Clean Power

Quadrennial Technology Review 2015

Chapter 4: Advancing Clean Electric Power Technologies

Technology Assessments

Advanced Plant Technologies

Biopower

Carbon Dioxide Capture and Storage

Value-Added Options

Carbon Dioxide Capture for Natural Gas

and Industrial Applications

Carbon Dioxide Capture Technologies

Carbon Dioxide Storage Technologies

Crosscutting Technologies in Carbon Dioxide Capture and

Storage

Fast-spectrum Reactors

Geothermal Power

High Temperature Reactors

Hybrid Nuclear-Renewable Energy Systems

Hydropower

Light Water Reactors

Marine and Hydrokinetic Power

Nuclear Fuel Cycles

Solar Power

Stationary Fuel Cells

Supercritical Carbon Dioxide Brayton Cycle

Wind Power

ENERGY

U.S. DEPARTMENT OF

Clean Power

Clean Power

Quadrennial Technology Review 2015

1

Quadrennial Technology Review 2015

Supercritical Carbon Dioxide

Brayton Cycle

Chapter 4: Technology Assessments

Introduction

e vast majority of electric power generation for the grid is accomplished by coupling a thermal power cycle

to a heat source. e nature and conguration of the thermal power cycle is designed so as to give as ecient

power production as is economically attractive. Much of the DOE R&D portfolio is focused on improving the

overall eciency and economics of electric power generation. To that end, there are three primary areas of

focus for R&D to improve electric power generation eciency: (1) increasing the fraction of the energy in the

heat source that can be harvested for use in the thermal power cycle; (2) increasing the intrinsic eciency of

the thermal power cycle; and (3) decreasing the parasitic power requirement for the balance of plant (BOP).

As will be discussed further below, the rst two focus areas cannot be pursued in isolation as they are oen

antagonistic. For example, recuperative heat exchange within the thermal power cycle can oen lead to a higher

cycle eciency but this may be at the expense of decreasing the amount of heat that can be transferred into the

cycle and lowering the overall process eciency.

Most of the thermal power cycles in commercial operation are either air-breathing direct-red open Brayton

cycles (i.e., gas turbines) or indirect-red closed Rankine cycles which use water as a working uid (typical in

pulverized coal and nuclear power plants). Within each group are a myriad of potential congurations that vary

in size and complexity. For any application, the best thermal power cycle will depend on the specic nature of

the application and heat source.

In addition to these conventional thermal power cycles, cycles based on other working uids can be considered.

In particular, the Brayton cycle based on supercritical carbon dioxide (sCO

2

) as the working uid is an

innovative concept for converting thermal energy to electrical energy.

Numerous studies have shown that these sCO

2

power cycles have the potential to attain signicantly higher

cycle eciencies than either a conventional steam Rankine cycle or even the state-of-the-art ultra-supercritical

(USC) steam Rankine cycle.

1,2,3

Higher cycle eciency will automatically lead to lower fuel cost, lower water

usage, and in the case of fossil fuel heat sources, lower greenhouse gas (GHG) emissions. Further, the sCO

2

cycles operate at high pressures throughout the cycle, resulting in a working uid with a high density which

may lead to smaller equipment sizes, smaller plant footprint, and therefore lower capital cost. Achieving the full

benets of the sCO

2

cycle will depend on overcoming a number of engineering and materials science challenges

that impact both the technical feasibility of the cycle as well as its economic viability.

As will be discussed in greater detail below, the main R&D challenges arise from the very factors that lead to

higher cycle eciency. ese include the use of: (1) elevated pressures throughout the cycle; (2) large duty heat

exchangers to minimize the energy lost in cooling the working uid; and (3) CO

2

as the working uid. R&D

will be needed to develop high eciency CO

2

expansion turbines. ese turbines oer the promise of relatively

Clean Power

Quadrennial Technology Review 2015

2

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

small size because of the low turbine pressure ratio and the high density of the working uid, but this will be

partially oset by the much higher mass ow rates required and the corrosion properties of high pressure CO

2

.

R&D will be required on seals, bearings, and materials, particularly in applications having elevated turbine inlet

temperatures. R&D will also be needed to develop low cost heat exchangers that are able to attain large heat

transfer duties with small temperature dierences between the hot and cold sides of the exchanger and with a

small pressure drop. is will require R&D into compact heat exchanger designs, assessment of materials for

suitability given the temperatures and pressures required, and advances in manufacturing techniques.

Brayton Cycles based on CO

2

as the working fluid

Power cycles using sCO

2

as the working uid take on two primary congurations relevant to power generation:

1) an indirect-red closed Brayton cycle that is applicable to advanced fossil fuel combustion, nuclear, and solar

applications; and 2) a semi-closed, direct-red, oxy-fuel Brayton cycle well-suited to fossil fuel oxy-combustion

applications with CO

2

capture. ese cycles are described in greater detail in the following sections.

Simple Indirect-fired Brayton Cycle

Figure 4.R.1 shows a block ow diagram for the simple indirect-red Brayton cycle. A working uid, which

may be a pure substance or a mixture, circulates between a compressor and an expansion turbine. ermal

energy is added to the working

uid just prior to the expansion

turbine and a cooler is required

to lower the temperature of the

working uid aer expansion

to the desired inlet temperature

to the compressor. In an ideal

cycle, with an ideal gas working

uid and no irreversibility in

the cycle, the cycle eciency

depends only on the cycle

pressure ratio and increases

monotonically with the

pressure ratio.

4

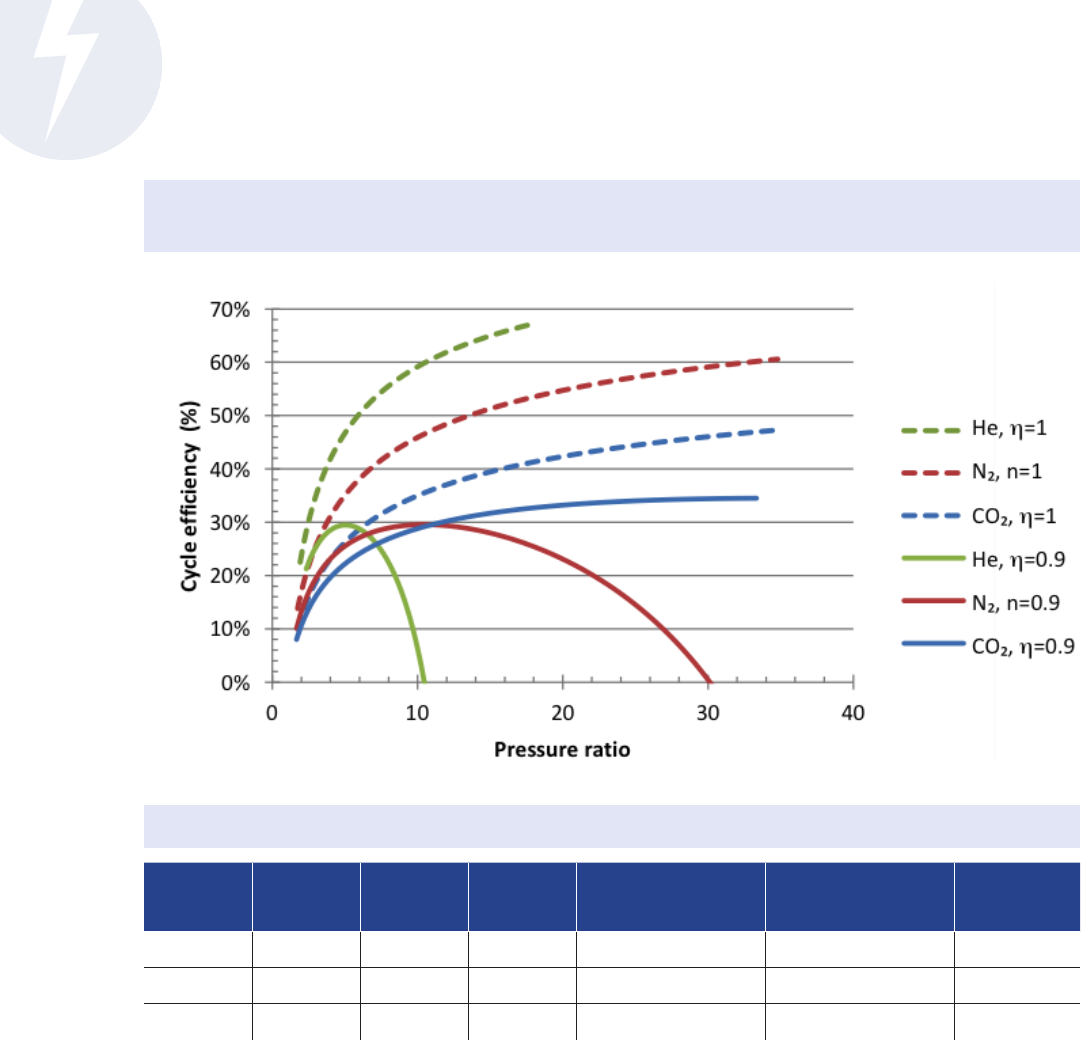

For non-ideal cycles, the cycle

eciency as a function of

pressure ratio passes through

a maximum at some pressure

ratio which depends on the

working uid. Figure 4.R.2

shows the cycle eciency as a

function of pressure ratio for three dierent working uids with an arbitrary turbine inlet temperature of 700°C.

e dashed lines in the gure correspond to ideal cycles in which the turbomachinery isentropic eciency (η)

is 1 and the solid lines correspond to a non-ideal cycle with turbomachinery isentropic eciencies of 0.9. For

each of these cases, heat and pressure losses were neglected so the cycle eciencies are optimistic. Note the

large decrease in eciency and the introduction of an eciency maximum for non-ideal cycles compared to

ideal cycles (see also Table 4.R.1).

