning screen will provide information on the limitation

imposed on the system if this information is not provided. Touch no to return

to the previous screen to complete the information requested or touch yes to

continue.

16

General Information

On this screen general information needs to be veried or changed. Touch

any item to change its contents. A pop-up screen will appear that will allow the

information to be added or changed.

1. Select country / region.

2. Select time and date which includes time, date, time zone and daylight

savings time (ON/OFF).

IMPORTANT

Time and date will be auto corrected when the system is connected to

Internet. When connected to Internet, time and date can not be adjusted.

3. Temperature unit (Fahrenheit or Celsius).

4. Once completed touch continue.

Equipment Found Screen

This screen will display any Comfort Sync

®

equipment the system has detected

(air handler, furnace, outdoor unit, Smart Hub and Comfort Sync

®

Zoning

system during initial commissioning of the system.

NOTE: When a Equipment Interface Module (EIM) is used and congured as

either a furnace or air handler, then the component would appear as

either EIM-Furnace or EIM-Air Handler. When using a EIM the outdoor

unit may be either an Allied Air Comfort Sync

®

A3 or any standard

24VAC non-communicating thermostat.

NOTE: Not all equipment may be visible from the equipment found system

screen. Touch and swipe up to access additional information (if

applicable) listed at the bottom of the system box.

If non-communicating equipment needs to be added, it can be done so from

this screen.

Non-Communicating Equipment

When selecting the non-communicating (24VAC) equipment icon a screen will

appear listing equipment that can be added. When selecting an applicable

component, a green check will appear next to the item. The capacity selection

of the outdoor unit will also be displayed on the screen after selecting the

applicable outdoor equipment type.

NOTE: A temporary dialog box will appear indicating: Updating - Wait while

we check for dependencies.

NOTE: Selecting an outdoor unit type only appears if a Comfort Sync

®

outdoor

unit is not detected by the system. Selections are one or two-stage

heat pumps or air conditioners. Outdoor unit capacity will also have to

be set. Other non-communicating equipment that can be added are:

» Humidiers

» Dehumidiers

» Auxiliary Dehumidier

» Fresh Air Damper

» 1 or 2 Speed ERV (energy recovery ventilation)

» 1 or 2 Speed HRV (heat recovery ventilation)

Once completed touch done which will display the equipment found screen.

There the additional non-communicating equipment will now be displayed

along with the Comfort Sync

®

equipment. Once completed touch continue.

Reminders

This screen allows you to set reminders as either disabled or 3, 6, 12 or 24

months and also custom by specic date. The other options on this screen is to

trigger the reminder event either by calendar or actual system run-time.

Reminders may be set for Replace lter 1, Replace lter 2, Replace UV bulb,

Replace humidier pad, Maintenance reminder, Ventilation maintenance and

Ventilation lter.

Once a reminder is set for a specic item, touch done to return to the previous

screen. An “expires on date” will appear next to the item just set.

Comfort Sync

®

Zoning

This screen will only appear if the Comfort Sync

®

Zoning is detected. This

screen allows you to rename each zone. You may use the preset names or

any custom name you may desire. If zoning is not applicable, proceed to the

next section.

1. Touch on any zone to rename it. A screen will display that list several

predened names that can be used which are master bedroom, guest

bedroom, kitchen, living room, media room, dining room, library or custom.

When a predene name is selected, a green check-mark will appear next

to the selected name.

2. When creating a custom name, touch custom, enter a name and touch

back to return to the previous screen. A new unique zone name can be

created for all four zones.

3. When completed, touch done to return to the zoning screen and verify the

new name is being used for the specic zone.

4. Once completed touch continue.

17

Setup Airow Per Zone

This screen will allow the installer to setup the airow per zone. The types of

circulation per zone are:

• Blower Circulation Airow (gray) which includes total, assigned, minimum

and maximum airow.

• Heating Circulation Airow (red) which includes total, assigned, minimum

and maximum airow.

• Cooling Circulation Airow (blue) which includes total, assigned, minimum

and maximum airow.

1. Touch on the circled green arrow to touch a specic zone. The that zone

settings will expand to allow the installer to adjust CFMs for each circulation

airow type. Use the plus and minus buttons to adjust CFMs up and down.

2. Once completed touch to continue. The next screen that will appear is the

Dealer Control Center.

Commissioning Completion

Once commissioning is completed, the system will leave you at the Dealer

Control Center. You can either touch exit to go to the main screen or perform

any function listed in the various categories displayed.