Figure 4.R.1 Block Flow Diagram for Simple Brayton Cycle

Credit: NETL

Clean Power

Quadrennial Technology Review 2015

3

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Figure 4.R.2 Simple Brayton Cycle Efficiency. Plot of cycle efficiency versus pressure ratio for three different working fluids with ideal turbomachinery

(dashed lines) and non-ideal cycles with turbomachinery isentropic efficiencies (η) of 0.9.

5

Credit: NETL

Table 4.R.1 Non-ideal Simple Brayton Cycle Performance

6

and Working Fluid Properties

7,8

Working

uid

T

c

(K) P

c

(bar) c

p

/c

v

Pressure ratio at

maximum eciency

Turbine exit pressure

at maximum

eciency (bar)

Maximum

eciency (%)

CO

2

304 73.8 1.289 34.9 82.7 34.5

N

2

126 33.9 1.4 10.5 1.0 29.5

He 5 2.3 1.66 5.0 1.0 29.5

Another interesting aspect of the Brayton cycle based on CO

2

is that the cycle eciency is strongly dependent

on the minimum pressure in the cycle. Figure 4.R.3 shows the maximum cycle eciency as a function of

turbine exit pressure for three dierent working uids with an arbitrary turbine inlet temperature of 700 °C

and turbomachinery isentropic eciencies of 0.9. For N

2

and He, the cycle eciency decreases monotonically

as the turbine exit pressure increases. For CO

2

, however, the cycle eciency shows a maximum of 34.5% when

the turbine exit pressure is approximately 82.7 bar (right vertical dashed line in Figure), a bit above the critical

pressure of 73.8 bar (le vertical dashed line in Figure). Note also that for a turbine exit pressure of 1 bar, the

maximum cycle eciency is nearly the same for all three working uids.

Clean Power

Quadrennial Technology Review 2015

4

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Figure 4.R.3 Maximum Simple Brayton Cycle Efficiency varies strongly with turbine exit pressure for CO

2

. Plot of cycle efficiency versus turbine exit pressure

ratio for three different working fluids and turbomachinery isentropic efficiencies of 0.9.

9

Credit: NETL

A thermodynamic critical point, as shown in a Phase Diagram (see Figure 4.R.4

10

) is the end point of a phase

equilibrium curve. e end point of the pressure-temperature curve is of interest because this point designates

conditions where a liquid and its vapor can coexist.

11

Table 4.R.1 lists the critical temperature (T

c

) and critical

pressure (P

c

) for CO

2

, N

2

, and Ar. e key property of a uid near its critical point is its higher gas phase

density, closer to the density of a liquid than of a gas. With the CO

2

near the critical pressure at the point of

entrance to the compressor, its

density will be relatively high

and the power requirement

for compression will be lower.

is directly increases cycle

eciency. Another advantage

to maintaining the working

uid above the critical pressure

is that the high uid density

throughout the cycle will

lead to relatively high power

density which is expected

to signicantly decrease the

footprint and capital cost of

the major pieces of equipment,

although this may be oset by

the need to utilize stronger and

more expensive materials.

Figure 4.R.4 CO

2

Phase Diagram

Credit: Wikimedia Commons

Clean Power

Quadrennial Technology Review 2015

5

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Recuperated Indirect-fired Brayton Cycle

A more advanced version of

the indirect-red Brayton

cycle incorporates thermal

recuperation. A block ow

diagram for such a cycle is

shown in Figure 4.R.5. e

only change in the cycle is

the introduction of a heat

exchanger between the

expander exhaust and the

compressor exhaust. is

heat exchange improves the

cycle eciency by reducing

the amount of heat lost in the

CO

2

cooler and increasing

the amount of working

uid that can pass through

the cycle for any specied

amount of thermal input.

A byproduct of this eect

is that the pressure ratio for

maximum cycle eciency is

considerably lower than for

simple indirect-red Brayton cycles. Figure 4.R.6 shows the cycle eciency as a function of pressure ratio for

three dierent working uids with a turbine inlet temperature of 700°C (recuperated Brayton cycle—RB). e

dotted curves show the cycle eciency for a simple or non-recuperated Brayton cycle (simple Brayton cycle—

SB). For all working uids, the recuperated Brayton cycle has a higher eciency than the corresponding

simple Brayton cycle over the entire range of feasible pressure ratios. e maximum feasible pressure ratio

for a recuperated Brayton cycle occurs at a much lower pressure ratio than for the simple Brayton cycle. is

maximum pressure ratio occurs

when the compressor outlet

temperature equals the turbine

exit temperature and further

recuperation is no longer

possible. For the recuperated

Brayton cycle, the point of

maximum cycle eciency

occurs at much lower pressure

ratios than for a simple Brayton

cycle. Although the CO

2

cycle

has the lowest maximum cycle

eciency, the eciency curve

is relatively at allowing for

more stable operation. Table

4.R.2 shows the maximum

cycle eciencies.

Figure 4.R.5 Block Flow Diagram for Recuperated Brayton Cycle

Credit: NETL

Figure 4.R.6 Recuperated Brayton Cycle Efficiency. Plot of cycle efficiency versus pressure ratio

for recuperated Brayton cycle (solid lines, RB) with three working fluids compared to the simple

Brayton cycle (dashed lines, SB).

12

Credit: NETL

Clean Power

Quadrennial Technology Review 2015

6

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Table 4.R.2 Recuperated Brayton Cycle Performance Compared to Simple Cycle Performance

14

Working uid

Recuperated Brayton Cycle Simple Brayton Cycle

Pressure ratio at

maximum eciency

Maximum eciency (%)

Pressure ratio at

maximum eciency

Maximum eciency (%)

CO

2

4.5 46.8 34.9 34.5

N

2

1.4 52.4 10.5 29.5

He 1.2 52.5 5.0 29.5

It is easy to show that for the recuperated indirect-red Brayton cycle, the cycle eciency increases with

increases in turbine inlet temperature and turbo-machinery eciencies, and decreases with increases in cycle

pressure drop, heat loss, and minimum approach temperature in the recuperator.

13

Recompression Indirect-fired Brayton Cycle

A secondary eect of having the minimum cycle pressure close to the CO

2

critical pressure is that it hampers

the eectiveness of the recuperator somewhat. Near the critical point, the heat capacity of the CO

2

increases

signicantly and the hot CO

2

on the low pressure side of the recuperator does not have as high a thermal

capacitance as the cold CO

2

on the high pressure side of the recuperator. is limits the maximum temperature

that the recuperator can raise the high pressure CO

2

and acts to lower cycle eciency. One approach to mitigate

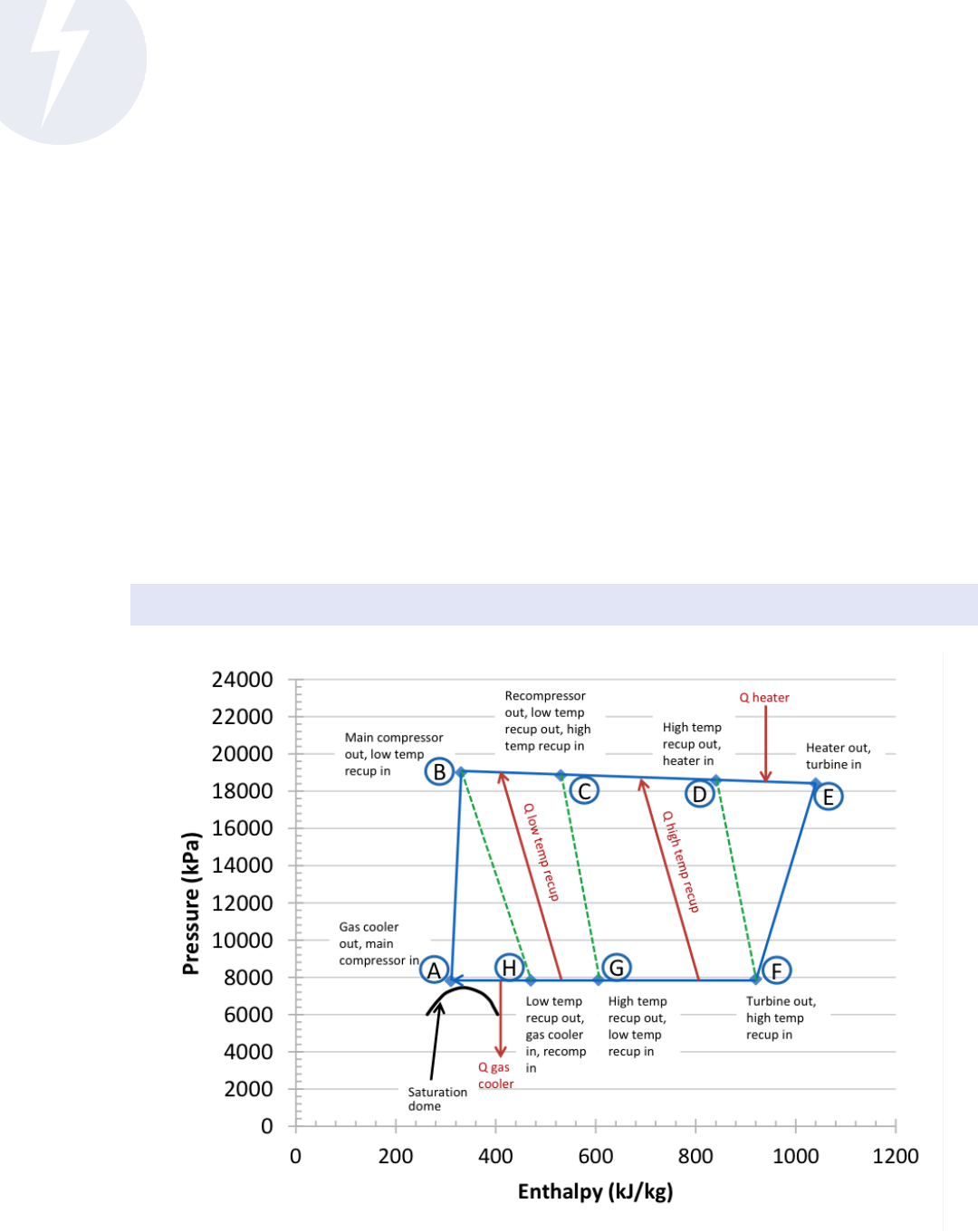

this eect is to use a recompression conguration for the cycle. Figure 4.R.7 shows the block ow diagram for the

recompression indirect-red Brayton cycle and Figure 4.R.8 shows the corresponding pressure-enthalpy diagram.

Figure 4.R.7 Block Flow Diagram for Recompression Closed Brayton Cycle.

15

The state points A through H are defined in Figure 4.R.8.

Credit: Sandia National Laboratories

Clean Power

Quadrennial Technology Review 2015

7

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

e labeled points A-H in Figure 4.R.8 correspond to state points in the recompression Brayton cycle and are also

depicted on Figure 4.R.7. e operating envelope shown in Figure 4.R.8 corresponds to a recompression sCO

2

Brayton cycle with a turbine inlet temperature of approximately 600°C and a cycle pressure drop of 700 kPa.

Points C-H in Figure 4.R.7 are the same as for the recuperated Brayton cycle. Where the recompression

cycle diers is downstream of point H. In this conguration, a portion of the low pressure CO

2

exiting

the recuperator bypasses the CO

2

cooler and is compressed to the maximum cycle pressure in a separate

compressor from the main CO

2

compressor. In addition to bypassing the CO

2

cooler, this stream bypasses

the low temperature portion of the recuperator. e net thermal eect is to provide a better match of

thermal capacity between the hot and cold sides of the recuperator and increase the overall eectiveness

of the recuperator. e disadvantage of this conguration is that the cycle is more complex and an extra

compressor is required. While the total amount of power required for CO

2

compression actually increases in

this conguration, the net cycle eciency increase because more CO

2

can pass through the cycle for any given

thermal input. Note that in Figure 4.R.7, two dierent values of the temperature and pressure are shown for

state point A. ese correspond to two dierent scenarios for the CO

2

cooler: a wet cooling case using water as

the cooling medium, and a dry cooling case using air cooling. e dry cooling case has a lower eciency than

the wet cooling case but the eciency reduction could be reduced by increasing the minimum cycle pressure.

Figure 4.R.8 Pressure Enthalpy Diagram for Recompression Closed Brayton Cycle.

16

The state points A through H are analogous to those shown in Figure 4.R.7.

Credit: Sandia National Laboratories

Clean Power

Quadrennial Technology Review 2015

8

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Figure 4.R.9 compares the cycle eciency of the recompression CO

2

Brayton cycle (RCBC) with the

recuperated Brayton cycle (RB) for CO

2

with a turbine inlet temperature of 700°C. e recuperated cycle

eciency curves for N

2

and He are also shown for comparison. For N

2

and He, the working uid is not near the

critical point at the exit of the cooler and so a recompression cycle oers no benet.

For CO

2

, at the pressure ratio of maximum cycle eciency, the eciency of the recompression cycle is over 5

percentage points higher than the recuperated Brayton cycle. Table 4.R.3 compares the maximum cycle eciency

for the recompression Brayton cycle compared to the recuperated Brayton cycle for the three working uids.

Figure 4.R.9 Recompression Brayton Cycle Efficiency.

17

Plot shows cycle efficiency versus pressure ratio for RCBC (solid line) and Recuperated Brayton Cycle

(dashed lines, RB).

Credit: NETL

Table 4.R.3 Recompression Brayton Cycle Performance Compared to Recuperated Cycle Performance

18

Working uid

Recompression Brayton Cycle Recuperated Brayton Cycle

Pressure ratio at

maximum eciency

Maximum eciency (%)

Pressure ratio at

maximum eciency

Maximum eciency (%)

CO

2

4.4 52.1 4.5 46.8

N

2

1.4 52.4 1.4 52.4

He 1.2 52.5 1.2 52.5

Clean Power

Quadrennial Technology Review 2015

9

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Recompression sCO

2

Brayton Cycle versus Rankine Cycle

A direct comparison of the conventional Rankine cycle with the RCBC is dicult because the Rankine cycle

is an established and mature technology and has undergone a century of development and renement. e

state-of-the-art in Rankine cycles today is the ultra-supercritical (USC) cycle having a main steam pressure of

250-290 bar and temperature of 600°C with a reheat temperature of 620°C. Since there are no commercial scale

power plants based on the RCBC, any comparison must be based on assumptions about the operating point.

Although the nature of these two cycles is dierent, they both exhibit an increase in eciency as the turbine

inlet temperature increases. However, the magnitude of that increase will be dierent for the two cycles and

hence each cycle will have a range of turbine inlet temperatures over which its eciency is higher than the

other cycle. ere have been some limited comparisons of the performance of these two power cycles in the

literature

19,20

and they consistently show that the RCBC has a higher cycle eciency at moderate to high values

of the turbine inlet temperature. e exact value of the turbine inlet temperature where the RCBC attains

a higher eciency will vary depending on the selected cycle congurations and assumptions used for the

operating state for the RCBC.

Figure 4.R.10 shows the results of a systems analysis performed at NETL comparing the RCBC with a Rankine

cycle having a single reheat. In this analysis the turbomachinery eciencies for the two cycles were made equal.

e results show the same trend as in prior studies and show that the RCBC has a higher eciency than the

Rankine cycle when the turbine inlet temperature exceeds approximately 425°C.

Semi-closed Direct-fired

Oxy-fuel Brayton Cycle

In addition to the indirect-red

cycles described previously,

direct-red Brayton cycles

using CO

2

as the working uid

are being actively investigated

for fossil energy applications.

Figure 4.R.11 shows a simplied

block ow diagram for this

cycle. e heat source is

replaced with a pressurized

oxy-combustor and hence, the

working uid is no longer high-

purity CO

2

. Since much of the

performance benet of sCO

2

cycles derive from the physical

properties of supercritical CO

2

,

the cycle eciency will decrease as the concentration of CO

2

decreases and hence a relatively pure and near

stoichiometric oxygen stream is advantageous. is will also have the benet of facilitating the capture of the

CO

2

generated during combustion, as part of a carbon capture and storage (CCS) process. e fuel for such a

system may be synthesis gas (syngas) produced by a coal gasier

23

or natural gas.

24,25

As with the indirect-red cycles, the working uid is recycled with thermal recuperation but the combustion

products must be removed from the working uid prior to the recycle. is is expected to be accomplished

through a cooling step to condense and remove water and a purge of a portion of the working uid to remove the

material introduced by combustion, including the CO

2

generated, excess oxygen, and other contaminants from

Figure 4.R.10 Comparison of Recompression Brayton Cycle and Rankine Cycle Efficiencies

21

Credit: NETL

Clean Power

Quadrennial Technology Review 2015

10

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Figure 4.R.11 Block Flow Diagram for Semi-closed sCO

2

Brayton Cycle

Credit: NETL

the oxidant or the combustion reactions. Semi-closed direct-red oxy-fuel Brayton cycles oer the possibility

for signicantly higher cycle eciencies than the indirect cycles due to the signicantly higher turbine inlet

temperature that can be achieved in a direct-red cycle. ey are also expected to have a higher power density

than the indirect-red cycles and will be simpler since a recompression bypass compressor is not needed.

Advanced sCO

2

Power Cycles

Both the indirect and direct sCO

2

power cycles are amenable to additional enhancements that can further

increase the cycle eciency. For example, the indirect cycle eciency may increase with the use of reheat

and/or compressor intercooling.