Dealer Control Center

This menu provides access for the installer or service technician to perform various functions. Advance equipment congurations, notications, tests, diagnostics,

installation reports and general information about the system.

dealer

control center

equipment

tests

notifications

information

diagnostics

exit

Use to make changes to equipment settings and add or remove

non-communicating equipment or accessories. In addition the reset all

equipment option is available. This will allow the installer to reset all

equipment and reconfigure.

Use to display

system notifications

Use to run test on

system components

Use to run

diagnostics on

system components

Use to display

system information

Exit to Home

screen.

To navigate back to the dealer control center,

touch on the center icon when available

on the top left-hand side of the screen.

<

<

To navigate back to the previous screen, touch

on the left arrow when available.

“Previous Screen

Name”

installation

report

Used to display installation results.

NOTE: This report is not available until after

exiting the dealer control center following the

commissioning procedure. Exit and return to

the dealer control center to view the installation

report.

Figure 15. Dealer Control Center

18

EquIpmEnt paramEtErS

Selections listed in this section are dependent on system hardware conguration. Not all options listed in this section will be available.

NOTE: When changing the default settings for any parameter, there is a possibility that it will affect the settings for another parameter. If this happens, a pop-up

message will be displayed listing the other affected parameters and their new automatically set values.

The following is a complete list of all possible parameters listed under System. Parameters actually available are dependent on the Allied Air communicating

equipment type detected and non-communicating equipment added.

Table 5. Smart Hub Parameters

Parameter

(In alphabetical

order)

Description

About

This screen provides information concerning language supported, equipment type name, control software revision, model, control

mode number, control serial number, control hardware revision, protocol revision number, device product level, 24VAC average power

consumption, 24VAC peak power consumption, compatible devices list, application code memory size and micro-controller part

number.

Auto Changeover

- Humidif.

Deadband

Prevents the Humidication and Dehumidication settings from being closer together than 5% or greater than 10% (Dead-band).

Range is 5 to 10%. Default is 5%. Adjustments are in increments of 1%.

Auto Changeover

- Temp

Deadband

Prevents the Heating and Cooling from being set closer together than 3ºF (1.67°C) or greater than 9ºF (5.0°C) (Dead- band).

Range is 3 to 9°F (1.67 to 5.0°C). Default is 3°F (1.67°C). Adjustments are in increments of 1°F (0.56°C).

Auto

Dehumidication

Overcooling

Threshold

Adjustments are in increments of 1%. This value can automatically be affected by adjusting other parameters. One example would be

when enabling Max Dehumidication Overcooling.

Range is 0 - 10%. Default is 4%.

Aux Heating

Activation

Threshold

This is an adjustment to hasten or delay the aux heat activation. This adjusts how far below the set point the temperature must fall

with the HP at 100% before allowing electric heat to come on.

Range is 0 - 10°F (0.0 to 5.56°C) with increments of 0.25°F (0.14°C). The default setting is 2.5°F (0.83°C).

Denition/Dependencies:

Step Change versus Steady State Modes

• Outdoor temperature below the high balance point or with balance points disabled.

• Heat Pump demand above 95% for 10 minutes.

• Sixty (60) minute temperature rise prediction = less than this Parameter Setting (value)

Result:

The Heating Proportional Integral Algorithm (as set for less, normal, or more aggressive) will begin to stage on the electric heat to

bring the space temperature up to set point.

Synopsis: The LOWER this parameter is set, the quicker the auxiliary heating will respond, in both step change mode and steady

state mode.

19

Table 5. Smart Hub Parameters

Parameter

(In alphabetical

order)

Description

Balance Point Control

If system is set up as dual fuel or heat pump with electric heat and a outdoor temperature sensor connected to Smart Hub, the low and high balance point

settings will appear. The balance points feature requires that a sensed outdoor temperature is provided to the thermostat. The outdoor ambient temperature

can be read from either a:

• Field-installed outdoor temperature sensor (X2658).

• Communicating heat pump. All communicating heat pumps have a factory-installed outdoor temperature sensor.

Options are enabled or disabled. Default is disabled. When enabled, both low and high balance points can be set.

High Balance Point

This setting is used to prevent the furnace or electric heat from heating the structure. (Alert 19 - Minor - Notication only - The outdoor

temperature is higher than the level where the furnace or electric heat is programmed to heat the home.)