26

Some studies have suggested that lowering the CO

2

cooler pressure below

the critical pressure and condensing the CO

2

into a liquid state will increase cycle eciency since the power

required to pump a liquid is much less than the power required to compress a gas.

27

Cycle congurations have

also been proposed that will increase the range of temperatures over which heat can be harvested in the power

cycle. is may be particularly advantageous with fossil fuel heat sources.

Brayton Cycles based on Other Supercritical Fluids

e supercritical recompression Brayton cycle could utilize working uids other than CO

2

. However, several

factors limit the number of candidate uids for a practical power cycle. To maintain high uid density through

the compression phase, and hence high cycle eciency, the cooler must operate near the critical point of the

uid. Since cycle eciency will increase as the cooler temperature decreases, uids having a critical temperature

that can be attained with coolants readily-available for power plant use (e.g., ambient temperature water)

will have an advantage – in this regard, sCO

2

(critical temperature of 304K, or 87°F) is well-suited. Also, the

critical pressure must be well below the maximum pressure in the cycle and this further limits the number

Clean Power

Quadrennial Technology Review 2015

11

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

of candidates. When other factors such as safety, thermal stability, corrosion, and cost are factored in, the

number of candidate working uids is quite small. Although extensive analyses have been performed,

29

no

other potential working uids have been identied that are better candidates for the supercritical recompression

Brayton cycle than CO

2

for terrestrial applications.

sCO

2

Brayton Cycles – Summary and Application Areas

A number of Brayton cycle congurations using sCO

2

have been described and their performance

characteristics highlighted. sCO

2

Brayton cycles have a clear potential to attain higher cycle eciencies

than conventional steam Rankine cycles, non-supercritical Brayton cycles, or geothermal power cycles. is

is achieved primarily by selecting the cycle operating conditions to minimize the power requirement for

compressing the working uid and by using a high degree of thermal recuperation.

e range of potential applications for the indirect sCO

2

Brayton cycle is broad since it can be used in

essentially any application that currently uses a Rankine cycle. Generally, the operating conditions where the

recompression sCO

2

Brayton cycle attains its highest eciency requires a large degree of thermal recuperation.

is reduces the heat loss in the CO

2

cooler and allows the heat source to heat the maximum amount of

working uid and hence, generate the maximum amount of power output. A potential disadvantage of this

high degree of recuperation is that the temperature increase of the CO

2

in the heat source is relatively low. If

the hot source operates across a wide temperature range it will create challenges in maintaining high cycle

eciency without discarding a signicant portion of the available hot source energy. Many of the promising

applications for indirect sCO

2

Brayton cycles have heat sources that have a narrow temperature range. Examples

include applications with nuclear, solar, and geothermal heat sources. In each of these cases, the sCO

2

Brayton

cycle operating state can be congured to utilize the maximum amount of energy available from the hot

source. When the hot source temperature range is large, more complex modications to the cycle are generally

required. is may entail a higher degree of process-level heat integration, or reduction in cycle recuperation

to increase the amount of hot source energy that can be utilized in the cycle, or employing a more complex

cascade cycle conguration, or possibly using a combined cycle process in which the sCO

2

Brayton cycle serves

as the topping cycle and a Rankine cycle is used as a bottoming cycle. Conceptual designs have been proposed

for each of these alternatives.

30,31,32

e sCO

2

Brayton cycle can also be congured for direct heating which increases its range of potential

applications. e most promising application areas for direct cycles are with fossil fuel sources. Although it is

overall process eciency and not cycle eciency that will determine whether a given power generation system

is more ecient, for many applications it is straightforward to demonstrate that a higher cycle eciency will

lead to a higher process eciency. is is because the fraction of energy from the heat source that can be

harvested by the power cycle is generally not diminished with the sCO

2

Brayton cycle and there is generally not

an increase in the balance of plant auxiliary power required by the plant for the sCO

2

Brayton cycle compared

to Rankine cycles. Direct cycles also provide an intrinsic method to capture the water generated during

combustion, as liquid water which will partially oset the water withdrawal in a water-cooled application. Oxy-

red direct cycles for fossil fuel applications have the additional benet of facilitating CO

2

capture, signicant

given the EPA’s Carbon Pollution Standards, issued under the authority of Section 111(b) of the Clean Air Act

in August, 2015, that limit CO

2

emissions from new coal-red power plants to 1,400 lb CO

2

/MWh-gross.

33

Table 4.R.4 provides a listing of the major categories of applications for the sCO

2

Brayton cycle, the expected

cycle conguration, the peak temperature for the working uid, and the major benets the sCO

2

Brayton cycle

may potentially demonstrate in each application.

e principal benet of the sCO

2

Brayton cycle is the potential for an increase in both cycle and process

eciency compared to processes that employ Rankine cycles. An increase in process eciency has many

secondary benets including a reduction in the thermal input needed to generate a xed amount of power

Clean Power

Quadrennial Technology Review 2015

12

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Table 4.R.4 Potential Applications for sCO

2

for Power Conversion – Modified from Workshop

34

Application Cycle type Motivation

Size

[MWe]

Temperature

(°C)

Pressure

[MPa]

Nuclear Indirect sCO

2

Eciency, Size, Water Reduction 10 - 300 350 - 700 20 - 35

Fossil Fuel (PC, CFB, …) Indirect sCO

2

Eciency, Water Reduction 300 - 600 550 - 900 15 - 35

Concentrating Solar Power Indirect sCO

2

Eciency, Size, Water Reduction 10 - 100 500 - 1000 35

Shipboard Propulsion Indirect sCO

2

Eciency, Size <10 - 10 200 - 300 15 - 25

Shipboard House Power Indirect sCO

2

Eciency, Size <1 - 10 230 - 650 15 - 35

Waste Heat Recovery Indirect sCO

2

Eciency, Size, Simple Cycles 1 - 10 < 230 - 650 15 - 35

Geothermal Indirect sCO

2

Eciency 1 - 50 100 - 300 15

Fossil Fuel (Syngas, nat gas) Direct sCO

2

Eciency, Water Reduction, CO

2

Capture

300 - 600 1100 - 1500 35

which lowers the size and capital cost, and for some applications, also lowers the fuel usage and operating costs.

Increasing process eciency also diminishes the environmental footprint of the process by reducing water

usage and in the case of fossil fuel applications, reducing greenhouse gas emissions.

ere are other potential benets of the sCO

2

Brayton cycle as well although they remain to be demonstrated

as convincingly as the potential for higher process eciency. Because of the relatively high density of the

working uid, there is a potential for some of the unit operations to be smaller and less costly on a $/kWe basis.

However, not all of the properties of the sCO

2

Brayton cycle lend themselves to size and cost reductions. For

example, the sCO

2

Brayton cycle is more complex than the Rankine cycle, requires compressors instead of

feedwater pumps, and requires recuperators having larger heat duties than the heat source.

Another potential benet is that the sCO

2

Brayton cycle may prove to be more practical than the Rankine

cycle for air cooling in locations where water cooling is not available.

35

is is because the working uid cooler

in the sCO

2

Brayton cycle requires signicantly less air ow than an air-cooled condenser in a Rankine cycle

having the same cooling duty. However, this benet is achieved through reduction in the average driving force

for heat transfer in the cooler which would act to increase the required surface area for heat transfer and some

investigators have questioned the practicality of air cooling in the sCO

2

Brayton cycle.

36

With further analysis,

development, and demonstration, the impact of this technology on power plant costs and water usage will

become clearer.

In summary, the supercritical CO

2

based recompression Brayton cycle oers the opportunity to increase

cycle eciency compared to Rankine cycles and some other Brayton cycles and lead to power plants with

higher process eciency. CO

2

appears to be an ideal working uid because it has a critical point well-suited

to terrestrial applications with a moderate critical pressure and a critical temperature that is low enough to be

reached with ambient cooling when the wet cooling option is available. e supercritical CO

2

Brayton cycle may

be applied to direct-heating applications, with potential for high eciency and capture of process water - such

a cycle also facilitates CO

2

capture from the combustion process. When its availability and low cost are factored

in, no other substance is a more attractive working uid for the supercritical Brayton cycle.

While some progress has been made in researching and developing sCO

2

systems, signicant challenges remain

in areas such as material performance, manufacturing, economics, and reliability.

Clean Power

Quadrennial Technology Review 2015

13

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Technology Readiness and R&D Needs

Technology readiness is a function of the application (e.g., fossil, nuclear, concentrating solar thermal power,

geothermal), the cycle concept (indirect versus direct cycles), the operating temperature (e.g., high vs low

turbine inlet temperatures) and the plant scale (e.g., small 10 MWe systems vs large utility scale plants). Figures

4.R.7 and 4.R.11 illustrate block ow diagrams for the indirect and direct cycle. e system components

requiring research and development include CO

2

turbines, recuperators, and CO

2

heaters. e technology

readiness is grouped into three categories:

Mature components: cycle components that do not contact sCO

2

Less-mature components

System integration

R&D needs are discussed in the following categories: mature components, less-mature components, system

integration, and specic technology development needs.

Mature Components

In general, components that will not contact the sCO

2

working uid are mature technologies. Design

optimization appropriate for a given application would be required, but none of these components appear to

present an obstacle to commercial deployment, and they can be assumed to be reasonably predictable in their

cost, reliability, and performance. Mature subsystems and components include:

Electrical generation subsystem

Gearbox

Heat rejection subsystem

sCO

2

inventory control

Plant controls

Instrumentation

High power electronics

Less Mature Components

e immature components can be sub-grouped into the indirect cycle needs and the direct cycle needs. e

indirect cycle needs include the CO

2

turbine, the recuperators, and the CO

2

heater. In addition to the CO

2

turbine and recuperators, the direct cycle will require R&D on: (1) advanced pressurized oxy-combustion;

(2) extreme turbine inlet temperatures and associated challenges with turbine materials and blade cooling;

(3) more extensive thermal integration at the cycle and process level; (4) sub-critical CO

2

pumping and

compression; and (5) perhaps additional challenges in fuel processing.

CO

2

turbines

A signicant technology gap is that there are no utility-scale sCO

2

turbines and operational experience at any

scale is limited. e fundamental scientic basis and engineering tools for turbine and compressor design are

fairly mature and reliable. us, there are not expected to be any insurmountable obstacles but it still has to be

designed and tested. Compared to an air breathing turbine, the sCO

2

design must account for dierences in

heat capacity, density, viscosity, and acoustic properties. Particular challenges include materials, seals, corrosion,

erosion, and blade cooling (for turbine inlet temperatures greater than nominal 1400°F [760 °C]). e trade-

o between operating at a high turbine inlet temperature that promises high eciency and the development

challenge is an important system analysis consideration.

Clean Power

Quadrennial Technology Review 2015

14

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

e high density, high pressure, and rapidly changing material properties of CO

2

near the critical point

represents a relatively new and very dierent regime for turbomachinery design. e small-scale sCO

2

research

turbines and compressors developed to date have performed very close to the design maps generated from

rst principles and have operated eectively above and below the critical temperature without the typical

mechanical slugging that occurs with steam. erefore, it is anticipated that there will not be major surprises

in the turbomachinery design and operating eciency as the technology is scaled up to higher power levels,

but high quality designs and precision machining of both the compressor wheel and turbine wheel are essential

to achieving high component eciency and resulting high system eciency. Selecting the scale for testing

is also important in order to simplify turbomachinery scale-up. Figure 4.R.12 shows the eect of design on

turbomachinery capacity. A nominal 10 MWe capacity is selected as a pilot scale capacity to facilitate eective

scale-up.

Recuperators

Internal heat transfer through recuperation signicantly increases the eciency of a cycle with xed

turbomachinery conditions by reducing the amount of external heating and cooling required by the cycle. e

technical challenge is determining the optimal cycle design, balancing increases in eciency with the increased

system costs as more recuperation is added.

A major constraint to the design is to avoid a large pressure drop along each leg of the heat exchanger, while

pursuing high heat transfer eectiveness. e design must accommodate high operating temperatures and

pressures, and reductions in costs need to be demonstrated. In addition, maturing manufacturing processes will

be needed to address diusion-bonding techniques, investment-casting research, and in-service inspections as

it relates to manufacturing economics.

Figure 4.R.12 Ranges of Application for Key Brayton Cycle Turbomachinery Components and Features

37

Credit: Sandia National Laboratories

Clean Power

Quadrennial Technology Review 2015

15

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

CO

2

Heaters

More so than for any other component, the design of and associated developmental challenges of the CO

2

heater will depend on the individual application and heat source. Of particular importance to the heat source is

the temperature prole.

For indirect sCO

2

Brayton cycles, the nal stage of heating the CO

2

before it enters the turbine poses a similar

set of challenges as for recuperators. While analogs exist in the existing Rankine cycles, the CO

2

heater poses

additional engineering challenges. e heat capacitance of the CO

2

is much lower than water on a weight

basis. Compounding this problem is the fact that the average driving force for heat transfer (i.e., temperature

dierence between the hot side and cold side) in the CO

2

heater is expected to be much lower than the

comparable driving force in a Rankine cycle boiler. is means that the required heat transfer area will be much

greater. e need for a design that minimizes pressure drop is just as important for the CO

2

heater as for the

recuperators.

With indirect fossil-fueled combustors and bottoming cycle applications, the heat source temperature prole

will be very broad and the sCO

2

cycle conguration will need to allow for the absorption of sensible heat from

the ue gas down to a low level. Otherwise, a high cycle eciency will be wasted due to a low overall recovery.

In the direct-red cycles, the driving forces are expected to be much higher but so too will be the nal

temperature of the heated CO

2

. A perhaps more signicant challenge is designing the oxy-combustor for high

pressure operation with a minimum amount of excess oxygen.

System Integration

For any given application, system integration is an important development eort that will be needed to

optimize the operating and design parameters of the cycle and address start-up, shut-down, transient, and part-

load operation. Dynamic processes within the system, such as pressure surging, heat transfer and convection,

turbulent ow conditions, pressure waves, and acoustics must be considered for the integrated plant operation.

System integration also requires taking into account the eects of unavoidable impurities in the sCO

2

working

uid such as carbon monoxide and water vapor on the critical properties of pure carbon dioxide, such as

forming carbonic acid.

Specific Technology Development Needs

e following provides examples of specic fundamental R&D needs.

Turbomachinery

As noted above, seals and bearings illustrate two specic technology development needs for achieving reliable

and economic turbomachinery.

Seals: Both the turbine and the compressor shas of sCO

2

systems must penetrate high pressure boundaries

yet have minimal friction to their rotation. is has not been demonstrated at the pressures and temperature

needed for sCO

2

applications, nor at the power levels required by industry (10 MWe to 1,000 MWe). A potential

solution is to isolate the sha seals for the generator, radial, and thrust bearings, and any necessary starter

motors from the high pressure/high temperature CO

2

environment. Placing these components outside the high

pressure/high temperature environment would allow use of industry standard bearings whereas keeping them

inside leads to shorter sha lengths and improved rotor dynamics.

Clean Power

Quadrennial Technology Review 2015

16

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Commercial experience with sCO

2

sha seals to date is largely based upon CO

2

transport and injection

operations in support of enhanced oil recovery. is application has been successfully met in a range of low

temperature supercritical uid conditions at low to moderate sha speeds (3,600 to 8,000 rpm) by non-

contacting CO

2

-lm dry-gas seals. O-the-shelf solutions for high pressure sCO

2

sealing do not presently meet

the requirements for the high temperatures that would be required at the turbine end of a sCO

2

power cycle.

Bearings: Proper design and selection of bearings is frequently one of the most important factors to

turbomachinery system performance and reliability. e technical challenge is to determine the approach that is

suitable for the conversion system and develop a specic conguration that results in acceptably low frictional

loss and also survives the corrosion and erosion environment. A number of dierent technologies may be

considered, but, for high-speed, high-load applications such as power production turbomachinery, uid lm

(hydrodynamic) bearings and rolling element bearings have historically been the industry workhorses.

Materials

Each application will have specic material design and code requirements. For example, ASME Code Section

III stipulates that only ve materials may be used for construction of nuclear reactor components for high

temperature service. e use of the high-temperature nuclear construction materials will be required for all the

components of the primary and secondary systems of advanced nuclear plants. However, it is not clear where

the boundary of material use for the balance-of-plant will be drawn and where other materials may be used.

Corrosion considerations for the use of the Section III high-temperature nuclear construction materials and

for the use of materials in Sections I and VIII power boilers and unred pressure vessels are not addressed by

the ASME Code, other than by the general requirement stating that such corrosion shall not compromise the

required section thickness or strength of the components.

Materials reliability uncertainties include: carburization and sensitization, high-temperature corrosion,

erosion, creep, and fatigue. e eects of material interactions can impact the design, reliability, and lifetime of

essentially all system components. ese uncertainties and R&D needs are discussed below.

Carburization and Sensitization: Internal carburization and sensitization is a long-term concern for

conventional austenitic stainless steels such as types 321 and 347, but is less of a concern for higher alloyed

materials like alloy 709 and Ni-base alloys where the solubility of C is much lower. Similar carburization of

ferritic-martensitic steels also has been observed at 550°-650°C. If these less expensive ferritic-martensitic and

austenitic steels are to be used, R&D is needed on the long-term carburization behavior and maximum use

temperature of these alloys to identify degradation mechanisms and for prediction of useful life.

High Temperature Corrosion: Based on relatively short-term oxidation tests, the high-temperature oxidation

behavior of candidate advanced ultra-supercritical steam cycle (A-USC) alloys was found to be as good as, or

better, in sCO

2

than in sH

2

O, making them candidate alloys for indirect sCO

2

power cycle components also.

ese leading alloy candidates need to be tested for longer time periods (e.g. 1,000-5,000 hours) at 20-35 MPa

at target temperatures (650-750°C) in sCO

2

to establish oxidation reaction kinetics and quantify the rate of

internal carburization. Furthermore, the long-term eect of various joining techniques (e.g. diusion bonding,

brazing, etc.) on reaction rates needs to be determined. For the direct-red concept, only information at 1 bar is

available on how impurities such as O

2

, H

2

O, and others introduced in the CO

2

stream from the combustion of

fuel may aect corrosion rates. us, oxidation/corrosion data results in supercritical conditions are needed.