Range is -17 to 75°F (-27.22 to 23.89°C). Default is 50°F (10.0°C). Adjustments are in increments of 1°F (0.56°C).

Low Balance Point

Setting used to prevent the heat pump from heating the structure. (Alert 18 - Minor - Notication only - The outdoor temperature is

below the level where the heat pump is programmed to heat the home).

Range is -20 to 72°F (-28.89 to 22.22°C). Default is 25°F (-3.89°C). Adjustments are in increments of 1°F (0.56°C).

NOTE: Dual-Fuel Applications (Communicating Systems Only) - Dual fuel applications, which include both a Heat Pump and a gas

furnace, will provide multiple stages of heating. For example, a two−stage heat pump would deliver two stages of heat. The gas

furnace can add two to four more stages of heat.

CFA Cooling

Discomfort

Threshold

Default is ON. The purpose of this algorithm when set to ON is to detect systems with faults which are causing measurable loss of

comfort and thus, need repair/service intervention.

The algorithm monitors the duration in which the indoor temperature is above the cool set point or below the heat set point and does

not approach the set-point. When an issue is detected alarm 901 is activated.

Cooling Mode

Options are Normal and Comfort. Default is Normal. When changing to Comfort Mode, several parameters are automatically modied

for optimal system operations. The changed parameters are listed on the screen when set to Comfort.

• Normal - This setting cools the home to the desired temperature setting. Once second-stage is activated by timer or differential, it

will not stage down to rst-stage until the next cooling cycle demand.

• Comfort - This is when the system could automatically stage up or down based on the current load demand.

Cooling

Prognostics

This algorithm will determine whether the unit will run out of capacity during the hottest time of summer. It will look back everyday

a minimum of three days to see if there is a pattern and compare it to the hottest day on record for that zip code before triggering

an notication. It must see a pattern before it will trigger the notication. There may be a component or components that will require

attention.

The sensitivity (threshold) selection options are OFF, LOW, MEDIUM, and HIGH. The default is HIGH. The alert code notication is

65545.

DAT Integral

Gain

(Allied Air Variable

capacity Outdoor

Units Only)

The indicates how stable the system is attempting to reach the discharge air temperature set point. You may hear the compressor

hunting (ramping up and down) adjusting to lower setting will correct.

Allied Air advises not to make changes to this setting without rst contacting Allied Air technical support or Allied Air eld technical

consultant.

Default is 3.0. Range is 1.0 to 15.0 in increments of 0.5.

DAT Offset

This parameter is only available when an Allied Air variable capacity outdoor units is installed along with a discharge air temperature

sensor (DATS) Installed is used.

Default is 0.0°F (0.0°C). Range is -5.0°F to 5.0°F (-2.88 to 2.78°C) in increments of 0.5°F (0.28°C).

20

Table 5. Smart Hub Parameters

Parameter

(In alphabetical

order)

Description

DAT Proportional

Gain

(Allied Air Variable

capacity Outdoor

Units Only)

This is how the system attempts to reach the discharge air temperature set point.

Allied Air advises not to make changes to this setting without rst contacting Allied Air technical support or Allied Air eld technical

consultant. Default is 3.0. Range is 1.0 to 15.0 in increments of 0.5.

Dew Point

Adjustment

These settings allow adjustments to the Dew Point setting for the home. Some homes may require an adjustment to help maintain

comfort. If condensation is present on windows, set the adjustment lower, between -15% to -5%. If the home feels dry, set the

adjustment upwards, between +5 to +15%.

Range is -15 to 15°F. Default is 0°F. Adjustments are in increments of 1°F.

NOTE: Dew Point - Adjustment requires an outdoor air (temperature) sensor (OATS) (X2658) and is automatically controlled by the

outside temperature.

Electric Heat

Control Mode

(Single and Two-Stage

Allied Air Communicating

Outdoor Units Only)

In heat pump applications, the electric heat is staged to provide supplemental heat to meet desired comfort levels. When the electric

heat section is used in applications that do not have a heat pump, the elements are staged to limit heat so that it meets heating

demands only.

Electric Heat

Stages During

Defrost

Can increase or decrease the number of electric elements to come on during a call for defrost. (Thermostat will have a demand for

heat.) Range is 0 to 5 electric heat stages. Default is 2. Adjustments are in increments of 1.

NOTE: Selecting 0 will not allow any electric heat stages during defrost.