Erosion: Erosion is a signicant issue for the closed Brayton Cycle systems at two sCO

2

test facilities: SNL and

Bettis. Substantial erosion in the turbine blade and inlet nozzle has been observed. It is believed that this is

caused by residual debris in the loop and/or small particulates that originate from the spallation of corrosion

products of dierent materials and at dierent locations within the loop. ese particles are entrained through

the nozzle vane and turbine, thus causing erosion. e problem in sCO

2

cycles is exacerbated by the fact that

Clean Power

Quadrennial Technology Review 2015

17

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

sCO

2

is nearly twice as dense as supercritical steam and moves 11 times faster (in terms of mass ow rate) than

supercritical steam in their respective systems. us, the compact size of the turbomachinery in the sCO

2

cycles

results in a ow of a high density uid at very high velocities. Owing to turbine speeds remaining constant,

the issue of erosion is expected to be encountered in scale-up. In addition, inspection of the printed circuit

heat exchanger within the closed Brayton Cycle system found an agglomeration of hydrocarbons and erosion

products at the inlet.

To address the erosion issues in gas and steam turbines, a wide variety of coating systems have been explored

by industry and various erosion-resistant coatings are in commercial use today. e selection of an appropriate

coating system depends on the underlying substrate metal as well as (perhaps more importantly) on the source

and properties of the particulate causing the erosion. For example, Bettis employs a procedure that lters the

CO

2

ve times before use.

Creep and Fatigue: Creep, the tendency of a solid material to deform slowly and permanently as a result of

mechanical stresses below its yield strength at elevated temperatures, and fatigue, a failure mechanism that

occurs when the component experiences cyclic stresses or strains that produce permanent damage, are primary

potential limitations that must be accommodated in the design of sCO

2

systems. R&D to better understand

creep and fatigue associated with sCO

2

turbomachinery and heat exchange components is necessary. In the

turbomachinery, the gaps between the turbine and compressor wheels and their housings are small, the tip

speeds are large, and the temperature (in the turbine) is high. us, creep and fatigue become lifetime issues.

In the compact heat exchangers used as recuperators or primary heaters in the sCO

2

cycles, the pressure

dierence between the hot and cold legs is large (up to about 25 MPa), and the design goal is to minimize

the wall thickness between them to maximize heat transfer and minimize cost while keeping ow passages

small and numerous. If the system design constraints drive designs to more-corrosion resistant materials

(e.g., due to CO

2

interactions), there may be a need to obtain creep rate data for those materials if sucient

data are not available from the manufacturer. Furthermore, diusion bonding or brazing is used to join the

layers of sheets to construct these compact heat exchangers. e diusion bonded regions (usually less than

50µm thick) of the sheet material may have dierent chemical composition and microstructure compared to

the rest of the sheet material resulting in dierent mechanical properties. Creep and fatigue behavior of joints

(diusion bonded or brazed) may need to be investigated as a part of the design methodology of compact heat

exchangers. In addition to creep and fatigue as purely mechanical considerations as discussed, above the eect

of the environment on these mechanical properties may need to be evaluated. For example, how carburization

and oxidation of alloys in sCO

2

aect the creep rate and fatigue crack growth rate should be investigated. Also,

for wall thicknesses below 0.5mm it should be recognized that creep behavior can be signicantly dierent

than for bulk material and relatively little information is available on some classes of material in thin sections,

particularly the precipitation strengthened Ni-base alloys. Considerable expertise in evaluating creep properties

of thin-walled steels and conventional Ni-base alloys for gas turbine recuperators (i.e. heat exchangers) was

developed during the development of the Mercury 50 turbine and that information and expertise would be

useful for the development of sCO

2

recuperators.

Valves

Any closed Brayton Cycle will require three valve functions: isolation, modulating/throttling, and pressure

relief. e isolation and throttling valves are highly engineered and are, therefore, the highest cost valves.

Operating mechanisms for these systems exist, but the valve body, internal components, and seat will be

immersed in hot sCO

2

and subject to materials eects that create uncertainty regarding the design of the

valves, requiring R&D. e valve actuator seals will require R&D to demonstrate that they can survive the hot

sCO

2

environment.

Clean Power

Quadrennial Technology Review 2015

18

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Market Opportunities

e recompression sCO

2

Brayton cycle allows the extraction of thermal energy at a high temperature

dierential, while compression at relatively high density results in low parasitic compression work, contributing

to the high eciency of the cycle and the anticipated lower capital cost due to reduced size. e market includes

diverse applications, opportunities for improved economics, and expanded market potential with successful

R&D. Benets that would accrue from successful R&D of the sCO

2

power conversion cycle include the

following:

1. Diverse applications: e recompression sCO

2

Brayton cycle can be congured to operate with a

variety of heat sources including nuclear, fossil-fuel, renewables such as concentrating solar thermal

power (CSP) and geothermal, and waste heat, oering a very broad range of applications.

2. Improved economics: e sCO

2

Brayton cycle technology, with successful R&D, may be able to provide

improved overall economics and operating conditions (e.g., higher eciencies [lower fuel costs, lower

GHG emissions], lower capital costs, reduced water usage) across various applications, infrastructures,

and scales.

3. Market growth through successful R&D: Initial R&D activities are expected to result in technological

and economic advantages for subsystems and components, which will help inuence early industry

participation and commercial adoption at the component level. As R&D activities advance beyond an

initial demonstration, the technology is expected to achieve higher operating temperatures, allowing for

increased potential market opportunities at scalable levels of power generation. At this point, both the

full-system and new sub-components/technologies (that apply to larger scales and higher temperatures)

may be adopted by industry. Later RD&D activities will leverage industry and stakeholder input and are

expected to result in an increase in demand (once technical risks are resolved) for a full-system at low

MWe levels.

In 2013, a commercialization review for sCO

2

Brayton cycle technology found that, if successfully developed,

it could have applicability across various power generation applications and might oer signicant economic

advantages over current technologies.

38

Due to the technical challenges briey described above and associated

uncertainties in technology development, cost, and performance, market projections are highly speculative and

additional research is required to better understand initial applications as well as applications where industry

demand would be highest. An extensive market review with industry stakeholders that leverages market/

economic data to identify early adopters and determine future market projections would help clarify some of

these issues.

Commercialization of sCO

2

Brayton cycle technology will depend on various nancial, technical, regulatory,

social, and value chain factors. ese must be properly understood and addressed before commercialization

and market risks are alleviated. In order to reduce the risks associated with these factors, it will be essential

to support smaller scale projects that mitigate potential risk elements. In addition, as R&D activities advance,

the sCO

2

Brayton cycle is expected to achieve higher operating temperatures, allowing for increased potential

market opportunities. is progress should be measured on a long-term timescale, with various factors aecting

the rate of deployment within given applications. Initial market opportunities for complete systems (oerings

from 5 to 10 MWe) will be more clearly understood aer concerns about technical risks have been addressed

through demonstration.

In the early stages of complete system deployment, the market opportunities are for small (<10 MWe)

installations that operate at temperatures below 550°C. Initial applications that meet these criteria include

small geothermal facilities or the installation of a sCO

2

Brayton cycle as a bottoming cycle for small (< 100

MW) turbine systems, for both new plants and potentially for retrot plants. As the technology advances, sCO

2

technology will start to compete with traditional cycles based on expected cost advantages associated with

eciency, capital costs, and operating costs.

Clean Power

Quadrennial Technology Review 2015

19

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

e critical point for wide-scale adoption is the demonstration of a system that operates up to 550°C and has

addressed technical risks associated with scaling up to higher temperatures. As the technology continues to

advance, enabling operational temperatures to increase beyond 700°C, potential market opportunities expand

further to include concentrating solar power and fossil fuel direct heating. Over the long-term, as operating

temperatures and scalability increase, leading to increased eciency, the potential market opportunities grow to

include large nuclear and fossil fuel plant designs (100 MWe and larger).

Very large market potential exists as technology achieves higher temperatures and eciencies:

Total installed capacity in the United States is expected to increase by 196 GW by 2040; however, the

projection is for fewer coal plants and for a large increase in natural gas combined cycles (130 GW) and

renewables (52 GW).

Global installed capacity is projected to grow by 3,200 GW by 2040; of that 1,200 GW is expected to be

in China. Approximately one-half of this total capacity growth is expected to be gas- or steam-turbine

based.

Dry cooling options are suited for arid regions, including the U.S. southwest, Middle East, and Africa.

Successful R&D on dry cooling sCO

2

cycles would increase siting options and may reduce costs

associated with water access and rights.

Because sCO

2

power cycles oer advantages across a range of operating temperatures, sCO

2

power cycles

are being considered for next generation utility scale fossil fuel power generation, modular nuclear power

generation, solar-thermal power generation, geothermal power, and industrial scale waste heat recovery.

Supercritical CO

2

(sCO

2

) Power Cycles Summary

Table 4.R.5 describes some of the challenges and desired outcomes for sCO

2

Power Cycles, and Table 4.R.6

summarizes the State-of-the-Art, current R&D activities, and key R&D opportunities for these technologies.

Table 4.R.5 Challenges and Desired Outcomes of sCO

2

Power Cycles

sCO

2

Power Cycles: Perform R&D on both direct and indirect sCO

2

systems, including the development of

turbomachinery, recuperators, and syngas oxy-fuel combustors.

Major R&D Challenges

Turbomachinery, heat exchanger, and balance-of-plant materials that can withstand 1300°F (700°C) to improve reliability and

cycle eciency

Control of kinetics in direct-red sCO

2

environments with suppression of instabilities and undesired products to improve

reliability of the system

Identify system design for optimization of performance and cost

Develop oxy-combustors for direct cycles to provide a direct-red system

Identify and model control strategies to optimize cycle performance for both indirect and direct-red systems

Integrate fossil energy heat sources for indirect cycles

39

to allow integration with existing ring technologies

Desired Outcomes

Pilot testing of a pre-commercial 50 MWe scale sCO

2

power cycle to demonstrate fully integrated, long term, and reliable

operation. Specic objectives would be to demonstrate a thermal cycle eciency (heat in/work out) of 50% or greater, explore

long term material performance, demonstrate operational performance (start up, shut down, trips and other transients) and

show progress toward a competitive COE for fossil energy, nuclear energy, and concentrating solar applications.

Clean Power

Quadrennial Technology Review 2015

20

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

Table 4.R.6 Technical Assessment and Opportunities of sCO

2

Power Cycles

sCO

2

Power Cycles: Perform R&D on both direct and indirect sCO

2

systems, including the development of

turbomachinery, recuperators, and syngas oxy-fuel combustors.

State-of-the-Art Current R&D Opportunities and Future Pathways

System studies have shown eciencies

higher than USC steam with reduced

plant size and simpler operation,

suggesting the potential for a COE

reduction. Further sCO

2

power

cycle and boiler optimization will be

required to demonstrate a reduced

COE for the sCO

2

power cycle relative

to coal based power generation using

supercritical steam.

Unique system features (e.g.,

compact turbo machinery), and the

potential for lower cost and higher

thermodynamic eciency make sCO

2

power cycles attractive for various

heat sources including fossil, nuclear,

and solar.

40,41,42

ere are sCO

2

power cycle test loops

in operation (e.g., Bechtel Marine

Propulsion Corp., Sandia National

Laboratories, Echogen Power Systems)

and other DOE-funded test facilities

in planning and/or construction

phases.

43,44,45

Materials testing and characterization

are being conducted for high

temperature and pressure sCO

2

operation.

Measurement of thermodynamic

(specic heat, density, and

conductivity) and transport properties

(viscosity) are being conducted to

characterize the sCO

2

, and identify

ideal CO

2

-water mixtures (10 –

20%)

46,47

Systems studies are underway to

establish optimum cycle operating

conditions and boundary conditions

for components.

48

Design, construction, and testing

of key components, including turbo

expanders, compressors, recuperators,

and primary heat exchangers, are

underway for indirect sCO

2

cycles as

well as oxy-combustors for directly

heated sCO

2

cycles.

49

Develop components and technologies

and scale them to 10MWe size as a

next phase of development, and if

successful, then to the next scale-up

step to a 50 MWe system.

Perform component testing and

performance evaluation in the 10

MWe pilot test facility, to then be

followed by scale-up to 50 MW and

higher.

Demonstrate cycle and component

performance that will lead to large

scale, highly ecient cycles.

Endnotes

1

Subbaraman, G., Mays, J.A., Jazayeri, B., Sprouse, K.M., Eastland, A.H., Ravishankar, S., and Sonwane, C.G., “Energy Systems, Pratt and

Whitney Rocketdyne, ZEPS Plant Model: A High Eciency Power Cycle with Pressurized Fluidized Bed Combustion Process,” 2nd Oxyfuel

Combustion Conference, Queensland, Australia, September 2011, http://www.ieaghg.org/docs/General_Docs/OCC2/Abstracts/Abstract/

occ2Final00143.pdf

2

Kacludis, A., Lyons, S., Nadav, D., and Zdankiewicz, E., “Waste Heat to Power (WH2P) Applications Using a Supercritical CO2-Based Power

Cycle”, Presented at Power-Gen International 2012, Orlando, FL, December 2012.

3

Shelton, W.W., Weiland, N., White, C., Plunkett, J., and Gray, D., “Oxy-Coal-Fired Circulating Fluid Bed Combustion with a Commercial

Utility-Size Supercritical CO2 Power Cycle”, e 5th International Symposium - Supercritical CO2 Power Cycles, San Antonio, TX, March 29-

31, 2016, http://www.swri.org/4org/d18/sco2/papers2015/104.pdf

4

White, C., “Analysis of Brayton Cycles Utilizing Supercritical Carbon Dioxide - Revision 1”, DOE/NETL-4001/070114, In Preparation. See also:

https://www.netl.doe.gov/energy-analyses/temp/AnalysisofBraytonCyclesUtilizingSupercriticalCarbonDioxide_070114.pdf

5

Ibid

6

Ibid

7

Lide, D., “Handbook of Chemistry and Physics”, 75th Edition, CRC Press, 1995.

8

Aspen Plus Version 8.8, AspenTech, HQ Aspen Technology, Inc., 20 Crosby Drive Bedford, Massachusetts 01730.

9

White, C., “Analysis of Brayton Cycles Utilizing Supercritical Carbon Dioxide - Revision 1”, DOE/NETL-4001/070114, In Preparation. See also:

https://www.netl.doe.gov/energy-analyses/temp/AnalysisofBraytonCyclesUtilizingSupercriticalCarbonDioxide_070114.pdf

10

Wikimedia Commons web site for CO2 Phase Diagrams, https://commons.wikimedia.org/wiki/Category:Carbon_dioxide_phase_diagrams#/

media/File:Carbon_dioxide_pressure-temperature_phase_diagram.svg

11

Engineers Edge web site, http://www.engineersedge.com/thermodynamics/critical_point.htm

12

White, C., “Analysis of Brayton Cycles Utilizing Supercritical Carbon Dioxide - Revision 1”, DOE/NETL-4001/070114, In Preparation. See also:

https://www.netl.doe.gov/energy-analyses/temp/AnalysisofBraytonCyclesUtilizingSupercriticalCarbonDioxide_070114.pdf

Clean Power

Quadrennial Technology Review 2015

21

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

13

Ibid

14

Ibid

15

Pasch, Jim, “Pressure-Enthalpy Diagram for Recompression Closed Brayton Cycle Using SCO2”, Nuclear Energy Systems Laboratory/Brayton,

Sandia National Laboratories, 2016, http://energy.sandia.gov/energy/renewable-energy/supercritical-co2/

16

Ibid

17

White, C., “Analysis of Brayton Cycles Utilizing Supercritical Carbon Dioxide - Revision 1”, DOE/NETL-4001/070114, In Preparation. See also:

https://www.netl.doe.gov/energy-analyses/temp/AnalysisofBraytonCyclesUtilizingSupercriticalCarbonDioxide_070114.pdf

18

Ibid

19

Ibid

20

Fleming, D., Conboy, T., Pasch, J., Rochau, G., Fuller, R., Holschuh, T., and Wright, S., “Scaling Considerations for a Multi-Megawatt Class

Supercritical CO2 Brayton Cycle and Path Forward for Commercialization”, SAND2013-9106, November 2013, http://prod.sandia.gov/techlib/

access-control.cgi/2013/139106.pdf.

21

White, C., “Analysis of Brayton Cycles Utilizing Supercritical Carbon Dioxide - Revision 1”, DOE/NETL-4001/070114, In Preparation. See also:

https://www.netl.doe.gov/energy-analyses/temp/AnalysisofBraytonCyclesUtilizingSupercriticalCarbonDioxide_070114.pdf

22

Ibid

23

EPRI, Performance and Economic Evaluation of Supercritical CO2 Power Cycle Coal Gasication Plant, 3002003734, Dec 014, http://www.epri.

com/abstracts/Pages/ProductAbstract.aspx?ProductId=000000003002003734

24

EPRI, Regen-SCOT: Rocket Engine-Derived High Eciency Turbomachinery for Electric Power Generation, 3002006513, Aug 2015, http://

www.epri.com/abstracts/Pages/ProductAbstract.aspx?ProductId=000000003002006513

25

Power Engineering web site, Mar 2016, http://www.power-eng.com/articles/2016/03/net-power-breaks-ground-on-zero-emission-gas-red-

demo-plant.html

26

Shelton, W.W., Weiland, N., White, C., Plunkett, J., and Gray, D., “Oxy-Coal-Fired Circulating Fluid Bed Combustion with a Commercial

Utility-Size Supercritical CO2 Power Cycle”, e 5th International Symposium - Supercritical CO2 Power Cycles, San Antonio, TX, March 29-

31, 2016, http://www.swri.org/4org/d18/sco2/papers2015/104.pdf

27

Wright, S., Radel, R., Conboy, T., and Rochau, G., “Modeling and Experimental Results for Condensing Supercritical CO2 Power Cycles”,

SAND2010-8840, January 2011, http://prod.sandia.gov/techlib/access-control.cgi/2010/108840.pdf

28

Kimzey, G., “Development of a Brayton Bottoming Cycle using Supercritical Carbon Dioxide as the Working Fluid”, EPRI, 2012, http://www.

swri.org/utsr/presentations/kimzey-report.pdf

29

Invernizzi, C.M., “Closed Power Cycles – ermodynamic Fundamentals and Applications”, DOI: 10.1007/ 978-1-4471-5140-1 © Springer-

Verlag London, 2013.