Electric Heating

Activation

Hold Time

This parameter represents the amount of time the system waits to check the slope of the temperature against the value in “Aux

Heating Activation Threshold” parameter. It checks the room temperature slope after a time to determine if aux heat is needed to

achieve a new room temperature set point) to allow the heating PI to accumulate past 100 (up to 200) which allows electric auxiliary

heat use. Range is 0~15 minutes with a default of 10 minutes. Increments are in 1 minute intervals.

Equipment

Name

A unique name can be assigned to this component. Name can be up to 29 characters. Name can consist of letters, numbers, special

characters and spaces. Default name is subnet controller.

Gas Heat Control

Mode

Options are Staged, Load Tracking Variable Capacity and Variable Capacity. Default is Load Tracking Variable Capacity

Staged: Some furnaces can be congured to provide up to four stages of gas heat operation. When staged heating is chosen, the

Comfort Sync

®

thermostat allows you to choose between 1, 2, 3 and 4 stages of heat. Single-stage heat: rst stage provides 100% of

full capacity.

• Two-stage heat: First stage provides 70% of full capacity; 2nd stage provides 100% of full capacity.

• Three-stage heat: First stage provides 60% of full capacity; 2nd stage provides 80% of full capacity; third stage provides 100% of

full capacity.

• Four-stage heat: First stage provides 35 or 40% of full capacity; second stage provides 60% of full capacity; third stage provides 80%

of full capacity; fourth stage provides 100% of full capacity.

Load Tracking Variable Capacity: Load tracking variable capacity will smoothly track the load (sensible temperature changes) up

and down and adjust the furnace heating rate both ways.

Variable Capacity: Variable capacity only tracks the load upward (rising temperature). Variable capacity uses the thermostat stage

differentials but not stage timers.

21

Table 5. Smart Hub Parameters

Parameter

(In alphabetical

order)

Description

Gas Heating

Activation Temp

Difference

(Allied Air Variable

capacity Heat Pumps)

When the system is dual-fuel and steady state while operating at full HP demand, this is the amount of °F (°C) below the set point that

is allowed before allowing to switch to gas heat.

Range is 0.5 to 10°F (0.0 to -5.56°C). Default is 1.5°F (1.30°C). Adjustments are in increments of 0.5°F (0.14°C).

Heat Cool Stages Locked In

Heat Cool (H/C) Stages Lock in default is disabled (heat/cool stages are turned off separately). If changed to Enabled, heat/cool stages are turned off

together. For non-variable speed systems only.

H/C

Stages

Locked =

Enabled

H/C

Stages

Locked =

Disabled

POINTS:

2nd stage

ON

2nd stage

OFF

1st stage

ON

1st stage

OFF

2nd stage

ON

2nd stage

OFF

1st stage

ON

1st stage

OFF

SP -1.5 SP -1.0 SP -0.5

SP

SP +1.5SP +1.0 0.2+ PS5.0+ PS

Stg1 Differential

Stg2 Differential

Stg2 Differential

Stg1 Differential

Cooling (1- and 2-Stages)

H/C

Stages

Locked =

YES

H/C

Stages

Locked =

NO

1st stage

ON

2nd stage

ON

1st stage

ON

2nd stage

ON

2nd

stage

OFF

1st

stage

OFF

1st

stage

OFF

2nd stage

OFF

SP -1.5SP -1.0 SP -0.5

SP

SP +0.5SP -2.0

Stg1 Differential

Stg2 Differential

SP -2.5SP -3.0

Stg1 Differential

Stg2 Differential

POINTS:

Heating - Non-Heat Pump or Heat Pump w/o backup heat - 1 or 2 stages

22

Table 5. Smart Hub Parameters

Parameter

(In alphabetical

order)

Description

H/C

Stages

Locked =

NO

H/C

Stages

Locked =

YES

POINTS:

3rd stage

ON

1st stage

ON

2nd stage

ON

3rd stage

ON

1st stage

ON

2nd stage

ON

2nd

stage

OFF

3rd stage

OFF

SP -1.5 SP -1.0 SP -0.5

SP

S

P

SP -2.0

Stg1 Differential

Stg3 Differential

Stg2 Differential

SP -2.5SP -3.0SP -3.5

Stg1 Differential

Stg3 Differential

Stg2 Differential

Heating - Heat Pump with Electric - 3 Stage

(2 compressor / 1 backup OR 1 compressor / 2 backup)