30

Kimzey, G., “Development of a Brayton Bottoming Cycle using Supercritical Carbon Dioxide as the Working Fluid”, EPRI, 2012, http://www.

swri.org/utsr/presentations/kimzey-report.

31

Ahn, Y., Baea, S.J., Kima, M., Choa, S.K., Baika, S., Lee, J.I., and Cha, J.E., Cycle layout studies of S-CO2 cycle for the next generation nuclear

system application, Transactions of the Korean Nuclear Society Autumn Meeting, Pyeongchang, Korea, October 30-31, 2014.

32

Bae, S.J., Lee, J., Ahn, Y., and Lee, J.I., Preliminary studies of compact Brayton cycle performance for small modular high temperature gas-

cooled reactor system, Ann. Nucl. Energy., 75, 2015, http://www.sciencedirect.com/science/article/pii/S0306454914003727

33

EPA web site, Carbon Pollution Standards for New, Modied and Reconstructed Power Plants, Aug 2015, https://www.epa.gov/cleanpowerplan/

carbon-pollution-standards-new-modied-and-reconstructed-power-plants#rule-summary

34

sCO2 Power Cycle Roadmapping Workshop, SwRI, San Antonio, TX, February 2013.

35

Conboy, T.M., Carlson, M.D., and Rochau, G.E., “Dry-Cooled Supercritical CO2 Power for Advanced Nuclear Reactors”, Journal of Engineering

for Gas Turbines and Power, Vol 137, 012901, August 2014, https://www.researchgate.net/publication/270772560_Dry-Cooled_Supercritical_

CO_2_Power_for_Advanced_Nuclear_Reactors

36

Moisseytsev, A., and Sienicki, J.J., “Investigation of a Dry Air Cooling Option For an s-CO2 Cycle”, e 4th International Symposium

- Supercritical CO2 Power Cycles, Pittsburgh, Pennsylvania, September 9-10, 2014, http://www.swri.org/4org/d18/sco2/papers2014/

systemModelingControl/44-Moisseytsev.pdf

37

Turchi, C., NREL Final Report “10 MW Supercritical CO2 Turbine Test”, NREL Nonproprietary Final Report, DE-EE0001589, January

2014, https://ay14-15.moodle.wisc.edu/prod/pluginle.php/99692/mod_resource/content/1/Final%20Report%20EE0001589%20

NONPROPRIETARY%20dra%202013-12-26.pdf

• Fleming, D., Holschuh, T., Conboy, T., Rochau, G., Fuller, R., “Scaling Considerations for a Multi-Megawatt Class Supercritical CO2 Brayton

Cycle and Path Forward for Commercialization”, Proceedings of ASME Turbo Expo 2012, June 11-15, 2012, Copenhagen, Denmark,

GT2012-68484, http://proceedings.asmedigitalcollection.asme.org/proceeding.aspx?articleid=1694663

• Fuller, R., Preuss, J., Noall, J, “Turbomachinery for Supercritical CO2 Power Cycles”, Proceedings of ASME Turbo Expo 2012, June 11-15,

2012, Copenhagen, Denmark, GT2012-68735, http://proceedings.asmedigitalcollection.asme.org/proceeding.aspx?articleid=1694664

Clean Power

Quadrennial Technology Review 2015

22

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

38

Fleming, D., Conboy, T., Pasch, J., Rochau, G., Fuller, R., Holschuh, T., and Wright, S., “Scaling Considerations for a Multi-Megawatt Class

Supercritical CO2 Brayton Cycle and Path Forward for Commercialization”, SAND2013-9106, November 2013, http://prod.sandia.gov/techlib/

access-control.cgi/2013/139106.pdf.

39

sCO2 FE Workshop Summary Report, http://www.netl.doe.gov/File%20Library/Events/2014/sco2workshop/sCO2-Workshop-Sept-11-2014-

Summary-Report_Final.pdf.

40

Gary, J., 2014, presentation, DOE EERE sCO2 Power cycle Applications, http://www.swri.org/4org/d18/sCO2/papers2014/keynotes/gary.pdf.

41

Golub, S., 2014, presentation, DOE NE sCO2 Power cycle Applications, http://www.swri.org/4org/d18/sCO2/papers2014/keynotes/golub.pdf.

42

Mollot, D., 2014, presentation, DOE FE sCO2 Power cycle Applications, http://www.swri.org/4org/d18/sCO2/papers2014/keynotes/mollot.pdf.

43

Clementoni et al., 2014, Proceedings of the sCO2 Workshop, Sept 11, 2014, http://www.swri.org/4org/d18/sCO2/papers2014/testing/11-

Clementoni.pdf.

44

Kimball et al., 2014, Proceedings of the sCO2 Workshop, Sept 11, 2014, http://www.swri.org/4org/d18/sCO2/papers2014/testing/33-Kimball.

pdf.

45

Kruizenga et al., 2014, Proceedings of the sCO2 Workshop, Sept 11, 2014, Sandia National Laboratory sCO2 Power Cycles Test facility, http://

www.swri.org/4org/d18/sCO2/papers2014/testing/71-Kruizenga.pdf.

46

NIST Project Fact Sheet, “ermophysical Properties of CO2 and CO2-Rich Mixtures”, http://www.netl.doe.gov/research/coal/energy-systems/

turbines/project-information/proj?k=FE0003931.

47

NETL web site with table of sCO2 turbo machinery projects (under the H2 Turbine Program) with associated landing pages / fact sheets, http://

www.netl.doe.gov/research/coal/energy-systems/turbines/project-information.

48

White, et al., 2014, Proceedings of the sCO2 Workshop, Sept 11, 2014, http://www.swri.org/4org/d18/sCO2/papers2014/systemConcepts/68-

White.pdf.

49

NETL, 2015, project website, http://www.netl.doe.gov/research/coal/energy-systems/advanced-combustion/project-information

Glossary terms are quoted from or adapted from the following sources:

50

Wikipedia, for the listed Glossary term, www.wikipedia.org

51

Wilson, D.G, “e Design of High Eciency Turbomachinery and Gas Turbines,” MIT Press, 1984.

52

Oates, G.C., “Aerothermodynamics of Gas Turbine and Rocket Propulsion”, American Institure of Aeronautics and Astronautics, Inc., 1988.

53

Adapted from “e Inside of a Wind Turbine,” http://energy.gov/eere/wind/inside-wind-turbine-0

54

“Investment Casting Waxes: Investment Casting,” https://investmentcastingwaxescto.wordpress.com/

55

eCourses, “ermodynamics eory”, Entropy Change of a Pure Substance,” http://www.ecourses.ou.edu/cgi-bin/ebook.

cgi?doc&topic=th&chap_sec=06.5&page=theory

56

Solar Turbines, a Caterpillar Company, “Gas Turbine Packages, Mercury 50,” https://mysolar.cat.com/en_US/products/power-generation/gas-

turbine-packages/mercury-50.html

57

Solar Turbines, a Caterpillar Company, “Renewable Energy Solutions,” http://s7d2.scene7.com/is/content/Caterpillar/C10550262

58

Industrial Metallurgists, LLC, Michael Pfeier, “Precipitation Strengthening,” http://www.imetllc.com/precipitation-strengthening/

49

Atkins, A.G., Atkins, T., and M. Escudier, “Dictionary of Mechanical Engineering”, OUP Oxford, 2013.

Acronyms

Adv Advanced

ASME American Society of Mechanical Engineers

AUSC Advanced ultra-supercritical

BOP Balance of plant

C Carbon

Cap Capture

CCS Carbon capture and storage

Clean Power

Quadrennial Technology Review 2015

23

TA 4.R: Supercritical Carbon Dioxide Brayton Cycle

CFB Circulating fluidized bed

cm Centimeter, unit of distance

CO

2

Carbon dioxide

COE Cost of electricity

cp Heat capacity at constant pressure

CSP Concentrating solar power

cv Heat capacity at constant volume

DOE Department of Energy

EPA Environmental Protection Agency

Freq Frequency

GHG Greenhouse gas

GW Gigawatt, unit of power

η

Isentropic efficiency

H

2

O

Water

He Helium

K Kelvin, unit of temperature

kg Kilogram, unit of mass

kJ Kilojoule, unit of energy

kJ/kg Kilojoule per kilogram, unit of specific energy

kPa Kilopascal, unit of pressure

Lab Laboratory

lb Pound, unit of mass

m

Meter, unit of distance

mm Millimeter, unit of distance

MPa Megapascal, unit of pressure

MW Megawatt, unit of power