H/C

Stages

Locked =

Enabled

H/C

Stages

Locked =

Disabled

3rd stage

ON

1st stage

ON

2nd stage

ON

4th stage

ON

3rd stage

ON

1st stage

ON

2nd stage

ON

4th stage

ON

Stg4 Differential

2nd

stage

OFF

3rd stage

OFF

4th stage

OFF

5.0- PS0.1- PS5.1- PS:STNIOP SP S

P

SP -2.0

Stg1 Differential

Stg3 Differential

Stg2 Differential

SP -2.5SP -3.0SP -3.5

Stg1 Differential

Stg3 Differential

Stg2 Differential

Stg4 Differential

Heating - Heat Pump with Electric - 4 Stage (2 compressor / 2 backup)

H/C

Stages

Locked =

Disabled

abled

2nd stage

ON

1st stage

ON

2nd

stage

OFF

1st

stage

OFF

SP -1.5 SP -1.0 SP -0.5

SP

SP +0.5SP -2.0

Stg1 Differential

SP -2.5SP -3.0

Stg2 Differential

POINTS:

Heating - Dual Fuel - 2 Stage (1 compressor / 1 backup)

23

Table 5. Smart Hub Parameters

Parameter

(In alphabetical

order)

Description

H/C

Stages

Locked =

Disabled

H/C

Stages

Locked =

Enabled

POINTS:

3rd stage

ON

1st stage

ON

2nd stage

ON

3rd stage

ON

1st stage

ON

2nd stage

ON

SP -1.5 SP -1.0 SP -0.5

SP

S

P

SP -2.0

Stg1 Differential

Stg3 Differential

Stg2 Differential

SP -2.5SP -3.0SP -3.5

Stg1 Differential

Stg3 Diff.

Stg2 Differential

3rd

stage

OFF

Heating - Dual Fuel - 3 Stage (1 compressor / 2 backup)

H/C

Stages

Locked =

Disabled

H/C

Stages

Locked =

Enabled

POINTS:

3rd stage

ON

1st stage

ON

2nd stage

ON

3rd stage

ON

1st stage

ON

2nd stage

ON

2nd

stage

OFF

SP -1.5 SP -1.0 SP -0.5

SP

S

P

SP -2.0

Stg1 Differential

Stg3 Differential

Stg2 Differential

SP -2.5SP -3.0SP -3.5

Stg1 Differential

Stg3 Differential

Stg2 Differential

Heating - Dual Fuel - 3 Stages (2 compressor / 1 backup)

24

Table 5. Smart Hub Parameters

Parameter

(In alphabetical

order)

Description

Stg4 Diff.

H/C

Stages

Locked =

Enabled

H/C

Stages

Locked =

Disabled

3rd stage

ON

1st stage

ON

2nd stage

ON

4th stage

ON

3rd stage

ON

1st stage

ON

2nd stage

ON

4th stage

ON

Stg4 Differential

2nd

stage

OFF

4th

stage

OFF

5.0- PS0.1- PS5.1- PS:STNIOP SP S

P

SP -2.0

Stg1 Differential

Stg3 Differential

Stg2 Differential

SP -2.5SP -3.0SP -3.5

Stg1 Differential

Stg3 Differential

Stg2 Differential

Heating - Dual Fuel - 4 Stage (2 compressor / 2 backup)

Group ID

Multiple Smart Hubs in a home can be assigned to a group (up to nine groups with up to ve Smart Hubs in each group). All Smart

Hubs in a group can communicate with other Smart Hubs in the same group over the home Wi-Fi network.

If a Smart Hub is set to Group ID 0, there will be no connectivity with another Smart Hub.

Default Group ID is 1. Valid range is 0 to 9. (Recommend no more than 5 smart hubs per group. Doing so will eliminate possible Wi-Fi

bandwidth issues.)

HP Heating

Lockout Time

The HP could not get a zone to progress 0.5 degrees towards the set point in 120 minutes (Alert Code 40 - Minor alert). System will

switch to secondary heat source. (Electric heat or furnace in dual fuel applications). Transition back to Heat Pump normal operation

when termination setting times out.

Range is 60 to 240 minutes. Default is 60 minutes. Adjustments are in increments of 30 minutes.

HP Heating

Mode

(Allied Air Variable

capacity Heat

Pumps Only)

Options are Normal and Comfort. Default is Normal. The normal setting heats the home to the desired temperature setting. Modify the

heating comfort mode to limit minimum compressor speed to 60 – 70 percent range and/or adjust comfort mode CFM.

• Normal is when the heat pump will heat the home will providing the highest efciency.

• Comfort is when the heat pump will deliver warmer air for comfort, but sacrices on efciency.

Comfort Adjust

Options are Maximum Overcooling, Midpoint Overcooling and Minimum Overcooling. Default is Maximum Overcooling.

• Maximum Overcooling: Indoor temperature > (greater than) two degrees above heating setpoint.

• Midpoint Overcooling: Indoor temperature > (greater than) HEAT setpoint + COOL setpoint / 2.

• Minimum Overcooling: Indoor temperature > (greater than) two degrees below cooling setpoint.

Humidity Reading

Calibration

If it is determined that the actual humidity percentage being detected at the thermostat is off based on independent readings using

other humidity reading devices, the display can be adjusted using this setting.

Range is -10.0 to 10.0%. Default is 0.0%.

25

Table 5. Smart Hub Parameters

Parameter

(In alphabetical

order)

Description

Lock In 2nd

Stage HP by

Outdoor Temp

(Allied Air Two-Stage

Communicating Heat

Pumps Only)

This accessory allows the unit to lock in second stage HP heating when the outdoor temperature goes below the jumper pin setting.

Options are off, 40°F (4°C), 45°F (7°C), 50°F (10°C) and 55°F (13°C). Default is off.

Max Heat

Setpoint

The highest temperature setting that the heat set point can be set on the thermostat. Default is 90.0F (32.33°C). Range is 60.0 to

90.0°F (15.56 to 32.22°C). Adjustable in increments of 1°F (0.56°C).

Max

Humidication

Setpoint

This setting will limit the highest humidication setting on the thermostat. This parameter will only appear when a humidier accessory

is installed. Range is 15 to 45%. Default is 45%. Adjustments are in increments of 1%.

Min Cool

Setpoint

This setting will limit the lowest cooling temperature setting on the thermostat. Range is Range is 60.0 to 90.0°F (15.56 to 32.22°C).

Default is 60°F (15.56°C). Adjustments are in increments of 1°F (0.56°C).

Min

Dehumidication

Setpoint

This setting will limit the lowest dehumidication setting on the thermostat. Range is 40 to 60%. Default is 40%. Adjustments are in

increments of 1%.

Modulating

Cooling Cycles

Per Hour

(Allied Air Variable

capacity Outdoor Units

Only)

This feature is activated when the structure BTU load is less than the minimum outdoor unit cooling capacity of the outdoor unit. The

system will be cycled “ON” and “OFF” at the selected cycles per hour to maintain the settings of the thermostat. (This governs how

many cycles per hour the system will try to run when it needs to run at less than minimum capacity).

Range is 3 to 6 cycles hours. Can be adjusted in increments of 0.5. Default is 4.

Understanding Modulating Step Change and Steady State PI Gains

Each of these terms has a multiplier (or gain) associated with it called the proportional gain and the integral gain respectively and affect responsiveness and

stability

• Standard is a moderate gain suitable for nearly all installations.

• More Aggressive is a set of slightly higher gains that will make the system more responsive to changes, and will try harder to stay on the set point. This

setting may cause some systems to oscillate.

• Less Aggressive is a set of slightly lower gains that will make the system less responsive and help to stabilize an oscillating system by sacricing a small

amount of time to set point.

None of the above options will cause the system to end a call if the demand for heating or cooling remains above the minimum capacity of the system since

the algorithm is designed to nd the demand that allows the system capacity to exactly match the house heating or cooling loss, creating a balance and

constant temperature.

Modulating

Cooling Step

Change PI Gain

(Allied Air Variable

capacity Outdoor Units)

Step change gains deal with set point changes and affects how fast the system reaches the next set point.

Options are less aggressive, standard and more aggressive. Default is standard.

Modulating

Cooling Steady

State PI Gain

(Allied Air Variable

capacity Outdoor Units

Only)

Steady state gain controls the demand when the system is not responding to a sensed temperature change away from the Comfort

Sync

®

A3 thermostat setting.

Options are less aggressive, standard and more aggressive. Default is standard.

26

Table 5. Smart Hub Parameters

Parameter

(In alphabetical

order)

Description

Modulating Gas

Heating Cycles

Per Hour

This feature is activated when the structure BTU load is less than the minimum Heat Pump heating capacity of the outdoor unit. The

system will be cycled “ON” and “OFF” at the selected cycles per hour to maintain the settings of the Comfort Sync

®

A3. (This governs

how many cycles per hour the system will try to run when it needs to run at less than minimum capacity.